Beruflich Dokumente

Kultur Dokumente

Lab Calibration Certification

Hochgeladen von

VAIBHAV INSTRUMENTATIONOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab Calibration Certification

Hochgeladen von

VAIBHAV INSTRUMENTATIONCopyright:

Verfügbare Formate

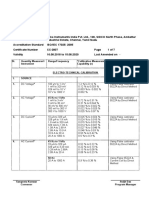

Laboratory Vaidyanatheshwara Instruments, No.

301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 1 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

ELECTRO-TECHNICAL CALIBRATION

I. SOURCE

1. DC Voltage# 1 mV to 10 mV 0.240 % to 0.025 % Using Standard

10 V to 100 mV 0.025 % to 0.0041 % Calibrator Fluke 5522A

100 V to 1 V 0.0041 % to 0.0016 % by Direct method

1 V to 10 V 0.0016 % to 0.0017 %

10 V to 1000 V 0.0017 % to 0.0024 %

2. AC Voltage# 45 Hz to 1 kHz 45 Hz to 10 kHz Using Standard

30 V to 3 V 0.712 % to 0.25 % Calibrator Fluke 5522A

3m V to 30m V 0.25 % to 0.044 % by Direct method

10 Hz to 10 kHz 10 Hz to 10 kHz

30 mV to 100 mV 0.12 % to 0.087 %

100 mV to 1 V 0.087 % to 0.081 %

1 V to 30 V 0.081 % 0.044 %

45 Hz to 1 kHz 45 Hz to 1 kHz

30 V to 300 V 0.20 % to 0.024 %

300 V to 1000 V 0.024 % to 0.036 %

100 kHz 100 kHz

30 mV to 30V 0.452 % to 0.055 %

30 V to 100 V 0.055 % to 0.026 %

450 kHz 450 kHz

30 mV to 3 V 1.122% to 0.304 %

3. DC Current# 10 µA to 100 µA 0.25 % to 0.025 % Using Standard

100 µA to 1 mA 0.035 % to 0.017 % Calibrator Fluke 5522A

1 mA to 100 mA 0.017 % to 0.012 % by Direct method

100 mA to 1 A 0.012 % to 0.028 %

Ram Ashray Avijit Das

Convenor Program Director

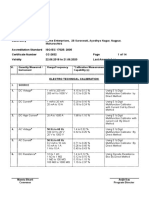

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 2 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

1 A to 10 A 0.028 % to 0.064 %

10 A to 20 A 0.064 % to 0.12 %

20 A to 200 A 0.12 % to 0.98 % With Current Coil Fluke

200 A to 1000 A 0.98 % to 0.34 % 5500A

4. AC Current# 1 kHz 1 kHz Using Standard

30 µA to 330 µA 0.55 % to 0.18 % Calibrator Fluke 5522A

330 µA to 3.3 mA 0.18 % to 0.16 % by Direct method

3.3 mA to 1A 0.16 % to 0.074 %

1 A to 10 A 0.074 % to 0.14 %

10 Hz to 1 kHz 10 Hz to 1 kHz

330 µA to 3.3mA 0.27 % to 0.28 %

3.3 mA to 3 A 0.28 % to 0.47 %

45 Hz to 5 kHz 45 Hz to 5 kHz

3 A to 20 A 0.24 % to 0.14 %

50 Hz 50 Hz With Current Coil Fluke

20A to 1000A 0.69 % to 0.38 % 5500A

5. Resistance# 1m 0.611% Using Standard

10m 0.611% Resistance by Direct

50m 0.611% method

150m 0.611%

150m to 1 0.611%

1 to 10 0.611 % to 0.12 %

0.120 % to 0.016 %

10 to 100 Ω

0.016 % to 0.005 % Using Standard

100 to 1 k

0.005 % to 0.0037 % Calibrator Fluke 5522A

1k to 10 k 0.0037 % to 0.0036 % by Direct method

10 to 100 k 0.0036 % to 0.0036 %

100 k to 1 M 0.0036 % to0.0042 %

1M to 10 M 0.0042 % to 0.016 %

10 M to 300 M 0.016 % to 0.39 %

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 3 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

300 M to 1 G 0.39 % to 1.79 %

0.1 M to 1 G 5.89 % to 4.92 % Using High Stability

1G to 100G 4.92 % to 8.68 % Megohm Box By Direct

100 G to 1 T 8.68 % to 5.89 % Method

6. Capacitance# 1 kHz Using Standard

220 pF to 300 nF 5.79 % to 0.29 % Calibrator Fluke 5522A

300 nF to 100 µF 0.29 % to 1.15 % by Direct method

100 Hz DCB by

1 µF to 30 µF 1.55 % to 0.58 % Direct Method

7. AC Power - 1Ø# 50 Hz @ UPF Using Standard

120V to 240V Calibrator Fluke 5522A

0.01A to 20A by Direct method

1.2 W to 4.8 kW 0.17 %

50Hz @ 0.8 Lead

120V to 240V

0.1A to 20A

9.6 W to 3.8 kW 0.28 % to 0.21%

50Hz @ 0.5 Lag

120V to 240V

0.1A to 20A

6 W to 2.4 kW 0.47 %

50Hz @ 0.2 Lag

120V to 240V

0.1A to 20A

2.4 W to 960 W 0.58 %

8. Power Factor# 0.2 Lead to UPF 0.004 PF (0.4 º) Using Standard

0.2 Lag to UPF Calibrator Fluke 5522A

by Direct method

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 4 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

9. Inductance# 1 kHz Using Decade

10 µH to 10 H 2.35 % to 1.14 % Inductance box By Direct

Method

10. Oscilloscope# a) DC Signal Using Scope Calibrator

2 mV to 130 V 0.29 % to 0.096 % Fluke 5522A By Direct

b) Amplitude – Method

Sq. wave

2 mV to 55 Vp-p 0.6 % to 0.3 %

(@ 1 kHz)

