Beruflich Dokumente

Kultur Dokumente

S 001 Link 2

Hochgeladen von

wael badawi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten1 SeiteThis document provides a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of groove and fillet joints in carbon steel piping. The WPS specifies the base and filler metals, joint design, welding positions, techniques, parameters, and qualifications. Welding will be performed manually with E7018 electrodes in the vertical up position for groove welds and all positions for fillet welds. Preheating is required for material over 25mm thick.

Originalbeschreibung:

Welding

Originaltitel

S-001-Link-2

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of groove and fillet joints in carbon steel piping. The WPS specifies the base and filler metals, joint design, welding positions, techniques, parameters, and qualifications. Welding will be performed manually with E7018 electrodes in the vertical up position for groove welds and all positions for fillet welds. Preheating is required for material over 25mm thick.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten1 SeiteS 001 Link 2

Hochgeladen von

wael badawiThis document provides a welding procedure specification (WPS) for shielded metal arc welding (SMAW) of groove and fillet joints in carbon steel piping. The WPS specifies the base and filler metals, joint design, welding positions, techniques, parameters, and qualifications. Welding will be performed manually with E7018 electrodes in the vertical up position for groove welds and all positions for fillet welds. Preheating is required for material over 25mm thick.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

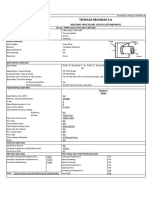

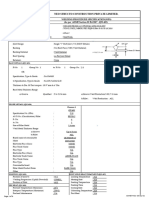

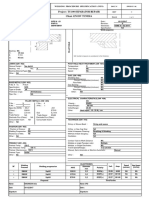

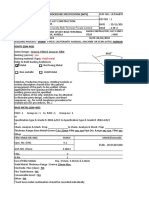

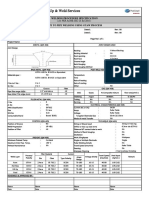

WENDT-WE-FOR-001, R0, Dated: 30/04/2019

Welding & NDT

QW-482 WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1,Section, IX, ASME Boiler and Pressure Vessel code )

PW.P.S. NO. : S-001 Supporting PQR(s) 001 POSTWELD HEAT TREATMENT (QW-407) ELECTRICAL CHARACTERISTICS (QW-409)

Revision No.: 0 Welding Process(es): SMAW .1 Ø Type of PWHT: NONE .4 (a) Ø Current (AC or DC): SEE BELOW

Date: 30/04/2019 Type(s): MANUAL .2 (a) Temperature Range :(°C) NA .4 (b) Ø Polarity (EN or EP): SEE BELOW

Equipment Name: Joint Type: GROOVE/FILLET .2 (b) Time Range:(Minute) NA .8 (a) Ø Amperes (Range): SEE BELOW

JOINTS (QW-402) Method of PWHT: NA .8 (b) Ø Voltage (Range): SEE BELOW

.1 Ø Joint Design: AS PER DRAWING Typical: .4 T Limits NONE .1 > Heat Input : NA

.4 - Backing: (Yes/No) Yes Rate Of Heating:(°C/hr) NA Others : NA

Backing Material (type): WELD/BASE METAL Rate Of Cooling:(°C/hr) NA

.10 Ø Root Spacing AS PER DRAWING Others : NA

.11 ± Retainers : NA GAS (QW-408)

Root face & Included Angle: 1-2 mm & 60° P1 G2 Back Chipped & Rewelded P1 G1 Gas(es) Mixture & Composition Flow rate (LPM)

BASE METALS (QW-403) Shielding Gas: NA NA NA

MATERIAL - 1 MATERIAL - 2 Backing Gas or Backing Flow: NA NA NA

.11 Ø P.NO.: 1 P.NO.: 1 Trailing Gas or Comp: NA NA NA

.5 Ø Group No.: 2 Group No.: 1 Backing Gas or Comp : NA NA NA

Specification/Grade: SA516GR70 Specification/Grade: SA516GR60 Shielding or Trailing : NA NA NA

