Beruflich Dokumente

Kultur Dokumente

Example Risk Assessment For Cold Storage Warehousing: Setting The Scene

Hochgeladen von

suremessyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Example Risk Assessment For Cold Storage Warehousing: Setting The Scene

Hochgeladen von

suremessyCopyright:

Verfügbare Formate

Health and Safety

Executive

Example risk assessment for cold storage warehousing

Setting the scene ■■ walked around all the areas where the staff, responsible for each of the actions that were needed,

contractors, customers and others may go, noting and by when each action should be done. He wrote

Frozen Foods Ltd provide cold storage and distribution things that might pose a risk and taking HSE’s this down and, when each action was completed,

facilities (at temperatures between -18° and -30° C) guidance into account; ticked if off and recorded the date. The manager told

at three locations. They serve customers of all sizes ■■ talked through the issues with the safety representative, staff about the risk assessment at a team meeting. The

across a variety of sectors. Each location has 10 000 including how knowledge of risks and risk controls Eastern European member of staff who spoke good

pallet spaces, uses fixed and mobile racking, and could effectively be communicated to the two staff English translated for his countrymen, and checked

averages a throughput of 2500 pallets a week. members who did not speak good English, and on that they understood it. The manager pinned up a copy

health and safety training for agency staff; of the risk assessment in the staff room, and made it

Twenty people are employed in the warehouses, ■■ talked to the two company first-aiders, to see if the part of the induction process for new staff.

working a variety of shifts. Three members of staff are health surveillance questionnaires they compile and

from an Eastern European country; only one speaks distribute have thrown up any additional issues that 5 The manager decided to review and update the

good English. At busy times, temporary staff from an need to be considered; assessment at least once a year or at any time when

employment agency may also be employed. ■■ talked to supervisors and other members of staff major changes to the workplace occurred, such as the

to learn from their detailed knowledge of particular introduction of a new plant or process.

The site manager did the risk assessment, which jobs and areas and to discuss whether safe working

covers goods inward from the gate to the cold store, procedures should be developed for certain jobs; and

their storage and their despatch. ■■ looked at the accident book to gather information on Important reminder

past problems.

How was the risk assessment done? This example risk assessment shows the kind of

2 The manager then wrote down who could be harmed approach a small business might take. Use it as a

The manager followed the guidance in Five steps to risk by the hazards and how. guide to think through some of the hazards in your

assessment (www.hse.gov.uk/pubns/indg163.pdf). business and the steps you need to take to control

3 For each hazard, the manager wrote down what the risks. Please note that it is not a generic risk

1 To identify the hazards, the manager: controls, if any, were in place to manage these assessment that you can just put your company

hazards, and compared the controls to the good name on and adopt wholesale without any thought.

■■ looked at HSE’s web pages for free health and safety practice guidance on the HSE website. Where he did This would not satisfy the law – and would not be

advice and guidance for the warehousing industry not consider existing controls good enough, he wrote effective in protecting people.

(www.hse.gov.uk/warehousing/index.htm), and at down what else was needed to control the risk.

HSG76 Warehousing and storage: A guide to Every business is different – you need to think

health and safety (available from HSE Books, 4 The manager discussed the findings with the safety through the hazards and controls required in your

www.hsebooks.com/ or 01787 881165), particularly representative. Then, to implement the findings of business for yourself.

the chapter on temperature controlled storage; the risk assessment, the manager decided who was

Example risk assessment: Cold storage warehousing 1 of 6 pages

Health and Safety

Executive

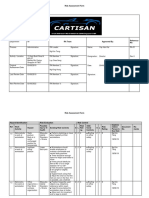

Company name: Frozen Foods Ltd Date of risk assessment: 1/10/07

What are the Who might be harmed and What are you already doing? What further action is Action by Action by Done

hazards? how? necessary? whom? when?

