Beruflich Dokumente

Kultur Dokumente

My Vent

Hochgeladen von

Rufus D SOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

My Vent

Hochgeladen von

Rufus D SCopyright:

Verfügbare Formate

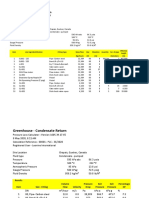

Boiler Design Program - BDP version 10.07.48.

76

Date - 16 Jul 2010

Job description - SLO 2200 - 350 special

Customer - Project

Client - My Customer Inc.

Calculation ID - 00006 - BDP - Mar/2005

Job number - 0160

Enquiry number -

Files used

Boiler file - TC320-11.bd10

Customer file - Design boiler

Fuel file - Digester gas in TC320-11.bd10

Site file - Whitecourt Canada.bs10

Calculation by Gary

Registration status - Legal copy.

This program run 8/1

This calculation 6

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Boiler data - SLO 2200 - 350

______________________________________________________________________

Boiler configuration = Wet back

Boiler type = Saturated steam

Boiler model = SLO 2200 - 350

Elevated drum = False

Rated equivalent evaporation = 3500 [kg/hour]

Turn down ratio = 5 []

Feed water temperature = 20 [°C]

Blow down = 2 [%]

Use the standard model size to calculate flow = False

Use the standard model dimensions = False

Which standard dimensions to use = CE

The data file above was changed for these results.

The data file had not been saved at the time of the report.

Hence the above data may not be the same as the data file used.

______________________________________________________________________

Fuel data - SLO 2200 - 350

______________________________________________________________________

Name of fuel = Digester gas

Fuel category = Gas

Fuel type = Gas

Gross CV = 25.053 [MJ/kg]

Fuel/furnace radiation factor = 0.675 []

Carbon monoxide = 0 [% vol]

Hydrogen = 0.485 [% vol]

My vent.txt[2019-06-29 1:16:46 PM]

Methane CH4 = 68.1 [% vol]

Ethylene C2H4 = 0 [% vol]

Ethane C2H6 = 0 [% vol]

Hydrogen sulphide H2S = 0.015 [% vol]

Oxygen O2 = 0.8 [% vol]

Carbon dioxide CO2 = 29.8 [% vol]

Nitrogen N2 = 0.8 [% vol]

Moisture H2O = 0 [% vol]

Propylene (or cyclopropane) C3H6 = 0 [% vol]

Propane C3H8 = 0 [% vol]

Butene C4H8 = 0 [% vol]

Butane C4H10 = 0 [% vol]

n-Pentane C5H12 = 0 [% vol]

n-Hexane C6H14 = 0 [% vol]

Argon Ar = 0 [% vol]

Sulphur dioxide SO2 = 0 [% vol]

Fuel constant = 127.4809 []

Fuel density = 1.0271 [kg/m³]

Temperature = 0 [°C]

Pressure = 0 [kPa g]

The data file above was changed for these results.

The data file had not been saved at the time of the report.

Hence the above data may not be the same as the data file used.

______________________________________________________________________

Ventillation results

______________________________________________________________________

Boiler house ventillation requirements...

BS 6644:2005 covers requirements for gas-fired hot water boiler installations.

In the range 70 kW to 1.8 MW

Gas firing does not stop with low excess air as with other fuels.

Gas firing is possible with sub stoichimetric levels of combustion air.

This has been known to promote high local levels of CO around the boiler.

In the worst instances this has lead to fatalities.

Take great care that required ventillation is adequate in the boiler house.

Danger is highest during winter, when all the windows and doors are shut.

There shall be a supply of air to the boiler house...

for combustion,

dilution of combustion products,

and ventillation to ensure that...

Maximum temperature at floor level 25.0 °C

Maximum temperature at 1.5 m above floor level 32.0 °C

Maximum temperature at ceiling level 40.0 °C

Total low level free area 10646.3 cm²

Total high level free area 5323.1 cm²

My vent.txt[2019-06-29 1:16:46 PM]

Mechanical ventillation inlet fan 2.1 m³/s

Mechanical ventillation exhaust fan 1.4 m³/s

NBIC 2007, Part 1 Section 2.5.4 Combustion Air Ventillation - Power Boilers

NBIC 2007, Part 1 Section 3.5.4 Combustion Air Ventillation - Heating Boilers

Unobstructed opening free area (2.5.4) 3.4 m²

Unobstructed opening free area (3.5.4) 3.3 m²

Fresh combustion air 3552.4 m³/hour

National Board Inspection Code - Notes

Minimum oxygen level in the boiler room 19.500 %

Recommendations are for oil and gas firing.

