Beruflich Dokumente

Kultur Dokumente

Automated System For Air Pollution Detection and Control of Speed in Vehicles

Hochgeladen von

ivanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Automated System For Air Pollution Detection and Control of Speed in Vehicles

Hochgeladen von

ivanCopyright:

Verfügbare Formate

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

AUTOMATED SYSTEM FOR AIR POLLUTION DETECTION

AND CONTROL OF SPEED IN VEHICLES

Chaitanya H P1, H. Prasanna Kumar2

1

Student, UVCE/Department of EE, Bangalore, India

2

Asst. Prof, UVCE Engineering/Department of EE, Bangalore, India

ABSTRACT

Every vehicle has a standard of emission of gases, but the difficulty occurs when the emission is beyond the

standardized values. The prime reason for this violation of emission level being the incomplete combustion of

fuel supplied to the engine which is due to the improper maintenance of vehicles. This emission from vehicles

cannot be completely avoided, but it can be definitely controlled. The aim of this paper is to monitor and control

the pollutants in the vehicle by using the pollution control circuit. This pollution control circuit consists of

various sensors like gas sensors, temperature sensor, GSM, Pulse width modulator (PWM) and all of them are

integrated and connected to a Controller. When a vehicle reaches beyond certain threshold pollution level then

the speed of the system gets automatically slow down and if the temperature reaches beyond some threshold

value fan is automatically turned on. The DC motor speed control of the system is done using PWM. It is also

demonstrated using MATLAB simulink simulation using PID and PWM.

KEYWORD: Gas sensors, GSM, PWM and controller.

I. INTRODUCTION

Day by day the number of vehicles is increasing very fast. In major cities like Delhi, Mumbai and

Pune number of vehicles is far more. Due to imperfect combustion in the vehicle engine the pollution

through vehicle increases. Increasing number of vehicles tend to increase in co2 concentration in the

atmosphere. According to Mumbai pollution control board, pollution levels particularly NOX, and

SPM perched particulate matter increased rapidly. SPM above 100 µgram/cubic meter and NOX

88µgram/cubic meter is very harmful for health. The main sources of pollution in metro cities like

Mumbai, Delhi, Pune and Bangalore are vehicles.

The imperfect (incomplete) combustion in the engine of a vehicle leads to emission of different

harmful gases leading to increase in the pollution and unfavorably affecting the environment.

Detection and control of these gases emission source in the environment is an important area of work.

Emission of these gases from vehicles cannot be completely avoided but, it definitely can be

controlled. As a solution to the above problems we aim to build an automated control system for

emission level control of vehicle. The system is provided with the sensors, data from the sensors is

used to make check the pollution level and accordingly the control action is carried out to control the

speed of the system. MATLAB is the tool used here. The system is organized with Hardware design

and methodology, project overview, simulation of motor using PID and PWM; Results are tabulated

and discussed followed by conclusion.

Recently, different pollution control systems discussed in literatures. Chi-Man Vong[1] uses a

pollution control system consists of RFID which is connected to the lambda sensors. The lambda

sensor mounted on exhaust pipe to measure air ratio when air ratio is less than one carbon monoxide

and hydrocarbon emission will increased and when air ratio greater than one more nitrogen oxide will

be produced. ChunxiaoLI[2] author presents a vehicle’s CO2 emission reduction scheme by an ETC-

Electronic Toll Collection (ETC) devices is used at each traffic junction and traffic at each junction

can be find out. ETC devices communicate with signals at each junction. With the help of this

443 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

communication traffic at each junction is obtained. Nishigandha Athare, Prof. P.R.Badadapure[3]

Human safety and air pollution detection in vehicles. KwangSooYo[4] demonstrates gas Sensors

sensing properties for Monitoring Air Pollution and different gases causing air pollution.

Objective of the system

The project has three parts: the traffic signal, the vehicle module and the client. Every vehicle

has a GSM module installed in it.

The traffic signal has the RF transmitter to activate the vehicle module.

Once activated the vehicle module will check for the pollution level and displayed in the

LCD.

Also an alert message is sent to the vehicle owner.

Speed of the system using PWM is reduced until corrective action is taken.

PID and PWM technique is used in MAT Lab to control the speed of a system.