Extreme cold Employees and others may ■■ Access to the store restricted to authorised, trained persons only. ■■ Check instructions remain Supervisors 04/10/07 First check

Accidental lock-in suffer death or serious injury ■■ ‘No entry’ signs clearly posted. clearly visible. done

in the cold store from prolonged exposure to cold ■■ Emergency exit provided, door fitted with strip heaters to ensure it does 04/10/07

temperatures if accidentally not freeze.

locked in the cold store. ■■ Emergency lighting provided (mains powered, battery back-up). ■■ Periodic checks to ensure Supervisors 04/10/07 02/10/07

■■ Daily check on emergency exit door to ensure it is not frozen shut. clear access to emergency exit

■■ Emergency exit door instructions posted on illuminated board by exit. maintained, and that door is

■■ Two trapped worker alarms (battery operated, mains back-up) next to both operational.

exits.

■■ Supervisor ensures thorough check of building before it is locked.

■■ Alarms and emergency lighting regularly tested/maintained by competent

person.

Extreme cold Employees may suffer ill health ■■ Pre-employment health screening by a responsible person. ■■ Staff reminded to regularly Manager 04/10/07 04/10/07

Working in a sub- or injury (eg frostbite) from ■■ Regular health surveillance by trained, responsible persons. check their PPE for wear and

zero environment prolonged exposure to sub zero ■■ System for referring to an occupational health professional staff whose tear, to ensure it remains

temperatures (particularly those health, following surveillance, is possibly being affected by cold work. effective.

with certain pre-existing medical ■■ Staff trained in risks of cold store working and to recognise symptoms of

conditions). Extreme cold may cold stress.

also lead to gradual loss of ■■ The right personal protective equipment (according to advice in HSE

awareness of risk. guidance and suppliers’ recommendations) issued and staff trained in its

use.

■■ Supervisors ensure PPE is worn.

■■ Only authorised, trained staff allowed in the cold store.

■■ Staff have regular warm-up breaks.

■■ Drying facilities for wet PPE.

Example risk assessment: Cold storage warehousing 2 of 6 pages

Health and Safety

Executive

What are the Who might be harmed and What are you already doing? What further action is Action by Action by Done

hazards? how? necessary? whom? when?

Accidental Employees and others ■■ Extraction and ventilation plant installed. ■■ Ensure that any work on Manager 04/10/07 04/10/07

release of may suffer fatal respiratory ■■ System designed as per industry practice. the system where there is a

Group 2 irritation following exposure to ■■ Written scheme of examination for all refrigeration plant, including vapour potential for ammonia release

refrigerant ammonia. Exposure to even low detectors. is done by at least two people

(ammonia) concentrations can cause severe ■■ Only authorised persons allowed in plant room and room locked when not (second person to help in an

eye and throat irritation. in use. emergency).

■■ Plant examined as per written scheme by a competent person.

■■ Plant maintained by a competent person. ■■ Set date for rehearsal of Manager 04/10/07 04/10/07

■■ High-hazard maintenance jobs (eg oil draining) are identified and done procedures in the event of an

by competent people, such as qualified refrigeration specialists, following emergency alarm going off.

safe systems of work and using the correct equipment.

■■ Staff trained in the risks of ammonia and its effect on health. ■■ Monthly checks on vapour Supervisors 04/10/07 02/10/07

■■ Emergency plan for ammonia release agreed, including victim rescue detectors and alarms.

policy and policy for neighbouring properties, and discussed with local fire

service. ■■ Shower to be checked weekly. Supervisors 04/10/07 04/10/07

■■ Staff trained in emergency plan.

■■ Vapour detectors near likely leakage points activate alarm and emergency

extraction if workplace exposure limit (25 parts per million) reached.

■■ Water shower nearby for those exposed to an ammonia spray.

■■ Windsock to show wind direction in event of release (staff can gather

upwind of leak).