.8 ØThickness Range : (mm) TECHNIQUE (QW-410)

Base Metal Groove : 5-32 Fillet : ALL Tubesheet: NA .1 Ø String/Weave Bead: STRING/WEAVE (WEAVING SHALL NOT EXCEED 3 TIMES THE ELECTRODE CORE DIA)

Pipe Dia Range Groove : ALL Fillet : ALL Ligament: Width : NA .9 Ø Multi/Single pass (per side): MULTI PASS

Overlay thickness (Min): NA Tube thickness: NA .10 Ø Multiple/Single Electrode: SINGLE

.6 T Limits : NA .9 t Pass> 12.7 mm EACH PASS THK < 6 mm .26 ± Peening: NA

FILLER METALS (QW-404) .5 Ø Initial or Interpass WIRE BRUSH OR GRIND/MACHINED ;SURFACE TO BE GROUND

ROOT PASS FILL UP PASS(es) COVERING PASS(es) Cleaning: OR POWER WIRE BRUSHED OR MACHINED

.4 Ø F.NO.: 4 4 4 .6 Ø Method of Back Gouging: BY AIR ARC GOUGING, MACHINING ,GRINDING etc

.5 Ø A.NO.: 1 1 1 .25 Ø Manual or Automatic MANUAL

Spec No.(SFA): 5.1 5.1 5.1 .64 Ø Use of Thermal Process : NONE

.12 & .33 Ø AWS No.(Class): %E7018 %E7018 %E7018 Others : NA

.6 Ø Size of Filler Metal (mm): 3.2,4.0,5.0 3.2,4.0,5.0 3.2,4.0,5.0 Filler Metal Current Travel Energy or Maximum Minimum

Weld Volt

.7 Ø Diameter > 6 mm NA NA NA Process Dia. Type & Amp. Speed Power Heat Input Bead Length

Layer(s) Classification (Range)

.30 Ø Weld Metal Thk Range: UPTO 20 mm (MAX) (mm) Polarity (Range) (mm/min) (Range) (KJ/mm) (mm)

Chemical Composition: NA AS REQ SMAW E7018 3.2 DCEP 100-140 22-28 AS PER PQR NA 1.5 150

Brand Name : % E7018 OF APPROVED BRAND SHALL BE USED AS REQ SMAW E7018 4.0 DCEP 150-180 22-28 AS PER PQR NA 1.5 180

Other : NA AS REQ SMAW E7018 ^ 5.0 DCEP 200-240 22-28 AS PER PQR NA 1.5 200

POSITIONS (QW-405)

.1 + (a) Position(s) of Groove : ALL

.2 & .3 Ø Welding Progression : VERTICAL UPHILL NA : NOT APPLICABLE NONE : ESSENTIAL VARIABLE BUT NOT USED

.1 + (b) Position(s) of Fillet : ALL Legend :

Other: NA + Addition > Increase/greater than ↑ Uphill ← Forehand ø Change

PREHEAT (QW-406) -Deletion < Decrease/less than ↓ Downhill → Backhand

Thickness Range (mm) ≤25 > 25-38

.1 Preheat Temp (MIN)⁰ C : 25 100

.3 Interpass Temp (MAX)⁰ C: 275 275 ^ FOR USE IN FLAT/HORIZONTAL POSITION ONLY

Preheat Maintenance : NA

Method of measuring .1 & .3 Temperature indicating crayon / Laser gun

PREPARED BY: WELDING ENGINEER REVIEWED BY: WELDING MANAGER APPROVED BY: CLIENT/CUSTOMER/TPI

ASME

DESIGNATOR

NAME: NAME: NAME:

REQ.

DATE: DATE: DATE:

NOT REQ.

