Beruflich Dokumente

Kultur Dokumente

03.SOP For Air Compressor

Hochgeladen von

Thangella Vijayaramaraju100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

3K Ansichten4 SeitenAir Compressor SOP

Originaltitel

03.SOP for Air Compressor

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAir Compressor SOP

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

3K Ansichten4 Seiten03.SOP For Air Compressor

Hochgeladen von

Thangella VijayaramarajuAir Compressor SOP

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

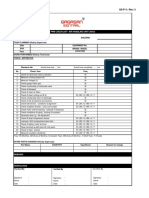

STANDARD OPERATING PROCEDURE

TITLE: Switching "On/Off" of Air compressor SOP No.: DAL/PBPL/SOP 03

EQUIPMENT :Air Compressor DATE :

SITE : PBPL-Punjub REVISION :R0

NAME PLATE DETAILS

Make: INGERSOLL RAND

Model: IN-15-7

LEGAL AND OTHER REQUIREMENTS

Oil Spillage and waste oil to be disposed as Hazardous waste

STEP No. OPERATING PROCEDURE

Switching ON of Air Compressor

1 Switch "On" respective air compressor feeder in panel located

2 Ensure incomer MCCB in local isolator compressor panel

3 Ensure all indicators are glowing in Compressor panel.

4 Switch 'On' one Air drier prior starting the Air compressor.

5 Switch "On" the in air compressor.

6 Open Delivery valve near compressor to allow air flow.

7 Ensure inlet Air filter and surrounding area are clean.

8 Check for any abnormal noise from the compressor.If abnormal, switch off the compressor.

9 Ensure compressor works with in the cut in and cut out pressure in the pressure gauge.

10 Record the parameters as per log sheet once in Four hours.

Switching OFF of Air Compressor

1 Press "O" button in the electronic control display and wait for 30 Seconds for the compressor to switch off.

2 Press the Emergency stop button on panel .

3 Close the compressor outlet vlave.

4 Switch off the local isolator near the compressor.

Note: Both the compressor should be switched on and in case of failure of one compressor , standby compressor will be automatically

set pressure.

Sl No. OPERATIONAL CONTROL

1 stop the compressor and clean inlet air filter daily once

2 Air end temperature range is <95⁰C .if the value is

increase to ensure cooling fan is running.

3 Lube oil pr range is 2 to 3.6 bar.if the value increase/decreae

to check and change lube oil & filter.

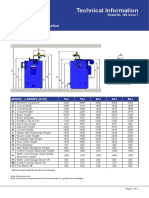

Picture of the Equipment

4 Lube oil level maintain above low level & upto max level

If oil level low,top up the oil up to max level.

5 Condensate is not discharged from Drain in every 30 sec.

valve for proper operation.

DAL/IMS/SOP/01 - Revision: R01 - 08/09/2010

6

PREPARED BY: APPROVED BY:

DAL/IMS/SOP/01 - Revision: R01 - 08/09/2010

mpressor will be automatically on due to drop in

PERATIONAL CONTROL

n inlet air filter daily once

<95⁰C .if the value is

n is running.

ar.if the value increase/decreae

ove low level & upto max level marked in SG.

p to max level.

ged from Drain in every 30 sec.to check drain

DAL/IMS/SOP/01 - Revision: R01 - 08/09/2010

PAGE No. 1 of 1

DAL/IMS/SOP/01 - Revision: R01 - 08/09/2010

Das könnte Ihnen auch gefallen

- 01 Air Compressure Operation SOP ME.2.1Dokument2 Seiten01 Air Compressure Operation SOP ME.2.1amzad06100% (1)

- Boilers SOPDokument18 SeitenBoilers SOPPrakash WarrierNoch keine Bewertungen

- HIRA Boiler Pressure Part Risk AssessmentDokument15 SeitenHIRA Boiler Pressure Part Risk AssessmentHARSHAL100% (2)

- Air Compressor Maintenance ChecklistDokument2 SeitenAir Compressor Maintenance ChecklistKhalied Hafeez71% (14)

- Compressor ChecklistDokument5 SeitenCompressor ChecklistJuanPabloAlvarezNoch keine Bewertungen

- Risk Assessment For Erection of Boiler Steam DrumDokument4 SeitenRisk Assessment For Erection of Boiler Steam DrumQuynh Tao100% (1)

