Beruflich Dokumente

Kultur Dokumente

Temperature

Hochgeladen von

Harshana PrabhathOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Temperature

Hochgeladen von

Harshana PrabhathCopyright:

Verfügbare Formate

Prediction of temperature rise Introduction

C660 - Prediction of the early-age temperature rise in concrete

This model provides a basis for the comparative assessment of early-age temperature rise and temperature differentials in concrete

The model is based on the numerical method of Ross and Bray (1949) and is described in detail in Appendix A2

Background data on heat generation were provided by the University of Dundee (Dhir et al, 2006) obtained using semi-adiabatic testing to EN196-9:2003

Data are input on pages 2 and 3. The model enables the following factors to be investigated;

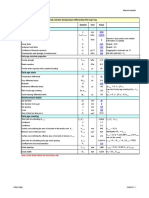

PAGE 2 ADIABATIC TEMPERATURE

The binder is the total content of cementitious material, including CEM I and CEM I in combination with either

Binder content kg/m3

fly ash or ground granulated blast-furnace slag, ggbs

Binder type Three binder options are available from a drop-down menu CEM I, fly ash, ggbs

Concrete mix

Percent addition % The percent of either fly ash or ggbs by weight of binder

details

Density kg/m3 The wet density of the concrete

The early-age value when the concrete is only partially hydrated. A value of 1 kJ/kgoC should be used unless

Specific heat kJ/kgoC

more reliable data are available

Temperature drop T1 This is calculated in page 3 but shown on page 2 to enable the effect of changes in the concrete mix to be

observed directly. Input on section geometry, formwork etc, is on page 3

PAGE 3 TEMPERATURE CALCULATIONS

Section thickness mm

Section and Formwork type Three options are available from a drop-down menu, Steel, 18mm plywood, 37 mm plywood

formwork

details Wind speed m/s Assumed to be 4 m/s for typical UK conditions

Formwork removal time hours The time after casting

Concrete mix Thermal conductivity W/m C o

Assumed to be 1.8 W/moC (see Appendix A2 for values for concrete using difference aggregates)

details Density and specific heat These values are used in the calculation but copied from page 2

This is the temperature of the concrete when placed into the form. This is not necessarily the same as the

Placing temperature concrete temperature at the mixing plant. When no data are available assume that the placing temperature is 5

o

C above the mean ambient temperature

Placing

conditions Constant or variable (based on a sinusoidal variation). Min. mean and max. values are required. For a

Ambient temperature o

C

calculation assuming a constant ambient temperature, these vales should all be the same

Placing time o

C Based on a 24 hour clock

CIRIA C660 PAGE 1

Prediction of temeprature rise Adiabatic temperature

Adiabatic temperature rise

H e a t g e n e r a te d ( k J /k g )

Cells for input data

Binder content 400 (kg/m3)

Binder type ggbs

Addition 50 (%) 400.0

Density 2400 (kg/m3) 300.0

Specific heat 1 kJ/kgoC 200.0 Reference curve

100.0

Temperature drop T1 31 C

o 0.0

0 12 24Time

36 (Hours)

48 60 72 84 96

Tem perature (oC)

Adiabatic temperature rise for concrete

90.00

80.00

70.00

60.00

50.00

40.00 Reference curve at 20oC

30.00 Adjusted for temperature

20.00 Modelled

10.00

0.00

0.00 24.00 48.00

Time (Hours) 72.00 96.00

CIRIA C660 Page 2

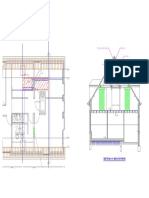

Prediction of temperature rise Temperature calculation

TEMPERATURE RISE AND DIFFERENTIALS

Tem p eratu re (o C )

Cells for input data

Element details 60.0

Pour thickness 500 mm Peak

Formwork type 18mm plywood 50.0 Surface

Wind speed 4 m/s Differential

40.0 Formwork removal

Surface conductance 5.2 W/m2K

Formwork removal 36 hours 30.0

Concrete properties 20.0

Thermal conductivity 1.8 W/moC

10.0

Temperature

0.0

Placing temperature 20 o

C 0.0 50.0 100.0 150.0 200.0 250.0

Time (hours)

Te m p e ra tu re (o C )

