Beruflich Dokumente

Kultur Dokumente

315 mhp@3800 rpm

Hochgeladen von

Jaime MksOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

315 mhp@3800 rpm

Hochgeladen von

Jaime MksCopyright:

Verfügbare Formate

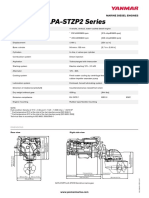

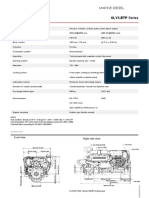

6LPA-STP2 MARINE DIESEL ENGINES

6LPA-STP2 Series

Series

Configuration

6LPA-STP2 Series

4-stroke, vertical, water cooled diesel engine

Configuration

Configuration 4-stroke, vertical, water4-stroke,

cooled diesel engine

vertical, water-cooled diesel engine

Maximum output at crankshaft * 232 kW (315 mhp) / 3800 rpm

Maximum output at output

Maximum crankshaft

at crankshaft * 232**kW 225(315

kWmhp) * 232

/ 3800

(306 mhp) kW@3800

/ rpm

3800 rpm rpm [315 mhp@3800 rpm]

** 225 kW (306 mhp) / 3800 rpm

** 220 kW@3800 rpm [299 mhp@3800 rpm]

Continuous rating output at crankshaft 211 kW (286.4 mhp) / 3682 rpm

Continuous rating output at crankshaft 211 kW (286.4 mhp) / 3682 rpm

Displacement 4.164 L [254 cu in]

Displacement 4.164 L (254 cu in)

Displacement

Bore x stroke

4.164 L (254 cu in) 94 mm x 100 mm [3.7 in x 3.94 in]

Bore x stroke 94 mm x 100 mm (3.70 in x 3.94 in)

Bore x stroke

Cylinders 94 mm x 100 mm (3.70In-line,in x 3.94 in) per cylinder

4 valves

Cylinders 6 in line cylinders, 4-valves per cylinder

Cylinders Combustion system 6 in line cylinders, 4-valves per

Direct cylinder

injection

Combustion system Direct injection

CombustionAspiration

system Direct injection Turbocharged with intercooler

Aspiration Turbocharged withElectric

intercooler

Aspiration Starting system Turbocharged with intercooler starting 12V - 2.5 kW

Starting system

Alternator Electrical starting 12V

12 V- -80A

2.5 kW

Starting system Electrical starting 12 V - 2.5 kW

Alternator

Cooling system 12 V - 80 A Fresh water cooling by centrifugal fresh water pump and

Alternator 12 V - 80 A rubber impeller seawater pump

Cooling system Fresh water cooling by centrifugal fresh water pump and rubber impeller seawater pump

Cooling system

Lubrication system Fresh water cooling by Enclosed,

centrifugalforced

fresh water pump

lubricating and rubber impeller seawater pump

system

Lubrication system Enclosed, forced lubricating system

LubricationDirection

systemof rotation [crankshaft] Counterclockwise

Enclosed, forced lubricating system viewed from stern

Direction of rotation (crankshaft) Counter clockwise viewed from flywheel side

Direction ofDry weight without

rotation gear

(crankshaft) 408from

Counter clockwise viewed kg flywheel side [899 lbs]

Dry weight without gear 408 kg (899 lbs) EU: RCD 1

Dry weight Emission

without compliance

gear 408 kg (899 lbs)

BSO II EMC

Environmental

Engine mounting EU RCD, US EPA Rubber

Tier2, BSO

type II, EMC mounting

flexible & Marpol 73/78 Annex VI

Environmental EU RCD, US EPA Tier2, BSO II, EMC & Marpol 73/78 Annex VI

Engine mounting

NOTE:

Rubber type flexible mounting

Engine mounting Rubber type flexible mounting

Fuel condition: Density at 15°C = 0.84 g/cm³; 1 kW = 1.3596 mhp = 1.3410 HP

NOTE: Fuel condition: Density at 15°C = 0.86 g/cm 3; 1kW = 1.3596 mhp = 1.3410 HP

* Fuel temperature 25°C at the inlet of the fuel injection pump [ISO 3046-1]

NOTE:*FuelFuelcondition:

temperature Density

25°Cat at15°C = 0.86

the inlet g/cm

of the fuel3; injection

1kW = 1.3596

pump mhp

(ISO = 1.3410 HP

3046-1)

* Fuel ** ** Fuel temperature

temperature 25°C at the 40°C

inlet at the

of the fuel

inlet injection

of the fuel injection

pump (ISOpump [ISO 8665: 2006]

3046-1)

Fuel temperature 40°C at the inlet of the fuel injection pump (ISO 8665)

Technical

** Fuel Technical

temperature data

40°C atisthe

according

inlet to ISO

fuel8665: 2006/3046-1

data is according toof the

ISO 8665 injection

/ 3046 pump (ISO 8665)

Technical data is according to ISO 8665 / 3046

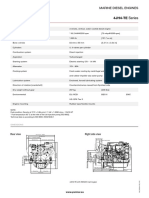

Dimensions (For detailed line-drawings, please refer to our web-site: www.yanmarmarine.com)

Dimensions (For detailed line-drawings, please refer to our web-site: www.yanmarmarine.com)

DIMENSIONS

Rear view Right side view

Rear viewRear view Right

Right side

side view viewo 102

mixing elbow

mixing elbow o 102

666 mm (26.2 in)

)

in)

.6 in

666 mm (26.2 in)

m (2.2

riser mixing elbow (option)

55 º m 6 in)

in)

)

2in

345 mm 321 mm

m mm (0

m (2.2

riser mixing elbow (option)

(5.