- Boiler Maintenance ChecklistDokument2 SeitenBoiler Maintenance ChecklistRidwanAlwi50% (4)

- FORMET Preventive Maintenance Check List of Air CompressorDokument1 SeiteFORMET Preventive Maintenance Check List of Air CompressorReza100% (1)

- Daily Checklist For Air CompressorDokument2 SeitenDaily Checklist For Air Compressor7Days Facility Management100% (1)

- Operations and Maintenance Preventive Maintenance Checklists PDFDokument35 SeitenOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeNoch keine Bewertungen

- SOP For Lux Level MeterDokument3 SeitenSOP For Lux Level MeterPE QANoch keine Bewertungen

- Transformer Check ListDokument2 SeitenTransformer Check ListKanhiya Prasad100% (3)

- 02 SOP Preventive Maintenance of DG SetsDokument4 Seiten02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNoch keine Bewertungen

- Dosing Pumps ChecklistDokument2 SeitenDosing Pumps ChecklistDeshan Sing100% (1)

- Standard Operating Procedure (SOP) Compressor Safety: HeadlinesDokument5 SeitenStandard Operating Procedure (SOP) Compressor Safety: HeadlinesKuliner Ning Fia100% (1)

- Method Statement of Chiller Preventive MaintenanceDokument5 SeitenMethod Statement of Chiller Preventive MaintenanceBalajiNoch keine Bewertungen

- SOP For Compressed Air SystemDokument14 SeitenSOP For Compressed Air SystemAbeer arif100% (1)

- Standard Operating Procedure For Ahu Start & StopDokument2 SeitenStandard Operating Procedure For Ahu Start & Stopdeekshitkumar77100% (1)

- PPM Task Sheet - MPGSDokument4 SeitenPPM Task Sheet - MPGSJacobNoch keine Bewertungen

- SOP For Measuring Monitoring of Noise LevelDokument2 SeitenSOP For Measuring Monitoring of Noise LevelPrince Moni67% (3)

- PPM Checklist-Air Handling Unit (Ahu) : GS-F11 - Rev: 3Dokument1 SeitePPM Checklist-Air Handling Unit (Ahu) : GS-F11 - Rev: 3Mohamed Firdaus Bin Zakaria100% (1)

- Afbc SopDokument4 SeitenAfbc SopemailNoch keine Bewertungen

- Preventative Maintenance GuideDokument6 SeitenPreventative Maintenance GuideReza JafariNoch keine Bewertungen

- Fire Hydrants ChecklistDokument1 SeiteFire Hydrants ChecklistAhmed AtefNoch keine Bewertungen

- JSA Sump CleaningDokument2 SeitenJSA Sump CleaningPanchdev Kumar100% (1)

- Sop For Flushing Water PumpDokument6 SeitenSop For Flushing Water PumpSonratNoch keine Bewertungen

- SOP For Air Handling UnitDokument10 SeitenSOP For Air Handling UnitFaisal Ahmed100% (1)

- Sop of Maintenance of Air Conditioning UnitsDokument9 SeitenSop of Maintenance of Air Conditioning Unitsruhy690Noch keine Bewertungen

- Boiler Safety ChecklistDokument2 SeitenBoiler Safety ChecklistAnand Pal Singh100% (1)

- Checklist For DG InspectionDokument1 SeiteChecklist For DG InspectionSatya NaiduNoch keine Bewertungen

- Sop For Total Power Failure.Dokument4 SeitenSop For Total Power Failure.anon_251342212Noch keine Bewertungen

- Certificate TPI Air Compressor Feb22 AbrajDokument2 SeitenCertificate TPI Air Compressor Feb22 AbrajSavad TS100% (1)

- Sop Pressure TestDokument5 SeitenSop Pressure TestRichard Adolf100% (1)

- AHU FAHU - AnnuallyDokument3 SeitenAHU FAHU - AnnuallyDreamliner100% (1)

- Maintenance and Operation of Air Compressor PlantsDokument118 SeitenMaintenance and Operation of Air Compressor PlantstenderncareNoch keine Bewertungen

- SOP For HSD UnloadingDokument5 SeitenSOP For HSD UnloadingAbraham DeVilliers50% (2)