Das könnte Ihnen auch gefallen

- Welding & NDTDokument1 SeiteWelding & NDTVijaya BaraniNoch keine Bewertungen

- GTAWDokument1 SeiteGTAWabdulNoch keine Bewertungen

- WPS VesselDokument1 SeiteWPS VesselNaqqash SajidNoch keine Bewertungen

- GS 001 Link 1 PDFDokument1 SeiteGS 001 Link 1 PDFhichemokokNoch keine Bewertungen

- Piping WPS SMAWDokument2 SeitenPiping WPS SMAWJk KarthikNoch keine Bewertungen

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDokument4 Seiten(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNoch keine Bewertungen

- For Fillet Weld Joint Project:Production ManifoldDokument1 SeiteFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- PWPS CS To SS446-3Dokument5 SeitenPWPS CS To SS446-3BIIS QAQC Babu SivaNoch keine Bewertungen

- 347 310 WPSDokument2 Seiten347 310 WPSBIIS QAQC Babu SivaNoch keine Bewertungen

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Dokument2 SeitenLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNoch keine Bewertungen

- WPS For A333 ADokument1 SeiteWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Dokument2 SeitenWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPS For Carbon Steel THK 7.11 GTAWDokument1 SeiteWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDokument1 SeiteWps For Carbon Steel THK 7.11 GtawAli MoosaviNoch keine Bewertungen

- WPS No. ST-CS-02-2Dokument1 SeiteWPS No. ST-CS-02-2Hussein JassimNoch keine Bewertungen

- (P1) NSC-1020-TR-0102-1.1-WPS-06Dokument6 Seiten(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNoch keine Bewertungen

- Wps For Steel RodsDokument5 SeitenWps For Steel RodsHamid MansouriNoch keine Bewertungen

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Dokument2 SeitenTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNoch keine Bewertungen

- Welding Procedure Specification: (As Per Asme Sec Ix)Dokument1 SeiteWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNoch keine Bewertungen

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDokument1 SeiteCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNoch keine Bewertungen

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Dokument2 SeitenTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNoch keine Bewertungen

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Dokument1 SeiteProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNoch keine Bewertungen

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Dokument9 Seiten(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNoch keine Bewertungen

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Dokument1 SeiteO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNoch keine Bewertungen

- Welding Procedure Specification "WPS": O O O ODokument1 SeiteWelding Procedure Specification "WPS": O O O OAli MoosaviNoch keine Bewertungen

- HHHHHHHHJJJJJJ: O O O ODokument1 SeiteHHHHHHHHJJJJJJ: O O O OAli MoosaviNoch keine Bewertungen

- WPS-035 - (Pno.15e To Pno.7) - 2Dokument2 SeitenWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNoch keine Bewertungen

- 19403955-WPS M.S. Is 2062Dokument10 Seiten19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Revised PWPS 001Dokument2 SeitenRevised PWPS 001stdshopNoch keine Bewertungen

- WPSDokument6 SeitenWPSYASH BARDHAN SinghNoch keine Bewertungen

- Wps For Ss 304Dokument3 SeitenWps For Ss 304Sajit PillaiNoch keine Bewertungen

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Dokument3 SeitenNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNoch keine Bewertungen

- WPS E6013+e7018Dokument2 SeitenWPS E6013+e7018Anvesh Vaddi100% (1)

- WPS For SSDokument1 SeiteWPS For SSdeepakNoch keine Bewertungen

- Welding Procedure Specification (WPS) : Code: Asme-IxDokument2 SeitenWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNoch keine Bewertungen

- WPS GTAW Stainless SteelDokument7 SeitenWPS GTAW Stainless SteelVarun MalhotraNoch keine Bewertungen

- Welding Proposed Pwps For Our Jubail WorkDokument2 SeitenWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPSDokument2 SeitenWPSAlam MD Sazid100% (1)

- WPS CuNiDokument1 SeiteWPS CuNiDieter Huaman ToscanoNoch keine Bewertungen

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Dokument2 SeitenBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNoch keine Bewertungen

- WPS PDFDokument5 SeitenWPS PDFHakanNoch keine Bewertungen

- WPS 03 GtawDokument3 SeitenWPS 03 GtawBiswajit DeyNoch keine Bewertungen

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNoch keine Bewertungen

- According To ASME IX: Welding Procedure Specification (W.P.S)Dokument4 SeitenAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNoch keine Bewertungen

