Beruflich Dokumente

Kultur Dokumente

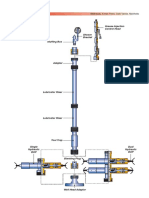

Control Valve Skid Arrangement

Hochgeladen von

rohitkushOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Control Valve Skid Arrangement

Hochgeladen von

rohitkushCopyright:

Verfügbare Formate

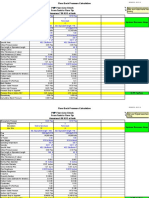

Case-1: When Two Phase at Upstream of Control Valve is Acceptable i.e.

Control Valve is Sized to Handle Two Phase flow

AT

1"

PDIT

1" 1"

RO FIT LCV

6" 6" 6" 6"

Pressure (Barg) 12.95 Press (Barg) 12.45 Press (Barg) 11.95 Press (Barg) 11.80

∆P (Bar) 0.5 ∆P (Bar) 0.5 ∆P (Bar) 0.1

Overall Line Loss (Bar) 0.05

Assumptions:

1)Maximum Pressure drop across RO at maximum flow is 0.5 bar

2) Maximum pressure drop across Strainer at maximum flow is 0.5 bar

3) Maximum pressure drop across Flowmeter at maximum flow is 0.1 bar

4) Overall Line Pressure Drop at Maximum Flow is 0.05 bar

Findings:

1) Two phase will be obseved at downstream of RO

2)Flowmeter and Control Valve shall be sized for two phase flow

3) During Turndown case (50 BBLPD) Analyser AT will not give correct reading as minimum flow required in slip stream is 275 BBLPD to acquire a velocity of 3ft/sec to ensure homogenious mixture in AT as per Vendor AGAR

4) Static Mixer can be considered in Main line if required by vendor to ensure homogenious mixer in slip stream provided that the velocity criteria of 3 ft/sec is not further required as that can't be met during turndown.

Case-2: When Two Phase at Upstream of Control Valve is not Acceptable i.e. Control Valve is Sized to Handle Single Phase at Upstream and Downstream of Control Valve may be Two Phase

AT

1"

PDIT

1" 1"

RO FIT LCV

6" 6" 6" 6"

Pressure (Barg) 12.95 Press (Barg) 12.87 Press (Barg) 12.85 Press (Barg) 12.73

∆P (Bar) 0.08 ∆P (Bar) 0.02 ∆P (Bar) 0.07

Overall Line Loss (Bar) 0.05

Assumptions:

1) Pressure drop at upstream of the control Valve shall be Higher than Liquid vapor Pressure i.e. 12.73 barg

2)Maximum Pressure drop across RO at maximum flow is 0.08 bar

3) Maximum pressure drop across Strainer at maximum flow is 0.02 bar

3) Maximum pressure drop across Flowmeter at maximum flow is 0.07 bar

4) Overall Line Pressure Drop at Maximum Flow is 0.05 bar

Findings:

1) Single phase will be obseved at Upstream of Control Valve

2)Flowmeter and Control Valve shall be sized for Single phase flow

3) Strainer Pressure drop can't be more than 0.02 to avoid two phase at upstream of control valve until upstream pressure increase some how to accommodate this pressure drop. So PDIT alram set point need to be revised for smooth operation.

4) Since RO has very low pressure drop, Velocity limitation need to be verify in slip stream for flow passing in slip stream to ensure homogenious mixture in AT to get accurate reading.

5) During Turndown case (50 BBLPD) Analyser AT will not give correct reading as minimum flow required in slip stream is 275 BBLPD to acquire a velocity of 3ft/sec to ensure homogenious mixture in AT as per Vendor AGAR

6) Static Mixer in Main Line can't be afforded to avoid extra pressure drop in line.