Time Marker

1 ns to 5 s 0.0003 %

Band Width

50 kHz to 1 GHz

with Reference to 0.23% to 0.87%

50 kHz

11. Frequency# 1 Hz to 1 GHz 0.004 % to 0.006 % Using Standard

Calibrator By Direct

Method

12. Temperature Simulation#

(Temperature Indicator/Recorder/Controller)

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 5 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

K Type (-) 200 °C to 1350 °C 0.50°C Using Standard

J Type (-) 200 °C to 1200 °C 0.27°C Calibrator Fluke 5522A

B Type 600 °C to 1750 °C 0.51°C By Direct Method

E Type (-) 200 °C to 900 °C 0.47°C

N Type (-) 200 °C to 1300 °C 0.47°C

R Type 10 °C to 1750 °C 0.65°C

S Type 10 °C to 1750 °C 0.63°C

T Type (-) 200 °C to 400 °C 0.59°C

RTD Type (-) 200 °C to 800 °C 0.207°C

II. MEASURE

1. DC Voltage# 1mV to 100 mV 0.467 % to 0.0004 % Using 8½ DMM Fluke

100m V to 1 V 0.0004 % to 0.0007 % 8508A by Direct Method

1V to 100 V 0.0007 % to 0.0007 %

100 V to 1000 V 0.0007 % to 0.0005 %

2. AC Voltage# 20 Hz to 50 kHz Using 8½ DMM Fluke

1 mV to 100 mV 0.822 % to 0.104 % 8508A by Direct Method

100 mV to 1 V 0 .104 % to 0.081 %

1 V to 100 V 0.081 %

45 Hz to 1 kHz

100V to 1000 V 0.01 % to 0.019 %

50 kHz to 500 kHz

1 V to 20 V 0.348 % to 0.232 %

3. DC Current# 10 µA to 100 µA 0.0021 % Using 8 ½ DMM Fluke

100 µA to 1 mA 0.0056 % to 0.003 % 8508A by Direct Method

1 mA to 100 mA 0.003 % to 0.009 %

100 mA to 1 A 0.064 % to 0.022 %

1 A to 20 A 0.022 % to 1.51 %

20 A to 1000 A 1.52 % Using Shunt

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 6 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

4. AC Current# 300 Hz to 10 kHz Using 8½ DMM Fluke

100 µA to 100 mA 0.052 % 8508A by Direct Method

100 mA to 1 A 0.053 % to 0.094 %

1 A to 20 A 0.094 % to 0.108 %

50 Hz

20 A to 700 A 2.52 % to 2.55 % Using Shunt

5. Resistance# 1m to 100 m 0.571 % to 0.592 % Using LCR Meter By

100 mΩ to 150 mΩ 0.592 % to 0.391 % Direct Method

150 m to 1 0.391 % to 0.0092 % Using 8½ DMM Fluke

1Ω to 100 Ω 8508A by Direct Method

100 Ω to 10 KΩ 0.0092 % to 0.0009 %

10k to 100 K 0.0009 % to 0.001 %

100K to 1M 0.001 % to 0.001 %

1MΩ to 10 MΩ 0.001 % to 0.0014 %

10 MΩ to 100MΩ 0.0014 % to 0.002 %

100 MΩ to 1 GΩ 0.002 % to 0.017 %

1 G to 10 G 0.017 % to 0.001 %

0.001 % to 0.135 %

6. Capacitance # @1 kHz

1nF to 100 nF 0.061 % to 0.060 % Using LCR Meter By

100 nF to 1 µF 0.06 % to 0.061 % Direct Method

1 µF to 100 µF 0.061 % to 0.058 %

7. Inductance# @1 kHz

100 µH to 100 mH 0.237 % to 0.066 % Using LCR Meter By

100 mH to 10 H 0.066 % to 0.074 % Direct Method

8. Temperature Simulation#

(Temperature Indicator/Recorder/Controller)

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 7 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

K Type (-) 200 °C to 1350 °C 0.49 °C Using Standard

J Type (-) 200 °C to 1200 °C 0.32 °C Calibrator Fluke 5522A &

B Type 600 °C to 1750 °C 0.54 °C 6 ½ DMM by Direct

E Type (-) 200 °C to 900 °C 0.49 °C method

N Type (-) 200 °C to 1300 °C 0.49 °C

R Type 10 °C to 1750 °C 0.68 °C

S Type 10 °C to 1450 °C 0.57 °C

T Type (-) 200 °C to 400 °C 0.61 °C

RTD Type (-) 200 °C to 800 °C 0.27 °C

9. Frequency# 10 Hz to 1 GHz 0.0012 % to 0.0025 % Using Frequency counter

/ Philips - PM 6669 by

Direct method

10. Timer# 1 sec to 9000 sec 0.07 % to 0.06 % Using Digital Timer

Beltronics 501 By

Comparison Method

11. DC Voltage♣ 1kV to 20kV 1.71 % to 1.68 % Using H.V. Probe Fluke

20 kV to 40kV 1.68 % to 1.66 % 80K with DMM Fluke

17B by Direct method

12. AC Voltage♣ 50 Hz Using H.V. Probe Fluke

1 kV to 25 kV 7.94 % to 7.58 % 80K with DMM Fluke

17B by Direct method

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 8 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECH

ANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Callipers$ 0 to 300 mm 11.0 µm Using Caliper checker

(Analog/Dial /Digital ) 0 to 600 mm 13.0 µm and Gauge Block

Res: 0.01mm Φ 0 to 1000 mm 21.0 µm By Comparison Method

As per IS 3651

2. Depth Micrometer$ 0 to 300 mm 7.0 µm Using Gauge Block Set

Res: 0.001mm Φ By Comparison Method

As per IS Based 2967

3. External Micrometer$ 0 to 450 mm 4.0 µm Using Gauge Block Set

(Analog / Digital / By Comparison Method

Flange / Point / As per IS 2967

V Anvil / Pitch)

Res: 0.001 mm* 0 to 1000 mm 9.0 µm

(0 to 450 mm)

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 9 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

