Beruflich Dokumente

Kultur Dokumente

APA Plywood Design1

Hochgeladen von

Daniel LarrínagaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

APA Plywood Design1

Hochgeladen von

Daniel LarrínagaCopyright:

Verfügbare Formate

Name Name

Date 2/6/2019

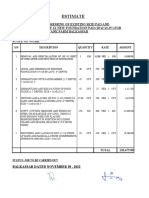

Forming and Shoring Equipment Subject APA Plywood Design - Beam

For Concrete Construction Contractor

Agreement #

www.efcoforms.com

www.HandsetFormwork.com Sht. Of

APA Plywood Design

Design Parameters b = 2"

Slab Thickness (T) = 6.30 inch

Concrete Wt. (CW) = 150 pcf

Live Load (LL) = 50 psf

t

Dead Load (DL) = 2.2 psf

Support Bearing Width (b) = 2 inch

APA Plywood Classification = Class I

Plywood Thickness (t) = 3/4 inch SPACING (L1)

L

Deflection Criteria = CANTILEVER (L1/2)

360

Joist Spacing Summary

Direction of Grain Spans ≤ 2 Spans ≥ 3 Maximum

in Relation to Support Spacing (L1) Spacing (L1) Cantilever

Perpendicular (Strong) 25.4 inches 28.1 inches 12.7 inches

Parallel (Weak) 20.8 inches 22.4 inches 10.4 inches

Note: The joist spacings above are minimum values base on APA Plywood Design Equations for Bending Stress, Shear

Stress, and Bending Deflection. To minimize plywood cuts, it is recommended to space joists at 8, 12, 16, or 24 inch

increments so ends of 8 ft plywood are supported at centerline of joists.

APA Plywood Section Properties

Modulus of Modulus of Effective Rolling Plywood

Elasticity Elasticity Bending Shear Moment Section Shear Shear

Adjusted Unadjusted Stress Stress of Inertia Modulus Constant Constant

Grain Direction E Ee Fb Fs I KS lbs/Q C

in Relation to Suport (psi) (psi) (psi) (psi) (in.4/ft) (in.3/ft) (in.2/ft)

Perpendicular (Strong) 1,650,000 1,500,000 1,930 72 0.199 0.455 7.187 120

Parallel (Weak) 1,650,000 1,500,000 1,930 72 0.092 0.306 4.063 60

Loading

Concrete = Concrete Weight (CW) * Slab Thickness (T)

= (150 pcf) * (6.30 inch)/(12 inch/ft)

= 79 psf (lb/ft2) W s used for Deflection

Calculations (Live Load

not included).

W s = Concrete + Live Load (LL) + Dead Load (DL)

= (79 psf) + (50 psf) + (2 psf)

= 131 psf (lb/ft2) or => => W s (No LL) = 81 psf

ALP 12/2010 (Revised Feb-11-2014) 1/5 APA Plywood Design1

Name Name

Date 2/6/2019

Forming and Shoring Equipment Subject APA Plywood Design - Beam

For Concrete Construction Contractor 0

Agreement # 0

www.efcoforms.com

www.HandsetFormwork.com Sht. 1 Of

-Find Joist Spacing Based on Plywood Bending Stress (0.75 Plywood; 6.30 inch Slab)

Stress Applied Parallel with Face Grain (Strong Direction)

L1 = (96)(1,930 psi)(0.455 in^3/ft)

96 Fb KS

Spans ≤ 2 ws 2 (131 psf)

L1 = 25.37 inches (span, center to center of supports)

L1 = (120)(1,930 psi)(0.455 in^3/ft)

120 F b KS

Spans ≥ 3 ws 2

(131 psf)

L1 = 28.37 inches (span, center to center of supports)

24 F b KS L1 = (24)(1,930 psi)(0.455 in^3/ft)

Cantilever ws 2 (131 psf)

L1 = 12.69 inches (cantilever, center of support to edge of plywood)

Stress Applied Perpendicular to Face Grain (Weak Direction)

L1 = (96)(1,930 psi)(0.306 in^3/ft)

96 Fb KS

Spans ≤ 2 ws 2 (131 psf)

L1

= 20.81 inches (span, center to center of supports)

L1 = (120)(1,930 psi)(0.306 in^3/ft)

120 F b KS

Spans ≥ 3 ws 2

(131 psf)

L1 = 23.26 inches (span, center to center of supports)