13 2in)

345 mm(13.6 in)321 mm(12.6 in)

(0.

m

(5.

(13.6 in) (12.6 in)

mm

1m

1 m15º

55 º m

260 mm

15º

260 mm(10.2 in)

13

(10.2 in)

497.1 mm (19.6 in)

in)

389 mm (15.3 in)

497.1 mm (19.6 in)

(13.1

132 mm 333 mm (13.1 in)

389 mm (15.3 in)

502 mm (19.8 in)

mm 502 mm (19.8 in)

mm

739 mm (29.1 in)

333

739 mm (29.1 in)

MIN.138 mm (5.4 in) 47 mm

MAX.148 mm (5.8 in) (1.9 in)

MIN.138 mm (5.4 in) 47 mm

MAX.148 mm (5.8 in) (1.9 in)

132 mm

(5.2 in)

(5.2 in)

237 mm

98.8 mm (3.9 in)

(9.3 in)

in)

23732mm

8º mm

98.8 mm (3.9 in)

in)

32 mm

(1.3 in)

748.4 mm (29.5 in)

(1.3

8º mm

(9.3

748.4

248.1 mmmm (29.5 in)

(0

248.1 mm(9.8 in)

.3 in)

(0

(9.8 in)

.3 in)

287 mm 287 mm 328.2 mm

287 mm(11,3 287

in) mm(11,3 in) 328.2 mm(12.9 in)

(11,3 in) (11,3 in) 1220 mm (48 in)

(12.9 in)

1220 mm (48 in)

EN_DS6LPA-STP2_0417

6LPA-STP2 with KMH50A marine gear 6LPA-STP2 / KMH50A marine gear

6LPA-STP2 / KMH50A marine gear

www.yanmarmarine.com

www.yanmarmarine.com

www.yanmarmarine.com

PERFORMANCE CURVES

Performance

PerformanceCurves

Curves(Output is according

(Output ISOISO

is according 8665)

8665)

Performance Curves (Output is according ISO 8665)

Power Torque

Torque FuelFuel

Consumption

Consumption

250 800 800

Torque 70

70 Fuel Consumption

mhp

250 18 18

Output (crankshaft/propeller shaft) kW

mhpmhp

kW kW

250 Maximum

Maximumoutput

outputatatcrankshaft

crankshaft 300

300 700 700

800 60 70 16 18

16

shaft)

500500

60

shaft)

shaft)

200

Fuel Consumption gal/hr

Crankshaft Torque lb-ft

Fuel Consumption L/hr

Crankshaft Torque Nm

200

Maximum output at crankshaft 300 600 600

700 14 16

14

Nm Nm

gal/hr

lb-ftlb-ft

250

L/hr L/hr

500 50 60

shaft)

250

shaft)

(crankshaft/propeller

200 400 50

400

(crankshaft/propeller

12

(crankshaft/propeller

14

12

gal/hr

500 600

Torque

250 500

Consumption

150

Torque

150 200 40 50

Consumption

200 400

(crankshaft/propeller

Maximum outputoutput 10

(crankshaft/propeller

40

Maximum 300 12

10

Torque

400 500

Consumption

Torque

300

150 at prop shaft 400

Consumption

200

atMaximum

prop shaftoutput

150 30 40 8

Crankshaft

100 150 10

8

Crankshaft

300 400 300 30

100 300 200

at prop shaft 6

Crankshaft

150

100 200 20 86

Crankshaft

30

100 100 200 300 20

FuelFuel

200 200 4

FuelFuel

50 64

50 100

50100 100 10 20

Output

100 200 2

Propeller power curve 2,5 50 100 10

Output

Output

50 42

0 Propeller power curve 2.5 0 50 0 100 0

100

0 10 0

Output

Output

0 0 0 0 20

1600 1800 2000 Propeller power

2200 2400 curve

2600 2.5

2800 3000 3200 3400 3600 3800 4000 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 1600 01800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000

