Beruflich Dokumente

Kultur Dokumente

PAT Iflex5 Parte004

Hochgeladen von

lecuellarq85gmailcomCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PAT Iflex5 Parte004

Hochgeladen von

lecuellarq85gmailcomCopyright:

Verfügbare Formate

General Information 1

1 GENERAL INFORMATION

This service manual is designed to assist a service or maintenance person in identifying system

problem areas or malfunctions. A digital voltmeter with the capability to measure current will be

required, along with standard maintenance and service tools. NOTE: Knowledge of how to use a

voltmeter to measure both voltage and current is assumed.

REFERENCE:

For system operation, refer to the consoles operator’s manual 9333101047 REV. B.

2 WARNINGS

The LMI is an operational aid that warns a crane operator of approaching overload conditions and over

hoist conditions that could cause damage to equipment and personnel.

The device is not, and shall not be, a substitute for good operator judgment, experience and use of

accepted safe crane operating procedures.

The responsibility for the safe crane operation shall remain with the crane operator who shall ensure

that all warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in this manual to ensure that he knows the operation and limitations of indicator and crane.

Proper functioning depends upon proper daily inspection and observance of the operating instructions

set forth in this manual. Refer to Section 6. Pre-Operation Inspection and Calibration Verification of the

operator’s manual.

The LMI can only work correctly, if all adjustments have been properly set. For correct

adjustment, the operator has to answer thoroughly and correctly all questions asked during

the setup procedure in accordance with the real rigging state of the crane. To prevent

material damage and serious or even fatal accidents, the correct adjustment of the LMI has

to be ensured before starting the crane operation.

© PAT Rev. F 07/29/03 IFLEX 5 REV_F

EQ: HC-3 / SN: 223090

2 Service Manual iFLEX5

3 DESCRIPTION OF THE SYSTEM

3.1 DESCRIPTION OF SYSTEM FUNCTION

The iFLEX5 system is a CAN bus system made up of a central microprocessor unit, operating

console, length/angle sensor, pressure transducers, and anti-two block switches. All components and

sensors are equipped with CAN bus controllers.

The PAT Load Moment Indicator system operates on the principle of reference/real comparison. The

real value, resulting from the pressure measurement is compared with the reference data, stored in the

central processor memory and evaluated in the microprocessor. When limits are reached, an overload

warning signal is generated at the operator’s console. At the same time, the aggravating crane

movements, such as hoist up, telescope out and boom down, will be stopped.

The fixed data regarding the crane, such as capacity charts, boom weights, centers of gravity and

dimensions are stored in memory chips in the central processor unit. This data is the reference

information used to calculate the operating conditions.

Boom length and boom angle are registered by the length/angle sensor, mounted inside the cable reel,

which is mounted on the boom. The boom length is measured by the cable reel cable, which also

serves as an electrical conductor for the anti two-block switches.

The crane load is measured by pressure transducer block attached to the piston and rod side of the

hoist cylinders.

The interactive user guidance considerably simplifies the input of operating modes as well as the

setting of geometry limit values.

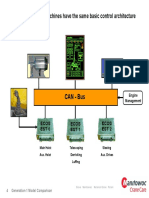

3.2 DESCRIPTION OF A CAN BUS SYSTEM

CAN stands for “Controller Area Network”. Its intended use is as a serial bus system for a network of

controllers. Each controller connected through a CAN chip is called a "node" and is mostly used to

acquire data from a sensor. All nodes are connected to a common bus and all nodes are able to

simultaneously read the data on that bus. Also, all nodes are able to transmit data on that bus however

only one node at a given time has write access to the bus. If the message is relevant, it will be

processed; otherwise it is ignored. The unique identifier also determines the priority of the message.

The lower the numerical value of the identifier, the higher the priority.

The cable bus is a twisted pair of shielded wire. Data can be transmitted in blocks from 0-8

bytes at a maximum transfer rate of 1 Mbit/s for networks up to 40 mtrs. For longer network

distances the maximum transfer rate must be reduced to 50 Kbit/s for a 1 km network distance.

CAN will operate in extremely harsh environments and the extensive error checking

mechanisms ensure that any transmission errors are detected.