L1 = (24)(1,930 psi)(0.306 in^3/ft)

24 F b KS

Cantilever ws 2

(131 psf)

L1 = 10.40 inches (cantilever, center of support to edge of plywood)

ALP 12/2010 (Revised Feb-11-2014) 2/5 APA Plywood Design1

Name Name

Date 2/6/2019

Forming and Shoring Equipment Subject APA Plywood Design - Beam

For Concrete Construction Contractor 0

Agreement # 0

www.efcoforms.com

www.HandsetFormwork.com Sht. 2 Of

-Find Joist Spacing Based on Plywood Shear Stress (0.75 Plywood; 6.30 inch Slab)

Stress Applied Parallel with Face Grain (Strong Direction)

L2 = (19.2)(72 psi)(7.187 in^2/ft)

19.2 Fs Ib / Q

Spans ≤ 2 ws (131 psf)

L2

= 75.87 inches (clear span, center to center minus b)

20 Fs Ib / Q L2 = (20)(72 psi)(7.187 in^2/ft)

Spans ≥ 3 ws (131 psf)

L2

= 79.03 inches (clear span, center to center minus b)

L2 = (12)(72 psi)(7.187 in^2/ft)

12 F s Ib / Q

Cantilever ws (131 psf)

L2 = 47.42 inches (cantilever, edge of support to edge of plywood)

Stress Applied Perpendicular to Face Grain (Weak Direction)

L2 = (19.2)(72 psi)(4.063 in^2/ft)

19.2 Fs Ib / Q

Spans ≤ 2 ws (131 psf)

L2

= 42.89 inches (clear span, center to center minus b)

20 Fs Ib / Q L2 = (20)(72 psi)(4.063 in^2/ft)

ws (131 psf)

Spans ≥ 3 L2

= 44.68 inches (clear span, center to center minus b)

L2 = (12)(72 psi)(4.063 in^2/ft)

Cantilever

12 F s Ib / Q (131 psf)

ws

L2 = 26.81 inches (cantilever, edge of support to edge of plywood)

Joist Spacing Summary Based on Plywood Shear Stress

Direction of Grain Spans ≤ 2 Spans ≥ 3 Maximum Maximum

in Relation to Support Spacing (L1) Spacing (L1) Spacing (L1) Cantilever (L1)

Perpendicular (Strong) 77.87 inches 81.03 inches 77.87 inches 48.42 inches

Parallel (Weak) 44.89 inches 46.68 inches 44.89 inches 27.81 inches

Span: Joist Spacing (L1) = (L2 + b) Cantilever: Cantilever (L1) = (L2 + b/2)

ALP 12/2010 (Revised Feb-11-2014) 3/5 APA Plywood Design1

Name Name

Date 2/6/2019

Forming and Shoring Equipment Subject APA Plywood Design - Beam Formin

For Concrete Construction Contractor 0

Agreement # 0

www.efcoforms.com

www.HandsetFormwork.com Sht. 3 Of

-Find Joist Spacing Based on Plywood Bending Deflection (0.75 Plywood; 6.30 inch Slab) -Find Joist Sp

Stress Applied Parallel with Face Grain (Strong Direction) Stress Applied

2 4

Spans ≤ 2 Cws t 2 l 2 ws l 3 Allowable L1 Spans ≤ 2

s b 1.0 ΔAllowable =

1270 E e I 2220 EI 360

s b

L2 = L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

L2 =

[(120)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.44E-5(L1-2.00)^2

Δs = Δs =

[(1270)(1,500,000 psi)(0.199 in^4/ft)] L1 L1

[(81 psf)(L1-1.75)^4] Δb = 1.11E-7(L1-1.75)^4

Δb = Δb =

[(2,220)(1,650,000 psi)(0.199 in^4/ft)]

(L1/360) Joist Spacing (L1) = 30.16 inch

1.0 = 1.0 =

[(1.44E-5(L1-2.00)^2) + (1.11E-7(L1-1.75)^4)]

2

Spans ≥ 3 Cws t 2 l 2 ws l3

4

Allowable L1 Spans ≥ 3

s ΔAllowable =

1270 E e I b 1.0 360

1743EI s b

L2 = L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

L2 =

[(120)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.44E-5(L1-2.00)^2

Δs = Δs =

[(1270)(1,500,000 psi)(0.199 in^4/ft)] L1 L1 L1

[(81 psf)(L1-1.75)^4] Δb = 1.41E-7(L1-1.75)^4

Δb = Δb =

[(1,743)(1,650,000 psi)(0.199 in^4/ft)]