Workplace Staff and visitors may suffer ■■ Pedestrians kept apart from moving vehicles by yellow lines, railings and ■■ Mark out ‘safe area’ for visiting Manager to 15/11/07 25/10/07

transport life-threatening injuries, such as marked walkways. drivers during loading and arrange with

Vehicle movement fractures and internal damage, if ■■ Road surfaces in good condition. unloading of their vehicle. facilities team

in the yard and they are struck by a vehicle. ■■ Measures in place to minimise reversing on site.

the loading bay ■■ Reversing aids (mirrors) in place. ■■ Extra signage reminding Manager to 15/11/07 25/10/07

– deliveries and ■■ Hi-viz tabards and safety boots worn by all in yard/loading bay. staff/visitors not to enter site arrange with

despatch. ■■ Drivers hand in keys when vehicle parked. through the main gate, used by facilities team

■■ All visitors receive site rules and a site map. Sufficient number of trained vehicles, but to use the marked

banksmen on site, for each shift. pedestrian route.

■■ Any reversing on site that is necessary is directed by a trained banksman,

working from a safe position.

Example risk assessment: Cold storage warehousing 3 of 6 pages

Health and Safety

Executive

What are the Who might be harmed and What are you already doing? What further action is Action by Action by Done

hazards? how? necessary? whom? when?

Workplace Staff and visitors may suffer life- ■■ Walkways clearly marked. ■■ Instruct drivers not to leave Manager 04/10/07 02/10/07

transport threatening injuries if they are ■■ Good lighting throughout. keys in unattended vehicles (to

Vehicle activity in struck by forklift trucks (FLTs) ■■ Mirrors at the end of aisles. prevent unauthorised use).

the cold store or other materials handling ■■ All drivers trained and follow safe systems of work.

equipment (MHE). ■■ Vehicles selected to minimise risk.

■■ Drivers do daily pre-use vehicle checks.

■■ FLTs/MHE maintained to manufacturers’ instructions and thoroughly

examined every 6 months by competent person.

■■ Supervisors monitor driver performance.

Slips and trips Staff and others may suffer ■■ Generally good housekeeping – shrinkwrap, pallet debris, strapping ■■ Shift managers to draw up and Shift managers 14/10/07 14/10/07

injuries such as fractures if bands, spillages etc cleared away promptly. monitor ‘planned cleaning’

they slip, eg on water or oil or ■■ Entrance/exit doors regularly checked for ice and ice deposits removed. arrangements.

trip over objects such as stock ■■ Floor in good condition, any damage quickly repaired.

protruding into gangways. ■■ Pallets stored in designated area. ■■ Remind staff to keep doors Shift managers 14/10/07 14/10/07

■■ Staff wear safety shoes with a good grip. closed to help prevent ice

forming at entrances.

Falls from height Staff may suffer severe or fatal ■■ All work at height (eg retrieving dislodged pallets, stock checking) is done ■■ Reminder to supervisors to Shift managers 14/10/07 14/10/07

injuries if they fall from any by trained, authorised staff using personnel lifting equipment to a safe check that safe systems of

height. system of work. work are followed for all work

■■ Control and use of ladders policy, monitored by supervisors. at height.

■■ Climbing on racking strictly forbidden.

■■ Post signs reminding staff Manager 15/11/07 25/10/07

never to climb racking.

Manual handling Staff may get injuries or back ■■ All staff trained in safe manual handling techniques, particularly when ■■ Remind staff that roll cages Shift managers 14/10/07 14/10/07

pain from handling heavy ‘picking’ goods by hand. with defective wheels must be

objects such as pallets. ■■ All staff trained in safe use of roll cages. taken out of use for repair.

■■ Roll cages with defective wheels taken out of use until repaired.

Example risk assessment: Cold storage warehousing 4 of 6 pages

Health and Safety

Executive

What are the Who might be harmed and What are you already doing? What further action is Action by Action by Done

hazards? how? necessary? whom? when?

Falling goods Staff may suffer injuries such ■■ Shrinkwrap policy on all inbound pallets. ■■ Instruct staff to immediately Shift managers 14/10/07 14/10/07

as fractures and bruising from ■■ Policy to report broken or dislodged pallets in racking aisles. report any concerns they have

falling stock. ■■ Racking selected according to the operating temperature and is to SEMA about the condition of racking

standard. to the manager or a supervisor.

