Beruflich Dokumente

Kultur Dokumente

Analogy

Hochgeladen von

Tony NarzaryCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Analogy

Hochgeladen von

Tony NarzaryCopyright:

Verfügbare Formate

Analogy between Stirling Engine and Petrol Engine

Stirling Engine Petrol Engine

Cycle Stirling Cycle Otto Cycle

Type External Combustion Internal Combustion Engine

Engine

Regenerator Required Not Required

Heat Exchangers Required Not Required

Type of Fuel Doesn’t Matter Only Petrol can be used

Vibrations Little or no vibrations More vibrations due to explosions during

combustion

Valves Not Required Required

Start Up Time Needs warm up time It can start instantaneously

Effect on Largely effected in No such influence

efficiency with Arid/Hot areas as it is

climatic difficult to maintain large

condition temperature difference in

hot and cold end

Pressurizing of Pressurized Fuel(He, N, During Compression Stroke, 100-200psi

Working Fuel Air) increases Efficiency

Efficiency 15-30% for small engines 25-50%(modern engines)

Ignition Not Required Required

Firing Order Not Required Required For Multiple Cylinder Engine

Configuration Alpha, Beta, Gamma V Type, Flat, Inline, Rotary

style

Power to weight Low High

ratio

Operation Style Four Cycle Four Stroke, Two Stroke

Power Delivery Constant power delivery Can be accelerated and decelerated

makes it difficult to be used

in automobiles

High-strength steel or a Cast iron and Aluminium alloy

Material used ceramic composite material

such as silicon carbide (SiC)

Maximum 25KW, Built by Ohio State 1,103 kW (Bugatti Veyron, W Type engine)

Power Recorded University

Till Date

Capability to Yes, Cryocoolers used in No

work in space applications

cryogenic

condition

Operating Hot side Temperature 300 25000C during combustion

Temperature °C. Cold-

side temperature is 25 °C.

Applications Variety of applications from Mostly limited to automobiles

space applications to

coolers

The amount of power an engine can produce is proportional to the cylinder pressure.

With a traditional Stirling this is usually less than 15 psi. It means a pretty big piston is

needed.

We could reduce this by pumping the system up to a higher pressure and by using a

light gas as the working fluid. We can therefore maintain helium at greater than

atmospheric pressure, which would mean we need high pressure seals to contain a gas

traditionally used for leak detection, because it is good at slipping thru the tiniest of

pinholes.

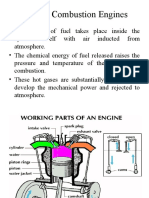

Internal Combustion Engine

Cylinder pressure- 40+ bar

Piston Area - 0.00193548 m2

Steam engine,

Cylinder pressure -10.13 bar

Piston Area-0.00774192m2

Stirling engine

Cylinder pressure -Less than 1 bar

Piston Area - 0.0774192m2

Displacer requires even more volume than the power piston

The chief advantage of internal combustion engines over external combustion engines is

the fact that they do not need a heat exchanger to transfer heat to the working fluid.

This GREATLY reduces the size, weight, and cost of an internal combustion engine of a

given power output (vs an external combustion engine). Because of this, internal

combustion engines are better suited for vehicle use and other situations where

physical size and weight are important.

Das könnte Ihnen auch gefallen

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- 2 Power ProducingDokument17 Seiten2 Power ProducingShashank AgrawalNoch keine Bewertungen

- 2023 - AMM - Chap02 - Engine & Tractors IDokument29 Seiten2023 - AMM - Chap02 - Engine & Tractors Itrisha.ara31Noch keine Bewertungen

- Ic Engines-Bme Ae&iDokument53 SeitenIc Engines-Bme Ae&iAshitaNoch keine Bewertungen

- Chapter 3Dokument29 SeitenChapter 3Hasif EnazNoch keine Bewertungen

- Internal Combustion EnginesDokument19 SeitenInternal Combustion EnginesSagar BhargavNoch keine Bewertungen

- Engine Firing OrderDokument6 SeitenEngine Firing Orderbobby aldave0% (1)

- EnE 250 Air Quality Management and Pollution Control Lecture 02 - 3 APC Mobile Sources Aug 2015 v2Dokument117 SeitenEnE 250 Air Quality Management and Pollution Control Lecture 02 - 3 APC Mobile Sources Aug 2015 v2Alexis Bryan RiveraNoch keine Bewertungen

- Combustion in CI Engine FDokument45 SeitenCombustion in CI Engine Fmahmudul adilNoch keine Bewertungen

