Beruflich Dokumente

Kultur Dokumente

System Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 Psig

Hochgeladen von

guhadebasisOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

System Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 Psig

Hochgeladen von

guhadebasisCopyright:

Verfügbare Formate

06/26/2019 - 06:21:16

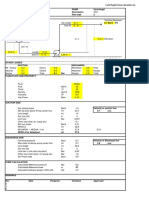

Flare Back Pressure Calculation

PMP Flare Line Check Enter your Company name he

Enter your Project name here

for printing

From Tank to Flare Tip printing

Assumes 7 IN H2O at tank

Atmospheric Pressure 14.87 Psia 14.70 Psia

Segment No. 1 2

Description Tank to flare base Flare stack

System Pressure Drop

Line Size 16 8

Est. Equivalent length = 500 Est. Equivalent length = 40

Flow 4.11 MMSCFD 4.11 MMSCFD

Flow 15,745 lb/hr 15,745 lb/hr

"Z" Factor 1.00 1.00

Mole Weight 35.0 lb./lbmol 35.0 lb./lbmol

Operating Temperature 100 F 100 F

Viscosity 0.011 cP 0.011 cP

Specific Heat 40.0 Btu/lbmol-F 40.0 Btu/lbmol-F

Critical Pressure (psia) 0.65 Psia 2.36 Psia

Pipe Length or Equivalent Length 500 ft 40 ft

Fittings (L/D's) 0 0

Other Resistances (K Value) 0 0

Total Resistances (K Value) 5.645 0.893

Nominal Pipe Diameter 16 inches 8 inches

Pipe Inside Diameter 15.25 inches 7.98 inches

Cross Sectional Area 1.27 sq. ft. 0.35 sq. ft.

Pipe Roughness 0.0018 inches 0.0018 inches

Relative Roughness 1.18E-4 2.26E-4

K (Cp/Cv) 1.052 1.052

Reynolds Number 5.98E+5 1.14E+6

Friction Factor (Estimate for Iteration) 0.0143 0.0149

Friction Factor 0.0143 0.0149

R (estimate) 1.01 1.012

Calculated 'R' (Pin/Pout) 1.01 1.01

Mach Number 0.043 0.161

Section Outlet Pressure 14.87 Psia 14.70 Psia

Section Inlet Pressure 14.95 Psia 14.87 Psia

Pressure Drop in Segment 0.07935 Psi 0.17289 Psi

Pressure Drop in Inches H2O 2.20 inches 4.79 inches 6.99 inches

Discontinuity 0.00 Psi 0.00 Psi

Cumulative Back Pressure 0.08 Psig 0.00 Psig

06/26/2019 - 06:21:16

Flare Back Pressure Calculation

PMP Flare Line Check Enter your Company name he

Enter your Project name here

From Tank to Flare Tip for printing

printing

Assumes 6 IN H2O at tank

Atmospheric Pressure 14.85 Psia 14.70 Psia

Segment No. 1 2

Description Tank to flare base Flare stack

System Pressure Drop

Line Size 16 8

Est. Equivalent length = 500 Est. Equivalent length = 40

Flow 3.80 MMSCFD 3.80 MMSCFD

Flow 14,569 lb/hr 14,569 lb/hr

"Z" Factor 1.00 1.00

Mole Weight 35.0 lb./lbmol 35.0 lb./lbmol

Operating Temperature 100 F 100 F

Viscosity 0.011 cP 0.011 cP

Specific Heat 40.0 Btu/lbmol-F 40.0 Btu/lbmol-F

Critical Pressure (psia) 0.60 Psia 2.19 Psia

Pipe Length or Equivalent Length 500 ft 40 ft

Fittings (L/D's) 0 0

Other Resistances (K Value) 0 0

Total Resistances (K Value) 5.691 0.897

Nominal Pipe Diameter 16 inches 8 inches

Pipe Inside Diameter 15.25 inches 7.98 inches

Cross Sectional Area 1.27 sq. ft. 0.35 sq. ft.