- Wps For Akbtpl E-6013 - ModifiedDokument13 SeitenWps For Akbtpl E-6013 - ModifiedvinayNoch keine Bewertungen

- WPS PQR ProcedureDokument31 SeitenWPS PQR Proceduresudeesh kumarNoch keine Bewertungen

- WPS PQR Procedure PDFDokument31 SeitenWPS PQR Procedure PDFsudeesh kumarNoch keine Bewertungen

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDokument2 SeitenWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNoch keine Bewertungen

- Aic Asf PQR 0121Dokument2 SeitenAic Asf PQR 0121AHMED MEDANYNoch keine Bewertungen

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Dokument2 SeitenWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNoch keine Bewertungen

- QW 482 WPS (Gtaw+smaw) 04.01.2015Dokument8 SeitenQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNoch keine Bewertungen

- Astm 537 CL.1 WPSDokument2 SeitenAstm 537 CL.1 WPSaudiihussain67% (3)

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDokument1 SeiteMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghNoch keine Bewertungen

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDokument5 SeitenWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDokument10 SeitenWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNoch keine Bewertungen

- Aic Asf PQR 133Dokument3 SeitenAic Asf PQR 133AHMED MEDANYNoch keine Bewertungen

- 37507022-WPS-PQR-SS-316 LDokument5 Seiten37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Subject: Recommendation Letter For Mr. Abdulrahmn Bakir - Dear Sir/MadamDokument1 SeiteSubject: Recommendation Letter For Mr. Abdulrahmn Bakir - Dear Sir/Madamwael badawiNoch keine Bewertungen

- Motivation Letter: Wael BadawiDokument2 SeitenMotivation Letter: Wael Badawiwael badawiNoch keine Bewertungen

- Gmaw Complete Aws d1.6Dokument1 SeiteGmaw Complete Aws d1.6Solda DorNoch keine Bewertungen

- In 2020 11414 JCDokument1 SeiteIn 2020 11414 JCwael badawiNoch keine Bewertungen

- F=τ ∙ A A=t ∙ L F=τ ∙ A A=t ∙ L L= t F=τ ∙ A A=t ∙ L l= h tgφ h=0.25 ∙t α=cos y R y= d −h−tDokument5 SeitenF=τ ∙ A A=t ∙ L F=τ ∙ A A=t ∙ L L= t F=τ ∙ A A=t ∙ L l= h tgφ h=0.25 ∙t α=cos y R y= d −h−twael badawiNoch keine Bewertungen

- 6sigma PDFDokument5 Seiten6sigma PDFwael badawiNoch keine Bewertungen

- Aws D1.1 - Field: Welding PlanDokument6 SeitenAws D1.1 - Field: Welding Planwael badawiNoch keine Bewertungen

- Six Sigma For Small BusinessDokument5 SeitenSix Sigma For Small Businesswael badawiNoch keine Bewertungen

- Welding Procedure Specification W - P - S: Technique Positions Project: Welding Piece MechanicalDokument2 SeitenWelding Procedure Specification W - P - S: Technique Positions Project: Welding Piece Mechanicalwael badawiNoch keine Bewertungen

- Authentic Listening X-Rays - ScriptDokument2 SeitenAuthentic Listening X-Rays - Scriptenfa.work.confNoch keine Bewertungen

- 2021 Test3 Part5Dokument9 Seiten2021 Test3 Part5Sicut DilexiNoch keine Bewertungen

- Cost Optimisation of Water Tanks Designed According To The Aci and Euro CodesDokument25 SeitenCost Optimisation of Water Tanks Designed According To The Aci and Euro CodesandysupaNoch keine Bewertungen

- Combustion and Flame: Victor Chernov, Qingan Zhang, Murray John Thomson, Seth Benjamin DworkinDokument10 SeitenCombustion and Flame: Victor Chernov, Qingan Zhang, Murray John Thomson, Seth Benjamin DworkinVictor ChernovNoch keine Bewertungen

