Beruflich Dokumente

Kultur Dokumente

Series 1630 Differential Pressure Switch: Specifications - Installation and Operating Instructions

Hochgeladen von

eeeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Series 1630 Differential Pressure Switch: Specifications - Installation and Operating Instructions

Hochgeladen von

eeeCopyright:

Verfügbare Formate

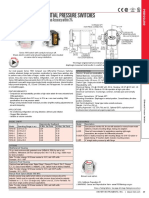

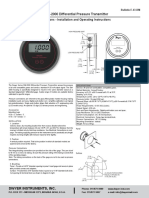

Bulletin E-52

Series 1630 Differential Pressure Switch

®

Specifications - Installation and Operating Instructions

2

[50.80]

TYP Ø7-7/8

1/2

[12.70]

TYP

3

4 [76.20] 3-1/8

[101.60] TYP [79.37]

Ø9/32 [7.14]

MOUNTING HOLE 22.5Ø

TYP 4 PLACES 3 [76.20] 1/2 CONDUIT

CONNECTION

21/32 [16.66] 1/8 FEMALE NPT

1/8 FEMALE HIGH PRESSURE

Model 1638 pressure switch - NPT LOW CONNECTION

6-1/2 [165.10] PRESSURE

U.L. and C.S.A. listed F.M. approved CONNECTION

Our highest precision conventional large diaphragm pressure switch provides SPECIFICATIONS

maximum dependability. In addition it incorporates a visible set point indicator for Temperature Limits: -30°F (-34.4°C) for dry air or gas to 110°F (43.3°C). (Consult

maximum convenience. U.L. and C.S.A. listed, F.M. approved for general service, factory for higher temperature applications.)

these switches are suitable for most applications in air conditioning and industrial Maximum Surge Pressure: 25 psig.

service. Electrical capability of 15 amps handles most small electrical loads. Rated Pressure: 10 psig.

Pressure Connections: 1/8″ NPT(F).

Environmental (MIL) Construction. Unlisted Model 1635 can be furnished with special Electrical Rating: 15 amps, 120-480 volts, 60 Hz. A.C. Resistive 1/8 H.P. @ 125

snap switch and silicone rubber diaphragm for high humidity and/or for government volts, 1/4 H.P. @ 250 volts, 60 Hz. A.C.

applications. Similar to standard Model 1638 except dead band is slightly greater. Wiring Connections: 3 screw type, common, normally open and normally closed.

Specify Model No. 1635 (range No.) MIL in ordering. Example: 1635-5-MIL. Set Point Adjustment: Screw type with enclosed scale.

Housing: 16 ga. steel, zinc plated, dichromate dipped for 200 hour salt spray test.

HOUSINGS FOR USE WITH MODEL 1638 SWITCH Diaphragm: Silicone rubber.

(also suitable for Models 1626, 1627 and 1640 switches) Calibration Spring: Stainless steel.

MODEL 1638: Weight: 3 lbs, 3 oz (1.50 kg).

Operating Ranges, Dead Bands and Ratings. Installation: Diaphragm vertical.

U.L. and C.S.A. Listed, F.M. Approved.

MODEL CHART

Approximate Dead Band

Model Operating Range At Min. At Max.

Number Inches, W.C. Set Point Set Point

1638-0 0.05 to 0.25 0.04 0.05

1638-1 0.20 to 1.0 0.04 0.06

1638-2 1.0 to 3.0 0.06 0.08

1638-5 2.0 to 6.0 0.07 0.25

1638-10 3.0 to 12 0.11 0.30

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Weatherproof Housing INSTALLATION

16 ga. steel enclosure for unusually wet or oily conditions. Withstands 200 hour salt 1. Select a location free from excessive vibration where oil or water will not drip on

spray test. Gasketed cover. Weight, 20 lbs. Switch must be installed at factory. Specify the switch and where ambient temperature will be within a range of -30°F

“WP” in addition to switch catalog. (-34.4°C) (dry air or gas) to 110°F (43.3°C). See special housing for unusual

requirements and MIL option for high humidity.

1/8 NPT LOW

PRESSURE CONNECTION 1/8 NPT HIGH 2. MOUNT THE SWITCH WITH THE DIAPHRAGM IN A VERTICAL PLANE. The

PRESSURE switch is position sensitive so it must be re-calibrated for each change in

CONNECTION operating position.

1-5/16

[33.34] 3. Connect switch to source of air pressure differential. Metal tubing with 1/4″ O.D.

1/2 NPT

ELECTRICAL is recommended, but any tubing system which will not restrict the air flow is

7

[177.80] CONNECTION satisfactory.

TYP 4. Electrical connections for all switches are marked Common, Normally Open and

Normally Closed. Be certain connections are properly made and that no

mechanical load can be transferred from the wiring to the snap switch.