1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000

0 0 0 0 0 0

Crankshaft Speed min-1 -1 Crankshaft Speed min

-1

Crankshaft Speed min -1

1400 1600 1800 2000 2200 2400 2600 2800 3000-1 3200 3400 3600 3800 4000

1400 1600 1800 2000 2200Crankshaft

2400 2600Speed

2800 min

3000 3200 3400 3600 3800 4000 Crankshaft Speed min Crankshaft

1400 1600 1800 2000 2200 2400 Speed

2600 2800 min3200

3000 -1 3400 3600 3800 4000

Drive systems Crankshaft Speed min-1 Crankshaft Speed min-1 Crankshaft Speed min-1

MARINEgear

Marine GEARS / DRIVE*

(example) ***

Marine gear (example) ***

Model ZT370 (Steerable Z-drive with dual prop)

Model

Model KMH50A

KMH50A ZF63AZF63A

[down angle 8°] [down angle 8°]

TypeModel KMH50A Hydraulic Actuated Multi-friction disc clutch ZF63A

Type

Type 8° down hydraulic

Hydraulically Actuated Multi-Disc Clutch 8° down

Hydraulically hydraulic

Actuated Multi-Disc Clutch

DryType

Weight 8° down hydraulic 100 Kg 8° down hydraulic

DryDry

weight

weight** 43 kg (95 lbs)[112 lbs]

51 kg 4444kgkg(97[97lbs)

lbs]

Reduction Ratio

Dry weight 1,65/1,65

43 kg (95 lbs) 1,78/1,78

44 kg (97 lbs)

Reduction

Reduction ratioRatio

(fwd/asn)

[fwd/rev] 1.67/1.67 1.67/1.67 2.13/2.13

2.13/2.13 2.43/2.43

2.43/2.43 1.22/1.21

1.22/1.21 1.56/1.58

1.56/1.58 2.04/2.10

2.04/2.10 2.52/2.53

2.52/2.53

propellor speed

Reduction ratio (fwd/asn) 1.67/1.67 2424/2424

2.13/2.13 2.43/2.43 1.22/1.21 2247/2247

1.56/1.58 2.04/2.10 2.52/2.53

Propeller speed

Propeller

(fwd/asn)

speed [fwd/rev]

2275 2275

1784 1784 1564 1564 3115/3140

3115/3140

2436/2405

2436/2405

1863/1810

1863/1810

1429/1423

1429/1423

Direction

Propeller speed (fwd/asn)from the stern

of rotation viewed 2275 1784 Clockwise (rear

1564 prop) & Counterclockwise

3115/3140 (front prop)2436/2405 1863/1810 1429/1423

Direction of rotation Counter clockwise Counter clockwise

LubDirection

oil specifications

Directionof of rotation

rotation Counter API class: GL5 SAE grade #80W90

(propeller shaft

(viewedshaft

- fwd)

from -stern)

viewed from clockwise

Clockwiseflywheel side

or Counterclockwise Counter

viewed fromclockwise

flywheel side

Counterclockwise

Dry(propeller

weight engine fwd)sterndrive

with viewed from flywheel side 550 kg (1213 lbs) viewed from flywheel side

Dry weight engine and gear/drive 449 kg (990 lbs) 452 kg (996 lbs)

Dry weight

Drycontrol

Shift –

weight engine engine & gear**

and gear/drive 449 kg459

(990kglbs)

[1012 lbs] Mechanical or Electro-magnetic 452

452 kgkg

(996[996lbs)lbs]

Length engine and gear/drive 1190 mm (46.9 in) 1205 mm (47.4 in)

Trim Length

Length engine and gear/drive

rangeengine and gear/drive 1190 mm

1190 mm (46.9 in) [46.9 in] -6° - +10° 1205 mm (47.4 in)in]

1205 mm [47.4

*** Gear also available in; ZF63 (Parallel) reduction ratio: 1.51 & 1.93; ZF63IV (V-drive) reduction ratio: 1.29, 1.56 & 2.00

* Other

Trailer marine

limitalso

***Other

Gear gearboxes

available in; ZF63 and configurations available

1.51 upon request. Contact your localratio:

supplier for more information. ** Dry weight includes cooler, brackets and damper disk.

& 51°

*** marine gearboxes and (Parallel) reduction

configurations ratio:

available upon &request.

1.93; ZF63IV (V-drive)

Contact reduction

your local supplier for 1.29,

more1.56 2.00

information.

