Beruflich Dokumente

Kultur Dokumente

Determinación Xilanasas Por Método DNS

Hochgeladen von

Marcelo TorresCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Determinación Xilanasas Por Método DNS

Hochgeladen von

Marcelo TorresCopyright:

Verfügbare Formate

Inexpensive, Rapid Procedure for Bulk

Purification of Cellulase-Free

P-l,4-~-Xylanaseof High Specific Activity

Larry U. L. Tan,* Ernest K. C. Yu, Gerald W. Louis-Seize, and

John N. Saddler

Biotechnology and Chemistry Department, Forintek Canada Corp.,

800 Montreal Road, Ottawa, Canada

Accepted for publication July 7, 1986

A process has been developed for the bulk purification steam exploded to enhance their subsequent enzymatic

of cellulase-free P-1,4-o-xylanase from the fungus Tri- hydrolysis to fermentable sugars. The hemicellulose,

choderma harzianum E58. The process involved the pri-

mary step of ultrafiltering the culture filtrate via a 10,000- lignin, and cellulose streams can then be separated by

molecular-weight cut-off membrane to separate the cel- selectively extracting the pretreated material by water

lulase (retentate) and xylanase (permeate) fractions. The and dilute alkali. The cellulose and hemicellulose streams

cellulase component was concentrated by 40- to 60-fold, are then, respectively, hydrolyzed by cellulases and

resulting in an enzyme complex that could effectively xylanases and fermented to ethanol and 2,3-butanediol

hydrolyze high concentrations of cellulose and xylan to

glucose and xylose. The xylanase was concentrated and by the appropriate microorganisms.

solvent exchanged by adsorption to a cationic exchanger, Previously, we had shown that high levels of cel-

SP-ZetaPrep 250, followed by elution with a pH change lulase and xylanase were efficiently produced by the

in the buffer to give a purified and concentrated xylanase fungus Triclioderma harzianum E58.3 As the hemicel-

complex dissolved in a low-salt buffer. The resultant xy- lulose- and cellulose-derived sugars are normally uti-

lanase system was pure by the criteria of sodium dodecyl

sulfate polyacrylamide electrophoresis, had a very high lized by different microorganisms for various products,

specific activity of 2400 IUimg protein, was virtually free the hemicellulose and cellulose fractions are routinely

of filter paper activity, and had a ratio of contaminating separated into different streams in our process.2 Ide-

filter paper activity of 2 x (0.009% endoglucanase ally, if an inexpensive process is available for the sep-

activity). Approximately 3.3 g protein, which contained aration of the xylanase complex from the cellulase

in excess of 7 x lo6 IU xylanase activity, was obtained

from 17 L original culture filtrate. The process scheme complex, the two enzyme streams could be efficiently

was designed to facilitate scale-up to an industrial level utilized for the hydrolyses of the hemicellulose and

of production. cellulose streams, respectively, while reducing the

overall cost of separate enzyme production steps.

A purified cellulase-free xylanase could also be used

INTRODUCTION

for the removal of contaminating hemicellulose com-

Lignocellulose, the world’s largest renewable bio- ponents from high-grade cellulose pulps. Other workers4

mass resource, is composed mainly of lignin, cellulose, have been partially successful at reducing the amount

and hemicellulose, of which a large part of the latter of hemicellulose in aspen mechanical pulps using pu-

is xylan.’ Much of the current research and develop- rified xylanase from Schizophyllum commune. Unfor-

ment effort has been directed toward the utilization of tunately, the viscosity of the pulp was also reduced,

the cellulose fraction for liquid fuel production. How- possibly because of the relatively high concentration

ever, if value-added products could be obtained from (-3%) of contaminating endoglucanase activity that

the hemicellulose and lignin streams, the economics of was present in their preparation. In addition, the cost

the process could be significantly improved. of producing the xylanase may be high since their pro-

For a number of years, our laboratory2 has been cess depended on fractional precipitation using a vol-

working on a process where aspenwood chips are first ume ratio of 3: 1 ethanol-culture filtrate. An inexpen-

sive process that produces virtually cellulase-free

* To whom all correspondence should be addressed; present ad- xylanase may be more amenable to this application.

