Beruflich Dokumente

Kultur Dokumente

Tooling Index Grid

Hochgeladen von

adrianCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tooling Index Grid

Hochgeladen von

adrianCopyright:

Verfügbare Formate

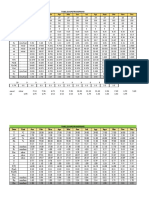

This chart shows how the 1/4 diopter cylinder powers of several common lens materials

relate to the exact lap tool cylinder curves required if lap tooling is cut in 1.530 index of

refraction or 1.600 index of refraction.

All numbers are expressed in true curve and relate to the back curve only.

1.530 INDEX TOOLING

PRESCRIBED CYLINDER POWER

0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

1.498 0.27 0.53 0.80 1.06 1.33 1.60 1.86 2.13 2.39 2.66 2.93 3.19 3.46 3.72 3.99 4.26 4.52 4.79 5.06 5.32

LENS MATERIAL INDEX

1.523 0.25 0.51 0.76 1.01 1.27 1.52 1.77 2.03 2.28 2.53 2.79 3.04 3.29 3.55 3.80 4.05 4.31 4.56 4.81 5.07

1.530 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

1.540 0.25 0.49 0.74 0.98 1.23 1.47 1.72 1.96 2.21 2.45 2.70 2.94 3.19 3.44 3.68 3.93 4.17 4.42 4.66 4.91

1.560 0.24 0.47 0.71 0.95 1.18 1.42 1.66 1.89 2.13 2.37 2.60 2.84 3.08 3.31 3.55 3.79 4.02 4.26 4.50 4.73

1.586 0.23 0.45 0.68 0.90 1.13 1.36 1.58 1.81 2.03 2.26 2.49 2.71 2.94 3.17 3.39 3.62 3.84 4.07 4.30 4.52

1.600 0.22 0.44 0.66 0.88 1.10 1.33 1.55 1.77 1.99 2.21 2.43 2.65 2.87 3.09 3.31 3.53 3.75 3.98 4.20 4.42

1.660 0.20 0.40 0.60 0.80 1.00 1.20 1.41 1.61 1.81 2.01 2.21 2.41 2.61 2.81 3.01 3.21 3.41 3.61 3.81 4.02

1.700 0.19 0.38 0.57 0.76 0.95 1.14 1.33 1.51 1.70 1.89 2.08 2.27 2.46 2.65 2.84 3.03 3.22 3.41 3.60 3.79

1.800 0.17 0.33 0.50 0.66 0.83 0.99 1.16 1.33 1.49 1.66 1.82 1.99 2.15 2.32 2.48 2.65 2.82 2.98 3.15 3.31

1.600 INDEX TOOLING

PRESCRIBED CYLINDER POWER

0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

1.498 0.30 0.60 0.90 1.20 1.51 1.81 2.11 2.41 2.71 3.01 3.31 3.61 3.92 4.22 4.52 4.82 5.12 5.42 5.72 6.02

LENS MATERIAL INDEX

1.523 0.29 0.57 0.86 1.15 1.43 1.72 2.01 2.29 2.58 2.87 3.15 3.44 3.73 4.02 4.30 4.59 4.88 5.16 5.45 5.74

1.530 0.28 0.57 0.85 1.13 1.42 1.70 1.98 2.26 2.55 2.83 3.11 3.40 3.68 3.96 4.25 4.53 4.81 5.09 5.38 5.66

1.540 0.28 0.56 0.83 1.11 1.39 1.67 1.94 2.22 2.50 2.78 3.06 3.33 3.61 3.89 4.17 4.44 4.72 5.00 5.28 5.56

1.560 0.27 0.54 0.80 1.07 1.34 1.61 1.88 2.14 2.41 2.68 2.95 3.21 3.48 3.75 4.02 4.29 4.55 4.82 5.09 5.36

1.586 0.26 0.51 0.77 1.02 1.28 1.54 1.79 2.05 2.30 2.56 2.82 3.07 3.33 3.58 3.84 4.10 4.35 4.61 4.86 5.12

1.600 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

1.660 0.23 0.45 0.68 0.91 1.14 1.36 1.59 1.82 2.05 2.27 2.50 2.73 2.95 3.18 3.41 3.64 3.86 4.09 4.32 4.55

1.700 0.21 0.43 0.64 0.86 1.07 1.29 1.50 1.71 1.93 2.14 2.36 2.57 2.79 3.00 3.21 3.43 3.64 3.86 4.07 4.29

1.800 0.19 0.38 0.56 0.75 0.94 1.13 1.31 1.50 1.69 1.88 2.06 2.25 2.44 2.63 2.81 3.00 3.19 3.38 3.56 3.75