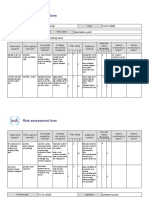

BLOCK DIAGRAM AND DESCRIPTION

2.1 Hardware design

The components used in this system are simple, cost efficient and the system is most indeed system,

which is added as a part to the vehicle.Fig.1 shows the schematic diagram of the pollution monitoring

and control of the system. The components used are explained below[4].

Fig.1 Schematic diagram of pollution monitoring system

Arduino Uno board- An Arduino Uno board consists of Atmega328 a *bit microcontroller with

components to facilitate programming and incorporation into other circuits. An important aspect

of the Arduino is the standard way that connectors are exposed, allowing the board to be

connected to a variety of interchangeable modules known as shields.

Sensors- MQ-7 carbon monoxide sensor, MQ-135 smoke sensor, LM 35 temperature sensor.

RF Transmitter and Receiver-RF module has a Radio Frequency transmitter at the traffic

signal and Radio Frequency receiver in the vehicle. The four inputs are for the frequency range

of 17 KHz, 19 KHz, 22 KHz and 25 KHz and four switches are provided for each range.

Different frequency can be assigned for different vehicles so that at each signal one type of

vehicle can be operated. FM modulation is used in this process. If the carrier frequency is 17

KHz then the modulated signal of 27 KHz is generated and transmitted from the transmitter.

Accordingly receiver is designed to get back the original data signal at the receiver end.

Timer: 555 timer is used here to generate the PWM signal.

444 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

DC motor- The speed control of any vehicle can be demonstrated using simple DC motor. The

speed of the motor depends on the voltage supplied to it. PWM technique is used to control the

seed of a motor. PWM generates a pulse proportional to the voltage that has to be provided for

the motor. In simulation PID and PWM is used to control the speed of the system. The basic

electrical and mathematical model is rigged up using mat lab simulink.

LCD display- LCD (16*2) is used to display the pollution level detected from the gas sensor and

continuously display the temperature.

GSM- GSM/GPRS Modem-RS232 is built with Dual Band GSM/GPRS. The baud rate of the

device is configurable from 9600-115200 using AT command. It is suitable for SMS, Voice as

well as data transfer application. The onboard Regulated Power supply allows you to connect

wide range unregulated power supply. Using this modem, you can make audio calls, SMS, Read

SMS, attend the incoming calls and internet etc through simple AT commands.

2.2. Methodology

Each traffic signal has a RF transmitter with one of the four frequency range assigned to it. Each

vehicle type is assigned with one of the four frequency range. For example if cars are assigned as 17

KHz, buses as 19 KHz and the rest accordingly. This reduces the clumsiness that occurs when all the

vehicles are assigned with the same frequency.

Once the vehicle enters the range of traffic signal the sensors get activated and checks for the

pollution level using the gas sensors and temperature sensor in the vehicle. If the gas sensors range is

higher than the predefined value then it is displayed in the LCD display, LED is turned on, Buzzer to

alert the rider is used. In case if owner is not same as the rider an alert message (SMS) is generated

using GSM device. If temperature is higher than the predefined value then fan is switched on.

DC motor is used in our project for demonstration of speed in our project. If the pollution is high then

the speed of the vehicle is limited. We are not completely stopping the vehicle because they have to

move to the service station and take the actions like servicing the engine. As the engine gets heated up

even that leads to incomplete combustion so to reduce this fan is automatically switched on.

The control algorithm used here is PWM and ON-OFF control.

1. PWM for motor speed control[5]: PWM is a method for supplying the electrical power to a load

having slow response. The supply produced is a continuous pulse. The voltage level to the load is

controlled by the pulse applied.. The PWM output on the Arduino can be varied by varying the duty

cycle from “0” to “255”. Thus the speed can be varied. Also timer can be used to generate pwm signal

in the system.

2. ON-OFF control: An on-off controller is one of the ways for temperature control of a device. The

output from the device is either on or off, with no intermediate state. An on-off controller will switch

the output only when the temperature crosses the set point. Continuously monitoring the temperature

using aurdino uno and once it reaches above the set point the fan is automatically turned on to cool

down the system.