Minimum 15 o

C

Ambient

MEAN 15 o

C

temperature

Maximum 15 o

C

Placing time (24 hour clock) 12 hours 60.0

50.0

Temperature OUTPUT

Maximum temperature 46 o

C 40.0

at time 28 hours 30.0

at maximum diffentail

at peak temperature

Maximum differential 17 o

C Column S

20.0

at time 39 hours

Temperature drop T1 31 o

C 10.0

0.0

0 100 Thickness

200 300

(mm)400

500 600

CIRIA C660 Page 3

Das könnte Ihnen auch gefallen

- Investigation of the Chirajara Bridge CollapseVon EverandInvestigation of the Chirajara Bridge CollapseNoch keine Bewertungen

- C660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Dokument2 SeitenC660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Harshana Prabhath100% (1)

- C660 - Estimation of Drying Shrinkage According To EN1992-1-1Dokument3 SeitenC660 - Estimation of Drying Shrinkage According To EN1992-1-1Madhusudan MandalNoch keine Bewertungen

- RestraintDokument2 SeitenRestraintSharyn Polley100% (1)

- Calculations of Early Thermal CrackingDokument2 SeitenCalculations of Early Thermal CrackingislamNoch keine Bewertungen

- Design For Early Thermal CrackingDokument10 SeitenDesign For Early Thermal Crackingdhruvgoku100% (1)

- Cracks in Immature ConcreteDokument2 SeitenCracks in Immature ConcreterasikamalNoch keine Bewertungen

- Crack Width MeasurementDokument5 SeitenCrack Width MeasurementKlLeeNoch keine Bewertungen

- Design For 11early Thermal CrackingDokument9 SeitenDesign For 11early Thermal CrackingdhruvgokuNoch keine Bewertungen

- THERMAL CRACK CHECK FOR BD 28/87Dokument1 SeiteTHERMAL CRACK CHECK FOR BD 28/87lakshmi1011Noch keine Bewertungen

- A3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Dokument3 SeitenA3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Harshana PrabhathNoch keine Bewertungen

- Crack control of internal restraint in Pile Cap TopDokument5 SeitenCrack control of internal restraint in Pile Cap TopSravanthi Mehar100% (1)

- Early Thermal Cracking ConcreteDokument13 SeitenEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- Tendon Grouting - VSLDokument46 SeitenTendon Grouting - VSLIrshadYasinNoch keine Bewertungen

- Concrete Bridges: The Benefits of Concrete in Bridge Design and ConstructionDokument16 SeitenConcrete Bridges: The Benefits of Concrete in Bridge Design and ConstructionsuheilbugsNoch keine Bewertungen

- EarlyThermal ShrinkageDokument5 SeitenEarlyThermal ShrinkageRafael GarciaNoch keine Bewertungen

- EAT Crack ControlDokument9 SeitenEAT Crack ControlkumarNoch keine Bewertungen

- ICE SPDokument3 SeitenICE SPtehNoch keine Bewertungen

- Thermal Cracking in Concrete: Causes, Identification and PreventionDokument2 SeitenThermal Cracking in Concrete: Causes, Identification and PreventionTim_CNoch keine Bewertungen

- Waler Beam Design TemplateDokument1 SeiteWaler Beam Design TemplateArjun RajaNoch keine Bewertungen

- Shotcrete Boiled Water AbsorptionDokument6 SeitenShotcrete Boiled Water AbsorptiondjajadjajaNoch keine Bewertungen

- Pile Cap ModellingDokument118 SeitenPile Cap ModellingIthihas Seventyone100% (1)

- Ciria Report 91 1981 PDFDokument19 SeitenCiria Report 91 1981 PDFimranmehfoozNoch keine Bewertungen

- ICE Manual of Geotechnical Engineering VDokument6 SeitenICE Manual of Geotechnical Engineering VĐỗ Quý TuấnNoch keine Bewertungen

- Shrinkage (CEB FIP)Dokument4 SeitenShrinkage (CEB FIP)Sabbir SiddiqueNoch keine Bewertungen

- Another Look at Cracking and Crack ControlDokument6 SeitenAnother Look at Cracking and Crack Controlmedianna100% (1)

- Control of Early Thermal Cracking of RaftDokument110 SeitenControl of Early Thermal Cracking of RaftRian Ibayan100% (1)

- TG13 - Concrete BridgesDokument98 SeitenTG13 - Concrete Bridgeszaidiamna9Noch keine Bewertungen

- Tw15 120 Wg5 Granular Platforms For Plant Draft For Discussion Final ReducedDokument134 SeitenTw15 120 Wg5 Granular Platforms For Plant Draft For Discussion Final ReducedWilliam HarrowNoch keine Bewertungen

- Crack WidthDokument2 SeitenCrack Widthnagaraju-rachamadugu-275185% (13)

- Shear friction and dowel action modellingDokument15 SeitenShear friction and dowel action modellingLordM00nNoch keine Bewertungen