dress: Allelix, Inc., 6850 Goreway Dr., Mississauga, Ontario L4V Other potential uses of xylanasesS include processes

IP1. Canada. for the manufacture of liquid coffee, the adjustment of

Biotechnology a n d Bioengineering, Vol. XXX, Pp. 96-100 (1987)

0 1987 ..John Wilev 81S o n s , Inc. CCC 0006-3592/87/’010096-05$04.00

wine characteristics, and the enhancement of astax- sodium acetate, pH 4.8,stirred at 4°C for 30 min, and

anthin (3,3'-dihydroxy-4,4'-diketo-p-carotene) extrac- centrifuged at 10,000g for 15 min. The supernatants

tion. Hemicellulases (a group of enzymes that includes were assayed for enzyme recovery. Ethanol and ace-

the xylanases) may also be used in the food industry tone precipitations were performed using final concen-

for the clarification of fruit juices.6 trations of 20,40,60,and 80% of the solvents prechilled

to -60°C. Following the addition of the solvents, the

mixtures were stirred at 4°C for 1 min, and the pre-

MATERIALS AND METHODS

cipitates were processed identically to those of the

ammonium sulfate precipitates.

Culture Conditions

The fungus Trichoderma harzianum E58 was ob-

Assays

tained from the Forintek culture collection and grown

in a 30-L fermentor using 1% (w/v) Solka Floc B.W. Xylanase and endoglucanase activities were assayed

300 FC (Brown and Co.,Berlin, NH) as carbon source in 50mM sodium citrate buffer, pH 4.8,at 50°C.One

as described e1sewhe1-e.~ milliliter of an appropriately diluted enzyme was added

to an equal volume of 1% (w/v) substrate and incubated

for 30 min. Reducing sugar was determined by the 3 5

Bulk Purification of Xylanase

dinitrosalicyclic acid method.* Oat spelt xylan and car-

Seventeen liters of a 4-day-old T . harzianum E58 boxymethylcellulose (Sigma Chemicals, St. Louis, MO)

culture was filtered through Whatman No. 1 paper to were used as substrates for the xylanase and endog-

obtain the crude culture filtrate. The culture filtrate was lucanase assays, respectively. Filter paper activity was

ultrafiltered on a Pellicon apparatus (Millipore Ltd.) assayed by the method of Mandels et al.' Enzyme units

fitted with 0.47 m2 polysulfone membrane with a mo- were expressed as micromoles of D-xylose or D-glucose

lecular weight cut-off of 10,000 daltons. Ultrafiltration equivalents released per minute. Protein was deter-

was performed at approximately 6 and 45 L/h for the mined by the method of Lowry et a1.I0 as modified by

filtration and recirculation rates, respectively, until ap- Tan et al."

proximately I-2% of the retentate remained. To obtain

maximum recovery of retained protein, the membrane

RESULTS AND DISCUSSION

was flushed with 125 mL 50mM sodium citrate buffer,

pH 4.8. The cellulase complex, which was retained, As shown elsewhere,I2 the xylanase and cellulase

was concentrated by 40- to 60-fold, while 62% of the enzyme components present in the culture filtrates of

original xylanase was detected in the filtrate. The ul- T. harzianum E58 can be efficiently and rapidly sep-

trafiltrate containing the xylanase was diluted with an arated by Pellicon ultrafiltration using a polysulfone

equal volume of water, and the pH was adjusted to 4 membrane with a molecular weight cut-off of 10,000

with acetic acid. The xylanase was concentrated and

solvent exchanged by binding to a cationic exchanger,

SP-ZetaPrep 250 cartridge (7 cm diameter by 7 cm

height) (AMF Molecular Separations Division, Meri- *r

den, CT), and equilibrated with lOmM sodium acetate

buffer, pH 4, at a flow rate of 7.5 L/h. The cartridge

was washed with 2 L lOmM sodium acetate buffer, pH

4, and eluted with 2 L 50mM sodium phosphate, pH

8. Fractions of 250 mL were collected. The eluates

were immediately titrated with acetic acid to pH 5.