- Power PlantDokument18 SeitenPower PlantIlichs ChávezNoch keine Bewertungen

- Internal Combustion EnginesDokument33 SeitenInternal Combustion EnginesDeepikaNoch keine Bewertungen

- 6CTAA-C245 Publicity Page 12.15Dokument2 Seiten6CTAA-C245 Publicity Page 12.15Handrawan Han-han SugiantoNoch keine Bewertungen

- FUEL Cycle in Diesel EngineDokument56 SeitenFUEL Cycle in Diesel Enginemajid aliNoch keine Bewertungen

- Gas Power Cycles: Lecture # 10Dokument9 SeitenGas Power Cycles: Lecture # 10zabidullahNoch keine Bewertungen

- Final PPT On Gas TurbinesDokument31 SeitenFinal PPT On Gas TurbinesKRISHNA KUMARI100% (2)

- Different Types of ENGINEDokument31 SeitenDifferent Types of ENGINEKarnal 0388Noch keine Bewertungen

- 0engine, Pranit GaikarDokument86 Seiten0engine, Pranit Gaikaranushkat7347Noch keine Bewertungen

- Assignment No. 1Dokument22 SeitenAssignment No. 1ahsan aliNoch keine Bewertungen

- AEMSDokument28 SeitenAEMSGARVIT SRIVASTAVANoch keine Bewertungen

- Unit 3 IC ENGINESDokument107 SeitenUnit 3 IC ENGINESSachidhanandam MNoch keine Bewertungen

- Engine Spec-AS6500-H5706Dokument2 SeitenEngine Spec-AS6500-H5706BradNoch keine Bewertungen

- IC Engines-ClassificationDokument21 SeitenIC Engines-ClassificationChintu Santhu0% (1)

- 4R1040TA-Engine 82.5kVA 50Hz Rev00-1Dokument3 Seiten4R1040TA-Engine 82.5kVA 50Hz Rev00-1Suresh SekharNoch keine Bewertungen

- A 60Hz Rev00-2Dokument3 SeitenA 60Hz Rev00-2D. Nanda KishoreNoch keine Bewertungen

- IC Engines IIDokument57 SeitenIC Engines IISahil SINGHNoch keine Bewertungen

- Engines: Prepared By: M.M.M MubarizDokument13 SeitenEngines: Prepared By: M.M.M MubarizMahike TeslaNoch keine Bewertungen

- 4R1040T-Engine 62.5kVA 50Hz Rev00-1Dokument3 Seiten4R1040T-Engine 62.5kVA 50Hz Rev00-1Mohan BabuNoch keine Bewertungen

- V1 Internal Combustion EngineDokument60 SeitenV1 Internal Combustion Enginemohammad umairNoch keine Bewertungen

- Unit4 - Part B ICE Power PlantDokument16 SeitenUnit4 - Part B ICE Power PlantahkumbharNoch keine Bewertungen

- Ic-Mid Exam N SolutnDokument9 SeitenIc-Mid Exam N SolutnFasilNoch keine Bewertungen

- 3885019 (2)Dokument2 Seiten3885019 (2)acere18100% (2)

- 4K1080TA-Engine 125kVA 50Hz Rev00Dokument3 Seiten4K1080TA-Engine 125kVA 50Hz Rev00CarlosNoch keine Bewertungen

- Engine Spec-AS6500-H5705Dokument2 SeitenEngine Spec-AS6500-H5705BradNoch keine Bewertungen

- Quasi Turbine 140505201837 Phpapp01Dokument16 SeitenQuasi Turbine 140505201837 Phpapp01pravesh singh100% (1)

- IC Engines Units-1 and 2 Lecture-2 Basic Components and Working Principles of IC EnginesDokument47 SeitenIC Engines Units-1 and 2 Lecture-2 Basic Components and Working Principles of IC EnginesRaviShankarDuggiralaNoch keine Bewertungen

- Unit IiDokument89 SeitenUnit IiDevkriti SharmaNoch keine Bewertungen

- AGG Engine Spec 0825kva AS25000-K0066Dokument2 SeitenAGG Engine Spec 0825kva AS25000-K0066BradNoch keine Bewertungen

- Richa NandaDokument24 SeitenRicha NandaRAJ DEO SINGHNoch keine Bewertungen

- Atd Ci Engine Combustion Phenomenon Unit-3Dokument34 SeitenAtd Ci Engine Combustion Phenomenon Unit-3Aryan YadavNoch keine Bewertungen

