Beruflich Dokumente

Kultur Dokumente

Welding Procedure Specification Structural 3G PDF

Hochgeladen von

sebincherian0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

1K Ansichten3 SeitenOriginaltitel

212641364-Welding-Procedure-Specification-Structural-3G.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

1K Ansichten3 SeitenWelding Procedure Specification Structural 3G PDF

Hochgeladen von

sebincherianCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

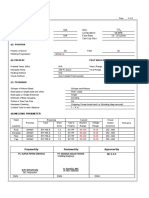

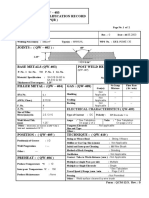

Doc No.

WELDING PROCEDURE SPECIFICATION(WPS) Revision :

STRUCTURAL 3G Page 1 of 3

WELDING PROCESS: SMAW TYPES: Manual

WPS No.: Supporting PQR No: PREQUALIFIED

Rev No.:

Date:

JOINT(QW-402) 60

Joint Design: See sketch

Backing: (Yes)__ (No) X

2mm

Applicable code/Spec: ASME IX/AWS D1.1.

3mm

Backing material (type): N/A.

STANDARD VEE BEVEL BUTT JOINT

4

3

1

SEQUENCE OF BEAD

BASE METALS (QW-403): P No 1 Group No 1 To P No 1 Group No 1

Material specification: ASTMA36TO A 1011

To Specification Type and Grade: Same or in Combination

Thickness Range:

Base Metal

Groove 7.5mm to 37.5mm Fillet 1/8” to Unlimited

Pipe Dia. 12”≤ OD ≤ 24” Fillet N/A

Others:

FILLER METALS (QW-404) ROOT FILL/CAP

Spec No. (SFA) A5.1 A5.1

AWS- No. E-7018 E-7018

F- No. 4 4

A- No. 1 1

Size of Filler Metals 3.2mm 3.2 & 4.0mm

Deposited Weld Metal Thickness 9mm MAX 12mm MAX

Welding Progression Uphill Uphill

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1. WPS STRUCTURAL 3G

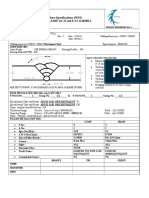

Doc No. :

WELDING PROCEDURE SPECIFICATION(WPS) Revision :

STRUCTURAL 3G Page 2 of 3

WELDING PROCESS: SMAW TYPES: Manual

Groove Position 3G 3G

Fillet ALL ALL

Electrode Flux (class) N/A N/A

Flux trade name Lincoln Electric Lincoln Electric Jetweld

Jetweld 5P 7018

Consumable insert N/A N/A

POSITIONS (QW-405) POST WELD HEAT TREATMENT

Position of Groove: 3G Temperature Range: N/A

Positions of Fillet: ALL Time Range: N/A

Welding Progression: UP: X Down:_

PREHEAT (QW-406) GAS (QW-408)

Preheat temperature Min: AWS TABLE 3.2 Percent composition

Interpass temperature: 250ºC MAX Gas(es) Mixture Flow Rate

Preheat Maintenance: None Shielding N/A N/A N/A

Trailing N/A N/A N/A

(Continuous or special heating where applicable Backing N/A N/A N/A

should be recorded)

ELECTRICAL CHARACTERISTICS (QW-409) Tungsten Electrode size and type; N/A

Current AC or DC: DC Electrode Wire feed Speed Range: N/A

Polarity: Reverse

Amps (Range): 70-190

Volts (Range) 24-30

TECHNIQUE (QW-410)

String or Weave Bead: BOTH Removal of line up clamp: After At Least 60% Of Root

Orifice or Gas cup size: N/A Pass Has Been Deposited

Initial & interpass cleaning: (Grinding & Brushing) Electrode: (single or multiple) Single

Method of back Gouging: N/A

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1. WPS STRUCTURAL 3G

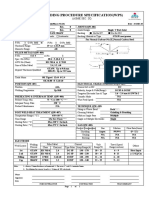

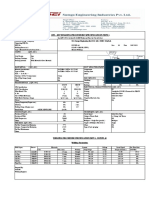

Doc No. :

WELDING PROCEDURE SPECIFICATION(WPS) Revision :

STRUCTURAL 3G Page 3 of 3

WELDING PROCESS: SMAW TYPES: Manual

Type of line up clamp: External (where

applicable)