(L1/360) Joist Spacing (L1) = 28.11 inch

1.0 = 1.0 =

[(1.44E-5(L1-2.00)^2) + (1.41E-7(L1-1.75)^4)]

2 4

Cantilever Cws t 2 l 2 ws l3 Allowable ΔAllowable =

L1 Cantilever

s b 1.0

1270 E e I 1536 EI 360

s b

L2 = L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

L2 =

[(120)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.44E-5(L1-2.00)^2

Δs = Δs =

[(1270)(1,500,000 psi)(0.199 in^4/ft)] L1 L1

2

[(81 psf)(L1-1.75)^4] Δb = 1.61E-7(L1-1.75)^4

Δb = Δb =

[(1,536)(1,650,000 psi)(0.199 in^4/ft)]

Joist Spacing (L1) = 27.09 inch

(L1/360)

1.0 = L1 1.0 =

[(1.44E-5(L1-2.00)^2) + (1.61E-7(L1-1.75)^4)] Cantilever 13.54 inch

2

ALP 12/2010 (Revised Feb-11-2014) 4/5 APA Plywood Design1

Name Name

Date 2/6/2019

Forming and Shoring Equipment Subject 0

For Concrete Construction Contractor 0

Agreement # 0

www.efcoforms.com

www.HandsetFormwork.com Sht. 4 Of

-Find Joist Spacing Based on Plywood Bending Deflection (0.75 Plywood; 6.30 inch Slab)

Stress Applied Perpendicular to Face Grain (Weak Direction)

2 4

Cws t 2 l 2 ws l 3 Allowable L1

s b 1.0 ΔAllowable =

1270 E e I 2220 EI 360

s b

L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

[(60)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.56E-5(L1-2.00)^2

[(1270)(1,500,000 psi)(0.092 in^4/ft)] L1 L1

[(81 psf)(L1-1.75)^4] Δb = 2.40E-7(L1-1.75)^4

[(2,220)(1,650,000 psi)(0.092 in^4/ft)]

(L1/360) Joist Spacing (L1) = 24.03 inch

[(1.56E-5(L1-2.00)^2) + (2.40E-7(L1-1.75)^4)]

2

Cws t 2 l 2 ws l3

4

Allowable L1

s ΔAllowable =

1270 E e I b 1.0 360

1743EI s b

L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

[(60)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.56E-5(L1-2.00)^2

[(1270)(1,500,000 psi)(0.092 in^4/ft)] L1 L1 L1

[(81 psf)(L1-1.75)^4] Δb = 3.06E-7(L1-1.75)^4

[(1,743)(1,650,000 psi)(0.092 in^4/ft)]

(L1/360) Joist Spacing (L1) = 22.41 inch

[(1.56E-5(L1-2.00)^2) + (3.06E-7(L1-1.75)^4)]

2 4

Cws t 2 l 2 ws l3 Allowable ΔAllowable =

L1

s b 1.0

1270 E e I 1536 EI 360

s b

L1 - b = (L1 - 2.00 in) L3 = L1 - b + 1/4 in = (L1 - 1.75) W

[(60)(81 psf)(0.750^2)(L1-2.00)^2] Δs = 1.56E-5(L1-2.00)^2

[(1270)(1,500,000 psi)(0.092 in^4/ft)] L1 L1

2

[(81 psf)(L1-1.75)^4] Δb = 3.47E-7(L1-1.75)^4

[(1,536)(1,650,000 psi)(0.092 in^4/ft)]

Joist Spacing (L1) = 21.61 inch

(L1/360)

L1

[(1.56E-5(L1-2.00)^2) + (3.47E-7(L1-1.75)^4)] Cantilever 10.81 inch

2

ALP 12/2010 (Revised Feb-11-2014) 5/5 APA Plywood Design1

Das könnte Ihnen auch gefallen

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeDokument5 SeitenVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathNoch keine Bewertungen

- One Way Slab Design Sheet: Un-Restrained EndDokument4 SeitenOne Way Slab Design Sheet: Un-Restrained EndAbdul Hamid BhattiNoch keine Bewertungen

- Beam SpliceDokument2 SeitenBeam SplicePaoloEduardoCarusid'EmpaireNoch keine Bewertungen