- Checklist Compressor - SAMPLEDokument1 SeiteChecklist Compressor - SAMPLESUKhan100% (1)

- Chapter 18 - Boiler Safety Compliance PDFDokument9 SeitenChapter 18 - Boiler Safety Compliance PDFLUIMING RUINoch keine Bewertungen

- 5S Checklist For ETPDokument1 Seite5S Checklist For ETPGanesh Gujjeti43% (7)

- 03 SOP Preventive Maintenance of TransformerDokument5 Seiten03 SOP Preventive Maintenance of TransformerPandu Birumakovela100% (2)

- Air Compressor Inspection Checklist Global EHS 029Dokument1 SeiteAir Compressor Inspection Checklist Global EHS 029Safety Mohini100% (1)

- Fire Hydrant ChecklistDokument1 SeiteFire Hydrant ChecklistTushar BabarNoch keine Bewertungen

- Drill Machine - ChecklistDokument1 SeiteDrill Machine - ChecklistarkonamtfplNoch keine Bewertungen

- Diesel Fire Pump Inspection ChecklistDokument2 SeitenDiesel Fire Pump Inspection ChecklistShabaaz Mohammed Abdul100% (1)

- Boiler ChecklistDokument3 SeitenBoiler ChecklistSegamaha Palm Oil Mill33% (3)

- Table Drill-Press SOPDokument1 SeiteTable Drill-Press SOPshahrul azharNoch keine Bewertungen

- Electrical MaintenanceDokument7 SeitenElectrical MaintenanceKHUSHBOO198450% (2)

- WINEWISE-Water Management ChecklistDokument3 SeitenWINEWISE-Water Management ChecklistCCR100% (1)

- Checklist For WeighbridgeDokument4 SeitenChecklist For Weighbridgemuhamad.badar9285Noch keine Bewertungen

- MaintenanceDokument4 SeitenMaintenanceNileshSondagarNoch keine Bewertungen

- 238 Preventive Check Sheet of Press Brake MachineDokument4 Seiten238 Preventive Check Sheet of Press Brake MachineAjay100% (2)

- AC PROV OPERATION & MAINTENANCE-rev2.compressedDokument2 SeitenAC PROV OPERATION & MAINTENANCE-rev2.compressedMuhammed RiazNoch keine Bewertungen

- Rotina de Inspeção em ManutençãoDokument11 SeitenRotina de Inspeção em ManutençãoBrender VictorNoch keine Bewertungen

- Utilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksDokument7 SeitenUtilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksShahzad AhmedNoch keine Bewertungen

- Operation and Maintenance Manual For ModelsDokument33 SeitenOperation and Maintenance Manual For ModelstgffcgfgNoch keine Bewertungen

- Warning: Section 5 Maintenance & LubricationDokument2 SeitenWarning: Section 5 Maintenance & LubricationJuan Reynaga CoronadoNoch keine Bewertungen

- tech-8-part-5-section-3-bauer-mv كومبريسور الغواصين PDFDokument4 Seitentech-8-part-5-section-3-bauer-mv كومبريسور الغواصين PDFMuhamedomar Jojo JojoNoch keine Bewertungen

- Instrument Air Compressor PDFDokument54 SeitenInstrument Air Compressor PDFpradeep1987cool100% (1)

- Manual Mantenimiento Compresor QR25 Modelo 325Dokument13 SeitenManual Mantenimiento Compresor QR25 Modelo 325Rafa D'voxNoch keine Bewertungen

- SECTION 2-General Maintanance PDFDokument18 SeitenSECTION 2-General Maintanance PDFDidin Delgado0% (1)

- Construction of Turbo Generator: G.Raviteja 16VD1A0230Dokument24 SeitenConstruction of Turbo Generator: G.Raviteja 16VD1A0230Raviteja GaddamNoch keine Bewertungen

- LPG SYSTEMS and AccessoriesDokument47 SeitenLPG SYSTEMS and AccessoriesBELLO SAIFULLAHINoch keine Bewertungen

- HydraulicscDokument15 SeitenHydraulicscAaron Tom VilaNoch keine Bewertungen

- Mono Splits York InverterDokument4 SeitenMono Splits York Inverterbride junior tchuensuNoch keine Bewertungen