*** Other marine gearboxes and configurations available upon request. Contact your local supplier for more information.

Instrument

INSTRUMENT Panels

PANELS

Instrument

Instrument Panels

Panels

New

NewB-type

B-typePanel

Panel New

New C-type

C-type Panel

Panel New

New D-type

D-type Panel

Panel

New B-type

2

2

3 Panel

3

1-4 1-5 1-5

1-4 103.6 New

4-1

4-1

C-type

4-2

4-2

Panel

3

3

1-4 1-5

1-4 1-5

New

4-3

4-3

D-type

4-1

4-1

4-2 Panel

4-2

3

3

1-4 1-5

1-4 1-5 103.6

103.6 103.6

2 3 1-4 1-5 103.6 4-1 4-2 3 1-4 1-5 4-3 4-1 4-2 3 1-4 1-5 103.6

76

76 76

1-4

160

180

160

180

160

180

1-4

160

180180

160160

180180

160160

180180

1-4

160

90

90 90

142.5 142.5 190 190 225 225

142.5 305 142.5 190 400 190 225 470 225

142.5 305 142.5 11 400 11

12.7 11 190 190 11 225 470 225

1-1 1-2 2 1-2 2 5470 1-3 1-1 1-2 12.7 11

1-3

305

1-3 1-1 1-2 12.7 11 2 4001-3 1-3

1-1

1-1

11

1-212.7 12.7 2 5 1-3 1-1 1-2 12.7

11 11

1-3 1-1 1-2 12.7 2 1-3 1-1 1-2 2 5 1-3 1-1 1-2 12.7

12.7

Type of instrument

Type panel

of instrument panel

Function Type of instrument panel

Function New B-type PanelTYPE

New B-type Panel OF New C-type

INSTRUMENT Panel

PANEL

New C-type Panel NewNew

D-type Panel

D-type Panel

1Function

1 Switch

Switch unit

unit New B-type Panel New C-type Panel New D-type Panel

Function

1 Switch unit DIGITAL B-TYPE PANEL NEW C-TYPE PANEL NEW D-TYPE PANEL

1-1

1-1Key Key switch

switch forfor

GLOW/OFF/ON/START

GLOW/OFF/ON/START (4-position switch)

(4-position switch) O O O O O O

1-21-1 Key

1-Switch switch

unit for GLOW/OFF/ON/START (4-position switch) O O O O O O

1-2Engine

Engine stop

stop switch

switch O O O

1-31-2 KeyEngine

1-1Alarm buzzer

switch stop switch

for(C.W. Temp., L.O.

GLOW/OFF/ON/START Pressure)

[4-position switch] Equipped on panel O O Equipped onO O

panel O O

Equipped

1-3 Alarm buzzer (C.W. Temp., L.O. Pressure) O O Oon panel

1-41-3 Alarm buzzer (C.W. Temp., L.O. Pressure) O O O O

1-2Alarm

1-4 Engine

Alarm buzzer

stop

buzzer stop

switchstopswitch

switch Equipped on panel O O Equipped onOpanel

O EquippedOon panel

1-51-4Illumination

Alarm buzzer switch stop switch

forfor

meters O O O O O O

1-5 Illumination

1-3 Alarm buzzer [C.W. switch Temp., meters

L.O. Pressure] Equipped on panel O O

Equipped on panel EquippedOon panel

2 1-5Alarm

Illumination

lamp unit switch for meters O O O

Alarm

2 Alarm

1-4

lampstop

buzzer

unit switch Equipped on panel O Equipped onOpanel Equipped on panel

Alarmnot

2 Battery lamp unit

charging O

Battery not charging O O O

1-5C.W.Battery not charging

high temperature

Illumination switch for meters Equipped on panel O O O

Equipped onOpanel O Oon panel

Equipped

C.W. high temperature O O O

L.O.

2-AlarmC.W.low

lamp high temperature

pressure

unit O O O O O O

L.O. low pressure O O O

F.O.L.O.

drain lowseparator

pressure (water level) O O O O O O

F.O. drain

2-1 Battery separator (water level)

not charging Equipped on panel O O

Equipped on panel EquippedOon panel

Sea F.O.

water drain flowseparator (water level) O O O O O O

Sea

2-2 C.W. water

high flow

temperature Equipped on panel O O

Equipped on panel EquippedOon panel

C.W. level forflow

Sea water fresh water tank X O O O O O

C.W. level for fresh water tank X O O

C.W.

2-3Boost

L.O. low level forhigh

pressure

pressure fresh water tank Equipped on panel X X O

Equipped onOpanel O Oon panel

Equipped

Boost pressure high O O O

Boost

drainpressure

3 2-4Tachometer

F.O. high meter

with hour

seperator Equipped on panel O O O

Equipped onOpanel O Oon panel

Equipped

3 Tachometer with hour meter O O O

3 Sub

4 2-5 Tachometer

meterflow unitwith hour meter X O O O

Sea water

4 Sub meter unit Equipped on panel Equipped on panel Equipped on panel

4-1 4 L.O.Sub meter meter

pressure unit X O O

4-1 L.O.level

2-6 C.W. pressure

for fresh meter

water tank Not equipped on panel X O

Equipped on panel EquippedOon panel

4-24-1C.W.L.O. pressure meter

Temperature meter X X O O O O

4-2

2-7 C.W.pressure

Boost Temperature high meter X

Equipped on panel X X O

Equipped onXpanel EquippedO

4-34-2Boost

C.W.meter Temperature

(turbo) meter O O Oon panel

4-3 Boost meter (turbo) X X O

4-3Quartz

Boostclock

5 3-Tachometer meter

with (turbo)

hour meter Equipped on panel X X X

Equipped onXpanel O Oon panel

Equipped

5 Quartz clock X X O

5 Quartz

4-Sub meter unit clock X X O

Note: O = Equipped on panel X = Not equipped on panel

Note:4-1

O L.O. pressure

= Equipped onmeter

panel X = Not equipped on panel Not equipped on panel Equipped on panel Equipped on panel