- Thrust Restraint OHAWWA 7 14 PDFDokument99 SeitenThrust Restraint OHAWWA 7 14 PDFABAMELANoch keine Bewertungen

- Base Plate - MammutDokument8 SeitenBase Plate - MammutAwais Hameed100% (1)

- Piping Support DesignDokument27 SeitenPiping Support DesignOmar TocmoNoch keine Bewertungen

- Beam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryDokument1 SeiteBeam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña Velasquez100% (1)

- Flat Plate Apartments: Considered Slab AreaDokument6 SeitenFlat Plate Apartments: Considered Slab AreaLavender HoneyNoch keine Bewertungen

- Cold Vent Stack Foundation DesignDokument13 SeitenCold Vent Stack Foundation Designdoverman0% (1)

- 4.T&Angle-Brace Connection (M Project) - 0618Dokument49 Seiten4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNoch keine Bewertungen

- 151 PearliteDokument3 Seiten151 PearlitetyannottiNoch keine Bewertungen

- Base Plate ProblemDokument2 SeitenBase Plate ProblemBun KunNoch keine Bewertungen

- Base Plate DesignDokument19 SeitenBase Plate DesignLeah Ann ManuelNoch keine Bewertungen

- Stand Jack CalculationDokument6 SeitenStand Jack Calculationageng sakokoNoch keine Bewertungen

- Load CombDokument50 SeitenLoad CombArnold VercelesNoch keine Bewertungen

- Halfen Fastenings Calculations For ChambersDokument2 SeitenHalfen Fastenings Calculations For Chambersnazeer_mohdNoch keine Bewertungen

- Genset Pad 10ftx2ftDokument7 SeitenGenset Pad 10ftx2ftAmmad AlizaiNoch keine Bewertungen

- TTWB 2014 Breneman CLT Floor DesignDokument58 SeitenTTWB 2014 Breneman CLT Floor DesignSimona SavastreNoch keine Bewertungen

- Double Shear Single ShearDokument3 SeitenDouble Shear Single ShearJoyce ChepkiruiNoch keine Bewertungen

- Pinned Base (I-Section) : Design CapacitiesDokument8 SeitenPinned Base (I-Section) : Design CapacitiesAwais HameedNoch keine Bewertungen

- Engineering Calculation Sheet Consulting EngineersDokument17 SeitenEngineering Calculation Sheet Consulting EngineersParthiban ArivazhaganNoch keine Bewertungen

- Connection Design Steel Base Plate Bs5950 v2015 01Dokument4 SeitenConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNoch keine Bewertungen

- Breadth Cheat SheetsDokument56 SeitenBreadth Cheat SheetssoftlikerockNoch keine Bewertungen

- 2016-XXX Stemwall Shearwall Footing SWLXDokument4 Seiten2016-XXX Stemwall Shearwall Footing SWLXIonFlorentaNoch keine Bewertungen

- Engineering Calculation Sheet Consulting EngineersDokument11 SeitenEngineering Calculation Sheet Consulting EngineersJONAS NGNoch keine Bewertungen

- Appendix A: Reinforcement CharacteristicsDokument9 SeitenAppendix A: Reinforcement CharacteristicsTareq Al ShyoukhyNoch keine Bewertungen

- M3D - SampleProblemSet ACI PDFDokument6 SeitenM3D - SampleProblemSet ACI PDFasaisenthilNoch keine Bewertungen

- M3D Validation ReportDokument59 SeitenM3D Validation ReportVasanth KumarNoch keine Bewertungen

- 03 Beam DesignDokument32 Seiten03 Beam Designnaveed1144Noch keine Bewertungen

- Squarefooting CalculatorDokument2 SeitenSquarefooting CalculatorNazar BazaraaNoch keine Bewertungen

- 2F BEAM DESIGN CALCULATIONS B3 - B3 - B4 at GRID 2 PDFDokument7 Seiten2F BEAM DESIGN CALCULATIONS B3 - B3 - B4 at GRID 2 PDFRandy ViolaNoch keine Bewertungen

- Ang Residence (Flatdeck 1.0mm X 100mm THK Slab)Dokument6 SeitenAng Residence (Flatdeck 1.0mm X 100mm THK Slab)Pandaman227Noch keine Bewertungen

- Grade Beam Design CalculationDokument3 SeitenGrade Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Cal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Dokument5 SeitenCal. Stanchion Pipe 3 In. SCH80 - Lifting Lug 2Anisa Rifqi0% (1)