Combustion and ventillation air can be supplied by:

- unobstructed air opening. To be kept clear at all times.

- fans.

Even when combustion air is ducted directly to the burner,

ventillation for the boiler room must still be considered.

Where fans are used they shall be interlocked so that the burners will not operate,

without the ventillation fans running.

Do not route steam, or water lines infront of the air inlet to prevent freezing.

______________________________________________________________________

My vent.txt[2019-06-29 1:16:46 PM]

Das könnte Ihnen auch gefallen

- Tips For Successful Citrus Grafting PDFDokument11 SeitenTips For Successful Citrus Grafting PDFiban0% (1)

- Mercury Grand Marquis Owners Manual 1998Dokument152 SeitenMercury Grand Marquis Owners Manual 1998Masood Alam FarooquiNoch keine Bewertungen

- Energy Audit & Efficiency Improvement of Operating Power PlantsDokument56 SeitenEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Boilers 101 PDFDokument27 SeitenBoilers 101 PDFsppatilNoch keine Bewertungen

- OpenTextExstreamCommandCenter DeliveryManagerDokument19 SeitenOpenTextExstreamCommandCenter DeliveryManagerBriar WoodNoch keine Bewertungen

- Boiler DesignDokument10 SeitenBoiler DesignbobNoch keine Bewertungen

- Plant EfficiencyDokument51 SeitenPlant EfficiencyknsaravanaNoch keine Bewertungen

- Fuel Savings and Efficiency CalculatorDokument6 SeitenFuel Savings and Efficiency Calculatorrajayu20002724Noch keine Bewertungen

- Boiler Efficiency MeasurementDokument7 SeitenBoiler Efficiency MeasurementManoj MishraNoch keine Bewertungen

- ZainalDokument23 SeitenZainalAbdul QodirNoch keine Bewertungen

- TB 03 Calculations Normalisations ConversionsDokument17 SeitenTB 03 Calculations Normalisations ConversionsRaul BxinNoch keine Bewertungen

- KelomplkDokument23 SeitenKelomplkAbdul QodirNoch keine Bewertungen

- 4.10.4 Performance Evaluation of BoilersDokument7 Seiten4.10.4 Performance Evaluation of BoilersGanti AsegarNoch keine Bewertungen

- Boiler Performance Calculation1Dokument41 SeitenBoiler Performance Calculation1chinmay sundar dashNoch keine Bewertungen

- Boiler Excess Air Tune-UpDokument15 SeitenBoiler Excess Air Tune-UpAlif Nur FirdausNoch keine Bewertungen

- Boiler Efficiency CalculationDokument5 SeitenBoiler Efficiency CalculationSuparna Bhose100% (3)

- Eff - TXT (2021-01-18 4:07:43 PM)Dokument8 SeitenEff - TXT (2021-01-18 4:07:43 PM)Rufus D SNoch keine Bewertungen

- Unit Heat RateDokument7 SeitenUnit Heat RateSelvaNoch keine Bewertungen

- Boiler EfficiencyDokument32 SeitenBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Anggi Bagus FixDokument23 SeitenAnggi Bagus FixAbdul QodirNoch keine Bewertungen

- Nitrogen CalcDokument1 SeiteNitrogen CalcSomayajula Suryaram100% (2)

- Y.pabbI - 28 July 15 - EE ImpOperatg PlantsDokument56 SeitenY.pabbI - 28 July 15 - EE ImpOperatg Plantsamerie joy onateNoch keine Bewertungen

- Boiler Total Air OptimizationDokument24 SeitenBoiler Total Air OptimizationSam100% (7)

- Emission Reduction With Partial Oxidation of Natural Gas in Combined CycleDokument21 SeitenEmission Reduction With Partial Oxidation of Natural Gas in Combined Cyclealiscribd46Noch keine Bewertungen

- Dual Pressure Nitric Acid Process Simulation Results - ProSim PDFDokument25 SeitenDual Pressure Nitric Acid Process Simulation Results - ProSim PDFPhuong PhamNoch keine Bewertungen

- Boiler Tune Auto ReportDokument55 SeitenBoiler Tune Auto ReportValiNoch keine Bewertungen