445 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

II. PROJECT REVIEW

Fig.2 Flow chart of the system

The system gets started once it receives the power from the power supply. Components like GSM,

LCD display, Temperature sensor gets initialized to the preset (default) values. On initializing the

temperature sensor keeps monitoring the temperature which is kept at the engine and checks for the

set point, if it is above the set point value automatically fan gets switched on to cool down the system

else it keeps monitoring the temperature. At the same time on getting supply RF transmitter at the

traffic signal starts sending the signal. Vehicles entering this region detect the signal through RF

receiver and on receiving signal the gas sensors kept at exhaust pipe gets activated and starts checking

for the pollution level. If the pollution level is above the set point value the signal is sent to the

microcontroller. Microcontroller triggers the buzzer to alert the driver and it is also displayed on the

vehicle’s LCD display. Sometimes driver and owner of the vehicle are different so an alert message to

the previously specified number is sent to the owner using GSM[7]. Speed of the motor also gets

reduced.

III. SIMULATION OF DC MOTOR FOR SPEED CONTROL

Matlab simulink is the tool use here to control the speed of a dc motor. PID controller and PWM

technique is used to control the speed of a DC motor. The control algorithm carried out to control the

speed, current flow of the system is used is PID. DC motor is modeled using its electrical and

mechanical equation.

PID (Proportional Integral Derivative):The most efficient controller type provides proportional with

integral and derivative control i.e PID. This controller combines proportional control with two

additional adjustments, which helps the unit automatically compensate for changes in the system.

These adjustments, integral and derivative, are expressed in time-based units.

The proportional, integral and derivative terms must be individually adjusted or “tuned” to a particular

system using trial and error. It provides the most accurate and stable control of the three controller

446 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

types, and is best used in systems which have a relatively small mass, those which react quickly to

changes in the energy added to the process. It is recommended in systems where the load changes

often and the controller is expected to compensate automatically due to frequent changes in set point,

the amount of energy available, or the mass to be controlled.

Fig.3 General Block diagram of PID controller

Fig.4 DC motor model

Fig.5 Simulation of DC motor using PID and PWM

IV. RESULTS AND DISCUSSION

The signals acquired from the gas sensors and temperature sensors are compared with the user defined

set point, crossing the threshold limit the pollution level gets displayed in the LCD and when it

crosses the set point it gives a buzzer indication, led on and fuel injection to the motor is limited there

by limiting the speed of the vehicle. This is carried out using PWM control of the speed motor. Also

an alert message to the client is sent using GSM module. The graph of variation of current, motor

torque and angle of rotation (theta) is shown in Fig 4.

447 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

PID controller and PWM technique[6] is used to maintain the constant speed of the motor. The

electrical and mechanical model preceded by the speed controller, current controller and pwm

generator is tuned manually and output of the current, motor torque and motor speed is tabulated. The

variation of current, motor torque is inversely proportional to the speed of the motor; it is as shown in

the fig.6. The PID tuned output of the system is shown in the fig.7. Here we are manually using P=1,

I=0.01 and D=0.

The gas sensor sensitivity is carried out using two point methods; for Carbon monoxide range is 0V-

3.2V and for smoke sensor it is 0V-4.2V. The range of this sensors voltage corresponds to the 20ppm-

2000ppm of the volumetric content of the gas. The temperature sensor output corresponding to

voltage at every 10 degree is tabulated and it is shown in table1.

Fig.6 Variation of current, motor torque and SpeedVs time

Fig.7 PID output

Table.1 Temperature sensor output and fan condition

448 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

Fig.8 Hardware setup

The complete hardware setup with buffer, driver, relay circuitry and all other components mounted on

the car model is shown in fig.8.

V. CONCLUSION

The concept of detecting the level of Pollution and indicating it to the driver (vehicle owner through

message) is implemented. There is an increase in the level of Pollution over the last couple of

decades, leading to several severe Environmental problems and health issues. Due to busy life an

automated system is needed to take the action against pollution control. This paper can be extended by

adding GPS device and maintaining the data base and sending a message to the user about the details

of the nearest service station.

VI. FUTURE SCOPE

This paper is extended by adding GPS with the GSM module and sending a message to the user about

the details of the nearest service station. A server and database can be maintained to keep track of the

pollution level of the system and control action on the owner can be taken if the pollution level alert is

ignored.

ACKNOWLEDGEMENTS

I would like express my sincere gratitude to my guide for helping me complete this work. Thanks to

my family members for their support, guidance and words of encouragement. Also I would like to

thank my friends, teaching and non teaching staff for their support.