Pipe Roughness 0.0018 inches 0.0018 inches

Relative Roughness 1.18E-4 2.26E-4

K (Cp/Cv) 1.052 1.052

Reynolds Number 5.54E+5 1.06E+6

Friction Factor (Estimate for Iteration) 0.0145 0.0149

Friction Factor 0.0145 0.0149

R (estimate) 1.00 1.010

Calculated 'R' (Pin/Pout) 1.00 1.01

Mach Number 0.040 0.149

Section Outlet Pressure 14.85 Psia 14.70 Psia

Section Inlet Pressure 14.92 Psia 14.85 Psia

Pressure Drop in Segment 0.06859 Psi 0.14816 Psi

Pressure Drop in Inches H2O 1.90 inches 4.10 inches 6.00 inches

Discontinuity 0.00 Psi 0.00 Psi

Cumulative Back Pressure 0.07 Psig 0.00 Psig

06/26/2019 - 06:21:16

Flare Back Pressure Calculation

PMP Flare Line Check Enter your Company name he

Enter your Project name here

From Tank to Flare Tip for printing

printing

Assumes 5 IN H2O at tank

Atmospheric Pressure 14.82 Psia 14.70 Psia

Segment No. 1 2

Description Tank to flare base Flare stack

System Pressure Drop

Line Size 16 8

Est. Equivalent length = 500 Est. Equivalent length = 40

Flow 3.46 MMSCFD 3.46 MMSCFD

Flow 13,255 lb/hr 13,255 lb/hr

"Z" Factor 1.00 1.00

Mole Weight 35.0 lb./lbmol 35.0 lb./lbmol

Operating Temperature 100 F 100 F

Viscosity 0.011 cP 0.011 cP

Specific Heat 40.0 Btu/lbmol-F 40.0 Btu/lbmol-F

Critical Pressure (psia) 0.54 Psia 1.99 Psia

Pipe Length or Equivalent Length 500 ft 40 ft

Fittings (L/D's) 0 0

Other Resistances (K Value) 0 0

Total Resistances (K Value) 5.750 0.901

Nominal Pipe Diameter 16 inches 8 inches

Pipe Inside Diameter 15.25 inches 7.98 inches

Cross Sectional Area 1.27 sq. ft. 0.35 sq. ft.

Pipe Roughness 0.0018 inches 0.0018 inches

Relative Roughness 1.18E-4 2.26E-4

K (Cp/Cv) 1.052 1.052

Reynolds Number 5.04E+5 9.62E+5

Friction Factor (Estimate for Iteration) 0.0146 0.0150

Friction Factor 0.0146 0.0150

R (estimate) 1.00 1.008

Calculated 'R' (Pin/Pout) 1.00 1.01

Mach Number 0.037 0.135

Section Outlet Pressure 14.82 Psia 14.70 Psia

Section Inlet Pressure 14.88 Psia 14.82 Psia

Pressure Drop in Segment 0.05749 Psi 0.12288 Psi

Pressure Drop in Inches H2O 1.59 inches 3.40 inches 5.00 inches

Discontinuity 0.00 Psi 0.00 Psi

Cumulative Back Pressure 0.06 Psig 0.00 Psig

06/26/2019 - 06:21:16

Flare Back Pressure Calculation

PMP Flare Line Check Enter your Company name he

Enter your Project name here

From Tank to Flare Tip for printing

printing

Assumes 8 IN H2O at tank

Atmospheric Pressure 14.90 Psia 14.70 Psia

Segment No. 1 2

Description Tank to flare base Flare stack

System Pressure Drop

Line Size 16 8

Est. Equivalent length = 500 Est. Equivalent length = 40

Flow 4.40 MMSCFD 4.40 MMSCFD

Flow 16,867 lb/hr 16,867 lb/hr

"Z" Factor 1.00 1.00

Mole Weight 35.0 lb./lbmol 35.0 lb./lbmol

Operating Temperature 100 F 100 F

Viscosity 0.011 cP 0.011 cP

Specific Heat 40.0 Btu/lbmol-F 40.0 Btu/lbmol-F

Critical Pressure (psia) 0.69 Psia 2.53 Psia

Pipe Length or Equivalent Length 500 ft 40 ft

Fittings (L/D's) 0 0

Other Resistances (K Value) 0 0

Total Resistances (K Value) 5.605 0.891

Nominal Pipe Diameter 16 inches 8 inches

Pipe Inside Diameter 15.25 inches 7.98 inches

Cross Sectional Area 1.27 sq. ft. 0.35 sq. ft.