Travel Speed Range 3- 15 inches per minute

Travel speed (see table)

Weld Process Filler Metal Current Volt Travel Others

layers Class Dia Type of Amp. Range Range Speed

(mm) polarity Range

(mm/min)

1 SMAW E7018 3.2 DCEP 60-130 20-40 66-198 Stringer

2 SMAW E7018 3.2 DCEP 60-130 20-40 66-198 Weave

3 SMAW E7018 4.0 DCEP 100-180 20-40 72-192 Weave

Time laps between completion of root pass and commencement of second pass: 5 minutes

Time laps between completion of second pass and commencement of other pass: 5 minutes

Welding to be a continuous operation. Weld to completion (one heat cycle)

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1. WPS STRUCTURAL 3G

Das könnte Ihnen auch gefallen

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDokument2 SeitenWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Dokument5 SeitenPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNoch keine Bewertungen

- Appendix 1 - Visual Inspection PlateDokument4 SeitenAppendix 1 - Visual Inspection PlateLaith Salman100% (1)

- WPS BhelDokument2 SeitenWPS BhelpradhankruhsnaNoch keine Bewertungen

- Draft WPSDokument3 SeitenDraft WPSWale OyeludeNoch keine Bewertungen

- WQTDokument1 SeiteWQTRamkunwar YadavNoch keine Bewertungen

- Ilcs-Smaw-D1.3-Deck (G) WPSDokument3 SeitenIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Reports - QAQC - R0Dokument10 SeitenReports - QAQC - R0talupurumNoch keine Bewertungen

- Aluminium WPSDokument2 SeitenAluminium WPSAnonymous yCpjZF1rF100% (1)

- Joint Detail (Qw-402)Dokument2 SeitenJoint Detail (Qw-402)Nitesh Patel100% (3)

- Weld Test Checklist: Welder (S) DetailsDokument2 SeitenWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- 004 Gtaw P5aDokument16 Seiten004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Sample API 1104 WpsDokument6 SeitenSample API 1104 Wpsjacquesmayol100% (2)

- 2G +5GDokument1 Seite2G +5GRahul Moottolikandy0% (1)

- Welding Consumable Baking Register PDFDokument1 SeiteWelding Consumable Baking Register PDFKandula Raju100% (1)

- WPS 316 LDokument4 SeitenWPS 316 Llaz_k100% (2)

- WPS Flow Proceess Chart PDFDokument1 SeiteWPS Flow Proceess Chart PDFSatish KeskarNoch keine Bewertungen

- Welder Performace Qualification Report 2014..Dokument132 SeitenWelder Performace Qualification Report 2014..Kayra Riri ChirulNoch keine Bewertungen

- WQT Form (ASME) 04-23Dokument1 SeiteWQT Form (ASME) 04-23hanz bermejoNoch keine Bewertungen

- WPSDokument2 SeitenWPSJuli Agus50% (2)

- PQR Gmaw3gDokument4 SeitenPQR Gmaw3gdevendrasingh2021100% (3)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokument5 SeitenWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Dokument12 SeitenPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNoch keine Bewertungen

- WPSDokument6 SeitenWPSNur Wijianto100% (1)

- Welding Procedure Specification Pipe - 6GDokument3 SeitenWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- WPS 2014-002 002 - 1G & 2G S 275 JRDokument2 SeitenWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Welding Procedure Specification: Page 1 of 1Dokument2 SeitenWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Dokument1 SeiteWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification Structural-3GDokument3 SeitenWelding Procedure Specification Structural-3Gdndudc78% (9)

- Welder Operators Qualification TestDokument2 SeitenWelder Operators Qualification Testlokifarad100% (1)

- Welder Continuity LogDokument3 SeitenWelder Continuity Log942519100% (1)

- Stainless Steel Electrode Comparison ChartDokument7 SeitenStainless Steel Electrode Comparison Chartmiker100Noch keine Bewertungen

- MEI - Aluminium MIG WeldDokument56 SeitenMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDokument2 SeitenWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNoch keine Bewertungen

- WPS PQR A36.20Dokument5 SeitenWPS PQR A36.20gchaves504100% (2)

- Slamet WPQRDokument1 SeiteSlamet WPQRChandra Bintang W.PNoch keine Bewertungen

- WPS-46 - Gtaw & Smaw Tig + SmawDokument8 SeitenWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNoch keine Bewertungen