Accessories

Note: O = Equipped on panel X = Not equipped on panel

Accessories Accessories

4-2 C.W. Temperature meter Not equipped on panel Equipped on panel Equipped on panel

Standard Package

4-3 BoostPackage

Standard meter [turbo] Not equipped on panel Not equipped on panel Equipped on panel

• Sensor for

Standard instrument panel (New B, C and D-type)

Package • Fuel water separator (integrated with fuel filter)

•5•Sensor

Quartz clock

• Exhaust for

mixing instrument

elbow

Sensor for instrument panel panel

(L-type thru' drive) • Cooling water hoses

Not equipped

• Cooling water hoses

on panel • Not equipped

Hydraulic Steering onpump

panel Equipped on panel

(New

(New B,

• Cooling C

C and

water

B, D-type)

hoses

and D-type) •• Fuel

Fuel water

water separator (integrated with

separator (integrated with fuel filter)

fuel filter)

• Alternator 12 V - 80 A

••Exhaust/water

Optional Exhaust/water mixing

ACCESSORIES mixing elbow

elbow (L-type)

(L-type) •• Alternator

Alternator 1212 VV -- 80

80 AA

• Analog instrument panels (New B,C and D-type)

Optional • Dipstick for opposite side

Optional

• Flexible

Standard mounts

engine (2pcs)

package Optional accessories • Various Wire Harnesses (4,6,10 m)

••Flexible

Flexiblemixingmounts

mounts (2 pcs)

(2 pcs) • Sensor for VDO instrument panels •• Control

Control heads

••Sensor

•Exhaust

Exhaust for instrument

mixing elbow,

elbow, U-type

panel [New(high

U-type B, Criser

(highand

riser)transom type)•• Sensor

D-type] Control

for VDO instrument panels

• heads • Tie Bar (for

Flexible mounts [2 pcs] • High-riser mixing

• Air elbow

heads

twinventing

installation)

[instead

device offor

L-elbow]

cooling water

water tank

tank

• Exhaust mixing elbow, U-type (high riser) • Control heads • Air ventingfor device

main for cooling

••Exhaust/water

•Lub

•

oil evacuation

Analog

Analog instrument

mixing

instrument

pump

panels

elbow

panels [L-type] •• Various

Various • Wire

Analog

Wire Harnesses

instrument

Harnesses (4,panels

(4, 6, 10M)

6,

•[New

10M) VDOB,instrumentation

C and

•• VDO

VDO instrumentation

D-type]

instrumentation

panelfor and

for mainflypanel

main

bridge

panel

• Remark:

(New Engine D-type)

also available without Hydraulic steering pump evacuation

for twin installation

(New B,C

• Cooling B,C and

water hoses

and D-type) •• Lub

Lub oil Dual stationpump

oil•evacuation Y-harness • Sensor for VDO

pump and fly bridge

bridge

instrument

and fly panels

•and

Dual station Y harness •• Dipstick

Dipstick for opposite side

side

EN_DS6LPA-STP2_0417

• Fuel

Texts water separator

• Dual station Y harness

illustrations are not [integrated

binding. Yanmar with fuel

Marine filter]

reserves the right to introduce • Control

adaptations heads

without prior •notification.

Extension wire harness [4m, 6m,for 10m]

opposite Version: 2011-01

• Alternator 12V - 80A • Lub oil evacuation pump

www.yanmarmarine.com

Texts and illustrations are not binding. Yanmar Marine reserves the right to introduce adaptations without prior notification. Yanmar Europe Version:BV

2011-09

Texts and illustrations are not binding. Yanmar Marine reserves the right to introduce adaptations without prior notification. • Air venting device for cooling water tank Version: 2011-09

www.yanmarmarine.com

www.yanmarmarine.com

NOTE: All data subject to change without notice. Text and illustrations are not binding. Yanmar

• VDO instrumentation for main panel and fly bridge • Dipstick for Europe BV

opposite side

Yanmar Europe BV

www.yanmarmarine.com

Das könnte Ihnen auch gefallen

- Marine Diesel Engines Under 40 CharactersDokument2 SeitenMarine Diesel Engines Under 40 CharactersJoseph JosiNoch keine Bewertungen

- 4LHA-STP marine diesel engines overviewDokument2 Seiten4LHA-STP marine diesel engines overviewFrederik CañabiNoch keine Bewertungen

- Yanmar 6LPA STP2datasheetDokument2 SeitenYanmar 6LPA STP2datasheetŠime StipaničevNoch keine Bewertungen