■■ Safe working load signage displayed.

■■ All racking inspected to an agreed programme, by a competent person,

and maintained as necessary.

Machinery Staff using the machine may ■■ Staff trained in use of machine. ■■ No further action needed at this

Conveyor belt for suffer injury from moving parts, ■■ Dangerous moving parts are guarded according to manufacturer’s stage.

unloading particularly where belt meets instructions, and staff do weekly check on guards.

rollers. ■■ Emergency stop buttons provided.

Pallet inverter Staff using the machine may be ■■ Machine maintained and inspected according to manufacturer’s ■■ Draw up safe working Supervisors 31/10/07 30/10/07

injured by moving parts. instructions. procedure, including for

■■ Staff trained in use of machine, including a pre-use guard check. clearing blockages, for use of

■■ When not in use, safety perimeter chain put up with a ‘No unauthorised pallet inverter.

use’ sign.

Recharging Burns or fractures as material ■■ Batteries charged in designated bay that is well ventilated. ■■ No further action at this stage.

MHE batteries ejected could injure anyone ■■ Safe system of work used.

(potential for nearby. ■■ Job done by trained, authorised staff only.

explosion)

Noise Staff may suffer discomfort and ■■ Refrigeration system, including fans, maintained in good condition ■■ No further action at this stage.

potential hearing damage if according to a planned system of work.

working in noisy areas, eg near ■■ Current work practices minimise time spent in noisy areas.

refrigeration fans.

Electricity Staff may suffer shock and ■■ Electrical installation and all equipment is inspected according to a ■■ No further action at this stage.

burns injuries from faulty planned schedule.

electrical equipment or ■■ Staff report any concerns to shift manager who will take appropriate

installation. action.

Example risk assessment: Cold storage warehousing 5 of 6 pages

Health and Safety

Executive

What are the Who might be harmed and What are you already doing? What further action is Action by Action by Done

hazards? how? necessary? whom? when?

Unfamiliarity Visitors, including contractors, ■■ Visitors to the cold store must be given appropriate PPE and accompanied ■■ Discuss with supervisors if Manager 31/10/07 29/10/07

with site risks may suffer injury or ill health by an authorised person. the permit-to-work system is

through lack of awareness of ■■ All work on site by contractors is done according to a permit-to-work operating effectively and if there

risks on site. system, monitored by supervisors. is scope to improve it.

Fire Staff trapped could suffer fatal ■■ Fire risk assessment done as at www.communities.gov.uk/fire and ■■ No further action at this stage.

injury from smoke inhalation/ necessary actions taken.

burns.

Assessment review date: 1/10/08

Example risk assessment: Cold storage warehousing 6 of 6 pages

Published by the Health and Safety Executive 11/10

Das könnte Ihnen auch gefallen

- Example Risk Assessment For A Convenience Store/newsagent: How Was The Risk Assessment Done? Setting The SceneDokument4 SeitenExample Risk Assessment For A Convenience Store/newsagent: How Was The Risk Assessment Done? Setting The SceneChristine Joy OriginalNoch keine Bewertungen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- Safety in the Chemical Laboratory and Industry: A Practical GuideVon EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNoch keine Bewertungen

- 4.2 Understanding Interested Parties NeedsDokument3 Seiten4.2 Understanding Interested Parties NeedsYen Trang Vo NhiNoch keine Bewertungen

- Engine Oil MSDSDokument7 SeitenEngine Oil MSDSSantos RexNoch keine Bewertungen

- Vehicle Inspection: Administrative Procedures & GuidelinesDokument1 SeiteVehicle Inspection: Administrative Procedures & GuidelinesAdi Mbah Rowo WibowoNoch keine Bewertungen

- Health and Safety Procedure - Hazard Identification Risk Assessment and ControlDokument6 SeitenHealth and Safety Procedure - Hazard Identification Risk Assessment and ControlMohamad Zakwan Zach ZakariaNoch keine Bewertungen