- TP TempDokument2 SeitenTP TempRufus D SNoch keine Bewertungen

- Production of Methyl Acetate Using Carbonylation of Dimethyl EtherDokument35 SeitenProduction of Methyl Acetate Using Carbonylation of Dimethyl EtherLuiz Rodrigo AssisNoch keine Bewertungen

- STEAM GENERATOR Part 1Dokument62 SeitenSTEAM GENERATOR Part 1Habtamu Tkubet EbuyNoch keine Bewertungen

- Energy Management Tutorial SolutionsDokument9 SeitenEnergy Management Tutorial SolutionsLucas LentzNoch keine Bewertungen

- Phthalic2 B PDFDokument11 SeitenPhthalic2 B PDFIzzati AhmadNoch keine Bewertungen

- Boilers HeatersDokument24 SeitenBoilers HeatersPato FuentesNoch keine Bewertungen

- Boiler BurnerDokument12 SeitenBoiler BurnerSumeet SawantNoch keine Bewertungen

- Measuring Boiler Efficiency - ASMEDokument8 SeitenMeasuring Boiler Efficiency - ASMEyvesdepermentier4622Noch keine Bewertungen

- Endothermic Gas Production Overview: Tmosphere Ngineering OmpanyDokument6 SeitenEndothermic Gas Production Overview: Tmosphere Ngineering OmpanyJhon ChitNoch keine Bewertungen

- Boiler Efficiency and CombustionDokument11 SeitenBoiler Efficiency and CombustionsenaNoch keine Bewertungen

- Petroleum Refining Materials and EquipmentDokument23 SeitenPetroleum Refining Materials and EquipmentAli AlengineerNoch keine Bewertungen

- Boilers FuelDokument2 SeitenBoilers FuelaladanNoch keine Bewertungen

- Combustion Theory Boiler Efficiency and Control - PpsDokument72 SeitenCombustion Theory Boiler Efficiency and Control - PpsRantau SilalahiNoch keine Bewertungen

- Draft and Efficiency Evaluation of Furnace and BoilersDokument59 SeitenDraft and Efficiency Evaluation of Furnace and Boilersmujeebmehar100% (3)

- Energy Production From Biomass Gasification by Molten Carbonate Fuel Cells: Process SimulationDokument6 SeitenEnergy Production From Biomass Gasification by Molten Carbonate Fuel Cells: Process SimulationNaason VelascoNoch keine Bewertungen

- Boiler EfficiencyDokument24 SeitenBoiler EfficiencyAmit ChauhanNoch keine Bewertungen

- Boiler Eff SolutionsDokument11 SeitenBoiler Eff SolutionsnpNoch keine Bewertungen

- Energy Performance Assessment of BoilersDokument43 SeitenEnergy Performance Assessment of BoilersPradyumna Dhamangaonkar100% (1)

- Clearstone II Appendix IIIDokument233 SeitenClearstone II Appendix IIIrezaNoch keine Bewertungen

- Rplug Name R-701: PolynrtlDokument13 SeitenRplug Name R-701: PolynrtlSolehah OmarNoch keine Bewertungen

- Tower HMBDokument26 SeitenTower HMBAnkur KoulNoch keine Bewertungen

- HP Simplify Your Thermal Efficiency Calculation PDFDokument9 SeitenHP Simplify Your Thermal Efficiency Calculation PDFGovind RaoNoch keine Bewertungen

- LimeKiln ModelingDokument40 SeitenLimeKiln Modelingarv_devNoch keine Bewertungen

- High-Pressure Steam Reforming of EthanolDokument23 SeitenHigh-Pressure Steam Reforming of EthanolMuhammad NaeemNoch keine Bewertungen

- Rocky Mountain Salvage and Equipment FCC Tool Kit Module #1 FCCU Regenerator Heat Balance CalculationsDokument6 SeitenRocky Mountain Salvage and Equipment FCC Tool Kit Module #1 FCCU Regenerator Heat Balance CalculationsSandeep KumarNoch keine Bewertungen

- Boiler Efficiency Combustion EfficiencyDokument8 SeitenBoiler Efficiency Combustion EfficiencyBelalNorNoch keine Bewertungen

- 64788Dokument35 Seiten64788ghatak2100% (1)

- Boiler Efficiency and CombustionDokument12 SeitenBoiler Efficiency and Combustionhafidhrahadiyan2Noch keine Bewertungen