- 4lha dtp1Dokument2 Seiten4lha dtp1Vasitha DenuwanNoch keine Bewertungen

- DS 6lpa-Ztzp2 A4 022021 HRDokument2 SeitenDS 6lpa-Ztzp2 A4 022021 HRMiguel Alcides Cueva HuamaliesNoch keine Bewertungen

- MARINE DIESEL ENGINESDokument2 SeitenMARINE DIESEL ENGINESPepebonillaNoch keine Bewertungen

- Yanmar 6LPA STZP2datasheet PDFDokument2 SeitenYanmar 6LPA STZP2datasheet PDFSoe Thura NyeinNoch keine Bewertungen

- B4 Engine Range B4AF40 Operation DatasheetDokument3 SeitenB4 Engine Range B4AF40 Operation DatasheetTruong NguyenNoch keine Bewertungen

- Yanmar-Datasheet 4JH5EDokument2 SeitenYanmar-Datasheet 4JH5EMuhammad rizkiNoch keine Bewertungen

- Marine Diesel 4JH4-TE Series EngineDokument2 SeitenMarine Diesel 4JH4-TE Series EngineRifkiHabibiNoch keine Bewertungen

- 8LV SterndriveDokument2 Seiten8LV SterndriveZNC Plamo and ToyzNoch keine Bewertungen

- Yanmar Type 6SY-650: Rear View Right Side ViewDokument2 SeitenYanmar Type 6SY-650: Rear View Right Side ViewAlbertoNoch keine Bewertungen

- Yanmar Datasheet 6LY3 ETPDokument2 SeitenYanmar Datasheet 6LY3 ETPCornelius Sebastian100% (1)

- Yanmar 3JH5E DatasheetDokument2 SeitenYanmar 3JH5E Datasheetvfxsm895rnNoch keine Bewertungen

- 8LV-320Z / 8LV-370Z: Marine Diesel EnginesDokument2 Seiten8LV-320Z / 8LV-370Z: Marine Diesel Enginesvfxsm895rnNoch keine Bewertungen

- AutogrederDokument12 SeitenAutogrederBaliban AntonNoch keine Bewertungen

- Yanmar 4JH4-HTEDokument2 SeitenYanmar 4JH4-HTEToniNoch keine Bewertungen

- C32B Tech SheetDokument2 SeitenC32B Tech SheetLeon ZwijnenburgNoch keine Bewertungen

- 12 and 16v92 Ta Spec SheetDokument4 Seiten12 and 16v92 Ta Spec SheetBrandon Atz67% (3)

- K-Series Loaders 624K/644K/724K: 139-197 KW (186-264 Net HP)Dokument9 SeitenK-Series Loaders 624K/644K/724K: 139-197 KW (186-264 Net HP)Francisco GuasumbaNoch keine Bewertungen

- FPT N45 SM1A DatasheetDokument3 SeitenFPT N45 SM1A DatasheethanspeterberigelNoch keine Bewertungen

- N45sm1a 51 To 59KWDokument3 SeitenN45sm1a 51 To 59KWsaiyedasadNoch keine Bewertungen

- Nef45sm1a 60kvaDokument3 SeitenNef45sm1a 60kvaOGNoch keine Bewertungen

- 6LY3-ETP Series: Marine Diesel EnginesDokument4 Seiten6LY3-ETP Series: Marine Diesel EnginesJUNIOR OLIVONoch keine Bewertungen

- Brosur Perkins 60 150kvaDokument2 SeitenBrosur Perkins 60 150kvaKanjeng Raden Aryo SaifuNoch keine Bewertungen

- tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderDokument2 SeitentAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 CylinderAdolfito PBNoch keine Bewertungen

- CUMMINS QSK38-DM-984kWDokument2 SeitenCUMMINS QSK38-DM-984kWIgor PancevskiNoch keine Bewertungen

- Cummins QSK38-DMDokument2 SeitenCummins QSK38-DMSonsai Quiru100% (1)

- Versatile 4WD TRACTORS Model 380 - 405 - 430 - 460Dokument1 SeiteVersatile 4WD TRACTORS Model 380 - 405 - 430 - 460Patrik GubinaNoch keine Bewertungen

- Daewoo Excavadora Hidráulica SOLAR 130W-VDokument8 SeitenDaewoo Excavadora Hidráulica SOLAR 130W-VMaquinza100% (3)

- Bomba de VacioDokument4 SeitenBomba de VacioJoel ArocaNoch keine Bewertungen

- 6LY2A-UTP / STP Series: Marine Diesel EnginesDokument2 Seiten6LY2A-UTP / STP Series: Marine Diesel EnginesHuỳnh Quý ThiênNoch keine Bewertungen

- Aksa Avp350Dokument4 SeitenAksa Avp350MarcosNoch keine Bewertungen

- @perkins: 1000 Series 1004TG1Dokument2 Seiten@perkins: 1000 Series 1004TG1Anas BasarahNoch keine Bewertungen

- Versatile 4WD DELTATRACK Model 520DT - 570DT - 610DTDokument1 SeiteVersatile 4WD DELTATRACK Model 520DT - 570DT - 610DTPatrik GubinaNoch keine Bewertungen