- Welding Procedure SpecificationDokument27 SeitenWelding Procedure SpecificationGopakumar K100% (2)

- How To Write A Welding Procedure SpecificationDokument14 SeitenHow To Write A Welding Procedure Specificationnizam1372100% (2)

- 385 2 Internal Gtaw+SmawDokument2 Seiten385 2 Internal Gtaw+Smawsubash1688Noch keine Bewertungen

- Val Caraig WPQTDokument1 SeiteVal Caraig WPQTMark Jason M. BrualNoch keine Bewertungen

- Welder Qualification Procedure PDFDokument13 SeitenWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Welding Proposed Pwps For Our Jubail WorkDokument2 SeitenWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNoch keine Bewertungen

- NDT Request FormDokument1 SeiteNDT Request FormSHANENoch keine Bewertungen

- Aluminim WPSDokument2 SeitenAluminim WPSKarthikeyan ShanmugavelNoch keine Bewertungen

- WPS D1.6 Annex m1 PDFDokument1 SeiteWPS D1.6 Annex m1 PDFbollascribdNoch keine Bewertungen

- WPS FormatDokument2 SeitenWPS FormatAmit SarkarNoch keine Bewertungen

- ASME P NumbersDokument3 SeitenASME P Numbersrajesh100% (1)

- SS WPSDokument1 SeiteSS WPSMOHAMEDABBASNoch keine Bewertungen

- Wps PQR Aws d11 FormDokument2 SeitenWps PQR Aws d11 Formflakosisas100% (1)

- WPS - Merd-01Dokument3 SeitenWPS - Merd-01Phuong NguyenNoch keine Bewertungen

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Dokument4 SeitenPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNoch keine Bewertungen

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDokument3 SeitenWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- WPS 03 2014Dokument2 SeitenWPS 03 2014vinuNoch keine Bewertungen

- Welding Procedure Specification Sample - New EditionDokument2 SeitenWelding Procedure Specification Sample - New EditiondanteNoch keine Bewertungen

- Procedure Qualification SpecificationDokument4 SeitenProcedure Qualification Specificationriyas.hvacworkNoch keine Bewertungen

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDokument2 Seiten0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNoch keine Bewertungen

- Preliminary - Welding Procedure Specification (WPS)Dokument1 SeitePreliminary - Welding Procedure Specification (WPS)Rudi DaNoch keine Bewertungen

- In Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditionDokument2 SeitenIn Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditioncrysNoch keine Bewertungen

- Jarir IT Flyer Qatar1Dokument4 SeitenJarir IT Flyer Qatar1sebincherianNoch keine Bewertungen

- BNC - Dana Gas PipelineDokument4 SeitenBNC - Dana Gas PipelinesebincherianNoch keine Bewertungen

- Ikea BillDokument6 SeitenIkea BillsebincherianNoch keine Bewertungen

- TCL TV SpecDokument1 SeiteTCL TV SpecsebincherianNoch keine Bewertungen

- BNC - Dana Gas PipelineDokument4 SeitenBNC - Dana Gas PipelinesebincherianNoch keine Bewertungen

- API 580 QB - Mock Up Exam For 5 TH Day-NO KEYDokument25 SeitenAPI 580 QB - Mock Up Exam For 5 TH Day-NO KEYsebincherianNoch keine Bewertungen

- Certificate: This Is To Certify ThatDokument1 SeiteCertificate: This Is To Certify ThatsebincherianNoch keine Bewertungen

- Alaska Maritime/Logistics Document Control and Records Management Procedure Shell Exploration & Production Company (Shell) Alaska Venture 2015Dokument10 SeitenAlaska Maritime/Logistics Document Control and Records Management Procedure Shell Exploration & Production Company (Shell) Alaska Venture 2015sebincherianNoch keine Bewertungen

- Project Quality Assurance and ControlDokument2 SeitenProject Quality Assurance and ControlsebincherianNoch keine Bewertungen

- DPR-KKBMPL Gail-24.10.2018Dokument46 SeitenDPR-KKBMPL Gail-24.10.2018sebincherianNoch keine Bewertungen

- Img 0002Dokument1 SeiteImg 0002sebincherianNoch keine Bewertungen

- Kerala State Road Transport CorporationDokument1 SeiteKerala State Road Transport CorporationsebincherianNoch keine Bewertungen

- C10 CBSEPhy QueDokument4 SeitenC10 CBSEPhy QueGeneric nameNoch keine Bewertungen

