Beruflich Dokumente

Kultur Dokumente

Zero Carbon Through Solar Thermal For Cement Production

Hochgeladen von

BiswasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zero Carbon Through Solar Thermal For Cement Production

Hochgeladen von

BiswasCopyright:

Verfügbare Formate

Methods of Lime (CaO) generation

Decomposition / Chemical reaction

Conventional heating system Solar Thermal concept for electrolysis method

CaCO3 = CaO (Lime)+ CO2 (Carbon Dioxide) i) CaCO3 = CaO(Lime) + C(Carbon)+ O2 (Oxygen) below 800°C

(Harmful) ii) CaCO3 = CaO(Lime) + CO+ ½O2 (Oxygen) above 800°C

Solar Thermal electrolysis method for lime

Electrolysis is the passage of a direct electric current through an ionic substance that is either molten or dissolved in a

suitable solvent, resulting in chemical reactions at the electrodes and separation of materials.

When separated through electrolysis method to decompose the CaCO3, the resultant carbon and oxygen atoms no longer

pose the threat to the atmosphere that they do as CO2.

Also at higher temperature (above 800°C), the by- products of electrolysis CO or C can be used for other industrial process

such as plastics, purify nickel etc , thereby reducing the cost of lime generation used for the cement.

Aanalysis :

Based on temperature requirement for electrolysis, Solar thermal can assist process and below Solar Thermal

technology can be used :

A. below 800°C ( CO2 shall not be produced)

Current Solar Thermal options:

- Power Tower (upto 535°C) with molten salt

- Parabolic trough ( upto 393°C) with HTF ; HTF has limitation of 393°C)

Conclusion : Power tower with Molten salt storage can gain above 500°C and 24 x 7 production , Molten

salt has limitation of 535°C. Advanced research ongoing.

B. Above 800°C(CO2 shall not be produced, further production of sellable by-product CO can drastically bring down

the cost of lime production ; even negative)

Current Solar Thermal Option: None

- Research ongoing

Das könnte Ihnen auch gefallen

- Aspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectDokument10 SeitenAspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectZhofran BintangNoch keine Bewertungen

- Alternative Iron Making Processes: by Mr. A MthisiDokument52 SeitenAlternative Iron Making Processes: by Mr. A MthisiTsebe HermanNoch keine Bewertungen

- Carbon Nano Fiber (From Fossil Fuel) Electric Power Plants and Transformation of CO2 Exhaust To Stable, Compact, Valued CommoditiesDokument10 SeitenCarbon Nano Fiber (From Fossil Fuel) Electric Power Plants and Transformation of CO2 Exhaust To Stable, Compact, Valued Commoditiesanil.gNoch keine Bewertungen

- AbstractDokument8 SeitenAbstractfaramarzkazemiNoch keine Bewertungen

- Coal and Coal ChemicalsDokument54 SeitenCoal and Coal ChemicalsVishal DhapaNoch keine Bewertungen

- Hatch and Northern Graphite PaperDokument6 SeitenHatch and Northern Graphite PaperNarayana Murthy GadiNoch keine Bewertungen

- Energy Requriement in Drying and CalcinationDokument29 SeitenEnergy Requriement in Drying and CalcinationAbhishek KumarNoch keine Bewertungen

- 3A5. Coke Dry Quenching Technology (CDQ) : Iron Making and General Industry Technologies (Iron Making Technologies)Dokument2 Seiten3A5. Coke Dry Quenching Technology (CDQ) : Iron Making and General Industry Technologies (Iron Making Technologies)reach_arindomNoch keine Bewertungen

- Calcination Roasting PredominaceAreaDokument48 SeitenCalcination Roasting PredominaceAreaVikramaditya MathkarNoch keine Bewertungen

- Cement Clinker Production in An ElectrolyserDokument18 SeitenCement Clinker Production in An Electrolyserمهندس فهمي عبدالعزيزNoch keine Bewertungen

- MokPhI Part 2 Draft01Dokument14 SeitenMokPhI Part 2 Draft01William MookNoch keine Bewertungen

- Hydrogen ProductionDokument23 SeitenHydrogen ProductionJAENoch keine Bewertungen

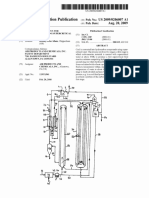

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Dokument13 SeitenPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaNoch keine Bewertungen

- Paper Accepted For Publication at Chemical Engineering Research and DesignDokument56 SeitenPaper Accepted For Publication at Chemical Engineering Research and Designjhay thegreatNoch keine Bewertungen

- UniMasr.com_f0922f3495133e72e29ab20ecea19ee2.docxDokument22 SeitenUniMasr.com_f0922f3495133e72e29ab20ecea19ee2.docxRuth LimboNoch keine Bewertungen

- Energy Analysis of Caco Calcination With Co CaptureDokument6 SeitenEnergy Analysis of Caco Calcination With Co CaptureFahrudin BayuNoch keine Bewertungen

- Overview of CCC Process, Economics & Market Opportunity: Profitable CCS Via Electrochemical Mineral CarbonationDokument19 SeitenOverview of CCC Process, Economics & Market Opportunity: Profitable CCS Via Electrochemical Mineral Carbonationmpriestnall100% (1)