Alternative Methods of Xylanase Concentration

Ultrafiltration was performed with the Pellicon ap-

paratus fitted with 0.47 m2 of a cellulosic membrane

with a molecular weight cut-off of 1000 daltons. The

0 1 2 3 4 5

filtration and recirculation rates were 0.9 and 9 L/h, FRACTION N U M B E R

respectively. Concentration by ammonium sulfate pre-

X Y L A N A S E (IUi PROTEIN (UG)

cipitation was carried out at 4°C using an ammonium

sulfate concentration of 20,40,60,and 80% saturation. 0 SPECIFIC ACTIVITY x (iU/rng)

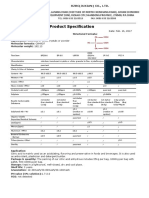

The mixtures were stirred for 30 min and vacuum fil- Figure 1. Elution profile of SP-ZetaPrep 250 column charged with

tered via glass fiber disks. The disks containing the 6 x 106 IU xylanase activity (3.3 g protein). Fractions of 250 mL

precipitated xylanase were macerated in 5 mL 50mM were collected.

TAN ET AL.: PURIFICATION OF CELLULASE-FREE B-1.4-D-XYLANASE 97

daltons. The ability of the xylanases to penetrate this

membrane was unique since their molecular sizes were

between 20,000 and 29,000 d a l t o n ~ . ’ The

~ ~ ’ cellulases

~

n

Z 25i

contained in the retentate were concentrated between

40- and 60-fold and were ideally suited for the hy-

drolysis of cellulose at high concentrations. The xy-

lanases, which were present in dilute solution in the

ultrafiltrate, were concentrated and solvent exchanged

by ion exchange chromatography using the cationic

SP-Zetaprep 250 cartridge. The Pellicon filtrate was

yi

v)

<

Z

4

2X

LL

0

k-

2ott.‘

0 5

15

10

diluted onefold prior to adsorption because the undi- 0

n

w

LL

luted filtrate contained excessive salt concentrations,

which interfered with efficient binding. Elution of the 0 5 10 15 20 25 30

column-bound xylanases was carried out by a com- LITERS OF DILUTED PELLICON FILTRATE APPLIED

bination of increased ionic strength and increased pH

Figure 2. Relationship between percentage of initial xylanase ac-

in the buffer. The relatively low salt concentration and tivity not bound and volume of xylanases applied to SP-ZetaPrep

the use of the nontoxic salt sodium phosphate in the 250 column. Column was equilibrated with lOmM sodium acetate

eluate avoided desalting of the enzyme when it was buffer, pH 4. Xylanases applied to column were Pellicon filtrate

used in conjunction with fermentative organisms. The diluted with equal volume of water. The pH of enzyme solution was

eluted xylanase had a very high specific activity of adjusted to 4 with acetic acid prior to application.

approximately 2400 IU/mg protein and was concen-

trated in the second and third fractions (Fig. 1). A

summary of the enzyme recovery is shown in Table I. corresponding 4 1-fold increase in concentration was

A comparison of different aliquots of the enzyme obtained while 127% of the original activity was re-

before and after passage through the ion exchange col- covered.

umn showed that the percentage of xylanase that was The isolated xylanase was essentially pure (Fig. 4)

not bound increased linearly with the volume of en- and was composed largely of the 20,000-dalton xylan-

zyme applied, up to a ratio of 0.25% (Fig. 2). By taking ases and small amounts of the 22,000-dalton xylanases.

the difference, it was apparent that more than 99.7% Previously, we had shown1*J3that these were the pre-

of the applied xylanase (3.3 g protein, 6,070,000 IU) dominant xylanases found in T . harzianum culture fil-

was bound. The recoveries of protein and xylanase trates. These partially purified xylanase preparations

activity were 100% and 132%, respectively, if all the were shown to be compatible with the bacteria Kleb-

fractions containing xylanase activity were combined. siella pneumoniae, and a simultaneous saccharification