Das könnte Ihnen auch gefallen

- K3VL Controls 2010 MDDokument55 SeitenK3VL Controls 2010 MDHamza Lashin100% (1)

- Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1Dokument1 SeiteAttachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1rohitkushNoch keine Bewertungen

- Fluid MechanicsDokument40 SeitenFluid MechanicsShahinur AlamNoch keine Bewertungen

- L3-Reservoir Fluids ClassificationDokument91 SeitenL3-Reservoir Fluids ClassificationadeeyoNoch keine Bewertungen

- NPSH Calculation PumpDokument3 SeitenNPSH Calculation PumpYosses Sang NahkodaNoch keine Bewertungen

- Oilfield Products - Valves & Wellheads: YyycwuvtcnkcprkrgnkpgxcnxgeqocwDokument48 SeitenOilfield Products - Valves & Wellheads: Yyycwuvtcnkcprkrgnkpgxcnxgeqocwjhonny barrantesNoch keine Bewertungen

- Gas Laws Practice Test - Ans. KeyDokument4 SeitenGas Laws Practice Test - Ans. Keycabbiemartinez100% (1)

- Biochemistry Lab NotesDokument2 SeitenBiochemistry Lab NotesEppNoch keine Bewertungen

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDokument4 SeitenGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNoch keine Bewertungen

- AGA5 Calculation-Imperial UnitDokument24 SeitenAGA5 Calculation-Imperial UnitlubangjarumNoch keine Bewertungen

- BOP Control System Calculation Sheet PDFDokument8 SeitenBOP Control System Calculation Sheet PDFAlecs Nedea100% (1)

- Grease Injection Control Head: ParveenDokument46 SeitenGrease Injection Control Head: ParveenKedai KopiNoch keine Bewertungen

- Deutz 1015 - 6Dokument2 SeitenDeutz 1015 - 6lilireneNoch keine Bewertungen

- B40EA - Distillation Unit Operations A PDFDokument144 SeitenB40EA - Distillation Unit Operations A PDFAnonymous vrKMTsa5qNoch keine Bewertungen

- DX80R Control Valve 9SX14Dokument34 SeitenDX80R Control Valve 9SX14ZawminhtunNoch keine Bewertungen

- Expectations For The Mi ProgramDokument3 SeitenExpectations For The Mi ProgramrohitkushNoch keine Bewertungen

- Haldor Topsoe Hter First ExperiencesDokument8 SeitenHaldor Topsoe Hter First ExperiencesGeorge Van BommelNoch keine Bewertungen

- Volume Calculation For BlowdownDokument6 SeitenVolume Calculation For BlowdownrohitkushNoch keine Bewertungen

- 3 - 4 - Power Train SystemDokument22 Seiten3 - 4 - Power Train SystemRamiro Castro Pacheco100% (3)

- 10.phase Diagrams PDFDokument24 Seiten10.phase Diagrams PDFMumpuniLuthfiNoch keine Bewertungen

- Science 8 Q3 Week 3Dokument12 SeitenScience 8 Q3 Week 3Jetami Yuna GoNoch keine Bewertungen

- Control Valve Sizing - EnggcyclopediaDokument4 SeitenControl Valve Sizing - EnggcyclopediaazitaggNoch keine Bewertungen

- Validated SheetDokument12 SeitenValidated SheetrohitkushNoch keine Bewertungen

- Calculation For Jet MixerDokument3 SeitenCalculation For Jet MixerrohitkushNoch keine Bewertungen

- Datasheet 4057 4457 3-Way Pilot Valves Rev1Dokument7 SeitenDatasheet 4057 4457 3-Way Pilot Valves Rev1Tuan NguyenNoch keine Bewertungen

- KS180 Badestnost От 1 До 12 СекцийDokument7 SeitenKS180 Badestnost От 1 До 12 СекцийДаниил СторчеусNoch keine Bewertungen

- Belgas p39Dokument4 SeitenBelgas p39Syach FirmNoch keine Bewertungen

- AW109E - CockpitDokument1 SeiteAW109E - CockpithmatuscNoch keine Bewertungen

- Valvula Proporcional 21IA4T15GP1-5Dokument2 SeitenValvula Proporcional 21IA4T15GP1-5Jorge Peñaloza GuerraNoch keine Bewertungen

- Denison Hydraulics Direct Operated Check Valves: In-Line SAE 61 &62 Flanges Series C5V Design BDokument7 SeitenDenison Hydraulics Direct Operated Check Valves: In-Line SAE 61 &62 Flanges Series C5V Design BMario SouzaNoch keine Bewertungen