- @perkins: 1000 Series 1004TG1Dokument2 Seiten@perkins: 1000 Series 1004TG1OG100% (1)

- Versatile MFWD - ROW CROP TRACTOR 265 - 295 - 315Dokument2 SeitenVersatile MFWD - ROW CROP TRACTOR 265 - 295 - 315Patrik GubinaNoch keine Bewertungen

- Industrial Diesel Engine: 1996 EPA and CARB Non-Road Emissions CertifiedDokument2 SeitenIndustrial Diesel Engine: 1996 EPA and CARB Non-Road Emissions CertifieddfheardNoch keine Bewertungen

- Marine Diesel Engine Series 4JH4-HTEDokument2 SeitenMarine Diesel Engine Series 4JH4-HTECengiz özdolapNoch keine Bewertungen

- Bukh DV36 Rme A4Dokument2 SeitenBukh DV36 Rme A4Thomas Irwin DsouzaNoch keine Bewertungen

- APD330PDokument4 SeitenAPD330PJayz Sii ReshegNoch keine Bewertungen

- Joyner 650cc Engine Workshop ManualDokument30 SeitenJoyner 650cc Engine Workshop ManualMarton AtiNoch keine Bewertungen

- Centrifugal PumpDokument2 SeitenCentrifugal Pumpsong LiNoch keine Bewertungen

- Dv29Rme: Bukh Lifeboat Diesel EngineDokument2 SeitenDv29Rme: Bukh Lifeboat Diesel EngineDinescu StefanNoch keine Bewertungen

- Daewoo Excavadora Hidráulica SOLAR 170W-VDokument10 SeitenDaewoo Excavadora Hidráulica SOLAR 170W-VMaquinzaNoch keine Bewertungen

- Heat Exchanger 120-180KVA-2Dokument2 SeitenHeat Exchanger 120-180KVA-2Agi AlghifariNoch keine Bewertungen

- Case 430 SkidstDokument4 SeitenCase 430 Skidstjlindsey84Noch keine Bewertungen

- 4LHA-STP Series: Marine Diesel EnginesDokument2 Seiten4LHA-STP Series: Marine Diesel EnginesRobert ChambersNoch keine Bewertungen

- Portable Specs 750Dokument2 SeitenPortable Specs 750Ismail AliNoch keine Bewertungen

- Case 445Dokument4 SeitenCase 445ForomaquinasNoch keine Bewertungen

- Apd300c 6 PDFDokument4 SeitenApd300c 6 PDFHéctor VilaNoch keine Bewertungen

- Technical Specifications: 50Hz Powered by Cummins SeriesDokument4 SeitenTechnical Specifications: 50Hz Powered by Cummins Serieschristian210789Noch keine Bewertungen

- AKSA APD344C-6 Generator Set SpecificationsDokument5 SeitenAKSA APD344C-6 Generator Set SpecificationsCristhian ChoqueNoch keine Bewertungen

- Yanmar-2YM15 DatasheetDokument2 SeitenYanmar-2YM15 DatasheetALEJANDRA PEÑALOZANoch keine Bewertungen

- APD300C-6: Diesel Generating SetDokument4 SeitenAPD300C-6: Diesel Generating SetCarlos AlvarezNoch keine Bewertungen

- Yanmar 3YM20 DatasheetDokument2 SeitenYanmar 3YM20 Datasheetvfxsm895rnNoch keine Bewertungen

- Cummins KTA50-DM1: Unit Injector Low Noise and VibrationsDokument2 SeitenCummins KTA50-DM1: Unit Injector Low Noise and VibrationsRian100% (3)

- Egs380 6Dokument2 SeitenEgs380 6anggieNoch keine Bewertungen

- APD50C-6: Diesel Generating SetDokument4 SeitenAPD50C-6: Diesel Generating SetLuis MendezNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- Manual 75 OptimaxDokument5 SeitenManual 75 OptimaxJaime Mks20% (5)

- 1a PDFDokument12 Seiten1a PDFJaime MksNoch keine Bewertungen

- 6lya STD 6lya Ste YanmarDokument101 Seiten6lya STD 6lya Ste YanmarYew LimNoch keine Bewertungen

- EnglishDokument7 SeitenEnglishJaime MksNoch keine Bewertungen

- Stern-Drive: Operation ManualDokument60 SeitenStern-Drive: Operation ManualJaime MksNoch keine Bewertungen

- Chinese Zodiac - Monkey: PersonalityDokument8 SeitenChinese Zodiac - Monkey: PersonalityJaime MksNoch keine Bewertungen

- HOSTERIADokument10 SeitenHOSTERIAJaime MksNoch keine Bewertungen

- Chapters 1Dokument7 SeitenChapters 1Jaime MksNoch keine Bewertungen

- Trip UpDokument1 SeiteTrip UpJaime MksNoch keine Bewertungen

- Good Industry Practice - LPG Road Tanker ManagementDokument64 SeitenGood Industry Practice - LPG Road Tanker ManagementSubhradeb PramanikNoch keine Bewertungen