Pipe Roughness 0.0018 inches 0.0018 inches

Relative Roughness 1.18E-4 2.26E-4

K (Cp/Cv) 1.052 1.052

Reynolds Number 6.41E+5 1.22E+6

Friction Factor (Estimate for Iteration) 0.0142 0.0148

Friction Factor 0.0142 0.0148

R (estimate) 1.01 1.013

Calculated 'R' (Pin/Pout) 1.01 1.01

Mach Number 0.047 0.172

Section Outlet Pressure 14.90 Psia 14.70 Psia

Section Inlet Pressure 14.99 Psia 14.90 Psia

Pressure Drop in Segment 0.09024 Psi 0.19838 Psi

Pressure Drop in Inches H2O 2.50 inches 5.50 inches 8.00 inches

Discontinuity 0.00 Psi 0.00 Psi

Cumulative Back Pressure 0.09 Psig 0.00 Psig

06/26/2019 - 06:21:16

Flare Back Pressure Calculation - Documentation

#REF!

#REF!

1 The calculation is based on the June 29th, 1981 Chemical Engineering article by Paul Kendall of PEDCO "Program sizes

pipe and flare manifolds for compressible flow" and API RP 521 practices. The calculation is done base on isothermal

conditions and for some cases may not be accurate.

2 The calculations are done based on the connections numbers inputted by the user in rows 5 & 7. The labels are for your

convenience only. Any number of branch connections may be specified by copying the input columns for each new branch

to the right of the columns given. Use any column but the first since the calculations are slightly different for the branch

exiting to atmosphere.

3 In normal designs the MACH number is kept under 0.7 to 0.75. Under no conditions should the MACH number be allowed to

exceed 1.0. The calculation will handle MACH Numbers up to 1.0 and calculates the pressure discontinuity at the

downstream end of the system.

4 The back pressure is limited to 10% of the PSV set pressure by code. Using balanced bellows type valves the back

pressure can be increased to 30-50% of the PSV set pressure. Consult the manufacturer for the exact number when using

balanced bellows valves. Note that the use of balanced bellows valves is generally discouraged because of the increased

maintenance and other factors. Avoid using this type of valve unless absolutely required.

5 The program uses standard wall thicknesses to calculate the inside diameter of the pipe as shown in the following table.

Nominal Diameter Inside Diameter

2 2.067

3 3.068

4 4.026

5 5.047

6 6.065

8 7.981

10 10.020

12 12.000

14 13.250

16 15.250

18 17.250

20 19.250

22 21.250

24 23.250

30 29.250

36 35.250

42 41.250

48 47.250

Das könnte Ihnen auch gefallen

- Revised Procedural Manual On Hazardous Waste Management (Revised DAO 04-36) I CONTENTS Chapter Page PDFDokument53 SeitenRevised Procedural Manual On Hazardous Waste Management (Revised DAO 04-36) I CONTENTS Chapter Page PDFdennisNoch keine Bewertungen

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDokument1 SeiteC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNoch keine Bewertungen

- Pump Sizing CalculationDokument26 SeitenPump Sizing Calculationnina eiffelinaNoch keine Bewertungen

- Remedies FlowDokument44 SeitenRemedies Flowzeebeelo100% (1)

- Transducer Handbook: User's Directory of Electrical TransducersVon EverandTransducer Handbook: User's Directory of Electrical TransducersNoch keine Bewertungen

- PSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarDokument1 SeitePSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. Varsugeng wahyudiNoch keine Bewertungen

- Storage Tank Gas Breathing For Purge Gas SizingDokument3 SeitenStorage Tank Gas Breathing For Purge Gas SizingguhadebasisNoch keine Bewertungen

- Bop Drawing TemplateDokument65 SeitenBop Drawing TemplateMohd AmaniNoch keine Bewertungen

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDokument6 SeitenCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNoch keine Bewertungen

- Centrifugal Pump CalculatorDokument1 SeiteCentrifugal Pump Calculatoranto3harrish3fdoNoch keine Bewertungen

- $TEMA Sheet Gas Chiller Rev 2Dokument1 Seite$TEMA Sheet Gas Chiller Rev 2HudaFiHayyatNoch keine Bewertungen

- Liquid Pipe Sizing: Group Technology SolutionsDokument1 SeiteLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNoch keine Bewertungen

- Om - 3M CaseDokument18 SeitenOm - 3M CaseBianda Puspita Sari100% (1)

- EU MDR FlyerDokument12 SeitenEU MDR FlyermrudhulrajNoch keine Bewertungen

- Hump Hydraulics CalculationsDokument13 SeitenHump Hydraulics CalculationsrutujaNoch keine Bewertungen