- System Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigDokument5 SeitenSystem Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigguhadebasisNoch keine Bewertungen

- Z2FS 6 New Series... 40BDokument6 SeitenZ2FS 6 New Series... 40Bnemi90Noch keine Bewertungen

- FAUCETDokument2 SeitenFAUCEThucyg63Noch keine Bewertungen

- High Pressure Control Valves: Applications: SpringsDokument5 SeitenHigh Pressure Control Valves: Applications: SpringsDaniel RiveraNoch keine Bewertungen

- Hazen-Williams Pipe Flow Calculations SI UnitsDokument25 SeitenHazen-Williams Pipe Flow Calculations SI UnitsJorge CottonNoch keine Bewertungen

- Relays & Volume Boosters: Type 20Dokument8 SeitenRelays & Volume Boosters: Type 20Jholman SanchezNoch keine Bewertungen

- Mini - General Purpose Regulators - R07, R46Dokument2 SeitenMini - General Purpose Regulators - R07, R46Miguel Camacho BalabarcaNoch keine Bewertungen

- Serviceability Limit State: Matara Katharagama New Rail Road Development Project Design Unit Epc DivisionDokument4 SeitenServiceability Limit State: Matara Katharagama New Rail Road Development Project Design Unit Epc DivisionrasikamalNoch keine Bewertungen

- Flow Control Valve, Type 2FRM5, 10, 16 and Rectifier Plate, Type Z4S5, 10, 16Dokument8 SeitenFlow Control Valve, Type 2FRM5, 10, 16 and Rectifier Plate, Type Z4S5, 10, 16Daniel Sandoval FernándezNoch keine Bewertungen

- Tech Bulletin 002: Inlet Pressure vs. Water TemperatureDokument2 SeitenTech Bulletin 002: Inlet Pressure vs. Water Temperaturesf wNoch keine Bewertungen

- Temakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPDokument1 SeiteTemakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPMohammad KamruzzamanNoch keine Bewertungen

- Performance Data For L/C Series Pump Model 2C: Iron Construction Standard Clearance 1" Std. Port SizeDokument2 SeitenPerformance Data For L/C Series Pump Model 2C: Iron Construction Standard Clearance 1" Std. Port Sizekosmc123Noch keine Bewertungen

- Omega Turbine Sel GuideDokument4 SeitenOmega Turbine Sel GuideHossam MagrabyNoch keine Bewertungen

- P39 Standard Gas Regulators: Applications SpecificationsDokument4 SeitenP39 Standard Gas Regulators: Applications SpecificationsAlexander Charry GiraldoNoch keine Bewertungen

- Serie 090 RTC CouplingsDokument12 SeitenSerie 090 RTC CouplingsHIDRAFLUIDNoch keine Bewertungen

- Chapter 11: Poppet Style Flow Controls: ObjectivesDokument16 SeitenChapter 11: Poppet Style Flow Controls: ObjectivesSangmin KimNoch keine Bewertungen

- Tor 48Dokument1 SeiteTor 48topoginoNoch keine Bewertungen

- Mesure de La Mecanique Pulmonaire, Thoracique Et Thoraco-PulmonaireDokument10 SeitenMesure de La Mecanique Pulmonaire, Thoracique Et Thoraco-PulmonaireAurélien LorimierNoch keine Bewertungen

- Husqvarna 181 Workshop ManualDokument33 SeitenHusqvarna 181 Workshop ManualNicolau FerreiraNoch keine Bewertungen

- Inserto S.C.Dokument2 SeitenInserto S.C.martin.riosNoch keine Bewertungen

- McCulloch Gas Trimmer Parts Manuals 12 400128 95 MAC 2827-12-92 To Current IPL 211704Dokument15 SeitenMcCulloch Gas Trimmer Parts Manuals 12 400128 95 MAC 2827-12-92 To Current IPL 211704Xavier_Leon_978150% (2)