- D Series Datasheet PDFDokument32 SeitenD Series Datasheet PDFryreddyNoch keine Bewertungen

- Caterpillar GeneratorDokument64 SeitenCaterpillar GeneratorDon Freeman100% (3)

- VLSI Question Bank UNIT IV V VI 2019Dokument3 SeitenVLSI Question Bank UNIT IV V VI 2019Savi AkolkarNoch keine Bewertungen

- Steeper and Servo MotorsDokument3 SeitenSteeper and Servo MotorsIan Justine JornalesNoch keine Bewertungen

- Synchronous Reluctance MotorDokument103 SeitenSynchronous Reluctance MotorSubramaniam GnanasekaranNoch keine Bewertungen

- A3941 PDFDokument20 SeitenA3941 PDFEzequiel AriasNoch keine Bewertungen

- EE2101 Unit5Dokument2 SeitenEE2101 Unit5Sadyant HbpNoch keine Bewertungen

- Trampa de Onda BPEG - BrochureDokument8 SeitenTrampa de Onda BPEG - BrochureseanwrestlerNoch keine Bewertungen

- TPS54531 5-A, 28-V Input, Step-Down SWIFT™ DC-DC Converter With Eco-Mode™Dokument33 SeitenTPS54531 5-A, 28-V Input, Step-Down SWIFT™ DC-DC Converter With Eco-Mode™hajaNoch keine Bewertungen

- CD8227GPDokument8 SeitenCD8227GPJosé Miguel Barbosa HernándezNoch keine Bewertungen

- CPC 100 User ManualDokument65 SeitenCPC 100 User ManualMuhammad Talha100% (2)

- Wireless World 1962 06Dokument58 SeitenWireless World 1962 06Jan PranNoch keine Bewertungen

- Drawing Seimens BRKRDokument14 SeitenDrawing Seimens BRKRrajeshNoch keine Bewertungen

- HP EQUIVWPN-wmDokument16 SeitenHP EQUIVWPN-wmstruja2010Noch keine Bewertungen

- Phys2 Midterm Exam F2019 20 With NotesDokument12 SeitenPhys2 Midterm Exam F2019 20 With NotesaamerbolookiNoch keine Bewertungen

- The Fender TBX Tone Control Mod, Part 2Dokument2 SeitenThe Fender TBX Tone Control Mod, Part 2ScrbertoNoch keine Bewertungen

- DE QuestionsDokument42 SeitenDE QuestionsK P DHANALAKSHMI100% (1)

- SCR100 User Manual V1.1Dokument35 SeitenSCR100 User Manual V1.1Luis Boch EnriquezNoch keine Bewertungen

- Power MOSFET V 500V, R 0.85 Ohm, I 8.0 A: N ChannelDokument1 SeitePower MOSFET V 500V, R 0.85 Ohm, I 8.0 A: N Channelลิขิตฟ้ากำหนดมา ให้เป็นช่างNoch keine Bewertungen

- Ekip DipDokument4 SeitenEkip DipDEADMANNoch keine Bewertungen

- Transmission ProtectionDokument111 SeitenTransmission Protectionmuaz_aminu1422100% (1)

- Catalogo Thyripol Ingles - ExcitacaoDokument14 SeitenCatalogo Thyripol Ingles - ExcitacaoErbil KeskinNoch keine Bewertungen

- Bus Impedance Matrix ApplicationsDokument12 SeitenBus Impedance Matrix Applicationsfreddy riveraNoch keine Bewertungen

- 721 Speed ControlDokument102 Seiten721 Speed Controlbondan_pertamaxNoch keine Bewertungen

- SBRTS 9 (Eng)Dokument39 SeitenSBRTS 9 (Eng)Balaji Classes washimNoch keine Bewertungen

- Basics of Rotary Encoders: Overview and New Technologies: Print CloseDokument13 SeitenBasics of Rotary Encoders: Overview and New Technologies: Print CloseholaNoch keine Bewertungen

- Principles of DC MotorsDokument14 SeitenPrinciples of DC MotorsAravind Raj PandianNoch keine Bewertungen

- 381listelect Items Req Sep14Dokument16 Seiten381listelect Items Req Sep14Ramy AbdallaNoch keine Bewertungen

- VKP 60 LT 515 CDokument8 SeitenVKP 60 LT 515 CBadar DayanNoch keine Bewertungen