- (David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution ManualDokument256 Seiten(David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution Manualsadegh_199067% (3)

- Comparison Between Gasoline Diesel CNG LPG 1664300610Dokument19 SeitenComparison Between Gasoline Diesel CNG LPG 1664300610richard100% (1)

- Grupos Electrogenos Nafta Kipor Kge12e Kge12e3Dokument19 SeitenGrupos Electrogenos Nafta Kipor Kge12e Kge12e3Jhonald LanzNoch keine Bewertungen

- DS310 (New Electric Box) - GDokument122 SeitenDS310 (New Electric Box) - GIrvinDiazOscategui100% (2)

- Data Sheet B11R 6x2 Euro 6 EN 2020Dokument4 SeitenData Sheet B11R 6x2 Euro 6 EN 2020Juan Manuel Villanueva uraccahuaNoch keine Bewertungen

- DENSO Diesel Common Rail Sell Sheet D1070 PDFDokument2 SeitenDENSO Diesel Common Rail Sell Sheet D1070 PDFFernando Garcia CortesNoch keine Bewertungen

- E383131 PDFDokument5 SeitenE383131 PDFJanova WilframNoch keine Bewertungen

- C18 OM Manual PDFDokument116 SeitenC18 OM Manual PDFMommy Mimma100% (3)

- EngineDokument8 SeitenEngineIRULES WARANNoch keine Bewertungen

- GSO Technical Regulations for Motor VehiclesDokument9 SeitenGSO Technical Regulations for Motor Vehiclesnightwish2010Noch keine Bewertungen

- Kubota Kx71Dokument6 SeitenKubota Kx71Nerijus SaldunasNoch keine Bewertungen

- BOBCAT T190 COMPACT TRACK LOADER Service Repair Manual SN 527811001 & Above PDFDokument15 SeitenBOBCAT T190 COMPACT TRACK LOADER Service Repair Manual SN 527811001 & Above PDFfujsjekkemm0% (1)

- rr321401 Principles of Machine DesignDokument8 Seitenrr321401 Principles of Machine DesignSRINIVASA RAO GANTANoch keine Bewertungen

- Operating Instructions: Diesel Engine 12 V 4000 M63 16 V 4000 M63 16 V 4000 M63RDokument239 SeitenOperating Instructions: Diesel Engine 12 V 4000 M63 16 V 4000 M63 16 V 4000 M63RИльмир ХафизовNoch keine Bewertungen

- Precision Motors Spec A MotorDokument91 SeitenPrecision Motors Spec A Motorjahosolaris5512Noch keine Bewertungen

- ITC 120 Service Manual - 2011-05-18-NeuDokument210 SeitenITC 120 Service Manual - 2011-05-18-NeuDisd100% (1)

- Oil PumpDokument2 SeitenOil PumpwahyuNoch keine Bewertungen

- ME407 Mechatronics Course NotesDokument129 SeitenME407 Mechatronics Course Notessultan1786Noch keine Bewertungen

- Grundfos Fire Presentation - NFPA, EN 12845, FS - Aug2017Dokument70 SeitenGrundfos Fire Presentation - NFPA, EN 12845, FS - Aug2017febousNoch keine Bewertungen

- Hdi (Diesel) Engines: Cylinder BlockDokument6 SeitenHdi (Diesel) Engines: Cylinder BlockfotonengineNoch keine Bewertungen

- Aero Commander 500 POHDokument94 SeitenAero Commander 500 POHRichard Lund100% (1)

- Waukesha F18GL-GLD - S-7775-45Dokument10 SeitenWaukesha F18GL-GLD - S-7775-45kman548Noch keine Bewertungen

- Data Collection Sheet 20181023Dokument79 SeitenData Collection Sheet 20181023Bisho AtefNoch keine Bewertungen

- Airbus A320 Eng OilDokument13 SeitenAirbus A320 Eng OilPanagiotis Diakidis100% (2)

- Propulsion of 7,000-10,000 DWT Small Tanker 20.05.2013Dokument20 SeitenPropulsion of 7,000-10,000 DWT Small Tanker 20.05.2013Phyo MgNoch keine Bewertungen

- Introduction to Motion Control TechnologiesDokument4 SeitenIntroduction to Motion Control TechnologiesKhadija RvNoch keine Bewertungen

- TB Series Tractor (35-70Hp)Dokument10 SeitenTB Series Tractor (35-70Hp)Павел МорозовNoch keine Bewertungen

- How VNT turbochargers optimize engine power and efficiencyDokument3 SeitenHow VNT turbochargers optimize engine power and efficiencymebarki aberraoufNoch keine Bewertungen

- Tata Sumo Grande MKIIDokument142 SeitenTata Sumo Grande MKIIDevNoch keine Bewertungen