- Chapter 5. Elementary ProbabilityDokument11 SeitenChapter 5. Elementary ProbabilityyonasNoch keine Bewertungen

- Science Year 5: MicroorganismsDokument8 SeitenScience Year 5: MicroorganismscthanifahNoch keine Bewertungen

- Dictum Giftideas 2012Dokument40 SeitenDictum Giftideas 2012Alexandre LetellierNoch keine Bewertungen

- Documents and Data RequirementsDokument2 SeitenDocuments and Data RequirementsGerardo Leon RoblesNoch keine Bewertungen

- 74HC4049Dokument11 Seiten74HC4049jnax101Noch keine Bewertungen

- SQF Edition 8 Quick Start GuideDokument27 SeitenSQF Edition 8 Quick Start Guidefourat.zarkounaNoch keine Bewertungen

- CBSE Class 10 Social Science Syllabus 2022 23Dokument12 SeitenCBSE Class 10 Social Science Syllabus 2022 23Bhavini SutarNoch keine Bewertungen

- Guard Rail Cataloge PDFDokument28 SeitenGuard Rail Cataloge PDFreza acbariNoch keine Bewertungen

- Representing Inverse Functions Through Tables and GraphsDokument18 SeitenRepresenting Inverse Functions Through Tables and GraphsJoseph BaclayoNoch keine Bewertungen

- Outline PatentsDokument37 SeitenOutline Patentspbp613Noch keine Bewertungen

- MBA: International Business: SchillerDokument2 SeitenMBA: International Business: SchillernancyekkaNoch keine Bewertungen

- Op QuesDokument7 SeitenOp QuessreelakshmiNoch keine Bewertungen

- 100kva DG Set - 100kva Koel GensetDokument3 Seiten100kva DG Set - 100kva Koel GensetMothilalNoch keine Bewertungen

- My Beamer TalkDokument85 SeitenMy Beamer TalkOtmane El ouardiNoch keine Bewertungen

- FILIPINO 2 LEARNING PLAN 3rd QuarterDokument4 SeitenFILIPINO 2 LEARNING PLAN 3rd QuarterMary Kryss DG SangleNoch keine Bewertungen

- NCQC Answer Paper-1Dokument4 SeitenNCQC Answer Paper-1Shyamal KumarNoch keine Bewertungen

- Descriptive Lab Report GuideDokument3 SeitenDescriptive Lab Report GuideOluwafisayomi LawaniNoch keine Bewertungen

- The Relationship Between International Innovation Collaboration, Intramural R&D and Smes' Innovation Performance: A Quantile Regression ApproachDokument6 SeitenThe Relationship Between International Innovation Collaboration, Intramural R&D and Smes' Innovation Performance: A Quantile Regression ApproachSurya DhNoch keine Bewertungen

- HTML5 and CSS3 Illustrated Complete 2nd Edition Vodnik Solutions Manual 1Dokument12 SeitenHTML5 and CSS3 Illustrated Complete 2nd Edition Vodnik Solutions Manual 1barbara100% (44)

- Online Vital RegistrationDokument70 SeitenOnline Vital RegistrationgashawNoch keine Bewertungen

- 10 Must Read Books For Stock Market Investors in India - Trade BrainsDokument35 Seiten10 Must Read Books For Stock Market Investors in India - Trade BrainsCHANDRAKISHORE SINGHNoch keine Bewertungen

- Unit 8 Technical Analysis: ObjectivesDokument13 SeitenUnit 8 Technical Analysis: Objectivesveggi expressNoch keine Bewertungen

- Accelerometer With VelocityDokument11 SeitenAccelerometer With VelocityAS_865025438Noch keine Bewertungen

- Application of Chain Drive and It's Selection MethodDokument21 SeitenApplication of Chain Drive and It's Selection MethodYogesh B0% (1)

- SSL ConfigDokument173 SeitenSSL Configsairamb_143Noch keine Bewertungen

- Alternating Current Bounce Back 2.0 22 DecDokument132 SeitenAlternating Current Bounce Back 2.0 22 Decayushmanjee1303Noch keine Bewertungen