In the above grids, given the cylinder power is described, you then see the tool cylinder necessary to polish the

lens for the type of material your using. Example 1; .25 cyl, 1.53 index, for cr39 is .27, and example 2,

for .25 cyl, 1.53 index, for hi-index 1.60 is .22. Example 3, for .75 cyl Cr39, Example 4, for 1.600

diopters 1/8th 10th 12th

Example 1 power 0.27 0.27 0.27

lap 0.25 0.3 0.25

change 0.02 -0.03 0.02

Example 2 diopters 1/8th 10th 12th

power 0.22 0.22 0.22

lap 0.25 0.2 0.25

change -0.03 0.02 -0.03

diopters 1/8th 10th 12th

Example 3 power 0.80 0.80 0.80

lap 0.75 0.8 0.833

change 0.05 0 -0.03

Example 4 diopters 1/8th 10th 12th

power 0.66 0.66 0.66

lap 0.625 0.7 0.666

change 0.035 -0.04 -0.01

Das könnte Ihnen auch gefallen

- Tirante (Y) Area Velocidad v2/2g E. EspecíficaDokument4 SeitenTirante (Y) Area Velocidad v2/2g E. EspecíficaHo AlexanderNoch keine Bewertungen

- 頁面 5Dokument1 Seite頁面 5洛霖Noch keine Bewertungen

- Core Capcity & Turns Per VoltDokument1 SeiteCore Capcity & Turns Per VoltDeepak BainsNoch keine Bewertungen

- Cara Cepat LP Msuk Cad 4Dokument9 SeitenCara Cepat LP Msuk Cad 4Audric GenterNoch keine Bewertungen

- Ansi - 600 - Norma de BridasDokument1 SeiteAnsi - 600 - Norma de BridasDaniel PorrasNoch keine Bewertungen

- Ansi B16 300 PDFDokument1 SeiteAnsi B16 300 PDFmahdi charfiNoch keine Bewertungen

- Generalized Indoor Lighting Calculation SpreadsheetDokument2 SeitenGeneralized Indoor Lighting Calculation SpreadsheetAshish DongreNoch keine Bewertungen

- Tabel Data Ansi FlangeDokument23 SeitenTabel Data Ansi FlangeMuhammad RizkyNoch keine Bewertungen

- Eyebolt Shouldered PDFDokument2 SeitenEyebolt Shouldered PDFAnna Claudia ZapanaNoch keine Bewertungen

- Offset Tabel Untuk ListkunDokument8 SeitenOffset Tabel Untuk ListkunWoke LossNoch keine Bewertungen

- ANSI B16.5 Class 150 & 300 Forged Flanges ChartDokument7 SeitenANSI B16.5 Class 150 & 300 Forged Flanges ChartAndres Rodriguez HerreraNoch keine Bewertungen

- Surface Calculation & PaintDokument14 SeitenSurface Calculation & Paintsaid aminNoch keine Bewertungen

- Thrust Block Designxls PDF FreeDokument8 SeitenThrust Block Designxls PDF FreeTAHANoch keine Bewertungen

- Best A/V Systems Pipe Dimension ChartDokument1 SeiteBest A/V Systems Pipe Dimension Chart黃亞美Noch keine Bewertungen

- Marutham Technical SolutionsDokument90 SeitenMarutham Technical SolutionsShashank ParmarNoch keine Bewertungen

- Data Kapal Pembanding dan Kapal yang DirancangDokument77 SeitenData Kapal Pembanding dan Kapal yang DirancangMuharom ApriliantoNoch keine Bewertungen

- % Var. COLCAP: Limite Inferior Limite Superio RDokument79 Seiten% Var. COLCAP: Limite Inferior Limite Superio RMonicaNoch keine Bewertungen

- Surface Calculation & PaintDokument14 SeitenSurface Calculation & PaintRajkumar ANoch keine Bewertungen

- CLASS 600 Weld Neck Flanges WeightDokument1 SeiteCLASS 600 Weld Neck Flanges WeightAwais IftikharNoch keine Bewertungen

- 08ANNEXESDokument132 Seiten08ANNEXESOscar CaceresNoch keine Bewertungen

- LWN FlangesDokument8 SeitenLWN Flangesfranckx1960Noch keine Bewertungen

- Calculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaDokument6 SeitenCalculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaMauro DelgadoNoch keine Bewertungen

- System Simulation Lab RashmiDokument19 SeitenSystem Simulation Lab RashmiRashmi RanjanNoch keine Bewertungen

- Electrical AccessoriessDokument47 SeitenElectrical Accessoriesssudiro100% (1)

- Flanges PDFDokument103 SeitenFlanges PDFAhnaf AriyantaNoch keine Bewertungen

- Catalogo BridasDokument23 SeitenCatalogo BridasYahayra PadillaNoch keine Bewertungen