© PAT Rev. F 07/29/03 IFLEX 5 REV_F

EQ: HC-3 / SN: 223090

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- All Generation 1 Machines Have The Same Basic Control ArchitectureDokument1 SeiteAll Generation 1 Machines Have The Same Basic Control Architecturelecuellarq85gmailcomNoch keine Bewertungen

- Cranes - Notable Features - RT775Dokument1 SeiteCranes - Notable Features - RT775lecuellarq85gmailcomNoch keine Bewertungen

- Band-pass and band-rejection filter design responsesDokument1 SeiteBand-pass and band-rejection filter design responseslecuellarq85gmailcomNoch keine Bewertungen

- A) A DW) A) A DW +: Table 16-2. Values of For Different Filter Types and Different QsDokument1 SeiteA) A DW) A) A DW +: Table 16-2. Values of For Different Filter Types and Different Qslecuellarq85gmailcomNoch keine Bewertungen

- PAT Iflex5 Parte003Dokument2 SeitenPAT Iflex5 Parte003lecuellarq85gmailcomNoch keine Bewertungen

- Example 16-5. Second-Order MFB Band-Pass Filter With F 1 KHZDokument1 SeiteExample 16-5. Second-Order MFB Band-Pass Filter With F 1 KHZlecuellarq85gmailcomNoch keine Bewertungen

- Op Amps37Dokument1 SeiteOp Amps37lecuellarq85gmailcomNoch keine Bewertungen

- PAT Iflex5 Parte005Dokument2 SeitenPAT Iflex5 Parte005lecuellarq85gmailcomNoch keine Bewertungen

- Notice: Service Manual iFLEX5Dokument2 SeitenNotice: Service Manual iFLEX5lecuellarq85gmailcomNoch keine Bewertungen

- Op Amps36Dokument1 SeiteOp Amps36lecuellarq85gmailcomNoch keine Bewertungen

- Example 16-6. Fourth-Order Butterworth Band-Pass FilterDokument1 SeiteExample 16-6. Fourth-Order Butterworth Band-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- F 10 KHZ 1.036 9.653 KHZ F 10 KHZ 1.036 10.36 KHZ: Filter 1: Filter 2Dokument1 SeiteF 10 KHZ 1.036 9.653 KHZ F 10 KHZ 1.036 10.36 KHZ: Filter 1: Filter 2lecuellarq85gmailcomNoch keine Bewertungen

- 16.5.1.1 Sallen-Key TopologyDokument1 Seite16.5.1.1 Sallen-Key Topologylecuellarq85gmailcomNoch keine Bewertungen

- 16.5.1.2 Multiple Feedback Topology: Figure 16-34. MFB Band-PassDokument1 Seite16.5.1.2 Multiple Feedback Topology: Figure 16-34. MFB Band-Passlecuellarq85gmailcomNoch keine Bewertungen

- Second Filter: R 1 2 F A C 1 2 10 HZ 0.756 100 10 F 2.105 KDokument1 SeiteSecond Filter: R 1 2 F A C 1 2 10 HZ 0.756 100 10 F 2.105 Klecuellarq85gmailcomNoch keine Bewertungen

- Low-Pass to Band-Pass Filter TransitionDokument1 SeiteLow-Pass to Band-Pass Filter Transitionlecuellarq85gmailcomNoch keine Bewertungen

- A C C A 2C C R CC B 2C C R CC: High-Pass Filter DesignDokument26 SeitenA C C A 2C C R CC B 2C C R CC: High-Pass Filter Designlecuellarq85gmailcomNoch keine Bewertungen

- 16.5.1 Second-Order Band-Pass Filter: A(s) A 1 S 1 S 1 SDokument1 Seite16.5.1 Second-Order Band-Pass Filter: A(s) A 1 S 1 S 1 Slecuellarq85gmailcomNoch keine Bewertungen

- First-Order High-Pass Filter Circuit Diagrams and Transfer FunctionsDokument1 SeiteFirst-Order High-Pass Filter Circuit Diagrams and Transfer Functionslecuellarq85gmailcomNoch keine Bewertungen

- 16.4.2.2 Multiple Feedback Topology: Figure 16-29. Second-Order MFB High-Pass FilterDokument25 Seiten16.4.2.2 Multiple Feedback Topology: Figure 16-29. Second-Order MFB High-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- Second Filter: Figure 16-21. Second-Order Unity-Gain Sallen-Key Low-Pass FilterDokument1 SeiteSecond Filter: Figure 16-21. Second-Order Unity-Gain Sallen-Key Low-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- Op Amps22Dokument24 SeitenOp Amps22lecuellarq85gmailcomNoch keine Bewertungen

- Adjustable second-order low-pass filter transfer function and coefficientsDokument1 SeiteAdjustable second-order low-pass filter transfer function and coefficientslecuellarq85gmailcomNoch keine Bewertungen

- Figure 16-24. Developing The Gain Response of A High-Pass FilterDokument21 SeitenFigure 16-24. Developing The Gain Response of A High-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- C C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass FilterDokument1 SeiteC C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- Figure 16-15. General Sallen-Key Low-Pass Filter: A(s) A 1 C R R 1 A R C S R R C C SDokument1 SeiteFigure 16-15. General Sallen-Key Low-Pass Filter: A(s) A 1 C R R 1 A R C S R R C C Slecuellarq85gmailcomNoch keine Bewertungen