The greater than 100% xylanase recovery may be due

to the elimination of enzyme inhibitors in the Pellicon

filtrate or to the reported problems associated with the

dinitrosalicylic acid reducing sugar assay. l4

Since the objectives of the ion exchange step were

to concentrate the xylanase, as well as to change the

solvent in which the enzymes were dissolved, a plot

z

\

of protein recovery vs. degree of concentration was W

made (Fig. 3). If fractions 2 and 3 were combined, a 0

k

3 I-fold increase in protein concentration was obtained IT

R

while approximately 96% of the original protein was

recovered. When the xylanase activity was assayed, a I-

\

Z

W

0

cc

W

n

Table I. Effect of various treatments on enzyme recoveries. 85C

’F

I I 1 I

Volume Xylanase FPase” Protein 4 / 1

15 25 35 45 55

(L) (106 IU) (IU) (B)

~ ~ ~ ~

NO OF FOLD CONCENTRATED

Culture filtrate 17.2 9.84 28600 33.3

Ultraretentate 0.3 2.78 21700 22.3 Figure 3. Relationship between percentage of protein recovered

Ultrafiltrate 17.0 6.07 6300 3.30 and degree of concentration relative to undiluted Pellicon filtrate.

SP-zeta 0.515 7.70 15.4 3.18 Various eluted fractions from the SP-ZetaPrep 250 column were

preparation pooled and total protein content was used in calculating protein

recovery. From left to right, points represent pooling of fractions

Filler paper activity. 1 4 , fractions 2 4 , fractions 2 and 3, and fraction 2 alone.

98 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 30, JULY 1987

Figure 4. Sodium dodecyl sulfate polyacrylamide gel electrophoresis of xylanase preparations. Lane 1

contained molecular weight standards corresponding to sizes of 94,000,67,000,43,000, 30,000,20,100, and

14,400 daltons. Lanes 2 and 3 contained 50 pg protein from Pellicon retentate and Pellicon filtrate, re-

spectively. Fifty micrograms of xylanase concentrated by ion exchange column was applied onto lane 4.

Lanes 5-7 contained 30, 20, and 5 pg purified xylanases with molecular weights of 20,000, 22,000, and

29,000 daltons, respectively.

and fermentation approach could be used to produce particulates were totally removed in the ultrafiltration

2,3-butanediol from aspenwood hemicellulose. I s step, the ultrafiltrate containing the xylanase enzyme

The 10,000-dalton cut-off polysulfone membrane in was ideal for subsequent ion exchange treatment. As

the ultrafiltration step was durable and was resistant a result, column clogging was not a problem, and the

to hydrolysis by the cellulase enzymes. The same same column was used for more than 10 runs without

membrane was used for over 3 years, during which change of properties.

more than 20 runs were carried out without a significant The above-described procedure for the production

deterioration of the membrane being observed. Since of cellulase-free xylanase has potentials for scale-up

Table 11. Comparison of methods for xylanase concentration.

Xylanase activity Processing Reagents needed per

recovered (%) rateb (Lih) liter processed' (g)

Ion exchange I27 2.7 Na acetate (0.15)

Na phosphate (0.36)

Acetic acid (4.4)

Ultrafiltration 93.7 0.8 Na dodecyl sulfate (0.12)

Na acetate (0.1)

Rotary ND 0.9 none

evaporation

Ammonium sulfate 70 ND ammonium sulfate (390)

precipitation

Ethanol 63 ND ethanol (3200)

precipitation

Acetone 55 ND acetone (3200)

precipitation

a ND = not determined.

Average rate including time needed for regeneration.

Reagents needed for regenerating apparatus included.