- Class 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 charactersDokument2 SeitenClass 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 characterskh88hmiNoch keine Bewertungen

- Folga Radial de RolamentoDokument1 SeiteFolga Radial de RolamentoDavid Lima de freitasNoch keine Bewertungen

- Transition Loss1 - Supply (Inspect)Dokument347 SeitenTransition Loss1 - Supply (Inspect)Phuc BVNoch keine Bewertungen

- Jadval Sath RangDokument1 SeiteJadval Sath RangAlireza KhodabandehNoch keine Bewertungen

- Analisis de Laboratios: Serie N1 (MORENO MIRANDA, Juan Carlos Manuel)Dokument2 SeitenAnalisis de Laboratios: Serie N1 (MORENO MIRANDA, Juan Carlos Manuel)Juan Carlos Manuel Moreno MirandaNoch keine Bewertungen

- HW3 - Chapter 3 PDFDokument5 SeitenHW3 - Chapter 3 PDFNadia Karima100% (1)

- Heat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)Dokument1 SeiteHeat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)amr kouranyNoch keine Bewertungen

- 頁面 4Dokument1 Seite頁面 4洛霖Noch keine Bewertungen

- N° #Tanque Válvula Tanque Válvula Unidades Unidades Unidades Gasto Probable Gasto ProbableDokument4 SeitenN° #Tanque Válvula Tanque Válvula Unidades Unidades Unidades Gasto Probable Gasto ProbableWilber Ccahuana BernaolaNoch keine Bewertungen

- EQ210 Reservatório de Água (Arrumado)Dokument56 SeitenEQ210 Reservatório de Água (Arrumado)Higor Ordine Carvalho FerreiraNoch keine Bewertungen

- Stainless Steel Pipe Fittings Product GuideDokument1 SeiteStainless Steel Pipe Fittings Product GuideRICHARDNoch keine Bewertungen

- ASME B16.5 Class 150 pipe dimensions reference chartDokument2 SeitenASME B16.5 Class 150 pipe dimensions reference chartKamal ElumalaiNoch keine Bewertungen

- SRN - 150 RatingDokument4 SeitenSRN - 150 RatingSales ShenggNoch keine Bewertungen

- ANSI 150 Tech DataDokument1 SeiteANSI 150 Tech DataLakshmiraj RajaramanNoch keine Bewertungen

- SS - CS Pipe DimensionDokument3 SeitenSS - CS Pipe DimensionKailasNoch keine Bewertungen

- Fishing Planet Ubersheet ProjectDokument26 SeitenFishing Planet Ubersheet ProjectRodrigoNoch keine Bewertungen

- Class 300 ASME B16.5: Bore Length Thru Hub Common DimensionsDokument1 SeiteClass 300 ASME B16.5: Bore Length Thru Hub Common DimensionsSIMON S. FLORES G.Noch keine Bewertungen

- Culvert Capacity Tables Pipe CulvertsDokument1 SeiteCulvert Capacity Tables Pipe CulvertsChristian NicolausNoch keine Bewertungen

- Shear Box Test ReportDokument6 SeitenShear Box Test Reportnishan_ravin50% (2)

- 1 Escalera MR DecisaDokument1 Seite1 Escalera MR DecisaGustavo Huesca RamosNoch keine Bewertungen

- 頁面 3Dokument1 Seite頁面 3洛霖Noch keine Bewertungen

- Master PipeDokument8 SeitenMaster PipeArifin ZakyNoch keine Bewertungen

- Single-Server Waiting Times ModelDokument3 SeitenSingle-Server Waiting Times ModelHaseebAshfaqNoch keine Bewertungen

- ANSI/ASME B16.5 Class 150 Forged Flanges SpecificationsDokument1 SeiteANSI/ASME B16.5 Class 150 Forged Flanges SpecificationsKebede YilmaNoch keine Bewertungen

- FVPsprint 2022Dokument73 SeitenFVPsprint 2022Adrian DiazNoch keine Bewertungen

- Distance Time Position AnalysisDokument73 SeitenDistance Time Position AnalysisSilvestre GutierrezNoch keine Bewertungen

- Note: Density of Insulation Material Considered As 150 KG/CMDokument1 SeiteNote: Density of Insulation Material Considered As 150 KG/CMHarsh KhatriNoch keine Bewertungen

- EPMS20: Head Office and Works: Tel No. +60 (3) 6092 0355 Fax No. +60 (3) 6092 0388Dokument1 SeiteEPMS20: Head Office and Works: Tel No. +60 (3) 6092 0355 Fax No. +60 (3) 6092 0388HauzhiNoch keine Bewertungen

- Irigasi Indah CauuuDokument8 SeitenIrigasi Indah CauuuYusrin R. PaudiNoch keine Bewertungen