- Designing of The Calcination Unit: Temperature and Energy ProfileDokument7 SeitenDesigning of The Calcination Unit: Temperature and Energy ProfileTJPRC PublicationsNoch keine Bewertungen

- Blast FurnaceDokument32 SeitenBlast FurnaceShailesh SharmaNoch keine Bewertungen

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Dokument8 SeitenYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherNoch keine Bewertungen

- Calcium Carbonate (PCC)Dokument15 SeitenCalcium Carbonate (PCC)Huyentrang NguyenNoch keine Bewertungen

- Synthesis of Aluminium TrihydrateDokument3 SeitenSynthesis of Aluminium TrihydrateCory AmeliaNoch keine Bewertungen

- Exp - 7 - Self Propagating High Temperature Synthesis, SHSDokument6 SeitenExp - 7 - Self Propagating High Temperature Synthesis, SHSIbrahim MücahitNoch keine Bewertungen

- Decarbonisation of Steam CrackersDokument7 SeitenDecarbonisation of Steam CrackersAtharva OfficeNoch keine Bewertungen

- Design of Heat Exchanger Mini ProjectDokument45 SeitenDesign of Heat Exchanger Mini ProjectSuraya Afriyani100% (1)

- Mini Project On The Design of Heat ExchangerDokument48 SeitenMini Project On The Design of Heat ExchangerSuraya AfriyaniNoch keine Bewertungen

- Carbonation-Calcination Cycle Using High Reactivity Calcium Oxide For Carbon Dioxide Separation From Flue GasDokument8 SeitenCarbonation-Calcination Cycle Using High Reactivity Calcium Oxide For Carbon Dioxide Separation From Flue GasPola PoliNoch keine Bewertungen

- 401 - 2007 - Fuels Metals EnergyDokument50 Seiten401 - 2007 - Fuels Metals EnergyNilton Rosenbach JrNoch keine Bewertungen

- Paper Accepted For Publication at Chemical Engineering Research and DesignDokument58 SeitenPaper Accepted For Publication at Chemical Engineering Research and Designjhay thegreatNoch keine Bewertungen

- Lecture 2 Si Growth - 2022Dokument20 SeitenLecture 2 Si Growth - 2022DrNasser MorganNoch keine Bewertungen

- Shell CorrosionDokument33 SeitenShell CorrosionManekGorisNoch keine Bewertungen

- Ironmaking Problems: Resources Environment EnergyDokument1 SeiteIronmaking Problems: Resources Environment EnergyrbcahyonoNoch keine Bewertungen

- Smelting Corex ProcessDokument19 SeitenSmelting Corex ProcessKrishna Teja JayanthiNoch keine Bewertungen

- New Approach of Retorting of Huadian Oil Shale in Order To Reduce CO and CO EmissionsDokument8 SeitenNew Approach of Retorting of Huadian Oil Shale in Order To Reduce CO and CO EmissionsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Termodinamika MetalurgiDokument4 SeitenTermodinamika Metalurgiriozulfahmi9Noch keine Bewertungen

- Ali Mohamed Awadallah Training ReportDokument9 SeitenAli Mohamed Awadallah Training Reportahmedameer20189Noch keine Bewertungen

- Pers Cct2003Dokument8 SeitenPers Cct2003VIJAYPORNoch keine Bewertungen

- IR Ni LanthanaDokument6 SeitenIR Ni LanthanaNelly RojasNoch keine Bewertungen

- Boiler Water BasicsDokument63 SeitenBoiler Water BasicsTin Aung Kyi100% (4)

- Adiabatic Fixed-Bed Gasification Using Colombian Coffee Husk and Air-Steam Blends For Partial Oxidation - 08!07!16 - Last VersionDokument27 SeitenAdiabatic Fixed-Bed Gasification Using Colombian Coffee Husk and Air-Steam Blends For Partial Oxidation - 08!07!16 - Last VersionJhon OtaloraNoch keine Bewertungen

- Chapter 2Dokument7 SeitenChapter 2pragati agrawalNoch keine Bewertungen

- Georgia Tech Sponsored ResearchDokument51 SeitenGeorgia Tech Sponsored ResearchChristian SmallenNoch keine Bewertungen

- Decarbonize The Natural GasDokument4 SeitenDecarbonize The Natural GasGabriel ColmontNoch keine Bewertungen

- Unit-Iv: Industrial GasesDokument45 SeitenUnit-Iv: Industrial Gasesomer faruqeNoch keine Bewertungen

- 7.carbonization and Combustion CalculationsDokument27 Seiten7.carbonization and Combustion CalculationsMuhammad Irfan Malik100% (1)

- Pre CombustionDokument62 SeitenPre CombustionigrjaaNoch keine Bewertungen

- Smelting Technologies For FerrochromiumDokument14 SeitenSmelting Technologies For FerrochromiumSantosh Kumar MahtoNoch keine Bewertungen