REFERENCES

[1]. Chi-Man Vong ―Application of RFID Technology and the Maximum Spanning Tree Algorithm for

Solving Vehicle Emissions in Cities on Internet of Things‖ 2014 IEEE World Forum on Internet of

Things (WF-iot)

[2]. Chunxiao LI and Shigeru shimamoto “Etc assisted traffic light control scheme for reducing vehicles”

International Journal of Managing Information Technology (IJMIT) Vol.4, No.2, May 2012.

[3]. Nishigandha Athare, Prof.P.R.Badadapure[3] “Human safety and air pollution detection in vehicles”

[4]. Anita kulkarni1, T. Ravi Teja ”Automated System for Air Pollution Detection and Control in Vehicles

” /ijareeie.2014.0309061

[5]. Poonam M Baikar , “Design of PID Controller Based Information Collecting Robot in Agricultural

Field”-IJAR,EEIE volume8-2014

449 Vol. 9, Issue 4, pp. xxxx-xxxx

International Journal of Advances in Engineering & Technology, Aug., 2016.

©IJAET ISSN: 22311963

[6]. Poonam M Baikar, Neelam Punjabi1, Chandrakant Kadu “Real Time DC Motor Speed Control using

PID Controller in LabVIEW”

[7]. J.N.Mohite, S.S.Barote Asst professor, Department of electronics “vehicle pollution control and traffic

management”

[8]. S. Arun2 , Dr. J.L Mazher Iqbal, “Embedded System Based Air Pollution Detection in Vehicles V.

Siva Krishna1” ,

[9]. George F. Fine, Leon M. Cavanaugh, Ayo Afonja and Russell Binions " Metal Oxide Semi-Conductor

Gas Sensors in Environmental Monitoring", Sensors 2010, 10, 5469-5502; doi:10.3390/s100605469

[10]. J.N.Mohite, S.S.Barote Professor, “Low Cost Vehicle Pollution Monitoring System”.

[11]. Areas SrinivasDevarakonda, ParveenSevusu, Hongzhang Liu, Ruilin Liu, LiviuIftode, BadriNath

“Real-time Air Quality Monitoring Through Mobile Sensing in Metropolitan”

[12]. Darshana N. Tambe and Ms. Nikita Chavan “Detection of air pollutant using ZIGBEE” International

Journal of Ad hoc, Sensor & Ubiquitous Computing (IJASUC) Vol.4, No.4, August 2013

AUTHORS

Chaitanya H P was born in Bangalore, India, in 1992. She received the Bachelor in

Telecommunication degree from the University of PESIT, Bangalore, in 2010 and She is

currently pursuing the masters degree with the Department of Electrical Engineering (Control

and Instrumentation), from Bangalore University, Bangalore.

H Prasanna Kumar was born in Hassan, Country, in 1974. He received the Bachelor in

Instrumentation degree from the Basaveshwara engineering college, Bagalkot, in 1997, the

Master in Biomedical Instrumentation degree from the JCE, in 2005 and doctorate degree in

the field of Biomedical image processing from Anna University. His research interests include

Biomedical Instrumentation and Control and Instrumentation.

450 Vol. 9, Issue 4, pp. xxxx-xxxx

Das könnte Ihnen auch gefallen

- Drive ShaftDokument34 SeitenDrive ShaftivanNoch keine Bewertungen

- 26-12 JanoskoDokument9 Seiten26-12 JanoskoivanNoch keine Bewertungen

- Filtration Handbook: Liquids: Theodore H. Melzer Maik W. JornitzDokument12 SeitenFiltration Handbook: Liquids: Theodore H. Melzer Maik W. JornitzivanNoch keine Bewertungen

- Basic HydraulicDokument106 SeitenBasic HydraulicKuthubuddin ArellaNoch keine Bewertungen

- 40 - Engine Coolant Temperature Sensor - InspectionDokument1 Seite40 - Engine Coolant Temperature Sensor - InspectionivanNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tycho BraheDokument3 SeitenTycho BraheAienna Lacaya MatabalanNoch keine Bewertungen

- Seismic Retrofitting2.0 BY PRIYANSHUDokument30 SeitenSeismic Retrofitting2.0 BY PRIYANSHUPriyanshu VarshneyNoch keine Bewertungen