- Kimplas Electrofusion CatalogueDokument20 SeitenKimplas Electrofusion CatalogueShaik MunawarNoch keine Bewertungen

- Copy of Form Amprahan New-1Dokument14 SeitenCopy of Form Amprahan New-1Adisty LukmanNoch keine Bewertungen

- 2 Valvula Reductora Presion Ayvaz BDV25 PDFDokument2 Seiten2 Valvula Reductora Presion Ayvaz BDV25 PDFjoaquin torrano veraNoch keine Bewertungen

- Grundfosliterature 5439466 PDFDokument11 SeitenGrundfosliterature 5439466 PDFDio MiNoch keine Bewertungen

- CHPT 4 FeedDokument6 SeitenCHPT 4 FeedManuelNoch keine Bewertungen

- Releasable Check Valve Type RH: Product DocumentationDokument15 SeitenReleasable Check Valve Type RH: Product DocumentationOmar EldrwanyNoch keine Bewertungen

- AB00 Valve LayoutDokument1 SeiteAB00 Valve LayoutDanielLeeNoch keine Bewertungen

- Serie 103 RTC CouplingsDokument4 SeitenSerie 103 RTC CouplingsHIDRAFLUIDNoch keine Bewertungen

- Bladder Type AccumulatorDokument24 SeitenBladder Type Accumulatorsmurfhans4Noch keine Bewertungen

- Wet Gas Metering With V-Cone Meters: RD TH THDokument14 SeitenWet Gas Metering With V-Cone Meters: RD TH THMichelle GuerraNoch keine Bewertungen

- Gamma Datasheet 1-Dgp-SeriesDokument2 SeitenGamma Datasheet 1-Dgp-Seriesprodn123Noch keine Bewertungen

- Electromechanical Pressure Switches: References, CharacteristicsDokument4 SeitenElectromechanical Pressure Switches: References, CharacteristicsEsquisofNoch keine Bewertungen

- Boerger Performance Curves AL Series 06Dokument3 SeitenBoerger Performance Curves AL Series 06Bernardo Eulogio Bobadilla RodriguezNoch keine Bewertungen

- JVCVReport1215 PDFDokument1 SeiteJVCVReport1215 PDFUlises BadilloNoch keine Bewertungen

- Manual Pull Valve: Poppet Type, Normally Closed Valve 45 L/Min (11.9 Usgpm) - 210 Bar (3000 Psi)Dokument2 SeitenManual Pull Valve: Poppet Type, Normally Closed Valve 45 L/Min (11.9 Usgpm) - 210 Bar (3000 Psi)Augusto PenessiNoch keine Bewertungen

- Norgren R05Dokument2 SeitenNorgren R05skinkcrowNoch keine Bewertungen

- CHPT 5 DrifterDokument4 SeitenCHPT 5 DrifterManuelNoch keine Bewertungen

- Technical Specifications: CV / CL Series FiltersDokument2 SeitenTechnical Specifications: CV / CL Series FiltersEmanuel MurilloNoch keine Bewertungen

- 125 PV 4714Dokument1 Seite125 PV 4714Pratik SangamNoch keine Bewertungen

- Liquid Cylinders TWM B014 Rev00Dokument8 SeitenLiquid Cylinders TWM B014 Rev00Mohd ZaidNoch keine Bewertungen

- Norgren PDFDokument18 SeitenNorgren PDFAbhayy DevNoch keine Bewertungen

- Serie RT Diagrama ElectricoDokument1 SeiteSerie RT Diagrama ElectricoThomas SatosquiNoch keine Bewertungen

- J1237 Asian Paints HAZOP WSDokument98 SeitenJ1237 Asian Paints HAZOP WSrohitkushNoch keine Bewertungen

- Criterion For Hazard Ranking ProcedureDokument1 SeiteCriterion For Hazard Ranking ProcedurerohitkushNoch keine Bewertungen

- Wind Speed (M/S) N NE E SE SDokument3 SeitenWind Speed (M/S) N NE E SE SrohitkushNoch keine Bewertungen