0.01 mm Φ

(0 to 1000 mm)

4. Setting Rods & 25 mm to 975 mm 10.0 µm Using Gauge Block Set

Extensions Rods$ By Comparison Method

5. Depth Vernier$ Using gauge block set

(Analog/Dial/Digital ) By Comparison Method

Res: 0.01 mm Φ 0 to 600 mm 20.0 µm As per IS 4213

6. Height Gauge$ 0 to 600 mm 13.0 µm Using Caliper checker

(Dial, Digital & By Comparison Method

Analog) 0 to 1000 mm 22.0 µm As per standard

Res: 0.01 mm Φ based on IS 2921

7. 3 Point Micrometer$ 0 to 100 mm 4.0 µm Using Master Ring

Res: 0.001 mm Φ Gauges By Comparison

Method

8. Dial Gauge-Plunger 0 to 1 mm 2.9 µm Using Electronic Dail

Type$ 0 to 10 mm 3.1 µm Calibration Tester As per

(Analog/Digital) 0 to 50 mm 6.5 µm standard based on IS

Res: 0.001 mm Φ 2092

9. Lever Dial 0 to 1 mm 6.3 µm Using Electronic Dail

Gauge $mm* Calibration Tester As per

(0 to 1 mm), standard based on IS

0.01mm Φ 0 to 0.2 mm 3.0 µm 11498

(0 to 0.2 mm)

0.002 mm

(0 to 0.14 mm) 0 to 0.14 mm 2.9 µm

0.001mm

10. Bore Gauge $ 1 mm Transmission only 3.7 µm Using Electronic Dail

0.001mm Φ gauge Calibration Tester

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 10 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

As per standard based

on IS 2092

11. Plain Plug Gauges$ 1 mm to 300 mm 1.5 µm Using Universal Length

Measuring Machine As

per standard based on

IS 3455

12. Plain Ring Gauges$ 4 mm to 300mm 3.3 µm Using Universal Length

Measuring Machine As

per standard based on

IS 3455

13. Snap Gauges / Dial 3 mm to 300 mm 3.5 µm Using Universal Length

Snap Gauges / Width Measuring Machine As

Gauges$ per standard based on

IS 3477 & 8023

14. Measuring Pins$ Up to 25 mm 0.6 µm Using Universal Length

(Grade 1 & 2) Measuring Machine As

per standard based on

IS 11103

15. Thread Plug Gauge$ Up to 300 mm 2.6 µm Using Universal Length

(Effective Dia) Measuring Machine As

per standard based on

IS 2344 & AMSI/ASME

B1.20.5

16. Thread Ring Gauge$ 3 mm to 300 mm 3.0 µm Using Universal Length

(Effective Dia) Measuring Machine As

per standard based on IS

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 11 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2344

17. Taper Thread Plug 0 to 100 mm 4.0 µm Using Universal Length

Gauge$ Measuring Machine As

(Effective Dia) per standard based on

IS 2344

18. Taper Thread Ring 0 to 110 mm 6.8 µm Using Universal Length

Gauge$ Measuring Machine

(Effective Dia.) As per standard based

on IS 2344

19. Bevel Protractor $ Using Profile Projector

Res: 1 min Φ 0 to 360° 3.4 arc of min As per standard based

on IS 4239

20. Combination Set $ 0 to 180 o 16.6 arc of sec Using Profile Projector

Res:1 o As per standard based

on IS 4239

21. Feeler Gauge$ 0.1 mm to 1 mm 2.5 µm Using Universal Length

Measuring Machine

As per standard based

on IS 3179

22. Comparator Dial Up to 300 mm 7.0 µm Using Lever Dial &

Stand $ Linear Height Master

( Flatness) By Comparison Method

23. Steel Scale / Taper 0 to 1000 mm 17.0 µm Using Tape & Scale

Scale $ Measuring Machine

Res: 0.1 mm Φ As per standard based

on IS 1481

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 12 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

24. Measuring Tape / 0 to 50,000 mm 17 + 5.9 L µm Using Tape & Scale

PI Tape$ (L in meters) Measuring Machine

Res: 0.5 mm Φ As per Standard Based

on IS 1269

25. Glass Scale $ Using Profile Projector

Res: 0.5 Mm Φ 0 to 300 mm 8.0 µm By comparison Method

26. Radius Gauges$ 0.5 mm to 25.0 mm 8.0 µm Using Profile Projector

As per IS 5273

27. Thread Pitch Gauge , 0.3 mm to 6.0 mm 4.0 µm Using Profile Projector

Set Pitch Flank 55 o to 60o 6.9 min of arc As per standard based

Angle$ on IS 4211

28. ‘V’ – Block$ Up to 200 mm Using Mandrel + Linear

(Squareness) 7.0 µm Height Master + Lever

(Parallelism) 7.0 µm Dial Gauge As per

(Symmetricity) 8.0 µm Standard Based on

IS 2949

29. Spirit Level / Frame Using Electronic Level

Level$ As per standard based

Res: 10µm /m Φ 0.12 mm/m 15.0 µm/m on IS 5706

30. Test Sieves$ 0.16 mm to 1 mm 5.0 µm Using Profile Projector

1 mm to 100 mm 20.0 µm As per standard based

on IS 460

31. Pistol Caliper $ Using Gauge Block Set

Res: 0.01 mm * 0 to 100 mm 10 µm By Comparison Method

32. Engineering Square / Using Digital Dial Gauge

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 13 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Angle Plates$ Up to 350 mm 9.0 µm + Linear Height Master