- Preventive Maintenance PlanDokument7 SeitenPreventive Maintenance PlanCuyapo Infirmary Lying-In HospitalNoch keine Bewertungen

- SOP On Handling of Critical and Non-Critical DeviationsDokument6 SeitenSOP On Handling of Critical and Non-Critical DeviationsRajnish PatilNoch keine Bewertungen

- Sop 11Dokument2 SeitenSop 11tary_nuryana100% (1)

- Revised CERT Audit ChecklistDokument15 SeitenRevised CERT Audit ChecklistSBNoch keine Bewertungen

- Save Driving ProcedureDokument4 SeitenSave Driving ProcedureM RHNoch keine Bewertungen

- Health and Safety Management Manual With Procedures ExampleDokument13 SeitenHealth and Safety Management Manual With Procedures ExampleVepxvia NadiradzeNoch keine Bewertungen

- What Is The Technical FileDokument6 SeitenWhat Is The Technical Filejohan janssensNoch keine Bewertungen

- ISO 28000 A Complete Guide - 2019 EditionVon EverandISO 28000 A Complete Guide - 2019 EditionBewertung: 4 von 5 Sternen4/5 (1)

- High Work Permit: InstructionsDokument1 SeiteHigh Work Permit: Instructionsjeas grejoyNoch keine Bewertungen

- D152: Demo of Iso 45001:2018 Document KitDokument10 SeitenD152: Demo of Iso 45001:2018 Document KitTFattahNoch keine Bewertungen

- Canteen - Risk AssessmentDokument8 SeitenCanteen - Risk Assessmentjoshisunil2Noch keine Bewertungen

- Laboratory Emergency PlanDokument35 SeitenLaboratory Emergency PlanMß WæžəəřNoch keine Bewertungen

- Final - Print Adh Lam Slit - May 6 2010Dokument22 SeitenFinal - Print Adh Lam Slit - May 6 2010Luis Miguel Blanco TovarNoch keine Bewertungen

- SOP Fire ExtinguishersDokument5 SeitenSOP Fire ExtinguishersYonatn DebebeNoch keine Bewertungen

- EHS in Pharmaceutical IndustryDokument19 SeitenEHS in Pharmaceutical IndustryARPITA MISHRANoch keine Bewertungen

- Chemical SpillDokument28 SeitenChemical Spillecoenv100% (1)

- 2) SOP-01 Handling Hazardous ChemicalDokument6 Seiten2) SOP-01 Handling Hazardous ChemicalMohd ZaeinNoch keine Bewertungen

- ISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0Dokument4 SeitenISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0asantosoNoch keine Bewertungen

- Introduction To ISO 9001 2015Dokument11 SeitenIntroduction To ISO 9001 2015chrisNoch keine Bewertungen

- ASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.Dokument11 SeitenASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.JHUPEL ABARIALNoch keine Bewertungen

- FSSC 22000 Webinar - SlidesDokument57 SeitenFSSC 22000 Webinar - SlidesFurqon HidayatullohNoch keine Bewertungen

- Summary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFDokument28 SeitenSummary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFEileen OngNoch keine Bewertungen

- Pallet Jack Safety: Wear Personal Protective EquipmentDokument2 SeitenPallet Jack Safety: Wear Personal Protective EquipmentRadhaKrishnan R100% (1)

- Amla MSDSDokument4 SeitenAmla MSDSarvind kaushikNoch keine Bewertungen

- Behavior-based safety A Clear and Concise ReferenceVon EverandBehavior-based safety A Clear and Concise ReferenceNoch keine Bewertungen

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Dokument40 SeitenGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- QA 5.15 Allergens Materials Handling General ProcedureDokument3 SeitenQA 5.15 Allergens Materials Handling General ProcedureangeldrandevNoch keine Bewertungen

- Final Extru Lam-May6 2010-1Dokument24 SeitenFinal Extru Lam-May6 2010-1Luis Miguel Blanco TovarNoch keine Bewertungen