- Double Suction Impeller Axial Suction Inlet: Pump Flowrate (USGPM)Dokument3 SeitenDouble Suction Impeller Axial Suction Inlet: Pump Flowrate (USGPM)ctorresmghNoch keine Bewertungen

- Pump Sizing Calculation: Tag No. Description Date by Checalc P-101 Feed Pump 28-Jan-15Dokument2 SeitenPump Sizing Calculation: Tag No. Description Date by Checalc P-101 Feed Pump 28-Jan-15anto3harrish3fdoNoch keine Bewertungen

- Pump Sizing CalculationDokument22 SeitenPump Sizing CalculationShikalgar JuberNoch keine Bewertungen

- Gas-Gas Exchanger DatasheetDokument3 SeitenGas-Gas Exchanger DatasheetidilfitriNoch keine Bewertungen

- Gas Pressure Drop Calculation Using SCFM: Pipe ValvesDokument3 SeitenGas Pressure Drop Calculation Using SCFM: Pipe ValvesDavid Muñoz CastroNoch keine Bewertungen

- 1 6 Presentation Echometer Pump SlippageDokument29 Seiten1 6 Presentation Echometer Pump SlippageRezha Aditya PratamaNoch keine Bewertungen

- Pump CalcDokument1 SeitePump CalcMoch WildanNoch keine Bewertungen

- Valve Sizing Calculation - Docx INEGAS 3Dokument2 SeitenValve Sizing Calculation - Docx INEGAS 3jhon.rojas.ery1489Noch keine Bewertungen

- Production of BiodieselDokument49 SeitenProduction of Biodieselteja100% (1)

- Ejercicio 246 PSV438 RESUELTODokument2 SeitenEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNoch keine Bewertungen

- Hydraulic Cal - Tanks Vent To FlareDokument1 SeiteHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Pump Sizing Calculation (2ggg)Dokument28 SeitenPump Sizing Calculation (2ggg)dhavalesh1Noch keine Bewertungen

- Jurnal PedodontiaDokument8 SeitenJurnal PedodontiaAndreas WallaceNoch keine Bewertungen

- Pump Sizing CalculationDokument12 SeitenPump Sizing Calculationionutlaur86Noch keine Bewertungen

- Pump SizeDokument1 SeitePump Sizekoko fikarNoch keine Bewertungen

- 14-NPSHA VESSEL PR Is KnownDokument10 Seiten14-NPSHA VESSEL PR Is KnownAhm AnNoch keine Bewertungen

- Pump Sizing CalculationDokument28 SeitenPump Sizing CalculationNguyễn DuyNoch keine Bewertungen

- Qty K Value: 532952369.xlsx - Kfitting Calculation 07/20/2021Dokument3 SeitenQty K Value: 532952369.xlsx - Kfitting Calculation 07/20/2021PrasadNoch keine Bewertungen

- Pump Sizing Fire Hydrant MojoDokument2 SeitenPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhNoch keine Bewertungen

- PSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarDokument4 SeitenPSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarfarshadNoch keine Bewertungen

- PD Pump SizingDokument11 SeitenPD Pump SizingSameer ChaturvediNoch keine Bewertungen

- Pump Sizing CalculationDokument28 SeitenPump Sizing CalculationLorenzoNoch keine Bewertungen

- Pump Sizing Calculation: Head Vs FlowDokument1 SeitePump Sizing Calculation: Head Vs FlowKevin DoNoch keine Bewertungen

- Pump Sizing CalculationDokument26 SeitenPump Sizing CalculationPacarnya Mas KhalidNoch keine Bewertungen

- Documents For Approval Rev-1 - ApprovedDokument42 SeitenDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNoch keine Bewertungen

- Pump Sizing CalculationDokument30 SeitenPump Sizing CalculationnachiappanNoch keine Bewertungen

- Solved Example With ExerciseDokument10 SeitenSolved Example With Exercisesarmistha patnaiKNoch keine Bewertungen

- PSV Calculation Report - Liquid Relief Sizing Case: Const. VarDokument1 SeitePSV Calculation Report - Liquid Relief Sizing Case: Const. VarIoana PopescuNoch keine Bewertungen

- Fines Tank Recirculation Pump Sizing Calculation - SCH 10 PipingDokument30 SeitenFines Tank Recirculation Pump Sizing Calculation - SCH 10 PipingRafaeles JovertNoch keine Bewertungen