- Working of Four Stroke and Two Stroke EngineDokument14 SeitenWorking of Four Stroke and Two Stroke EngineSunil DhankharNoch keine Bewertungen

- Lecture IC Engines 5Dokument9 SeitenLecture IC Engines 5engineeringdesignNoch keine Bewertungen

- An Unending Search For Best Artificial Horse .. This Search Is A Biological Need of HumansDokument24 SeitenAn Unending Search For Best Artificial Horse .. This Search Is A Biological Need of HumansShreyansh ShuklaNoch keine Bewertungen

- Engine Spec-AS25000-K0083Dokument2 SeitenEngine Spec-AS25000-K0083BradNoch keine Bewertungen

- 4BTA-C105 Publicity Page 8.22Dokument2 Seiten4BTA-C105 Publicity Page 8.22AsteriaA.SusantoNoch keine Bewertungen

- Fuel Properties and Use of Hydrogen I.C.enginesDokument95 SeitenFuel Properties and Use of Hydrogen I.C.enginesSiemensNoch keine Bewertungen

- Engine Spec-AS8900-DBL5736Dokument2 SeitenEngine Spec-AS8900-DBL5736BradNoch keine Bewertungen

- 4 Diesel PropulsionDokument52 Seiten4 Diesel Propulsionsudhanshu22kumar22Noch keine Bewertungen

- IC EngineDokument21 SeitenIC EngineArvind KatyayanNoch keine Bewertungen

- Engine Spec-AS4300-H5702Dokument2 SeitenEngine Spec-AS4300-H5702BradNoch keine Bewertungen

- RCV Flyer DF Engines A4 Size Air CooledDokument2 SeitenRCV Flyer DF Engines A4 Size Air CooledJohn WickNoch keine Bewertungen

- Air Standard CyclesDokument45 SeitenAir Standard CyclesVedant ChoudharyNoch keine Bewertungen

- C.S.I Institute of Technology, Thovalai: Department of Mechanical Engineering Semester: 5Dokument32 SeitenC.S.I Institute of Technology, Thovalai: Department of Mechanical Engineering Semester: 5samuelben87Noch keine Bewertungen

- ClasificationDokument30 SeitenClasificationSanjay SwainNoch keine Bewertungen

- 6BTAA-C190 Publicity Page 8.22Dokument2 Seiten6BTAA-C190 Publicity Page 8.22Handrawan Han-han SugiantoNoch keine Bewertungen

- 2 CI Engine Normal and Abnormal Combustion-KnockingDokument9 Seiten2 CI Engine Normal and Abnormal Combustion-Knockingselvaraj9223Noch keine Bewertungen

- What Is Royal EnfieldDokument2 SeitenWhat Is Royal EnfieldSathesh SakthiNoch keine Bewertungen

- 1.internal Combustion EngineDokument40 Seiten1.internal Combustion Enginesujit kcNoch keine Bewertungen

- Thermodynamic Cycles: Carlos Silva November 18 2009Dokument29 SeitenThermodynamic Cycles: Carlos Silva November 18 2009Tahir JamalNoch keine Bewertungen

- Comparison of Four Stroke and Two Stroke Cycle EnginesDokument10 SeitenComparison of Four Stroke and Two Stroke Cycle EnginesMoiz zararNoch keine Bewertungen

- IC Engine Part2Dokument25 SeitenIC Engine Part2Venkatesh KabraNoch keine Bewertungen

- (27-6-2) NPTEL - CryocoolersDokument35 Seiten(27-6-2) NPTEL - CryocoolersThermal_EngineerNoch keine Bewertungen

- 0 - 40 Must Solve Logic Based DI Sets For CAT PDFDokument5 Seiten0 - 40 Must Solve Logic Based DI Sets For CAT PDFTony NarzaryNoch keine Bewertungen

- 10 1 1 167 3624Dokument26 Seiten10 1 1 167 3624mongrel73Noch keine Bewertungen

- Business Analytics InterviewsDokument1 SeiteBusiness Analytics InterviewsTony NarzaryNoch keine Bewertungen

- R Programming CheatsheetDokument6 SeitenR Programming CheatsheetAnand PrasadNoch keine Bewertungen

- Tricks Graphs For Isi Exam PDFDokument44 SeitenTricks Graphs For Isi Exam PDFTony NarzaryNoch keine Bewertungen

- Stirling Simulation PDFDokument7 SeitenStirling Simulation PDFTony NarzaryNoch keine Bewertungen

- Reviewpaper NewDokument5 SeitenReviewpaper NewTony NarzaryNoch keine Bewertungen