- Appendix 02 Elastomeric Bearing Calculation ReportDokument8 SeitenAppendix 02 Elastomeric Bearing Calculation ReportYasela100% (1)

- 233R-17 Guide To The Use of Slag Cement in Concrete and MortarDokument36 Seiten233R-17 Guide To The Use of Slag Cement in Concrete and MortarKhaled Abdel Salam100% (1)

- LDSA Piling Guide 2017 PDFDokument26 SeitenLDSA Piling Guide 2017 PDFLeandroNoch keine Bewertungen

- MASONRY CANTILEVER RETAINING WALL DESIGNDokument7 SeitenMASONRY CANTILEVER RETAINING WALL DESIGNDerek AngNoch keine Bewertungen

- Flextural Cracking in Concrete StructureDokument11 SeitenFlextural Cracking in Concrete StructuresjmorabadNoch keine Bewertungen

- Life Prediction ConcreteDokument79 SeitenLife Prediction Concrete100livNoch keine Bewertungen

- Black 1962Dokument12 SeitenBlack 1962Jawad Abidi100% (1)

- Precast Floor Diaphragm ActionDokument41 SeitenPrecast Floor Diaphragm ActionMohd IllahiNoch keine Bewertungen

- Ciria Guide C766: An Overview of The Updated Ciria C660 Guidance On Control of Cracking in Reinforced Concrete StructuresDokument6 SeitenCiria Guide C766: An Overview of The Updated Ciria C660 Guidance On Control of Cracking in Reinforced Concrete StructuressiidharthkmahajanNoch keine Bewertungen

- 2 3 2 PD6694 1Dokument17 Seiten2 3 2 PD6694 1hellios8502Noch keine Bewertungen

- The Design of Temporary Excavation Support To EC7Dokument10 SeitenThe Design of Temporary Excavation Support To EC7Michael Batley100% (4)

- Early Age CrackingDokument4 SeitenEarly Age CrackingAngga Fajar SetiawanNoch keine Bewertungen

- No. 6 Fire Design of Concrete Columns and Walls To Eurocode 2Dokument6 SeitenNo. 6 Fire Design of Concrete Columns and Walls To Eurocode 2spid003Noch keine Bewertungen

- CAS47 Assessment of In-Situ Concrete Strength From CoresDokument8 SeitenCAS47 Assessment of In-Situ Concrete Strength From CoresJohnNoch keine Bewertungen

- Crane Platform Design EssentialsDokument11 SeitenCrane Platform Design EssentialsKelvin bongNoch keine Bewertungen

- Special Design Considerations For Precast Prestressed Hollow Core Floors - Guide To Good Practice. 6-FIB (2000)Dokument176 SeitenSpecial Design Considerations For Precast Prestressed Hollow Core Floors - Guide To Good Practice. 6-FIB (2000)Hassan MokhtarNoch keine Bewertungen

- Reportbakker PDFDokument203 SeitenReportbakker PDFShaileshRastogiNoch keine Bewertungen

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Dokument1 SeiteLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNoch keine Bewertungen

- 463b62e Cis888614800303964Dokument8 Seiten463b62e Cis888614800303964PPLLMMNNBBNoch keine Bewertungen

- Concrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IDokument3 SeitenConcrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IHAFEEL100% (1)

- Aci Crack WidthDokument6 SeitenAci Crack WidththirumalaichettiarNoch keine Bewertungen

- EC2 Strut and Tie DesignDokument69 SeitenEC2 Strut and Tie DesignWai Hoong EngNoch keine Bewertungen

- Calculating Furnace EfficiencyDokument20 SeitenCalculating Furnace EfficiencyChandra C ManurungNoch keine Bewertungen

- Efisiensi Tungku: Ikhwan Fajeri, M.TDokument20 SeitenEfisiensi Tungku: Ikhwan Fajeri, M.Tsigit prabowoNoch keine Bewertungen

- C 8 H 0 VM 0000 F 8 TtuzDokument390 SeitenC 8 H 0 VM 0000 F 8 TtuzHashim BukhariNoch keine Bewertungen

- Metal Rod-24-30Dokument7 SeitenMetal Rod-24-30Vidhya NairNoch keine Bewertungen

- Journal Utilitas GenapDokument6 SeitenJournal Utilitas GenapDidi WardoyoNoch keine Bewertungen

- CFD Simulation of Plate Heat ExchangerDokument17 SeitenCFD Simulation of Plate Heat ExchangerMARYAM shahNoch keine Bewertungen