TAN ET AL.: PURIFICATION OF CELLULASE-FREE p-l.4-D-XYLANASE 99

studies. The ultrafiltration process has been proven to tivity recovered. The quantities of chemicals needed

be cost-effective on an industrial scale in comparison for column regeneration, enzyme elution, and pH ad-

to other processes such as evaporation, lyophilization, justments were small when compared with those for

and salt and solvent Scaling up of precipitation processes.

the ion exchange step using the SP-ZetaPrep cartridges In conclusion, we have shown that a highly purified

has been claimed by the manufacturer (AMF Molec- xylanase system with high activity can be prepared in

ular Separations Division, Meriden, CT) to be straight- large quantities using relatively simple procedures. We

forward. Industrial-scale apparatus (multicartridge are currently assessing the commercial opportunities

systems) with a filtration rate of 720 Wh and a capacity for applying this technology.

to process kilogram quantities of protein is already

available. We wish to thank D. Turnbull and M. K.-H. Chan for ex-

The efficiency of the ion exchange method for con- cellent technical assistance and the Canadian Forestry Ser-

centrating the xylanase in the ultrafiltrate was com- vice for funding this work.

pared to other methodsI9 that are frequently used in

industrial processes (Table 11). Salt or solvent precip-

itation was found to result in poor enzyme recoveries References

of between 55 and 70%, probably because of the low

1. T. K. Ng, R. M. Busche, C. C. McDonald, and R. W. F. Hardy,

initial protein concentration. When the large quantities

Science, 219, 733 (1983).

of reagents needed for precipitation were taken into 2. J . N. Saddler, M. Mes-Hartree, E. K. C. Yu, and H. H. Brow-

consideration, these processes were concluded to be nell, Biotechnol. Bioeng. Symp., 13, 225 (1983).

economically nonviable. In addition, these processes 3. E. K. C. Yu, L. Deschalelets, and J . N. Saddler, Biotechnol.

result in the need for wastewater treatment and/or re- Bioeng. Symp., 14, 341 (1984).

4. M. G. Paice and L. Jurasek, J . Wood Chem. Techno/.,4, 187

quire devices for the removal of toxic and explosive

(1984).

vapors as well as explosion-proof motors and switches.19 5 . J . Woodward, Top. Enz. Ferment. Biotechnol., 8, 9 (1984).

These capital expenditures all add to the cost of en- 6. R. F. H. Dekker, in Polysaccharides in Food, J. M. V . Blanshard

zyme production. Xylanases concentrated by rotary and J. R. Mitchell, Ed. (Butterworth, London and Boston, 1979).

evaporation were found to contain inhibitory sub- 7. J. N. Saddler, H. H. Brownell, L. P. Clermont, and N. Levitin,

Biotechnol. Bioeng., 24, 1389 (1982).

stances that interfered with their utilization in com-

8. G. L. Miller, Anal. Chem., 31, 426 (1959).

bination with K . pneumoniae during the simultaneous 9. M. Mandels, R. Andreotti, and C. Roche, Biotechnol. Bioeng.

hydrolysis and fermentation of various hemicellulose Symp., 6 , 21 (1976).

fraction^.'^ The need to dialyze the enzyme to remove 10. 0. H. Lowry, N . J. Rosebrough, A . C. Fan, and R. J. Randall,

these inhibitory materials would add another step to J . Biol. Chem., 193, 265 (1951).

11. L. U . L. Tan, M. K.-H. Chan and J. N . Saddler, Biotechnol.

the process. Concentration by ultrafiltration was pos-

Lett., 6 , 199 (1984).

sible using the 1000-dalton cut-off membrane; how- 12. L. U. L. Tan, K. K. Y. Wong, E. K. C. Yu, and J. N. Saddler,

ever, the processing rate was less than one-third that Enz. Microbiol. Technol., 7, 425 (1985).

of the ion exchange method. In addition, the necessity 13. L. ti. L. Tan, K. K. Y. Wong, and J. N. Saddler, Enz. Microbiol.

to direct 90% of the flow into recirculation rather than Technol., 7,431 (1985).