(Squareness) As per standard based

on IS 2103

33. Surface Plate$ (6000 mm x 2000 mm) 1.0 √L+W/150 µm Using Electronic Level

(Granite / Cast Iron “L” in mm As per standard based

Surface Table) on IS 7327 for granite

2281 for cast Iron

34. Coating Thickness Using Standard

Gauge$ Thickness Foils

Res: 0.1 µm Φ 0 to 1250 µm 3.0 µm By Comparison Method

35. Calibration Foils$ 10 µm to 2000 µm 1.0 µm Using Universal Length

Measuring Machine

By Comparison Method

36. Groove Dial / Leg Using Gauge Block Set

Caliper $ By Comparison Method

(OD & ID) Gauge

Res: 0.025mm Φ Up to 150 mm 8.0 µm

37. Internal Micrometer/ Using Gauge Block set

Stick Micrometer and Gauge Block

(Including Extension Accessories By

rod) $ Comparison Method

Res: 0.01mm Up to 300 mm 8.0 µm IS 2966

38. Dial Thickness Using Gauge Block Set

Gauge $ By Comparison Method

Res: 0.001 mm/ 0 to 10 mm 8.0 µm

0.01mm Φ

39. Height Measuring Using Gauge Block Set

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 14 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

System $ By Using Gauge Block

Res: 0.001 µm Φ 0 to 1000 mm 5.6 µm Set

40. Dial Calibration Using ULM By

Tester / LVDT Probe Comparison Method

With Indicator$

Res: 0.01 µm Φ 0 to 25 mm 2.0 µm

41. Caliper Checker $ 0 to 950 mm 10.0 µm Using Gauge Block Set

and Linear Height Master

As per standard based

on IS 13709

42. Pitch Micrometer $ Using Gauge Block Set

Res: 0.01mm Up to 200 mm 7.0 µm By Comparison Method

43. Micrometer Head$ Using ULM By

Res: 0.001mm Φ 0 to 25 mm 2.0 µm Comparison Method

44. Parallel Block $ Up to 1000 mm 10.0 µm Using Lever Dial Gauge

By Comparison Method

45. Ultra Sonic Thickness Up to 200 mm 8.3 µm Using Slip Gauge Set

Gauge$ BY Comparison Method

46. Gauge Block Set$ 0.5 mm to 25 mm 0.10 µm Using Slip Gauge

25 mm to 50 mm 0.14 µm Calibrator

50 mm to 75 mm 0.13 µm By Comparison Method

75 mm to 100 mm 0.20 µm

47. Universal Length Up to 100 mm 0.8 µm Using Grade ‘K’ Slip

Measuring Machine$ Gauge Set By

Comparison Method

II. ACCELERATION & SPEED

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 15 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

1. Tachometer $ 100 rpm to 5000 rpm 1.7 % to 2.3 % Using Tachometer

(Contact Type) Calibrator By

Comparison Method

2. Stroboscope, 60 rpm to 25000 rpm 1.02 % to 0.01 % Using Master

Tachometer $ 25000 rpm to 45000 rpm 0.01 % to 0.005 % Tachometer By

(Non-contact Type) Comparison Method

III. TORQUE GENERATING DEVICES

1. Torque Wrench $ 0 to 20 Nm 0.36 % Using Torque Transducer

(Type-I Class with Indicators IS/ISO

B,C,D,E & Type-II 20 Nm to 200 Nm 1.5 % 6789 : 2003 Using

Class A,B,C,D) Torque Wrench

200 Nm to 1000 Nm 1.2 % calibration System

IV. PRESSURE INDICATING DEVICES

1. Hydraulic Pressure 0 to700 Bar 0.20 bar Using Digital Pressure

Digital/Analog Gauge Dial Test Gauge

Pressure Gauges, 0 to 1000 bar 0.32 bar Based on DKD-R6-1

Compound Gauge,

Pressure Indicator

With Transducer/

Transmitter ,

Pressure Switch#

2. Pneumatic Pressure 0 to 500 mbar 0.16 mbar Using Digital Manometer

Magnehelic Gauges, 0 to 2000 mbar 4.8 mbar Based on DKD-R6-1

Differential Pressure

transmitters, Low

Pressure Indicators/

Transducers,

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 16 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Barometer#

3. Pneumatic Pressure 0 to 35 bar 0.01 bar Using Digital Pressure

Digital / Dial Gauges/ 0 to 70 bar 0.15 bar Gauge Based on

Pressure Indicator DKD-R6-1

with Transmitter/

Transducer,

Compound Gauge#

4. Digital / Dial Vacuum 0 to (-) 0.75 bar 0.0062 bar Using Digital Vaccum

Gauges/Transmitters/ Gauge Based on

Transducers, DKD-R6-2

Compound Gauge#

V. DIMENSION (PRECISION INSTRUMENTS)

1. Height Measuring 0 to 1000 mm 5.6 µm Using Gauge Block Set

System♣ By Comparison Method

Res: 0.1 µm*

2. Surface Plate♣ Up to 1.0 √L+W/150 µm Using Electronic Level

(Granite / Cast Iron (6000 mm x 2000 mm) As per standard based

Surface Plate) “L” in mm on IS 7327 & 2283

3. Bench Centre♣ Up to 500 mm Parallelity: 9.0 µm By Comparison Method

Co-axiality: 8.0 µm

4. Centrifuge / 10 RPM to 15000 RPM 0.79 % to 1.1 % By Comparison Method

Centrifugal Motor/

Speed

(Non-Contact ) ♣

5. Profile Projector/ Linear : 0 to 200 mm 2.6 µm Using Slip Gauge set +

Video Measuring L.C.: 0.001 mm Glass Angle Gauge +

System / Micro Angular : 0o to 360 o Glass Scale By

Scope $ L.C.: 12 arc sec 50 min of arc Comparison Method

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 17 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Magnification:

10x to 100x 0.6 %

6. Profile Projector/ Linear: 0 to 200 mm 2.4 µm Using Slip Gauge set +

Video Measuring L.C.- 0.001 mm Glass Angle Gauge +

System / Micro Angular: 0o to 360 o 50 min of arc Glass Scale

Scope♣ L.C.- 12 arc sec By Comparison Method

Mag.: 10x to 100x 0.6 %

VI. MASS

1. Weights$ 20 kg 0.084 g Using Weights of

(F2 Class & Coarser) Accuracy ClassF1

And Precision Balances

as per OIML R 111-

1:2004 By Substitution

Method ABBA Weighing

Cycle

Weights 10 kg 0.083 g Using Weights of

(M1 Class & Coarser) Accuracy ClassF1

And Precision Balances

as per OIML R 111-

1:2004 By Substitution

Method ABBA Weighing

Cycle

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 18 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Weights$ 5 kg 0.010 g Using Weights of