- Bothwell 12Dokument6 SeitenBothwell 12Bagja KusumahNoch keine Bewertungen

- Pipe Schedules Chart Summary Imperial Metric TDS HFT50-WEB-PDokument1 SeitePipe Schedules Chart Summary Imperial Metric TDS HFT50-WEB-PTasmanijskaNemaNoch keine Bewertungen

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesVon EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesBewertung: 5 von 5 Sternen5/5 (3)

- The Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionVon EverandThe Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionNoch keine Bewertungen

- The Science and Engineering of Thermal Spray CoatingsVon EverandThe Science and Engineering of Thermal Spray CoatingsNoch keine Bewertungen

- Lecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanDokument18 SeitenLecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanLaura AmwayiNoch keine Bewertungen

- Time TableDokument7 SeitenTime TableChethan .H.GNoch keine Bewertungen

- Nso User Guide-5.3 PDFDokument178 SeitenNso User Guide-5.3 PDFAla JebnounNoch keine Bewertungen

- ISO 8243 2013 Cigarettes - SamplingDokument18 SeitenISO 8243 2013 Cigarettes - SamplingEko YuliantoNoch keine Bewertungen

- Python - How To Compute Jaccard Similarity From A Pandas Dataframe - Stack OverflowDokument4 SeitenPython - How To Compute Jaccard Similarity From A Pandas Dataframe - Stack OverflowJession DiwanganNoch keine Bewertungen

- Introduction - Week 2Dokument37 SeitenIntroduction - Week 2Tayyab AhmedNoch keine Bewertungen

- Indian Standards List As On Jan2009Dokument216 SeitenIndian Standards List As On Jan2009Vasudeva Pavan VemuriNoch keine Bewertungen

- Epoxy Hardeners, Water-Reducible: ProductsDokument1 SeiteEpoxy Hardeners, Water-Reducible: ProductsDhruv SevakNoch keine Bewertungen

- PDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressDokument7 SeitenPDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressErickson Brayner MarBerNoch keine Bewertungen

- Craig Vaughan CHPTR 07Dokument44 SeitenCraig Vaughan CHPTR 07Jorge CananeaNoch keine Bewertungen

- HFM Currency CubeDokument2 SeitenHFM Currency CubeSudhakar kNoch keine Bewertungen

- Bash 101 Hacks PDFDokument5 SeitenBash 101 Hacks PDFAmira A MarreiNoch keine Bewertungen

- LTE and SchedulingDokument25 SeitenLTE and SchedulingKrunoslav IvesicNoch keine Bewertungen

- 2.6 Rational Functions Asymptotes TutorialDokument30 Seiten2.6 Rational Functions Asymptotes TutorialAljun Aldava BadeNoch keine Bewertungen

- Methods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1Dokument3 SeitenMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1ilijarskNoch keine Bewertungen

- F (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )Dokument9 SeitenF (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )muhammad abrarNoch keine Bewertungen

- Instrument Resume OIL and GAS.Dokument3 SeitenInstrument Resume OIL and GAS.RTI PLACEMENT CELLNoch keine Bewertungen

- Centrifugal Compressor Operation and MaintenanceDokument16 SeitenCentrifugal Compressor Operation and MaintenanceNEMSNoch keine Bewertungen

- ASTM D 1510 - 02 Carbon Black-Iodine Adsorption NumberDokument7 SeitenASTM D 1510 - 02 Carbon Black-Iodine Adsorption Numberalin2005100% (1)

- Pipeline Corrosion Assessment MethodsDokument21 SeitenPipeline Corrosion Assessment MethodsGilletNoch keine Bewertungen

- Unit-3 BioinformaticsDokument15 SeitenUnit-3 Bioinformaticsp vmuraliNoch keine Bewertungen

- FDokument1 SeiteFDiego PorrasNoch keine Bewertungen

- Login Form: User Name Password Remember MeDokument8 SeitenLogin Form: User Name Password Remember MeBridget Anne BenitezNoch keine Bewertungen

- PM Master Data Template v1Dokument72 SeitenPM Master Data Template v1Naseer SultanNoch keine Bewertungen

- Data Warehousing: Modern Database ManagementDokument49 SeitenData Warehousing: Modern Database ManagementNgọc TrâmNoch keine Bewertungen

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDokument16 SeitenGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNoch keine Bewertungen

- XS Power Batteries D Series InstructionsDokument2 SeitenXS Power Batteries D Series InstructionsAutopiezas PanaNoch keine Bewertungen

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDokument10 SeitenA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENoch keine Bewertungen

- 12 Animation Q1 AnswerDokument38 Seiten12 Animation Q1 AnswerBilly Joe TanNoch keine Bewertungen

- General 04 Fixed Flow Pump To Three TanksDokument13 SeitenGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemNoch keine Bewertungen