- 16.4 High-Pass Filter Design: Figure 16-22. Fifth-Order Unity-Gain Butterworth Low-Pass FilterDokument1 Seite16.4 High-Pass Filter Design: Figure 16-22. Fifth-Order Unity-Gain Butterworth Low-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- C C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass FilterDokument1 SeiteC C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass Filterlecuellarq85gmailcomNoch keine Bewertungen

- Op Amps13 PDFDokument1 SeiteOp Amps13 PDFlecuellarq85gmailcomNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- CMMP AS M3 HW - 2012 03 - 760322g1 PDFDokument112 SeitenCMMP AS M3 HW - 2012 03 - 760322g1 PDFViick MartinezNoch keine Bewertungen

- Filter overview and capacities for John Deere 7030 tractorsDokument2 SeitenFilter overview and capacities for John Deere 7030 tractorsАндрій ДзядевичNoch keine Bewertungen

- 'Identifying Basic Hand Tools and Test Equipment: General ClassificationDokument15 Seiten'Identifying Basic Hand Tools and Test Equipment: General ClassificationGaming AmbinNoch keine Bewertungen

- AWD60A User's ManualDokument32 SeitenAWD60A User's Manualbulacanhomesite100% (1)

- Motoweld SR350 ManualDokument101 SeitenMotoweld SR350 Manualouyangxin1991Noch keine Bewertungen

- MX 10-20KVA 31 (1) - 044304.pdf-030346Dokument4 SeitenMX 10-20KVA 31 (1) - 044304.pdf-030346Salim Abi zeidNoch keine Bewertungen

- MC56F8013Dokument126 SeitenMC56F8013Asad AhmedNoch keine Bewertungen

- Severe Duty Water Cannon Styles 3491 & 3492 Electric & Hydraulic Disassembly/Assembly Service Repair Procedure Australian OnlyDokument16 SeitenSevere Duty Water Cannon Styles 3491 & 3492 Electric & Hydraulic Disassembly/Assembly Service Repair Procedure Australian OnlyJL Z AvilesNoch keine Bewertungen

- Postflood Restartprocedure HOFFMAN LAMSONDokument1 SeitePostflood Restartprocedure HOFFMAN LAMSONLuis Fernando BravoNoch keine Bewertungen

- Bobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFDokument29 SeitenBobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFjnfksmemms0% (1)

- Mercedes W245 Owner's ManualDokument262 SeitenMercedes W245 Owner's Manualgelu uNoch keine Bewertungen

- Automatic Straightening Machine From Coil: The History of InnovationDokument5 SeitenAutomatic Straightening Machine From Coil: The History of InnovationLuiz HenriqueNoch keine Bewertungen

- Marzo 2022 plan Mar codigos y descripciones de piezasDokument11 SeitenMarzo 2022 plan Mar codigos y descripciones de piezasGuadaLuphe FLoorezzNoch keine Bewertungen

- 2010 Ford Pickup SVT RaptorDokument115 Seiten2010 Ford Pickup SVT RaptorMiguel Quema100% (1)

- Practical Physics (Part-II)Dokument66 SeitenPractical Physics (Part-II)Raju SinghNoch keine Bewertungen

- Physical Transmission MediaDokument47 SeitenPhysical Transmission MediaabdulazizNoch keine Bewertungen

- P Series Strain GaugesDokument1 SeiteP Series Strain Gaugesjbmune6683Noch keine Bewertungen

- Supercap Leveler PDFDokument11 SeitenSupercap Leveler PDFCazimir BostanNoch keine Bewertungen

- ANSI CodesDokument12 SeitenANSI CodesmgkvprNoch keine Bewertungen

- XQ500 Spec SheetDokument4 SeitenXQ500 Spec Sheetvbazan5299100% (1)

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Dokument3 SeitenASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Andres SilveyraNoch keine Bewertungen

- ELE3-18 MostUpdated 04052022Dokument43 SeitenELE3-18 MostUpdated 04052022葉朗Noch keine Bewertungen

- 6 BLP Spesifikasi Teknis NOC 14920Dokument3 Seiten6 BLP Spesifikasi Teknis NOC 14920Ka BudiKaNoch keine Bewertungen

- Binzel Gorilniki Robo enDokument116 SeitenBinzel Gorilniki Robo enalessia olgiatiNoch keine Bewertungen

- HyundaiDokument11 SeitenHyundaiSebastian BryceNoch keine Bewertungen

- Mpi Unit 1Dokument22 SeitenMpi Unit 1sree ramyaNoch keine Bewertungen

- LT Cable ScheduleDokument3 SeitenLT Cable ScheduleSaquib Khan100% (2)

- CatioLift Technical InformationDokument9 SeitenCatioLift Technical InformationNazihCosmetics0% (1)

- Bipolar Forceps 3-3 - 8in CrvreuseDokument4 SeitenBipolar Forceps 3-3 - 8in CrvreuseSalma El MamouniNoch keine Bewertungen

- 6113 e enDokument28 Seiten6113 e enPenyair SufiNoch keine Bewertungen