(F2 Class & Coarser) Accuracy ClassF1

2 kg 0.009 g And Precision Balances

as per OIML R 111-

1:2004 By Substitution

Method ABBA Weighing

Cycle

Weights$ 1 kg 0.001g Using Weights of

(F1 Class & Coarser) Accuracy Class E2 And

500 kg 0.001 g Precision Balances as

per OIML R 111-1:2004

By Substitution Method

ABBA Weighing Cycle

Weights$ 200 g 0.099 mg Using Weights of

(E2 Class & Coarser) Accuracy Class E1 And

100 g 0.089 mg Precision Balances as

per OIML R 111-1: 2004

By Substitution Method.

ABBA Weighing Cycle

Weights$ 50 g 0.014 mg Using Weights of

(E2 Class & Coarser) 20 g 0.012 mg Accuracy Class E1 And

10 0.012 mg Precision Balances as

per OIML R 111-1:2004

By Substitution Method.

ABBA Weighing Cycle

5g 0.006 mg Using Weights of

2g 0.004 mg Accuracy Class E1 And

1g 0.004 mg Precision Balances as

500 mg 0.003 mg per OIML R 111-1:2004

200 mg 0.003 mg By Sub-division Method

100 mg 0.003 mg ABBA Weighing Cycle

50 mg 0.002 mg

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 19 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

20 mg 0.002 mg

10 mg 0.002 mg

5 mg 0.002 mg

2 mg 0.002 mg

1 mg 0.002 mg

2. Weighing Balance$

Readability:

0.0001 mg (1 mg to 2.1 g) 0.003 mg Using Weights of

Readability: 0.001 mg (1 mg to 5.1 g) 0.005 mg Accuracy Class E1 As

per OIML R-76:2006

Readability: 0.1 mg (1 mg to200 g) 0.060 mg

Readability: 0.01 mg (1 mg to 50 g) 0.011m g Using Weights of

Accuracy Class E1 As

per OIML R-76:2006

Readability: 1 mg (1mg to 1kg) 0.002g Using Weights of

Readability: 10 mg (0.1 mg to 5 kg) 0.014 g Accuracy Class E2 As

per OIML R76-:2006

Readability: 100 mg (0.1 mg to 2 kg) 0.011g Using Weights of

Readability: 100 mg (0.1g to 35kg) 0.186 g Accuracy Class E2 As

Readability: 100 mg (0.1g to 20kg) 0.109 g per OIML R76-:2006

(0.1mg to10kg) 0.037 g

Readability: 1 g (1g to100 kg) 1g Using Weights of

Readability: 10 g (10g to100 kg) 10g Accuracy Class M1 As

Readability: 50 g (2kg to500 kg) 20g per OIML R76-:2006

Readability: 100 g (2kg to1000 kg) 50g

VII. VOLUME

1. Micropipette$ 1µl 0.01µl Using Weights of

2µl 0.01µl Accuracy Class E1 &

5µl 0.02µl Distilled water by

10µl 0.03µl Gravimertic method on

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 20 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

ISO 8655 (Part 6) :2002

20µl 0.05µl Using Weights of

50µl 0.20µl Accuracy Class E2 &

100µl 0.62µl Distilled water by

200µl 1.30µl Gravimertic method on

500µl 3.10µl ISO 8655 (Part 6) :2002

1000µl 6.20µl

2000µl 12.5µl

5000µl 32.0µl

2. Graduated One Mark$ 5 ml 0.02 ml Using Weights of

(Pipette & Burette) 10 ml 0.03 ml Accuracy Class E2 &

25 ml 0.06 ml Distilled water by

50 ml 0.11 ml Gravimertic method on

100 ml 0.21 ml ISO 4787:2010 &

ISO 20461

3. Volumetric $ 5 ml 0.02 ml Using Weights of

(Flask/Beaker) 10 ml 0.03 ml Accuracy Class E2 &

20 ml 0.06 ml Distilled water by

50 ml 0.11 ml Gravimertic method on

100 ml 0.21 ml ISO 4787:2010 &

200 ml 0.41 ml ISO 20461

500 ml 1.03 ml

1000 ml 2.2 0ml

2000 ml 4.60 ml

4. Measuring Cylinder$ 5 ml 0.1 ml Using Weights of

10 ml 0.8 ml Accuracy Class E2 &

20 ml 1.5 ml Distilled water by

50 ml 1.5 ml Gravimertic method on

100 ml 1.9 ml ISO 4787:2010 & ISO

200 ml 2.3 ml 20461

500 ml 10.5 ml

1000 ml 11.5 ml

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 21 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2000 ml 12.0 ml

5000 ml 25.0 ml

10000 ml 75.0 ml

VIII. DENSITY AND VISCOSITY

1. Density $ Using Standard

(Hydrometer) Hydrometer By

L.C.: 0.0005 g/ml 0.600 g/ml to 1.8 g/ml 0.0009 g/ml Comparison Method

IX. UTM, TENSION CREEP AND TORSION TESTING MACHINE

1. Force Measuring 0 to 500 kN 0.72 % For UTM of accuracy

System of UTM class 0.5 and coarser

Compression Mode♣ as per IS:1828 (Part 1)

2015

X. HARDNESS TESTING MACHINES

1. Rockwell Hardness HRA 1.0 HRA Using Standard Blocks

Testing Machine♣ HRB 1.76 HRB by indirect Method

HRC 0.85 HRC as per IS:1586 (Part 2)

2012

2. Vickers Hardness HV1 5.12 % Using Standard Blocks

Testing Machine♣ HV5 3.0 % by indirect Method

HV10 2.50 % as per IS:1501 (Part 2)