- Pump Sizing CalculationDokument4 SeitenPump Sizing CalculationHatif AlamNoch keine Bewertungen

- JVCVReport1215 PDFDokument1 SeiteJVCVReport1215 PDFUlises BadilloNoch keine Bewertungen

- ROOTS Meters & Instruments: Series B3-Hpc: 11M1480 Roots MeterDokument2 SeitenROOTS Meters & Instruments: Series B3-Hpc: 11M1480 Roots MetercartarNoch keine Bewertungen

- Valve Sizing Calculation8Dokument2 SeitenValve Sizing Calculation8PIDNoch keine Bewertungen

- Centrifugal Pump CalculationDokument8 SeitenCentrifugal Pump CalculationLorenzoNoch keine Bewertungen

- Sizing Trim BDokument1 SeiteSizing Trim Bachmad hermansyahNoch keine Bewertungen

- Pump Sizing Calculation - Twopump RunningDokument2 SeitenPump Sizing Calculation - Twopump RunningMuthuKumar ArunachalamNoch keine Bewertungen

- KSB MIL Controls Limited Valve Specification SheetDokument2 SeitenKSB MIL Controls Limited Valve Specification SheetPablo TorresNoch keine Bewertungen

- 39G Performance (v3.13)Dokument10 Seiten39G Performance (v3.13)Kumar sssssNoch keine Bewertungen

- Pumps Calculation Rev.a1Dokument1 SeitePumps Calculation Rev.a1Abdelhakim ChaouchNoch keine Bewertungen

- VCP MecayucanDokument3 SeitenVCP MecayucanAlberto ReyesNoch keine Bewertungen

- Cálculo SRDT SuperficieDokument1 SeiteCálculo SRDT SuperficieRuben MatiazzoNoch keine Bewertungen

- 2 Technical DataDokument1 Seite2 Technical DataFazri CMENoch keine Bewertungen

- Booster Pump SizingDokument1 SeiteBooster Pump SizingjibinNoch keine Bewertungen

- Cylinder Calculations: Don's Cheat SheetDokument2 SeitenCylinder Calculations: Don's Cheat Sheetrobyn100Noch keine Bewertungen

- N2 PRVDokument1 SeiteN2 PRVPratik SangamNoch keine Bewertungen

- It 1.1.4-HV 1244002 ABCDEF CV-Calc Rev4Dokument2 SeitenIt 1.1.4-HV 1244002 ABCDEF CV-Calc Rev44122acaNoch keine Bewertungen

- WellPlan Report 36Dokument7 SeitenWellPlan Report 36E Alejandro GilNoch keine Bewertungen

- 8101 - (11may2022)Dokument4 Seiten8101 - (11may2022)Pedro Alfredo Peña CastilloNoch keine Bewertungen

- PT Gheni Arta Sejahtera: LNG Feed PumpDokument4 SeitenPT Gheni Arta Sejahtera: LNG Feed PumpAbdulWasiNoch keine Bewertungen

- Gas Ultrasonic Meter Sizing ReportDokument4 SeitenGas Ultrasonic Meter Sizing ReportWUMINGNoch keine Bewertungen

- Pump TemplateDokument2 SeitenPump TemplateamitkrayNoch keine Bewertungen

- Haz ChemDokument5 SeitenHaz ChemguhadebasisNoch keine Bewertungen

- Two Fa: Interpreting Ure RatesDokument14 SeitenTwo Fa: Interpreting Ure RatesguhadebasisNoch keine Bewertungen

- Sweetening: Fig. 26-1 Merox Treating-LPG UnitDokument3 SeitenSweetening: Fig. 26-1 Merox Treating-LPG UnitguhadebasisNoch keine Bewertungen

- Form Lopa Summary SheetDokument1 SeiteForm Lopa Summary SheetguhadebasisNoch keine Bewertungen

- Tail Gas Clean UpDokument2 SeitenTail Gas Clean UpguhadebasisNoch keine Bewertungen

- Waste Treatment and DisposalDokument2 SeitenWaste Treatment and DisposalguhadebasisNoch keine Bewertungen

- LT HC ProcessDokument9 SeitenLT HC ProcessguhadebasisNoch keine Bewertungen

- Bypass Worksheet: Check The Appropriate BoxDokument1 SeiteBypass Worksheet: Check The Appropriate BoxguhadebasisNoch keine Bewertungen