- Ronstan Regatta Watch InstructionsDokument7 SeitenRonstan Regatta Watch InstructionsMatt HartmanNoch keine Bewertungen

- Omnivision Man lp06xx Rev0 0611Dokument18 SeitenOmnivision Man lp06xx Rev0 0611ivan ramirezNoch keine Bewertungen

- MCQ Rewriting 1Dokument10 SeitenMCQ Rewriting 1Quỳnh Anh NguyễnNoch keine Bewertungen

- Material of OFFERING HELPDokument7 SeitenMaterial of OFFERING HELPShorn x NyteNoch keine Bewertungen

- Mikrotik Kung Fu Kitab 2Dokument68 SeitenMikrotik Kung Fu Kitab 2aditya ferdiansyahNoch keine Bewertungen

- Dell Inspiron 16 5000 (5625) Laptop - Dell IndiaDokument5 SeitenDell Inspiron 16 5000 (5625) Laptop - Dell IndiamubbunNoch keine Bewertungen

- Portland PortDokument18 SeitenPortland PortAnonymous Lx3jPjHAVLNoch keine Bewertungen

- Proyector SNF 111Dokument3 SeitenProyector SNF 111Liliana Patricia PederneraNoch keine Bewertungen

- RJ1801 WebDokument100 SeitenRJ1801 WebPaulo FerreiraNoch keine Bewertungen

- Transcendental Meditation (Four Lectures by Silo)Dokument49 SeitenTranscendental Meditation (Four Lectures by Silo)nmjoshi77859100% (2)

- Prince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyDokument1 SeitePrince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyPRC Industrial SupplyNoch keine Bewertungen

- Electrical Inspections: Infrared ThermographyDokument28 SeitenElectrical Inspections: Infrared ThermographyManish RajNoch keine Bewertungen

- ISNGI 2017 ProgrammeDokument6 SeitenISNGI 2017 ProgrammeJoanna JohnsonNoch keine Bewertungen

- Risk Assessment Project Iosh - MsDokument2 SeitenRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- 100% Chemical-Free Solution For Organic Farming: Where Health Is A HabitDokument2 Seiten100% Chemical-Free Solution For Organic Farming: Where Health Is A Habitamit4118Noch keine Bewertungen

- Psychological Factors Influencing Technology Adoption A Case S - 2021 - TechnovDokument17 SeitenPsychological Factors Influencing Technology Adoption A Case S - 2021 - Technov6helmi6nauval6Noch keine Bewertungen

- Hardie Reveal Panel Installation Instructions 1597005Dokument29 SeitenHardie Reveal Panel Installation Instructions 1597005David TorskeNoch keine Bewertungen

- A Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFDokument2 SeitenA Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFPutra GagahNoch keine Bewertungen

- Cleavage in MammalsDokument51 SeitenCleavage in MammalsIrfan Azram100% (4)

- HSE Plan For RSPL ProjectDokument10 SeitenHSE Plan For RSPL ProjectSaibabu SiripurapuNoch keine Bewertungen

- MEAMTA2-Assignment 2Dokument5 SeitenMEAMTA2-Assignment 2pfukanisibuyi7Noch keine Bewertungen

- 01 Overview of The F & B IndustryDokument8 Seiten01 Overview of The F & B Industrynikki abalosNoch keine Bewertungen

- Favino Circulation of Scientific Knowledge AcroDokument8 SeitenFavino Circulation of Scientific Knowledge AcroPeter FryNoch keine Bewertungen

- Notes On Peck&Coyle Practical CriticismDokument10 SeitenNotes On Peck&Coyle Practical CriticismLily DameNoch keine Bewertungen

- 12V-100Ah FTA DatasheetDokument1 Seite12V-100Ah FTA Datasheetchandrashekar_ganesanNoch keine Bewertungen

- CCNP 300 410 ENARSI NetworkTUT 26 5 2021Dokument104 SeitenCCNP 300 410 ENARSI NetworkTUT 26 5 2021Olga BradyNoch keine Bewertungen

- Mechanical Smoke Ventilation Calculations For Basement (Car Park)Dokument7 SeitenMechanical Smoke Ventilation Calculations For Basement (Car Park)Mahmoud Abd El-KaderNoch keine Bewertungen

- SC607 Assignment2Dokument2 SeitenSC607 Assignment2Tirthankar AdhikariNoch keine Bewertungen