HV30 2.0 % 2013

3. Brinell Hardness HBW 5/750 7.10% Using Standard Blocks

Testing Machine♣ HBW 10/3000 3.65% by indirect Method as per

IS:1500 (Part 2) 2013

4. Shore Hardness 0 to 100 Shore A 2.2 Shore A Using Rubber Hardness

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 22 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Tester$ 0 to 100 Shore D 2.2 Shore D Tester Calibrator

By Comparison Method

As per ASTMD 2240

THERMAL CALIBRATION

I. TEMPERATURE

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 23 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

1. Thermocouples & @(-) 95°C 0.083 °C Using RTD Sensor with

RTD Sensors/ Indicator Oil Bath, Dry

Temperature Sensors @140 °C 0.18 °C Block Furnace By

with indicators / Comparison Method

Temperature gauges/

Transmitters/ 140 °C to 600 °C 0.32 °C

Temperature Using Fluke S- Type

Switches & Thermocouple with Fluke

Transmitters With 600 °C to 1200 °C 1.8 °C Reference Thermometer,

Indicators# Dry Block Furnace By

Comparison Method

2. Oil Baths/Low & high @ (-) 95 °C 0.083 °C Using RTD

Temp bath/Dry bath$ Thermometer,

@140 °C 0.18 °C Multichannel

Temperature Recorder &

Fluke S type

140 °C to 600 °C 0.32 °C Thermocouple with cold

Bath & Dry Block

Furnaces By Comparison

600 °C to 1200 °C 1.9 °C Method

3. Non-Contact 50 °C to 650 °C 6.67 °C Using Black Body,

Thermometer Pyrometer by

Pyrometer$ 650 °C to 1200 °C 8.32 °C Comparison Method

4. Glass Thermometer$ (-) 20 °C to 150 °C 0.34 °C Using RTD sensor with

Oil Bath by Comparison

Method

5. Temperature 10° C to 50° C 0.21°C Using Standard RTD &

(Digital & Analog Temperature Generator

Thermo hygrometer) By Comparison

Temperature & Method

Humidity Meter,

Ram Ashray Avijit Das

Convenor Program Director

Laboratory Vaidyanatheshwara Instruments, No. 301/A, 9th Main Road, 3rd Cross,

Rajiv Gandhi Nagar, J.B Kaval, Nandini Layout Post, Bangalore,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2473 (in lieu of C-0579, C-0766 & Page 24 of 24

C-0767)

Validity 27.10.2017 to 26.10.2019 Last Amended on 06.12.2017

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Humidity Indicator,

Humidity &

Temperature

Transmitter With

Indicator) $

6. Thermal Freezers (-) 80 °C to 200 °C 0.95 °C Using Standard Humidity

Chambers/Ovens/ 200 °C to 1200 °C 1.88 °C Meter With Humidity

Incubators & Furnace Generator By

(Multipoint) ♣ Comparison Method

II. SPECIFIC HEAT AND HUMIDITY

1. Humidity Chambers/ 15%RH to 95%RH 1.36 % RH Using Temperature and

Climatic Chamber/ Humidity meter By Single

Environmental @ 10 ºC to 60 ºC Point Method

Chamber♣

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Φ

Laboratory can also calibrate instruments/devices of coarser resolution / least count within the

accredited range using same reference standard/ master equipment under the scope of accreditation.

Ram Ashray Avijit Das

Convenor Program Director

Das könnte Ihnen auch gefallen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument25 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Laboratory Calibration Centre ISO Accreditation CertificateDokument25 SeitenLaboratory Calibration Centre ISO Accreditation CertificateVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- 37.scope Location 1 CC-2913Dokument7 Seiten37.scope Location 1 CC-2913Ravichandran DNoch keine Bewertungen

- Hi Tech Calibration Services PDFDokument28 SeitenHi Tech Calibration Services PDFVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument19 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- 113.scope Location 1 CC-2807Dokument7 Seiten113.scope Location 1 CC-2807Ravichandran DNoch keine Bewertungen

- Sl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument16 SeitenSl. Quantity Measured/ Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNoch keine Bewertungen

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument3 SeitenQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksRavichandran DNoch keine Bewertungen

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDokument4 SeitenQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability Remarkssaquib hasanNoch keine Bewertungen

- 26.scope Location 1 CC-2688Dokument14 Seiten26.scope Location 1 CC-2688Ravichandran DNoch keine Bewertungen

- Belz Calibration Lab ISO AccreditationDokument24 SeitenBelz Calibration Lab ISO AccreditationrohanmanimaniNoch keine Bewertungen

- 10.scope Location 1 CC-2088Dokument23 Seiten10.scope Location 1 CC-2088Ravichandran DNoch keine Bewertungen

- National Voluntary Laboratory Accreditation Program: Scope of Accreditation To Iso/Iec 17025:2017Dokument20 SeitenNational Voluntary Laboratory Accreditation Program: Scope of Accreditation To Iso/Iec 17025:2017Eduard SastoqueNoch keine Bewertungen

- MPC India Scope 2018 - 2020Dokument7 SeitenMPC India Scope 2018 - 2020AcuteNoch keine Bewertungen

- 1953Dokument5 Seiten1953rohanmanimaniNoch keine Bewertungen

- 0717 04Dokument8 Seiten0717 04OSCAR YOBANY VEGA HERNANDEZNoch keine Bewertungen

- Surge Generator 2067 01Dokument18 SeitenSurge Generator 2067 01ebbasinghNoch keine Bewertungen

- Ertl NorthDokument18 SeitenErtl NorthSharath KarnatiNoch keine Bewertungen

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDokument14 SeitenLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- 0839 03 PDFDokument30 Seiten0839 03 PDFAmitNoch keine Bewertungen

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDokument3 SeitenQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksrohanmanimaniNoch keine Bewertungen

- 5025C Extended SpecsDokument7 Seiten5025C Extended SpecsJigme Cee ChogyalNoch keine Bewertungen