- Bodily Fluids Spillage: Standard Operating ProcedureDokument5 SeitenBodily Fluids Spillage: Standard Operating ProcedureLinda Setya Wati100% (1)

- HSE SOP-04 HSE Hazard Identification Risk Assessment and C.Dokument6 SeitenHSE SOP-04 HSE Hazard Identification Risk Assessment and C.Imad ChaudharyNoch keine Bewertungen

- Emergency PreparednessDokument14 SeitenEmergency PreparednessV Subramanyam QCNoch keine Bewertungen

- Corrective And Preventative Action A Complete Guide - 2020 EditionVon EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNoch keine Bewertungen

- FDA Recall Procedure TemplateDokument9 SeitenFDA Recall Procedure TemplatedhafyajaaNoch keine Bewertungen

- 4 Sop General Lab 2013-07Dokument25 Seiten4 Sop General Lab 2013-07EmaNoch keine Bewertungen

- Environmental Monitoring and Control A Complete GuideVon EverandEnvironmental Monitoring and Control A Complete GuideNoch keine Bewertungen

- HACCP Food Safety System: Course Outline For Whom Other Details Related TrainingsDokument3 SeitenHACCP Food Safety System: Course Outline For Whom Other Details Related TrainingsagentrinaNoch keine Bewertungen

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDokument7 SeitenHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshNoch keine Bewertungen

- Hse Manager Interview Questions and AnswersDokument3 SeitenHse Manager Interview Questions and AnswerssureshNoch keine Bewertungen

- Food Safety and Quality Systems in Developing Countries: Volume III: Technical and Market ConsiderationsVon EverandFood Safety and Quality Systems in Developing Countries: Volume III: Technical and Market ConsiderationsNoch keine Bewertungen

- Heat Illness Prevention ProgramDokument7 SeitenHeat Illness Prevention ProgramSPIQCNoch keine Bewertungen

- Control of Work Environment: Reporters: Emie Duhaylungsod Jecris Velarde Mark Sabay-SabayDokument15 SeitenControl of Work Environment: Reporters: Emie Duhaylungsod Jecris Velarde Mark Sabay-SabayRaymond FuentesNoch keine Bewertungen

- Frequently Asked Questions About The Life-Saving RulesDokument6 SeitenFrequently Asked Questions About The Life-Saving RulesTFattahNoch keine Bewertungen

- Threat And Risk Assessment A Complete Guide - 2020 EditionVon EverandThreat And Risk Assessment A Complete Guide - 2020 EditionNoch keine Bewertungen

- NFPA Label and GHS PictogramsDokument2 SeitenNFPA Label and GHS PictogramsPrakharNoch keine Bewertungen

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDokument5 SeitenDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelNoch keine Bewertungen

- Funding Application Form: Details of ParticipantDokument1 SeiteFunding Application Form: Details of ParticipantsuremessyNoch keine Bewertungen

- TT6 R 3Dokument1 SeiteTT6 R 3suremessyNoch keine Bewertungen

- Application For Renovation PermitDokument3 SeitenApplication For Renovation PermitsuremessyNoch keine Bewertungen

- Warwick Arts Centre - Risk Assessment Form Area: Toilets Responsible Staff: House ManagerDokument3 SeitenWarwick Arts Centre - Risk Assessment Form Area: Toilets Responsible Staff: House ManagersuremessyNoch keine Bewertungen

- Duo PDFDokument76 SeitenDuo PDFPaul JimNoch keine Bewertungen

- QCDokument1 SeiteQCsuremessyNoch keine Bewertungen

- FACheckDokument1 SeiteFAChecksuremessyNoch keine Bewertungen

- D1 - Different Spaces Between Sets of WindowsDokument2 SeitenD1 - Different Spaces Between Sets of WindowssuremessyNoch keine Bewertungen

- 222, Phetchaburi Road - Thanon Phetchaburi, Ratchathewi, Bangkok 10400, ThailandDokument2 Seiten222, Phetchaburi Road - Thanon Phetchaburi, Ratchathewi, Bangkok 10400, ThailandsuremessyNoch keine Bewertungen