- Tank SizeDokument7 SeitenTank SizeSteve WanNoch keine Bewertungen

- Design Report: Project: Building ModificationDokument7 SeitenDesign Report: Project: Building ModificationHarshana PrabhathNoch keine Bewertungen

- Sri Lanka Procurement ManualDokument163 SeitenSri Lanka Procurement ManualvihangimaduNoch keine Bewertungen

- Project: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenDokument1 SeiteProject: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenHarshana PrabhathNoch keine Bewertungen

- Project: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenDokument1 SeiteProject: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenHarshana PrabhathNoch keine Bewertungen

- Procurement Guidelines 2006 - Goods & WorksDokument85 SeitenProcurement Guidelines 2006 - Goods & WorksRanaweera AriyamanjulaNoch keine Bewertungen

- Project: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenDokument1 SeiteProject: Building Modification CLIENT:Dhr. M. Hooijmans, Franseweg 57, 4651GE, SteenbergenHarshana PrabhathNoch keine Bewertungen

- Drawing1 ModelDokument1 SeiteDrawing1 ModelHarshana PrabhathNoch keine Bewertungen

- Design Structural EngineeringDokument12 SeitenDesign Structural EngineeringHarshana PrabhathNoch keine Bewertungen

- A3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Dokument3 SeitenA3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Harshana PrabhathNoch keine Bewertungen

- TemperatureDokument3 SeitenTemperatureHarshana Prabhath100% (1)

- Procurement of General GoodsDokument75 SeitenProcurement of General GoodsRanaweera AriyamanjulaNoch keine Bewertungen

- Design Report: Project: Building ModificationDokument7 SeitenDesign Report: Project: Building ModificationHarshana PrabhathNoch keine Bewertungen

- A4 Estimating Autogenous ShrinkageDokument12 SeitenA4 Estimating Autogenous ShrinkageHarshana PrabhathNoch keine Bewertungen

- ProcurementManual2006 20060817 With Sup8Dokument80 SeitenProcurementManual2006 20060817 With Sup8Harshana PrabhathNoch keine Bewertungen

- Consultant Guideline August 2007r1Dokument53 SeitenConsultant Guideline August 2007r1Harshana PrabhathNoch keine Bewertungen

- Procurement of 20 General Goods NCBDokument25 SeitenProcurement of 20 General Goods NCBHarshana PrabhathNoch keine Bewertungen

- NSProcedures GoodsDokument13 SeitenNSProcedures Goodsmiyuru_jNoch keine Bewertungen

- Consultancy Agreement Building Department Ed. 2015. 12. 11Dokument21 SeitenConsultancy Agreement Building Department Ed. 2015. 12. 11Harshana PrabhathNoch keine Bewertungen

- Procurement Manual: Democratic Socialist Republic of Sri LankaDokument161 SeitenProcurement Manual: Democratic Socialist Republic of Sri LankaHarshana PrabhathNoch keine Bewertungen

- Procurement of General GoodsDokument75 SeitenProcurement of General GoodsRanaweera AriyamanjulaNoch keine Bewertungen

- Template - Proposal - Report Without Model 3Dokument10 SeitenTemplate - Proposal - Report Without Model 3Harshana PrabhathNoch keine Bewertungen

- IESL Wasala HdyDokument8 SeitenIESL Wasala HdyHarshana PrabhathNoch keine Bewertungen

- Leed Report GBCSLDokument64 SeitenLeed Report GBCSLHarshana PrabhathNoch keine Bewertungen

- Sri Lanka Road Map LegendDokument1 SeiteSri Lanka Road Map LegendHarshana PrabhathNoch keine Bewertungen

- Numerical Analysis of Concrete Temperature Using Semi-Adiabatic Test Presentation 6Dokument23 SeitenNumerical Analysis of Concrete Temperature Using Semi-Adiabatic Test Presentation 6Harshana PrabhathNoch keine Bewertungen

- Sri Lanka Road Map EnglishDokument1 SeiteSri Lanka Road Map EnglishHarshana PrabhathNoch keine Bewertungen

- Resume - Jeremy DeLaBruereDokument1 SeiteResume - Jeremy DeLaBruerejeremyd82Noch keine Bewertungen

- Get mailbox quotas and usageDokument4 SeitenGet mailbox quotas and usagecopoz_copozNoch keine Bewertungen

- Macropoxy 646 PW: Protective & Marine CoatingsDokument4 SeitenMacropoxy 646 PW: Protective & Marine CoatingsAnn HewsonNoch keine Bewertungen

- 2005 ARTAS External Interface Requirements Sepecification EIRS PDFDokument264 Seiten2005 ARTAS External Interface Requirements Sepecification EIRS PDFhisitepuNoch keine Bewertungen