- FMT 05 - Vendor Evaluation VITDokument2 SeitenFMT 05 - Vendor Evaluation VITSrirevathi BalapattabiNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument11 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNoch keine Bewertungen

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDokument6 SeitenQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksrohanmanimaniNoch keine Bewertungen

- G128 - Guidance For DC - AC Power Scope Presentation-14545-2Dokument6 SeitenG128 - Guidance For DC - AC Power Scope Presentation-14545-2walterNoch keine Bewertungen

- Hig Volt Accreditation Scope ReferenceDokument9 SeitenHig Volt Accreditation Scope ReferenceebyjoyNoch keine Bewertungen

- Versatile 77IV Digital Multimeter for Field Service or Bench RepairDokument2 SeitenVersatile 77IV Digital Multimeter for Field Service or Bench RepairSuleyman KapucuNoch keine Bewertungen

- 2099Dokument12 Seiten2099rohanmanimaniNoch keine Bewertungen

- Scope Example 1Dokument11 SeitenScope Example 1czarmunecasgmailcomNoch keine Bewertungen

- Fluke115 MultimeterDokument2 SeitenFluke115 MultimeterRicardo QueirósNoch keine Bewertungen

- Fluke 115: MultimeterDokument2 SeitenFluke 115: MultimetergokulrajeNoch keine Bewertungen

- PF2010 Digital Power Meter (Multifunction & High Accuracy & Wide Bandwidth)Dokument3 SeitenPF2010 Digital Power Meter (Multifunction & High Accuracy & Wide Bandwidth)PMSi Cal6Noch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument20 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Fluke 115: MultimeterDokument2 SeitenFluke 115: Multimeterjean de Dieu pagoreNoch keine Bewertungen

- 0 Scope 2023 02 27Dokument29 Seiten0 Scope 2023 02 27Laboratorio 001Noch keine Bewertungen

- Process Calibrator Fluke 753 2581005: Measured Quantity Range Resolution AccuracyDokument6 SeitenProcess Calibrator Fluke 753 2581005: Measured Quantity Range Resolution AccuracyfahimNoch keine Bewertungen

- SPEC-2450C August 2020Dokument7 SeitenSPEC-2450C August 2020MayoNoch keine Bewertungen

- Insulation Testers: Technical DataDokument5 SeitenInsulation Testers: Technical DataBeshoy RedaNoch keine Bewertungen

- Insulation Testers: Technical DataDokument5 SeitenInsulation Testers: Technical DatadavisspmNoch keine Bewertungen

- Digital Insulation Testers Fluke 1507 1503Dokument5 SeitenDigital Insulation Testers Fluke 1507 1503industrialindiaNoch keine Bewertungen

- Institute For DesignDokument48 SeitenInstitute For DesignVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Ideal 61-702 200 Amp Clamp Meter/DMM Data Sheet SpecsDokument2 SeitenIdeal 61-702 200 Amp Clamp Meter/DMM Data Sheet SpecsenticoNoch keine Bewertungen

- LK-059-IDN (Length, & Time)Dokument6 SeitenLK-059-IDN (Length, & Time)Aries SupiyantoNoch keine Bewertungen

- BK 2831D Service ManualDokument26 SeitenBK 2831D Service ManualtodorloncarskiNoch keine Bewertungen

- 170 Series DatasheetDokument3 Seiten170 Series DatasheetpletenkaNoch keine Bewertungen

- Specifications: 9.1 Source and MeasurementDokument7 SeitenSpecifications: 9.1 Source and Measurementquantum_quantumNoch keine Bewertungen

- Ganga Calibration Services ISO 17025 AccreditationDokument3 SeitenGanga Calibration Services ISO 17025 AccreditationBALAJINoch keine Bewertungen

- Form Spesifikasi: Detailed SpecificationsDokument4 SeitenForm Spesifikasi: Detailed Specificationsheru pratiknoNoch keine Bewertungen

- 4420 enDokument4 Seiten4420 enLevent MertNoch keine Bewertungen

- Troemner Scope of Accreditation 2023 24Dokument13 SeitenTroemner Scope of Accreditation 2023 24maruthi prasad KNoch keine Bewertungen

- XDM2041 Digital Multimeter Technical Specifications: Function Range Resolution Accuracy: (% of Reading + LSB)Dokument2 SeitenXDM2041 Digital Multimeter Technical Specifications: Function Range Resolution Accuracy: (% of Reading + LSB)peladillanetNoch keine Bewertungen

- Manual IchromaDokument48 SeitenManual IchromaFernanda MontesNoch keine Bewertungen

- 5051 PlusDokument12 Seiten5051 PluspenityNoch keine Bewertungen

- True RMS: 600 A AC/DC Auto-Ranging Digital Clamp MeterDokument64 SeitenTrue RMS: 600 A AC/DC Auto-Ranging Digital Clamp MeterAlberto GarciaNoch keine Bewertungen

- Programmable Panel Meter for Electrical MeasurementsDokument6 SeitenProgrammable Panel Meter for Electrical MeasurementsredzwanNoch keine Bewertungen

- Fluke 289 SpecDokument2 SeitenFluke 289 SpecMakassar TeknikNoch keine Bewertungen

- TINSLEY5910TESTSETDokument2 SeitenTINSLEY5910TESTSETiyan supriadiNoch keine Bewertungen