- Projeto - ProcessosDokument11 SeitenProjeto - ProcessosRoberta ResendeNoch keine Bewertungen

- Integration of CCGT Plant and LNG TerminalDokument28 SeitenIntegration of CCGT Plant and LNG Terminalcicko45100% (1)

- 302 Sow GathDokument6 Seiten302 Sow GathMierza SaputraNoch keine Bewertungen

- Paper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Dokument14 SeitenPaper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Muthiah Chidambaram MuthiahNoch keine Bewertungen

- Interview Q and Ans FOR THARMAL POWER PLANTDokument15 SeitenInterview Q and Ans FOR THARMAL POWER PLANTRajkumar Prasad100% (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesVon EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNoch keine Bewertungen

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsVon EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNoch keine Bewertungen

- 0611 SZL25 2.45 PaDokument2 Seiten0611 SZL25 2.45 PaRufus D SNoch keine Bewertungen

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDokument30 SeitenWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNoch keine Bewertungen

- Superheat HeaderDokument2 SeitenSuperheat HeaderRufus D SNoch keine Bewertungen

- Vancouver HumidtyDokument2 SeitenVancouver HumidtyRufus D SNoch keine Bewertungen

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDokument30 SeitenWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNoch keine Bewertungen

- Dioxin FuransDokument2 SeitenDioxin FuransRufus D SNoch keine Bewertungen

- Gas Properties No CoolingDokument8 SeitenGas Properties No CoolingRufus D SNoch keine Bewertungen

- SZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursDokument1 SeiteSZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursRufus D SNoch keine Bewertungen

- S 4500 - 1100 - Wood - 55% Wood - 8760 HoursDokument1 SeiteS 4500 - 1100 - Wood - 55% Wood - 8760 HoursRufus D SNoch keine Bewertungen

- 0446 - MU To Surge Tank - 900Dokument2 Seiten0446 - MU To Surge Tank - 900Rufus D SNoch keine Bewertungen

- VU-40 - NG - Enbridge - 8760 HoursDokument1 SeiteVU-40 - NG - Enbridge - 8760 HoursRufus D SNoch keine Bewertungen

- Secondary SH SummaryDokument2 SeitenSecondary SH SummaryRufus D SNoch keine Bewertungen

- 8000.1700 - Wood - 30% Moisture - 8760 HoursDokument1 Seite8000.1700 - Wood - 30% Moisture - 8760 HoursRufus D SNoch keine Bewertungen

- 0611 - HPS200-250Dokument2 Seiten0611 - HPS200-250Rufus D SNoch keine Bewertungen

- GlassfilterDokument1 SeiteGlassfilterRufus D SNoch keine Bewertungen

- 0574 - CR240-80Dokument2 Seiten0574 - CR240-80Rufus D SNoch keine Bewertungen

- Heating System Pressure DropDokument4 SeitenHeating System Pressure DropRufus D SNoch keine Bewertungen

- Tube ExpansionDokument1 SeiteTube ExpansionRufus D SNoch keine Bewertungen

- 0259 - HMIP Chimney HeightDokument1 Seite0259 - HMIP Chimney HeightRufus D SNoch keine Bewertungen

- 1615.00209 - BCPDokument4 Seiten1615.00209 - BCPRufus D SNoch keine Bewertungen

- SoftenerDokument2 SeitenSoftenerRufus D SNoch keine Bewertungen

- DealkalizerDokument2 SeitenDealkalizerRufus D SNoch keine Bewertungen

- GreensandfilterDokument1 SeiteGreensandfilterRufus D SNoch keine Bewertungen

- CipDokument2 SeitenCipRufus D SNoch keine Bewertungen

- 0259 - CAA Chimney HeightDokument2 Seiten0259 - CAA Chimney HeightRufus D SNoch keine Bewertungen

- Chimney CodesDokument3 SeitenChimney CodesRufus D SNoch keine Bewertungen

- Safety Valve VentDokument3 SeitenSafety Valve VentRufus D SNoch keine Bewertungen

- G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MDokument11 SeitenG/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MRufus D SNoch keine Bewertungen

- 0234 - Chimney Structural - R0Dokument7 Seiten0234 - Chimney Structural - R0Rufus D SNoch keine Bewertungen