- PF2501/PF2102 Tutorial 1: Ice-Cream Stick Challenge: Table 1 Criteria For Assessing Final StructureDokument2 SeitenPF2501/PF2102 Tutorial 1: Ice-Cream Stick Challenge: Table 1 Criteria For Assessing Final StructuresuremessyNoch keine Bewertungen

- Safe Work Procedure 04 Terrorism: Approved byDokument1 SeiteSafe Work Procedure 04 Terrorism: Approved bysuremessyNoch keine Bewertungen

- 09-Parkland@Hougang (Reno Guidelines) PDFDokument11 Seiten09-Parkland@Hougang (Reno Guidelines) PDFsuremessyNoch keine Bewertungen

- First Aid ChecklistDokument1 SeiteFirst Aid Checklistsuremessy100% (1)

- Facility Inspection ChecklistDokument10 SeitenFacility Inspection Checklistvas777100% (1)

- Mast Safe Work Procedure: 92 FlooringDokument2 SeitenMast Safe Work Procedure: 92 FlooringsuremessyNoch keine Bewertungen

- Welcome To The Safety and Health Induction Training by The Department of BuildingDokument24 SeitenWelcome To The Safety and Health Induction Training by The Department of BuildingsuremessyNoch keine Bewertungen

- Ch01 The Tourism BusinessDokument25 SeitenCh01 The Tourism BusinesssuremessyNoch keine Bewertungen

- Technical Advisory For Forklift (SWP) PDFDokument5 SeitenTechnical Advisory For Forklift (SWP) PDFsuremessyNoch keine Bewertungen

- Method Statement - WeldingDokument2 SeitenMethod Statement - WeldingsuremessyNoch keine Bewertungen

- Top 20 Concept For Leadership SuccessDokument5 SeitenTop 20 Concept For Leadership SuccesssuremessyNoch keine Bewertungen

- AnnexesDokument15 SeitenAnnexessuremessyNoch keine Bewertungen

- Panel Installation PDFDokument18 SeitenPanel Installation PDFUtku Can KılıçNoch keine Bewertungen

- Risk Assessment FormDokument9 SeitenRisk Assessment FormsuremessyNoch keine Bewertungen

- Handtool Safety Training Electric Hand Drill 1. Training Safety PrerequisitesDokument3 SeitenHandtool Safety Training Electric Hand Drill 1. Training Safety Prerequisitesretheep0% (1)

- Doing Well in An ExamDokument1 SeiteDoing Well in An ExamsuremessyNoch keine Bewertungen

- L02-Impacts of TourismDokument19 SeitenL02-Impacts of TourismsuremessyNoch keine Bewertungen

- Xia Chun Tong Qiao Fu ZhaoDokument2 SeitenXia Chun Tong Qiao Fu ZhaosuremessyNoch keine Bewertungen

- Example Bricklaying Risk AssessmentDokument3 SeitenExample Bricklaying Risk AssessmentsuremessyNoch keine Bewertungen

- Dimension PaperDokument1 SeiteDimension PapersuremessyNoch keine Bewertungen

- 4 6001055797780414555 PDFDokument245 Seiten4 6001055797780414555 PDFAtomNoch keine Bewertungen

- Dietschi Poste IDokument12 SeitenDietschi Poste IAxelJaraNoch keine Bewertungen

- ADHD: Clinical Practice Guideline For The Diagnosis, Evaluation, and TreatmentDokument18 SeitenADHD: Clinical Practice Guideline For The Diagnosis, Evaluation, and TreatmentBen CulpepperNoch keine Bewertungen

- Comprehensive Pharmacy Review SummaryDokument143 SeitenComprehensive Pharmacy Review SummaryjaninamariesarmientoNoch keine Bewertungen

- Dentists in LimassolDokument26 SeitenDentists in LimassolANDREASBOULNoch keine Bewertungen

- Chapter 1Dokument20 SeitenChapter 1luiperdvrouNoch keine Bewertungen

- Schedule Y, MK SharmaDokument50 SeitenSchedule Y, MK SharmaManish Sharma100% (1)