- Nabl Scope 2020Dokument65 SeitenNabl Scope 2020sharanNoch keine Bewertungen

- Questionnaire for mass, balance and volume calibrationDokument3 SeitenQuestionnaire for mass, balance and volume calibrationVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument18 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- ZXX ZXDokument35 SeitenZXX ZXVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sushma Industries Calibration CentreDokument11 SeitenSushma Industries Calibration CentreVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDokument14 SeitenLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- ZCZCXZDokument17 SeitenZCZCXZVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Institute For DesignDokument48 SeitenInstitute For DesignVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Institute For DesignDokument48 SeitenInstitute For DesignVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Accurate Engineering Co.Dokument7 SeitenAccurate Engineering Co.VAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument12 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument12 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- ZCZCXZDokument17 SeitenZCZCXZVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Tempsens Calibration CentreDokument5 SeitenTempsens Calibration CentreVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Institute For Design of Electrical Measuring InstrumentsDokument48 SeitenInstitute For Design of Electrical Measuring InstrumentsVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Godrej & Boyce PDFDokument43 SeitenGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument12 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Godrej & Boyce PDFDokument43 SeitenGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDokument18 SeitenSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Laboratory Calibration Capabilities for Measuring InstrumentsDokument12 SeitenLaboratory Calibration Capabilities for Measuring InstrumentsVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Sri Gokul Cal Lab.Dokument4 SeitenSri Gokul Cal Lab.VAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Godrej & Boyce PDFDokument43 SeitenGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDokument14 SeitenLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Indigo Passenger (S) : Delhi MumbaiDokument2 SeitenIndigo Passenger (S) : Delhi MumbaiVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Automotive Research Association of IndiDokument31 SeitenAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Accurate Engineering Co.Dokument7 SeitenAccurate Engineering Co.VAIBHAV INSTRUMENTATIONNoch keine Bewertungen

- Datasheet PDFDokument10 SeitenDatasheet PDFitmNoch keine Bewertungen

- Altistart 48 - ATS48C32QDokument5 SeitenAltistart 48 - ATS48C32Qabdur rafayNoch keine Bewertungen

- Sales Support Document: Product FeaturesDokument9 SeitenSales Support Document: Product Featuresbc020400673Noch keine Bewertungen

- Solution - Manual The 8051 Microcontroller Based Embedded SystemsDokument14 SeitenSolution - Manual The 8051 Microcontroller Based Embedded Systemsmanishpatel_79Noch keine Bewertungen

- 74738Dokument12 Seiten74738sontuyet82Noch keine Bewertungen

- 45 60055 Ee416 2017 5 2 1 Ee413 Laboratory Experiments GroupDokument80 Seiten45 60055 Ee416 2017 5 2 1 Ee413 Laboratory Experiments Groupraghad zuhair yousifNoch keine Bewertungen

- Partial Discharge AnalysisDokument28 SeitenPartial Discharge AnalysisRemya Manuel100% (3)

- Diccionario Tomo 2Dokument924 SeitenDiccionario Tomo 2Fernando Alberto Lira Gómez100% (3)

- Laboratory Experiment 5 - Gonzales-ZairusDokument5 SeitenLaboratory Experiment 5 - Gonzales-Zairuszairus gonzalesNoch keine Bewertungen

- MEE - 1011 Module-Iii Photovoltaic Cells and SystemsDokument22 SeitenMEE - 1011 Module-Iii Photovoltaic Cells and SystemsErmias NigussieNoch keine Bewertungen

- 2VV-33C-R4: General SpecificationsDokument5 Seiten2VV-33C-R4: General SpecificationsCristian GhicaNoch keine Bewertungen

- Week 7 ActivityDokument2 SeitenWeek 7 ActivityJohnCris B. FornilosNoch keine Bewertungen

- DSX1 Digital Signal Cross Connect 103253AEDokument76 SeitenDSX1 Digital Signal Cross Connect 103253AEGeoffrey AlleyneNoch keine Bewertungen

- I/O Organization Modes DMA and ChannelsDokument7 SeitenI/O Organization Modes DMA and ChannelsDivyansh KumarNoch keine Bewertungen

- Lab 1 Answer Sheet (ELEC201)Dokument9 SeitenLab 1 Answer Sheet (ELEC201)KHAN BROTHERSNoch keine Bewertungen

- Synchronous Motors SlidesDokument55 SeitenSynchronous Motors SlidesKaye Freyssinet Nermal Abanggan100% (1)

- JTMK Visit ReportDokument9 SeitenJTMK Visit Reportram010Noch keine Bewertungen

- Two-Stage Power Decoupling For A Single-Phase Photovoltaic Inverter by Controlling The DC-Link Voltage Ripple in The DQ FrameDokument6 SeitenTwo-Stage Power Decoupling For A Single-Phase Photovoltaic Inverter by Controlling The DC-Link Voltage Ripple in The DQ FrameAkbar aliNoch keine Bewertungen

- Pflex Sg002p en PDokument86 SeitenPflex Sg002p en Phartman_mdNoch keine Bewertungen

- CWPHDokument3 SeitenCWPHVijay Kumar SiripurapuNoch keine Bewertungen

- Edc Lab ManualDokument92 SeitenEdc Lab ManualPranav GangwarNoch keine Bewertungen

- AD9283 ADC Expansion Module: User GuideDokument8 SeitenAD9283 ADC Expansion Module: User GuideNegrea CristianNoch keine Bewertungen

- Diesel Generator Ratings and SpecificationsDokument4 SeitenDiesel Generator Ratings and SpecificationsoscarNoch keine Bewertungen

- AlohaDokument9 SeitenAlohaanuragmishra2112Noch keine Bewertungen

- Kempomat: EN FI SV NO DA DE NL FR ES PL RUDokument26 SeitenKempomat: EN FI SV NO DA DE NL FR ES PL RUmcombaleNoch keine Bewertungen

- InstrumentationDokument7 SeitenInstrumentationNagaValliNoch keine Bewertungen

- Apxvll13n CDokument2 SeitenApxvll13n CMayara Dal SantoNoch keine Bewertungen

- Design and Development of Microcontroller Based Electronic Queue Control SystemDokument5 SeitenDesign and Development of Microcontroller Based Electronic Queue Control SystemFrederico MailaNoch keine Bewertungen

- Communication System Jto Lice Study Material SampleDokument16 SeitenCommunication System Jto Lice Study Material SampleArghya PalNoch keine Bewertungen

- Main Specifications of Generator SetsDokument3 SeitenMain Specifications of Generator SetsReal IDNoch keine Bewertungen