- 0 PDFDokument19 Seiten0 PDFmonsterspyNoch keine Bewertungen

- SchmidtDokument8 SeitenSchmidtEduardo AntonioNoch keine Bewertungen

- C15 Cooling System OperationDokument4 SeitenC15 Cooling System OperationTakaNoch keine Bewertungen

- Gas CompressorDokument4 SeitenGas CompressorTitus FelixNoch keine Bewertungen

- Project Ip SampleDokument19 SeitenProject Ip SampleNori Jayne Cosa RubisNoch keine Bewertungen

- Piping CalculationsDokument19 SeitenPiping CalculationskakoullisgNoch keine Bewertungen

- Assignment 4Dokument1 SeiteAssignment 4G.Chaitanya KiranNoch keine Bewertungen

- ARABACA - XDD - Module 3 Activity No. 4 - REFSYSDokument4 SeitenARABACA - XDD - Module 3 Activity No. 4 - REFSYSXAVIERDOMINIC ARABACANoch keine Bewertungen

- LOPA Group 3 - Batac, Benabdussalam, Gathercole, Maravilla, Opena PDFDokument2 SeitenLOPA Group 3 - Batac, Benabdussalam, Gathercole, Maravilla, Opena PDFChristelle Paula C. BatacNoch keine Bewertungen

- Duct Static CalculationDokument1 SeiteDuct Static Calculationapi-26699613Noch keine Bewertungen

- Technical Seminar Solar PondDokument17 SeitenTechnical Seminar Solar PondSumanth ReddyNoch keine Bewertungen

- New Microsoft Office Word Document PDFDokument2 SeitenNew Microsoft Office Word Document PDFRoshan ShejwalNoch keine Bewertungen

- VCR SeminarDokument19 SeitenVCR SeminarJyothi Reddy100% (2)

- Agrest-Berkes Biomass Technologies Proviso Rio en InglesDokument27 SeitenAgrest-Berkes Biomass Technologies Proviso Rio en InglesJuan GomezNoch keine Bewertungen

- KKS Designation SystemDokument19 SeitenKKS Designation SystemTamer Ahmed SalemNoch keine Bewertungen

- Diesel EngineDokument32 SeitenDiesel EngineWira SentanuNoch keine Bewertungen

- Process Safety KPIsDokument2 SeitenProcess Safety KPIssheerazali100% (1)

- Taco 1400Dokument4 SeitenTaco 1400sas999333Noch keine Bewertungen

- Bci - 750gpm@250psi PDFDokument2 SeitenBci - 750gpm@250psi PDFSergio ZegarraNoch keine Bewertungen

- F&G Layout Rev 0Dokument1 SeiteF&G Layout Rev 0Motaz Hashim100% (1)

- P&IDDokument23 SeitenP&IDmagarciaprieto100% (2)

- 0.romania New 6 Projects Prezentare Millennium (22 01 2020) enDokument32 Seiten0.romania New 6 Projects Prezentare Millennium (22 01 2020) enGheorghe CiobanuNoch keine Bewertungen

- Dellorto Quick Guide Tom BarthDokument4 SeitenDellorto Quick Guide Tom BarthGonçalo PequenoNoch keine Bewertungen

- Aisi 2012Dokument33 SeitenAisi 2012suronocaturatmojoNoch keine Bewertungen

- 5kw Off Grid System To Eng. Morris PDFDokument16 Seiten5kw Off Grid System To Eng. Morris PDFMorris BahgatNoch keine Bewertungen

- 01 - Hydroelectric PPDokument5 Seiten01 - Hydroelectric PPSweta MorabiyaNoch keine Bewertungen

- CondenserDokument37 SeitenCondenserGaurav SrivastavaNoch keine Bewertungen

- Types of TurbinesDokument7 SeitenTypes of Turbinestoufik khedim100% (1)

- 22 April Optimised Pump Solutions For HVAC Application - CPD Certified - QAndA ReportDokument16 Seiten22 April Optimised Pump Solutions For HVAC Application - CPD Certified - QAndA ReportmarrukhjNoch keine Bewertungen

- WS-01 - Flow SwitchDokument1 SeiteWS-01 - Flow SwitchSHARAB IMTIAZNoch keine Bewertungen

- Ione 1B02 SP PR 0002Dokument8 SeitenIone 1B02 SP PR 0002Peruri ManoharNoch keine Bewertungen

- Ps Compressed Air ArticlesDokument59 SeitenPs Compressed Air ArticlesFahad Khan100% (1)