- Golf Range Structural Calcs 2016Dokument10 SeitenGolf Range Structural Calcs 2016Popano GamingNoch keine Bewertungen

- Footing GayakDokument26 SeitenFooting GayakJhoe SamNoch keine Bewertungen

- Example 10 - Sign Structure Foundation Design: General InformationDokument13 SeitenExample 10 - Sign Structure Foundation Design: General InformationWahid wrbelNoch keine Bewertungen

- FINAL Design - of - RCC Two Way Slab S2Dokument5 SeitenFINAL Design - of - RCC Two Way Slab S2sujit naikwadiNoch keine Bewertungen

- AISC 13ed LRFD HSS Steel Design Post r1Dokument383 SeitenAISC 13ed LRFD HSS Steel Design Post r1RIYA HAZARIKANoch keine Bewertungen

- Grade Beam Design CalculationDokument3 SeitenGrade Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Steel DesignDokument36 SeitenSteel DesignthetsoeNoch keine Bewertungen

- Base PlateDokument29 SeitenBase PlateRakesh SharmaNoch keine Bewertungen

- Calculation PDFDokument126 SeitenCalculation PDFmohammed almahrooqiNoch keine Bewertungen

- Formwork and Falsework For Moawa Bridge-Steel DesignDokument10 SeitenFormwork and Falsework For Moawa Bridge-Steel DesignAbner Ramos ApazaNoch keine Bewertungen

- Brace DesignDokument457 SeitenBrace DesignRyan Goh Chuang HongNoch keine Bewertungen

- WEB - Welding DesignDokument2 SeitenWEB - Welding DesignAdam MillerNoch keine Bewertungen

- Secondfloor Beam Design CalculationDokument7 SeitenSecondfloor Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Anti-Roll Force Calculations: 0.76 1.0 UphillDokument1 SeiteAnti-Roll Force Calculations: 0.76 1.0 Uphilljigarshah21Noch keine Bewertungen

- RC One Way Slab Design (ACI318)Dokument2 SeitenRC One Way Slab Design (ACI318)Bunkun15100% (1)

- Slab Design Calculation: f (5* f A /8 A βDokument1 SeiteSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Third Floor Beam Design CalculationDokument3 SeitenThird Floor Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Third Floor Beam Design CalculationDokument3 SeitenThird Floor Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Proposed Two Storey Aparment Building Struct AnalysisDokument26 SeitenProposed Two Storey Aparment Building Struct AnalysisIver Ace BihisNoch keine Bewertungen

- B-1 - Canopy Base PlateDokument2 SeitenB-1 - Canopy Base PlateSaurabh GuptaNoch keine Bewertungen

- Beam With TorsionDokument8 SeitenBeam With TorsionRayodc100% (1)

- Third Floor Beam Design CalculationDokument5 SeitenThird Floor Beam Design CalculationArnold VercelesNoch keine Bewertungen

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseDokument4 SeitenAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalNoch keine Bewertungen

- DesignOfFooting JOSDokument26 SeitenDesignOfFooting JOSJhoe SamNoch keine Bewertungen

- Appendix C - Properties of Roller-Steel Shapes - BeerDokument13 SeitenAppendix C - Properties of Roller-Steel Shapes - BeerDaniel LarrínagaNoch keine Bewertungen

- TI-NspireCAS ReferenceGuide EN PDFDokument262 SeitenTI-NspireCAS ReferenceGuide EN PDFDaniel LarrínagaNoch keine Bewertungen

- Design of Spandrel Beams, G.J. KleinDokument24 SeitenDesign of Spandrel Beams, G.J. KleinDaniel LarrínagaNoch keine Bewertungen

- Design of Spandrel Beams, G.J. KleinDokument24 SeitenDesign of Spandrel Beams, G.J. KleinDaniel LarrínagaNoch keine Bewertungen

- Obe Phy 2105 B C Fall 2021Dokument5 SeitenObe Phy 2105 B C Fall 2021Mizanur Rahman Azhari fan's ClubNoch keine Bewertungen

- Compression TestDokument18 SeitenCompression TestMohamed Essam Abdelmeguid50% (4)

- Drying & Curing of Paint FilmsDokument5 SeitenDrying & Curing of Paint FilmsOmar DhiebNoch keine Bewertungen