- Boiler Data Sheet (J50)Dokument2 SeitenBoiler Data Sheet (J50)rafaelmelo89Noch keine Bewertungen

- Marine Internal Combustion Diesel Egine I-SbrDokument232 SeitenMarine Internal Combustion Diesel Egine I-SbrRENGANATHAN P100% (1)

- Daniel Nitrogen Loaded Valve (CV7NL) - DatasheetDokument16 SeitenDaniel Nitrogen Loaded Valve (CV7NL) - DatasheetMarcelo PinheiroNoch keine Bewertungen

- Geothermal Power Plant Problem SetDokument8 SeitenGeothermal Power Plant Problem SetAriel GamboaNoch keine Bewertungen

- Turbine Lube Oil Cooler ChargingDokument4 SeitenTurbine Lube Oil Cooler Chargingjp mishraNoch keine Bewertungen

- Shell and Tube Heat ExchangerDokument6 SeitenShell and Tube Heat Exchangeradil alameenNoch keine Bewertungen

- Boiler and Auxiliaries: Steam Coil Air HeatersDokument2 SeitenBoiler and Auxiliaries: Steam Coil Air HeatersRamalingam PrabhakaranNoch keine Bewertungen

- Engineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemDokument23 SeitenEngineering Design and Exergy Analyses For Combustion Gas Turbine Based Power Generation SystemInemie-ebi NiweighaNoch keine Bewertungen

- Consultation and Questionnaire 2021 Peric ElectrolyzersDokument2 SeitenConsultation and Questionnaire 2021 Peric ElectrolyzersCristian BarrazaNoch keine Bewertungen

- Centrifugal Compressor Axial Thrust: Hassan Mohamed A. M. HassanDokument12 SeitenCentrifugal Compressor Axial Thrust: Hassan Mohamed A. M. HassanMosab AmmarNoch keine Bewertungen

- Kawasaki GPB180DDokument2 SeitenKawasaki GPB180DfrdnNoch keine Bewertungen

- Chapter 1 Pneumatic SystemDokument19 SeitenChapter 1 Pneumatic Systemdivien rajNoch keine Bewertungen

- Aayush Pandey (2003002) Siddharth Mandal (2003020) : About Topic Major Components Example Block DiagramDokument2 SeitenAayush Pandey (2003002) Siddharth Mandal (2003020) : About Topic Major Components Example Block Diagramumesh choudharyNoch keine Bewertungen

- D1 620en PlungerpumpDokument4 SeitenD1 620en PlungerpumpAkhil JoseNoch keine Bewertungen

- Marvair ManualDokument44 SeitenMarvair ManualCecilio TinalNoch keine Bewertungen

- M Dolphin LX-0260-0430B, A PL SG Enus C 1.0Dokument2 SeitenM Dolphin LX-0260-0430B, A PL SG Enus C 1.0dwi alfianto NugrohoNoch keine Bewertungen

- HVAC TrainingDokument36 SeitenHVAC TrainingAizat Razak100% (1)

- Introduction To World EnergyDokument47 SeitenIntroduction To World Energyjylee@Noch keine Bewertungen

- Turbine Load Rejection N300-16Dokument8 SeitenTurbine Load Rejection N300-16ramnadh803181100% (1)

- Carrier 30WG 140Dokument1 SeiteCarrier 30WG 140Stjepan KrpanNoch keine Bewertungen

- Hydraulically Actuated Valve Deluge SystemDokument2 SeitenHydraulically Actuated Valve Deluge Systemzepol051Noch keine Bewertungen

- Compressed Air PlantDokument24 SeitenCompressed Air Plantliezaebot100% (4)

- Sheet (3) Regenerative Rankine Cycle A. Review QuestionsDokument6 SeitenSheet (3) Regenerative Rankine Cycle A. Review QuestionsHamadaMohassabNoch keine Bewertungen

- Oil and Gas Production Operations: Artificial LiftDokument18 SeitenOil and Gas Production Operations: Artificial LiftRizwan FaridNoch keine Bewertungen

- HVAC CatalogueDokument4 SeitenHVAC CatalogueMAHIPALNoch keine Bewertungen

- Absorption Refrigeration UnitDokument20 SeitenAbsorption Refrigeration UnitAlyan YousafNoch keine Bewertungen