- EffDokument7 SeitenEffRufus D SNoch keine Bewertungen

- Testing of Concrete Masonry: Laboratory Experiment NoDokument10 SeitenTesting of Concrete Masonry: Laboratory Experiment NokeishasantiagoNoch keine Bewertungen

- Lexmark Device Quotas Administrator's GuideDokument22 SeitenLexmark Device Quotas Administrator's Guidegeko1Noch keine Bewertungen

- SCC Containing Coal Fly Ash and Bottom AshDokument9 SeitenSCC Containing Coal Fly Ash and Bottom AshGeorgeEdwardNoch keine Bewertungen

- 7.2.5 Configuring Trusted Authentication For The Web ApplicationDokument2 Seiten7.2.5 Configuring Trusted Authentication For The Web Applicationjhixs31Noch keine Bewertungen

- DOC-02-080 RevD HON OnyxWorks Datasheet 1 2Dokument4 SeitenDOC-02-080 RevD HON OnyxWorks Datasheet 1 2PabloNoch keine Bewertungen

- ARIS Administration GuideDokument125 SeitenARIS Administration Guidedengyuany9983Noch keine Bewertungen

- Networking ReportDokument25 SeitenNetworking ReportyogeshNoch keine Bewertungen

- CCSK Vs CCSP - The Best Cloud Security Certification To Go For?Dokument3 SeitenCCSK Vs CCSP - The Best Cloud Security Certification To Go For?CCSK CLOUD SECURITY100% (1)

- Zimbra CLI CommandsDokument5 SeitenZimbra CLI Commandsmohit.oracledbaNoch keine Bewertungen

- MB Manual Ga-h61m-Ds2 v2.x eDokument40 SeitenMB Manual Ga-h61m-Ds2 v2.x erdos14Noch keine Bewertungen

- PD I 2000 LecturesDokument624 SeitenPD I 2000 LecturesBhaskar ReddyNoch keine Bewertungen

- Smartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFDokument2 SeitenSmartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFGopal KrishnanNoch keine Bewertungen

- Group Policy Adobe Acrobat Reader - Spiceworks PDFDokument5 SeitenGroup Policy Adobe Acrobat Reader - Spiceworks PDFEmilio MartinezNoch keine Bewertungen

- Black Berry Technology Seminar REportDokument24 SeitenBlack Berry Technology Seminar REportparzpinku100% (1)

- Lab 1Dokument6 SeitenLab 1John BowersNoch keine Bewertungen

- Patternsinc Sample PDFDokument20 SeitenPatternsinc Sample PDFMateo LundenNoch keine Bewertungen

- HP-UX 11i v3 Delta Support - Student Guide Part 3 - March 2007 PDFDokument364 SeitenHP-UX 11i v3 Delta Support - Student Guide Part 3 - March 2007 PDFRakesh Singh100% (1)

- CADS - M Dense Sand Unreinforced Phi 40Dokument2 SeitenCADS - M Dense Sand Unreinforced Phi 40DavidNoch keine Bewertungen

- Owners Manual Inverter Europe 5400554301Dokument18 SeitenOwners Manual Inverter Europe 5400554301niknikolNoch keine Bewertungen

- Hvac Sys Verification Checklist v2 5 PDFDokument4 SeitenHvac Sys Verification Checklist v2 5 PDFtsraj10100% (1)

- ReportDokument16 SeitenReportJohn Louie GonzalesNoch keine Bewertungen

- ASTMDokument3 SeitenASTMSustika PratiwiNoch keine Bewertungen

- Introduction To An Architectural Theory: Design As Theory ApplicationDokument4 SeitenIntroduction To An Architectural Theory: Design As Theory ApplicationAliaa Ahmed ShemariNoch keine Bewertungen

- 2E Forgotten Realms Miscellaneous Modules - Calimport PDFDokument98 Seiten2E Forgotten Realms Miscellaneous Modules - Calimport PDFRandy Grosswiler100% (4)

- Example Kitchen Quote 1Dokument7 SeitenExample Kitchen Quote 1Shikhar BansalNoch keine Bewertungen

- Cobiax Abz SlimLine Z151307 11 2018 en FinalDokument25 SeitenCobiax Abz SlimLine Z151307 11 2018 en Finalkhalil_82423297Noch keine Bewertungen

- Design of Elastomeric BearingDokument12 SeitenDesign of Elastomeric BearingSuman Nakarmi100% (3)