- 1SVR730750R0400 CM Efs 2sDokument5 Seiten1SVR730750R0400 CM Efs 2slaura pizaNoch keine Bewertungen

- Why Compression Ratio MattersDokument7 SeitenWhy Compression Ratio MattersMTOLNoch keine Bewertungen

- A1021Dokument4 SeitenA1021Aleksei AvilaNoch keine Bewertungen

- Fatigue of Materials Solved Problems UnlockedDokument20 SeitenFatigue of Materials Solved Problems UnlockedMAT-LIONNoch keine Bewertungen

- Analysis of Anaerobic Adhesive's Role in Abutment Screw Final ReportDokument13 SeitenAnalysis of Anaerobic Adhesive's Role in Abutment Screw Final ReportKevinTWilkinsNoch keine Bewertungen

- Industrialrefrcryo-03 11 15Dokument72 SeitenIndustrialrefrcryo-03 11 15ASHITA K BNoch keine Bewertungen

- Investigation of Transistor Characteristics of N-P-N and P-N-PDokument9 SeitenInvestigation of Transistor Characteristics of N-P-N and P-N-PMOKAYANoch keine Bewertungen

- Shell and Tube Heat Exchanger SpreadsheetDokument2 SeitenShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Assignment Reg 2013 Tuesday1Dokument2 SeitenAssignment Reg 2013 Tuesday1Abubakar AdeniNoch keine Bewertungen

- Small Pellicle Laser InterferometersDokument4 SeitenSmall Pellicle Laser InterferometersOluwamayokun AdetoroNoch keine Bewertungen

- Department of Mining, Metallurgical and Materials EngineeringDokument24 SeitenDepartment of Mining, Metallurgical and Materials EngineeringDrakeNoch keine Bewertungen

- Large Fog Collectors New Strategies For Collection Efficiency and Structural Response To Wind Pressure 2015 Atmospheric ResearchDokument14 SeitenLarge Fog Collectors New Strategies For Collection Efficiency and Structural Response To Wind Pressure 2015 Atmospheric ResearchChristianNoch keine Bewertungen

- Slender Column and Two Way SlabsDokument83 SeitenSlender Column and Two Way Slabsshakirhamid6687100% (1)

- Lab1 - ELECTRONIC COMPONENT MEASUREMENT LATESTDokument7 SeitenLab1 - ELECTRONIC COMPONENT MEASUREMENT LATESTMohd AsriNoch keine Bewertungen

- History of PiezopolymersDokument14 SeitenHistory of PiezopolymersrachmajuwitaNoch keine Bewertungen

- Discovery of Sub Atomic ParticlesDokument4 SeitenDiscovery of Sub Atomic ParticlesManasvi SharmaNoch keine Bewertungen

- Chapter 7. Covalent and Metallic BondingDokument23 SeitenChapter 7. Covalent and Metallic Bondingnacha meyyNoch keine Bewertungen

- Metals: Optimization of PWHT of Simulated HAZ Subzones in P91 Steel With Respect To Hardness and Impact ToughnessDokument21 SeitenMetals: Optimization of PWHT of Simulated HAZ Subzones in P91 Steel With Respect To Hardness and Impact ToughnessPEMCO InspectionNoch keine Bewertungen

- HW 2. ProblemsDokument5 SeitenHW 2. ProblemsAruzhanNoch keine Bewertungen

- Nur Afiqah Binti Mohd Radzi (2019848282) - Assignment 1 FSG567Dokument7 SeitenNur Afiqah Binti Mohd Radzi (2019848282) - Assignment 1 FSG567Wsr HalilahNoch keine Bewertungen

- Vultex XLPE Medium Voltage Electric Cable - 6,6kV To 33kVDokument27 SeitenVultex XLPE Medium Voltage Electric Cable - 6,6kV To 33kVWayne KitchingNoch keine Bewertungen

- DNV RP-F201Dokument26 SeitenDNV RP-F201Mr. EngineerNoch keine Bewertungen

- API 570 Study Guide - FullDokument18 SeitenAPI 570 Study Guide - Fullochable100% (1)

- ExperimentDokument13 SeitenExperimentHandcrafting BeautiesNoch keine Bewertungen

- Spherical Dome 2013 MDokument39 SeitenSpherical Dome 2013 Mrahulgehlot2008Noch keine Bewertungen

- Res lvk-3082595Dokument4 SeitenRes lvk-3082595f4bxwNoch keine Bewertungen