14. J. F. Robyt and W. J. Whelan, Anal. Biochem., 45, I121 (1972).

filtration, as recommended by the manufacturer for the

15. E. K. C. Yu, L. Deschatelets, L. U. L. Tan, and J. N. Saddler,

ultrafiltration process, ultimately resulted in higher Biotechnol. Lett., 7, 425 (1985).

capital costs for high-output pumps and increased 16. T. J. O’Sullivan, A. C. Epstein, S. R. Korchin, and N. C. Bea-

pumping costs. l6 Such recirculation is not necessary ton, Chem. Eng. Progr., 80, 68 (1984).

in the ion exchange method so that pumping costs can 17. M.-R. Kula, H. Hustedt, K . H. Kroner, and H. Schutte, in

Biotech ’83,Northwood, U.K. (Online Publications, Pinner, U.K.,

be expected to be lower. The ion exchange method

1983), p. 359.

was found to have the highest processing rate when 18. A. V. Quirk and J . R. Woodrow, Biotechnol. Lert., 5,277 (1983).

compared to the other concentration methods as well 19. B. Volesky and J. H. T. Luong, CRC Crit. Rev. Biotechnol.. 2,

as resulting in the greatest percentage of xylanase ac- 119 (1985).

100 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 30, JULY 1987

Das könnte Ihnen auch gefallen

- Producción Hongos en Pomaza de Cranberry PDFDokument7 SeitenProducción Hongos en Pomaza de Cranberry PDFMarcelo TorresNoch keine Bewertungen

- Constructed WetlandsDokument74 SeitenConstructed WetlandsMarcelo TorresNoch keine Bewertungen

- Fosforilacion OxidativaDokument40 SeitenFosforilacion OxidativaMarcelo TorresNoch keine Bewertungen

- Defectos Del Ciclo de La UreaDokument4 SeitenDefectos Del Ciclo de La UreaMarcelo TorresNoch keine Bewertungen

- Fosforilacion OxidativaDokument40 SeitenFosforilacion OxidativaMarcelo TorresNoch keine Bewertungen

- Water Hammer and Other Pipe Transient ProblemsDokument5 SeitenWater Hammer and Other Pipe Transient ProblemsMarcelo TorresNoch keine Bewertungen

- Carcinogenesis: Genes and Multistep ProcessDokument34 SeitenCarcinogenesis: Genes and Multistep ProcessMarcelo TorresNoch keine Bewertungen

- Defectos Del Ciclo de La UreaDokument4 SeitenDefectos Del Ciclo de La UreaMarcelo TorresNoch keine Bewertungen

- Analysis of TRS emissions from recovery boilers and dissolving tanksDokument7 SeitenAnalysis of TRS emissions from recovery boilers and dissolving tanksMarcelo TorresNoch keine Bewertungen

- Chromatographic Separation of Cholesterol in FoodsDokument20 SeitenChromatographic Separation of Cholesterol in FoodsMarcelo TorresNoch keine Bewertungen

- Use of Dinitrosalicylic Acid Reagent For Determination of Reducing SugarDokument3 SeitenUse of Dinitrosalicylic Acid Reagent For Determination of Reducing SugarArthur96% (27)

- Producción Hongos en Pomaza de Cranberry PDFDokument7 SeitenProducción Hongos en Pomaza de Cranberry PDFMarcelo TorresNoch keine Bewertungen

- Chromatographic Separation of Cholesterol in FoodsDokument20 SeitenChromatographic Separation of Cholesterol in FoodsMarcelo TorresNoch keine Bewertungen

- Chromatographic Separation of Cholesterol in FoodsDokument20 SeitenChromatographic Separation of Cholesterol in FoodsMarcelo TorresNoch keine Bewertungen

- Horaepaulinaeor00palegoog PDFDokument441 SeitenHoraepaulinaeor00palegoog PDFMarcelo TorresNoch keine Bewertungen

- Pioneer Elite CD CDV LD Player CLD 79 Users Manual 334720Dokument31 SeitenPioneer Elite CD CDV LD Player CLD 79 Users Manual 334720Marcelo TorresNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Drug Targeting May Improve Drug Delivery Through Prodrug StrategiesDokument61 SeitenDrug Targeting May Improve Drug Delivery Through Prodrug StrategiesBima AnestyaNoch keine Bewertungen

- Semiotica - Roma AntiguaDokument25 SeitenSemiotica - Roma Antiguarafasolano1610Noch keine Bewertungen