- Catalytic PolymerisationDokument7 SeitenCatalytic PolymerisationguhadebasisNoch keine Bewertungen

- 201906beaconenglish-Corrosion Under InsulationDokument1 Seite201906beaconenglish-Corrosion Under InsulationguhadebasisNoch keine Bewertungen

- Cost of Compressed Air FormulaDokument1 SeiteCost of Compressed Air FormulaguhadebasisNoch keine Bewertungen

- Avoiding Pressure Relief Problems: Silver Edition My Account Logout Adv. SearchDokument3 SeitenAvoiding Pressure Relief Problems: Silver Edition My Account Logout Adv. SearchguhadebasisNoch keine Bewertungen

- Subject Requirement Description: Document 31 Identification and Colour Coding of Piping, Equipment and Work AreasDokument2 SeitenSubject Requirement Description: Document 31 Identification and Colour Coding of Piping, Equipment and Work AreasguhadebasisNoch keine Bewertungen

- Assignment Brief HNHM301 The Contemporary Hospitality IndustryDokument6 SeitenAssignment Brief HNHM301 The Contemporary Hospitality IndustryTanjum Tisha100% (1)

- Eco SPARDokument3 SeitenEco SPARMohammad LabinNoch keine Bewertungen

- W6 Lesson 7 Find, Evaluate, and Use Online Information ResourcesDokument14 SeitenW6 Lesson 7 Find, Evaluate, and Use Online Information Resourcescharimaine hernandezNoch keine Bewertungen

- Questionnaire On EthnocentrismDokument14 SeitenQuestionnaire On Ethnocentrismkalpa vrikshaNoch keine Bewertungen

- Incident Log - TemplateDokument10 SeitenIncident Log - TemplateRajaNoch keine Bewertungen

- 1GR FE LubricationDokument19 Seiten1GR FE LubricationJesus LayaNoch keine Bewertungen

- The US Navy - Fact File - MQ-8C Fire ScoutDokument2 SeitenThe US Navy - Fact File - MQ-8C Fire ScoutAleksei KarpaevNoch keine Bewertungen

- What Is Highway EngineeringDokument4 SeitenWhat Is Highway EngineeringNagesh SinghNoch keine Bewertungen

- The World Wide WebDokument22 SeitenThe World Wide WebSa JeesNoch keine Bewertungen

- PDF Applied Failure Analysis 1 NSW - CompressDokument2 SeitenPDF Applied Failure Analysis 1 NSW - CompressAgungNoch keine Bewertungen

- FEDokument20 SeitenFEKenadid Ahmed OsmanNoch keine Bewertungen

- RMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceDokument5 SeitenRMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceZineddine BENOUADAHNoch keine Bewertungen

- Relational NotationDokument3 SeitenRelational NotationTweetrudi WhyteNoch keine Bewertungen

- CHAPTER 22-Audit Evidence EvaluationDokument27 SeitenCHAPTER 22-Audit Evidence EvaluationIryne Kim PalatanNoch keine Bewertungen

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDokument10 SeitenMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaNoch keine Bewertungen

- UN - Towards Sustainable DevelopmentDokument17 SeitenUN - Towards Sustainable Developmentviva_33Noch keine Bewertungen

- DTR For ReadingDokument2 SeitenDTR For ReadingTimosa TeyobNoch keine Bewertungen

- Santa Letters 2013Dokument16 SeitenSanta Letters 2013Lebanon_PublishingNoch keine Bewertungen

- FIN323 Project 2021-2022Dokument6 SeitenFIN323 Project 2021-2022saleem razaNoch keine Bewertungen

- Eligibility To Become IAS Officer: Career As A IAS Officer About IAS OfficerDokument4 SeitenEligibility To Become IAS Officer: Career As A IAS Officer About IAS Officersamiie30Noch keine Bewertungen

- Lezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityDokument26 SeitenLezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityWB_YeatsNoch keine Bewertungen

- U90 Ladder Tutorial PDFDokument72 SeitenU90 Ladder Tutorial PDFMarlon CalixNoch keine Bewertungen

- Lower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & AboveDokument2 SeitenLower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & Abovezeeshan tanveerNoch keine Bewertungen

- Power of Company Law BoardDokument21 SeitenPower of Company Law Boardraman raghavNoch keine Bewertungen