- PSM GoalDokument2 SeitenPSM GoalrohitkushNoch keine Bewertungen

- Line Sizing HYSYS PDFDokument1 SeiteLine Sizing HYSYS PDFrohitkush100% (1)

- Cover Sheet (West Qurna - 2 Project. Early Phase Production Stage)Dokument2 SeitenCover Sheet (West Qurna - 2 Project. Early Phase Production Stage)rohitkushNoch keine Bewertungen

- Hydraulic Expansion (Liquid)Dokument1 SeiteHydraulic Expansion (Liquid)rohitkushNoch keine Bewertungen

- SPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalDokument10 SeitenSPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalRonald LlerenaNoch keine Bewertungen

- ChE 311 Problem Set With Answer KeyDokument5 SeitenChE 311 Problem Set With Answer KeyGian BanaresNoch keine Bewertungen

- 09 Science Matter in Our Surrounding Test 02Dokument1 Seite09 Science Matter in Our Surrounding Test 02Himanshu GuptaNoch keine Bewertungen

- Linear and Planar DensitiesDokument22 SeitenLinear and Planar DensitiesIpul MuhammadNoch keine Bewertungen

- Chapter 4 Phase DiagramDokument24 SeitenChapter 4 Phase Diagrampoom2007Noch keine Bewertungen

- Guide To Gases: NitrogenDokument3 SeitenGuide To Gases: Nitrogenbilalak1990Noch keine Bewertungen

- Lewis SymbolDokument20 SeitenLewis SymbolVivian May J. GuibalaNoch keine Bewertungen

- Fluid Mechanics Sample ProblemsDokument10 SeitenFluid Mechanics Sample ProblemsDenver BanlasanNoch keine Bewertungen

- Refregeration and Air-ConditioningDokument16 SeitenRefregeration and Air-ConditioningMenard SoniNoch keine Bewertungen

- MFET Magnetic Field Effect Transistor With Spin Transport Control by Mahalu & Graur PDFDokument4 SeitenMFET Magnetic Field Effect Transistor With Spin Transport Control by Mahalu & Graur PDFScutul_CrestinNoch keine Bewertungen

- Super Critical CO2 As Green SolventDokument11 SeitenSuper Critical CO2 As Green SolventAnushka ChakrabortyNoch keine Bewertungen

- Solid State Physics PPT - Compatibility ModeDokument124 SeitenSolid State Physics PPT - Compatibility ModeBibhu Prasad SahooNoch keine Bewertungen

- DPP 3 SolutionDokument1 SeiteDPP 3 SolutionOmprakash DhakaNoch keine Bewertungen

- Themodynamics 1 C&o - Ideal Gas ProblemDokument3 SeitenThemodynamics 1 C&o - Ideal Gas ProblemBasil BautistaNoch keine Bewertungen

- Physical / Inorganic Chemistry (BT 303) : Course Co-Ordinator Dr. Mahera Moin DCOB, Dow University of Health SciencesDokument78 SeitenPhysical / Inorganic Chemistry (BT 303) : Course Co-Ordinator Dr. Mahera Moin DCOB, Dow University of Health SciencesMed RynnNoch keine Bewertungen

- Tutorial1 SolutionDokument6 SeitenTutorial1 SolutionAnonymous C5daqjUIQYNoch keine Bewertungen

- Fluid Phase Equilibria, 87 (1993) 133-152Dokument20 SeitenFluid Phase Equilibria, 87 (1993) 133-152Gaurav KunduNoch keine Bewertungen

- Leonid SurguchevDokument12 SeitenLeonid SurguchevkglorstadNoch keine Bewertungen

- 2.1 Transition Metals General Properties MSDokument11 Seiten2.1 Transition Metals General Properties MSJesulayomi BolajiNoch keine Bewertungen

- Interactive Textbook 2 1 Water in The Air14Dokument9 SeitenInteractive Textbook 2 1 Water in The Air14api-240094705Noch keine Bewertungen

- INTRODUCTION TO GASES AND GAS LAWSJanuary 04Dokument10 SeitenINTRODUCTION TO GASES AND GAS LAWSJanuary 04Ameerah Sophia TanedoNoch keine Bewertungen