- H2 ProductionDokument43 SeitenH2 Productionnouman khanNoch keine Bewertungen

- CO HazardousDokument29 SeitenCO HazardousDibya Ranjan RoutNoch keine Bewertungen

- 001 DavenportDokument16 Seiten001 Davenportjlg314Noch keine Bewertungen

- Gold Adsorption On Activated CarbonDokument3 SeitenGold Adsorption On Activated CarbongtdomboNoch keine Bewertungen

- 4-Emission ControlDokument27 Seiten4-Emission ControlRASHEED MUHAMMADNoch keine Bewertungen

- CO2 DecompositionDokument28 SeitenCO2 DecompositionPiyush MouryaNoch keine Bewertungen

- Gaseous FuelsDokument8 SeitenGaseous FuelsvaibhavNoch keine Bewertungen

- ULSI (Nano) Fabrication: 1 GirijaDokument48 SeitenULSI (Nano) Fabrication: 1 GirijaSHAIK MUSTHAFANoch keine Bewertungen

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementVon EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyVon EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNoch keine Bewertungen

- © Ncert Not To Be Republished: Hemical QuilibriumDokument7 Seiten© Ncert Not To Be Republished: Hemical QuilibriumSoumik MukhopadhyayNoch keine Bewertungen

- Journal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaDokument11 SeitenJournal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaAbiel Angel GarciaNoch keine Bewertungen

- Behavior DS MM247LC (Bae2001)Dokument6 SeitenBehavior DS MM247LC (Bae2001)Alex CostaNoch keine Bewertungen

- Icml Mla IDokument3 SeitenIcml Mla IDeepak100% (1)

- Particulate Nature of MatterDokument4 SeitenParticulate Nature of MatterSandy ItabNoch keine Bewertungen

- GF-304CR Dossier.Dokument35 SeitenGF-304CR Dossier.suria qaqcNoch keine Bewertungen

- Safety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Dokument24 SeitenSafety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Librany RioNoch keine Bewertungen

- TBP, ASTM, and EFV ComparedDokument2 SeitenTBP, ASTM, and EFV Comparedvicktorinox230388Noch keine Bewertungen

- Tmecc 0411Dokument6 SeitenTmecc 0411Karen BenteoNoch keine Bewertungen

- Gas Laws Worksheet #2 Boyles Charles and CombinedDokument3 SeitenGas Laws Worksheet #2 Boyles Charles and CombinedJeromeNoch keine Bewertungen

- 3330604Dokument3 Seiten3330604dhwaniNoch keine Bewertungen

- Comparing Microstructure and Mechanical Properties of AISI D2 Steel PDFDokument7 SeitenComparing Microstructure and Mechanical Properties of AISI D2 Steel PDFToramaru UtsunomiyaNoch keine Bewertungen

- 3b.boiler Treatment MethodsDokument76 Seiten3b.boiler Treatment Methodsalokbdas100% (1)

- Separating Corn Starch From CornDokument3 SeitenSeparating Corn Starch From CornJagna LannaoNoch keine Bewertungen

- Operative Dentistry: Dental AdhesionDokument12 SeitenOperative Dentistry: Dental AdhesionJohn CenaNoch keine Bewertungen

- AlkanolamideDokument5 SeitenAlkanolamidebellesuperNoch keine Bewertungen

- USP-NF Atorvastatin CalciumDokument8 SeitenUSP-NF Atorvastatin CalciumPhạm Đức LộcNoch keine Bewertungen

- Atomic Spectrum of HydrogenDokument3 SeitenAtomic Spectrum of HydrogenlovemynaturecountryNoch keine Bewertungen

- Consolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)Dokument33 SeitenConsolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)ASAMENEWNoch keine Bewertungen

- Introduction To Turbulence1Dokument28 SeitenIntroduction To Turbulence1Mustafa YılmazNoch keine Bewertungen

- The Slope of A PH SensorDokument17 SeitenThe Slope of A PH SensorMehdi SalariradNoch keine Bewertungen

- DRRG Equipmentlist 29032022 RDokument49 SeitenDRRG Equipmentlist 29032022 RjayapalNoch keine Bewertungen

- Epoxy 2kDokument3 SeitenEpoxy 2kMitra YuningsihNoch keine Bewertungen

- Introduction To Sensors PDFDokument211 SeitenIntroduction To Sensors PDFVũ Mạnh Cường100% (2)

- Heat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFDokument46 SeitenHeat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFAnaQatarina50% (4)

- 0708 0369Dokument27 Seiten0708 0369iledinamo1Noch keine Bewertungen

- p1 Bab 1-5Dokument19 Seitenp1 Bab 1-5cikguana79Noch keine Bewertungen

- Chitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringDokument14 SeitenChitin and Chitosan: Structure, Properties and Applications in Biomedical EngineeringTrần QuangNoch keine Bewertungen

- 8 Vol. 3 9 Sept. 2012IJPSR 636paper 8Dokument8 Seiten8 Vol. 3 9 Sept. 2012IJPSR 636paper 8Ingrid ContrerasNoch keine Bewertungen

- CellcommworksheetDokument1 SeiteCellcommworksheetYolpy AvukovuNoch keine Bewertungen