- Fluid Mechanics - Multiple Choice Questions and Answers (MCQ) - ScholarexpressDokument4 SeitenFluid Mechanics - Multiple Choice Questions and Answers (MCQ) - Scholarexpressnitesh_kumar079976Noch keine Bewertungen

- Numerical Modeling of A 90° Open-Channel Confluence Flow Using Openfoam CFDDokument86 SeitenNumerical Modeling of A 90° Open-Channel Confluence Flow Using Openfoam CFDVictor Lira0% (1)

- Sixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)Dokument574 SeitenSixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)firox2005Noch keine Bewertungen

- Earth Materials and ProcessesDokument60 SeitenEarth Materials and ProcessesZarlene SierraNoch keine Bewertungen

- Free Damped VibrationsDokument7 SeitenFree Damped VibrationsYob YnnosNoch keine Bewertungen

- Schedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)Dokument161 SeitenSchedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)sagar mukulNoch keine Bewertungen

- 771.lecture Notes 1Dokument49 Seiten771.lecture Notes 1fortuneNoch keine Bewertungen

- The Nano World A. DefinitionDokument6 SeitenThe Nano World A. DefinitionSavy CruzNoch keine Bewertungen

- Lab Report MayonnaiseDokument5 SeitenLab Report Mayonnaiseapi-295870217Noch keine Bewertungen

- MeteorologyDokument2 SeitenMeteorologyIoniță AndreeaNoch keine Bewertungen

- Psychrometry and Industrial Drying ProcessesDokument4 SeitenPsychrometry and Industrial Drying ProcessesShania LoveresNoch keine Bewertungen

- Redox Titration Calculations and AnalysesDokument7 SeitenRedox Titration Calculations and AnalysesAtikaRahayuNoch keine Bewertungen

- WRM Proceses - Copy (Autosaved)Dokument41 SeitenWRM Proceses - Copy (Autosaved)Vikrant HanwatNoch keine Bewertungen

- 5991 5571enDokument10 Seiten5991 5571enHoanghanh LequangNoch keine Bewertungen

- 2017 - Product Specification - RZBC (JUXIAN) - CAADokument1 Seite2017 - Product Specification - RZBC (JUXIAN) - CAAediasianagri100% (1)

- Science Syllabus Class IX-XDokument12 SeitenScience Syllabus Class IX-XAbhishekNoch keine Bewertungen

- Practical ElectricityDokument104 SeitenPractical Electricityray davis100% (1)

- AssignmentDokument1 SeiteAssignmentKen LaguiabNoch keine Bewertungen

- Spectrophotometric Determination of in SodiumDokument6 SeitenSpectrophotometric Determination of in Sodiumgasan4ikNoch keine Bewertungen

- Araldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFDokument8 SeitenAraldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFneerajaNoch keine Bewertungen

- Significance of PH Pka and PKBDokument7 SeitenSignificance of PH Pka and PKBibadullah shah50% (2)

- Nox Abatement TechnologiesDokument16 SeitenNox Abatement TechnologiesMohita JaiswalNoch keine Bewertungen

- High-Solids Polyester Resins For Appliance and General Metal CoatingsDokument6 SeitenHigh-Solids Polyester Resins For Appliance and General Metal CoatingsSyed Ubaid AliNoch keine Bewertungen

- VD-SEAL II Final Report2Dokument4 SeitenVD-SEAL II Final Report2Arturo CordovaNoch keine Bewertungen

- Makalah-Work Energy PowerDokument29 SeitenMakalah-Work Energy PowerSastri DwisariniNoch keine Bewertungen

- Ammonia and Urea Plants PDFDokument48 SeitenAmmonia and Urea Plants PDFbenon100% (1)

- 19 Is 000003 BRO Symmetry Cracking Furnace Feb 2020Dokument5 Seiten19 Is 000003 BRO Symmetry Cracking Furnace Feb 2020ab_bn_1Noch keine Bewertungen

- 08.solutions To ConceptsDokument16 Seiten08.solutions To ConceptsPallav Jyoti PalNoch keine Bewertungen