- Wood Fasteners Joinery AdhesivesDokument9 SeitenWood Fasteners Joinery AdhesivesTudor CalomirNoch keine Bewertungen

- Enson: Ar. Johnny V. Henson Uap Ar. Gabrielle Jan S. Henson UapDokument1 SeiteEnson: Ar. Johnny V. Henson Uap Ar. Gabrielle Jan S. Henson UapBrylle De GuzmanNoch keine Bewertungen

- CAN Physical Layer and Termination Guide - National InstrumentsDokument3 SeitenCAN Physical Layer and Termination Guide - National InstrumentsdubimouNoch keine Bewertungen

- Chapter 6 Plate GirderDokument23 SeitenChapter 6 Plate GirderolomuNoch keine Bewertungen

- 2016 PostgraduateCourse Domestic4.3Dokument53 Seiten2016 PostgraduateCourse Domestic4.3agus prabawaNoch keine Bewertungen

- BoQ GRP Pipe Contructor 20180918Dokument8 SeitenBoQ GRP Pipe Contructor 20180918Mohammad SyeduzzamanNoch keine Bewertungen

- Restricting AD Replication Traffic To A Specific Port (KB224196)Dokument3 SeitenRestricting AD Replication Traffic To A Specific Port (KB224196)AldineYapNoch keine Bewertungen

- Sunlite GigeDokument2 SeitenSunlite GigeJhon SendokNoch keine Bewertungen

- 2017 Laureates Rafael Aranda, Carme Pigem and Ramon Vilalta Spain Media KitDokument26 Seiten2017 Laureates Rafael Aranda, Carme Pigem and Ramon Vilalta Spain Media KitManu ChackoNoch keine Bewertungen

- Proposed White Cross Medical Centre Bills of QuantitiesDokument10 SeitenProposed White Cross Medical Centre Bills of Quantitiesmasumba patrickNoch keine Bewertungen

- 2 Storey PDFDokument23 Seiten2 Storey PDFcollins unankaNoch keine Bewertungen

- Cablofil RussiaDokument15 SeitenCablofil RussiaSourav BhattacharyaNoch keine Bewertungen

- Ubuntu (Operating System) - Wikipedia, The Free EncyclopediaDokument21 SeitenUbuntu (Operating System) - Wikipedia, The Free Encyclopediad_richard_dNoch keine Bewertungen

- Nokia's Downfall: Leadership and Change Management IssuesDokument14 SeitenNokia's Downfall: Leadership and Change Management Issuesnauman naikNoch keine Bewertungen

- LLRP 1 0 1-Standard-20070813Dokument194 SeitenLLRP 1 0 1-Standard-20070813Keny BustillosNoch keine Bewertungen

- National Institute of Fashion TechnologyDokument13 SeitenNational Institute of Fashion TechnologymayutwatNoch keine Bewertungen

- Three Storey Commercial BuildingDokument2 SeitenThree Storey Commercial Buildingrichard romasantaNoch keine Bewertungen

- AutoCAD System VariablesDokument11 SeitenAutoCAD System VariablesAllan David100% (1)

- Tldhighlights2013 2014Dokument8 SeitenTldhighlights2013 2014sharma5544Noch keine Bewertungen

- Solution Manual For Computer Math: Problem Solving For Information Technology With Student Solutions Manual, 2/E 2nd Edition Charles Marchant ReederDokument33 SeitenSolution Manual For Computer Math: Problem Solving For Information Technology With Student Solutions Manual, 2/E 2nd Edition Charles Marchant Reedermasonandersonphdkpgtrenxwf100% (11)

- A Neoteric Funerary Design Approach: Sustainable Modular Entombment in Baguio CityDokument15 SeitenA Neoteric Funerary Design Approach: Sustainable Modular Entombment in Baguio CityEd dela Pena100% (1)

- Chief Architect x8 Users Guide Roof TutorialDokument44 SeitenChief Architect x8 Users Guide Roof TutorialcharlieaizaNoch keine Bewertungen

- Lecture 2 Bearing and Punching Stress, StrainDokument16 SeitenLecture 2 Bearing and Punching Stress, StrainDennisVigoNoch keine Bewertungen

- Ancient Egyptian Town Planning and ArchitectureDokument18 SeitenAncient Egyptian Town Planning and ArchitectureAlok VenuNoch keine Bewertungen

- Concrete Mix Design M20 GradeDokument4 SeitenConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaNoch keine Bewertungen

- TreeSize PDFDokument79 SeitenTreeSize PDFGustavoVegaNoch keine Bewertungen