- Term Breech TrialDokument9 SeitenTerm Breech TrialAndy Tan Wei KeatNoch keine Bewertungen

- Rcog PpromDokument7 SeitenRcog PpromDevi SyamNoch keine Bewertungen

- Guillian-Barr e Syndrome - A Case StudyDokument11 SeitenGuillian-Barr e Syndrome - A Case StudyHecan ComeNoch keine Bewertungen

- FemaraDokument2 SeitenFemaraMyraIntisarNoch keine Bewertungen

- Journal Reading - Impact of PreRamadan Intervention Program On Diabetic PatientsDokument13 SeitenJournal Reading - Impact of PreRamadan Intervention Program On Diabetic PatientsQurrota Ayun RumayshahNoch keine Bewertungen

- TX 5005002Dokument9 SeitenTX 5005002Rio Van Der SarNoch keine Bewertungen

- Emergency Management of Severe BurnsDokument97 SeitenEmergency Management of Severe BurnsAyu SyartikaNoch keine Bewertungen

- Stromberg Gross Path Text Handout AU DVP 2016Dokument29 SeitenStromberg Gross Path Text Handout AU DVP 2016Rachel Autran100% (1)

- Guru Nanak Mission HospitalDokument16 SeitenGuru Nanak Mission HospitalAbhishek Singh Raghuvanshi100% (1)

- Extracorporeal Shockwave Lithotripsy For Ureteral StonesDokument5 SeitenExtracorporeal Shockwave Lithotripsy For Ureteral StonesTatik HandayaniNoch keine Bewertungen

- Avoiding The Internal Mammary Artery During Parasternal Blocks: Ultrasound Identification and Technique ConsiderationsDokument9 SeitenAvoiding The Internal Mammary Artery During Parasternal Blocks: Ultrasound Identification and Technique ConsiderationsTheUdoNoch keine Bewertungen

- 4 671945747968557164Dokument67 Seiten4 671945747968557164McMillanNoch keine Bewertungen

- Puberty: Arshiya Sultana Lecturer, Dept. of Obstetrics & Gynaecology NIUM, Bangalore, KarnatakaDokument63 SeitenPuberty: Arshiya Sultana Lecturer, Dept. of Obstetrics & Gynaecology NIUM, Bangalore, KarnatakamickageliNoch keine Bewertungen

- Fever NCPDokument3 SeitenFever NCPFretzy Quirao Villaspin100% (2)

- PMLS PRESENTATION (Lesson 3&4) (10.5 × 9 CM)Dokument4 SeitenPMLS PRESENTATION (Lesson 3&4) (10.5 × 9 CM)Rhygn SarmientoNoch keine Bewertungen

- Master Atc DDDDokument216 SeitenMaster Atc DDDMas EmNoch keine Bewertungen

- 2011 Pediatric Anesthesia - BissonnetteDokument2.287 Seiten2011 Pediatric Anesthesia - BissonnettePaulo HibernonNoch keine Bewertungen

- MCQ's With KEY GAYNAE - BDokument7 SeitenMCQ's With KEY GAYNAE - BSiraj Ul IslamNoch keine Bewertungen

- Session 1. Drug and Therapeutics Committee-OverviewDokument12 SeitenSession 1. Drug and Therapeutics Committee-OverviewNunik Dewi KumalasariNoch keine Bewertungen

- Methods of Space GainingDokument34 SeitenMethods of Space GainingSasikumar Rasappan0% (1)

- Yati Soenarto - RACP AucklandDokument34 SeitenYati Soenarto - RACP AucklandIntan HartandyNoch keine Bewertungen

- Deleuze - Critical and ClinicalDokument139 SeitenDeleuze - Critical and Clinicalbornon8thofjulyNoch keine Bewertungen

- List of Licensed Private and Public Hospital 2011Dokument7 SeitenList of Licensed Private and Public Hospital 2011TJ NgNoch keine Bewertungen