8-7/8 1-1/4 3-7/8

[225.43] SQ [31.75] [98.43]

9-3/4 7-1/8 ADJUSTMENT AND CALIBRATION

[247.65] TYP [180.98] 1. The calibration or actuation point of the switch is indicated on the scale secured

10-7/8 to the transparent range spring enclosure. Recalibration to another setting within

[276.23] TYP

the range of the switch is readily accomplished by turning the adjustment screw,

counter-clockwise to increase the pressure setting or clockwise to decrease the

setting. Note that the indicated calibration is correct only if the switch is mounted

Explosion-proof Housing with the diaphragm assembly in a vertical plane. If mounted in any other position,

Killark cast alum. housing No. 4GRH with dome for No. 1638 switches and No. GRH the switch must be re-calibrated as follows:

with flat cover for No. 1626 and 1627 switches rated for Class I, Group D; Class a. Using a “T” assembly with three rubber tubing leads, all as short as possible

II, Groups E, F and G and Class III. Approximate weight, 47 lbs. Specify “EXPL” in and offering minimum flow resistance, run one lead to the pressure switch

addition to switch catalog number. and the second lead to a manometer of appropriate range and known

accuracy. Apply pressure through the third tube, preferably by successively

Ø3/8 [9.53] pinching the tube tight with the fingers. Pinch off the tube and make the final

MOUNTING HOLES approach to the set point slowly. Check the set point by listening for the click

TYPE 4 PLACES 3/4 NPT

ELECTRICAL of the switch or by using a volt meter.

13-5/8 1/8 NPT HIGH

PRESSURE CONNECTION b. Note that the manometer and pressure switch will have different response

[346.08]

TYP 12 CONNECTION characteristics due to their different internal volumes, lengths of tubing,

[304.80] 6 fluid drainage, etc. Be certain that the switch is checked in the position it will

TYP BREATHER [152.40] assume in use, or preferably, that it is installed in its final location and

11 then checked. When pressure reading has been established, replace scale

[279.4] 1/8 NPT LOW 2-1/8 to proper position, relating set point indicator to markings on scale.

PRESSURE [53.98]

10-3/4 CONNECTION

3-1/2 3/4 [19.05]

[273.05] TYP 3/4 [88.90]

[19.05] TYP

12 [304.80] TYP 11-3/4 [298.45]

Suggested Specification

Differential pressure switches shall be diaphragm operated to actuate a single pole

double throw snap switch. Motion of the diaphragm shall be restrained by a calibrated

spring that can be adjusted to set the exact pressure differential at which the electrical

switch will be actuated. Motion of the diaphragm shall be transmitted to the switch

button by means of a direct mechanical linkage. Set point adjustment shall be screw

type with set point indicated on a visual scale. Switches shall be Dwyer Instruments,

Inc. Catalog No. 1638-_____ for the required operating ranges.

©Copyright 2018 Dwyer Instruments, Inc. Printed in U.S.A. 3/18 FR# 440200-00 Rev. 3

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Das könnte Ihnen auch gefallen

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileVon EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNoch keine Bewertungen

- Dwyer-1910-1-Product OverviewDokument1 SeiteDwyer-1910-1-Product OverviewRusty AllenNoch keine Bewertungen

- Dwyer - 1630-Presostato SwitchDokument2 SeitenDwyer - 1630-Presostato Switchomorales.cyvsaNoch keine Bewertungen

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Von EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Noch keine Bewertungen

- Explosion-Proof Differential Pressure SwitchDokument1 SeiteExplosion-Proof Differential Pressure SwitchTadau EnergyNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Dokument1 SeiteCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNoch keine Bewertungen

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDokument1 SeiteDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983Noch keine Bewertungen

- Transmisor Presion Diferencial dm-2007-lcdDokument2 SeitenTransmisor Presion Diferencial dm-2007-lcdhanshr87Noch keine Bewertungen

- 603A - Transmisor de Presion DiferencialDokument3 Seiten603A - Transmisor de Presion Diferencialugui81Noch keine Bewertungen

- 01 - 1950G 1 B24 - DPSwitch FanDokument1 Seite01 - 1950G 1 B24 - DPSwitch FanJosephus RavaneraNoch keine Bewertungen

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyDokument1 SeiteDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyMike Alex Herrera DominguezNoch keine Bewertungen

- Dual-Action Explosion-Proof Pressure SwitchDokument1 SeiteDual-Action Explosion-Proof Pressure Switchjose amadeo martinez ramirezNoch keine Bewertungen

- P - 616KD Manual TransmiterDokument2 SeitenP - 616KD Manual TransmiterFR PERANoch keine Bewertungen

- Dwyer Tte ManualDokument4 SeitenDwyer Tte ManualFatih Al BaridNoch keine Bewertungen

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNoch keine Bewertungen

- Explosion-Proof Differential Pressure Switch: SERIES 1950Dokument2 SeitenExplosion-Proof Differential Pressure Switch: SERIES 1950Alex RamirezNoch keine Bewertungen

- Series 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument4 SeitenSeries 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsjguerrerosperuNoch keine Bewertungen

- 616wl 14 Manual PDFDokument2 Seiten616wl 14 Manual PDFcoolguy19895Noch keine Bewertungen

- DWYER DS 626 628 Rev.6 PDFDokument2 SeitenDWYER DS 626 628 Rev.6 PDFmarinaadduciNoch keine Bewertungen

- Model: Differential / Vacuum/ Low Pressure SwitchDokument4 SeitenModel: Differential / Vacuum/ Low Pressure Switchzinstr1Noch keine Bewertungen

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyDokument1 SeiteDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyNic DziemianNoch keine Bewertungen

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNoch keine Bewertungen

- Differential Pressure Transmitter: Series 616WDokument2 SeitenDifferential Pressure Transmitter: Series 616Wcoolguy19895Noch keine Bewertungen

- Castel Magn O8Dokument14 SeitenCastel Magn O8Daniel Fancis Amabran BarrientosNoch keine Bewertungen

- Series 1950 Explosion-Proof Differential Pressure Switches: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries 1950 Explosion-Proof Differential Pressure Switches: Specifications - Installation and Operating Instructionsaaquib76Noch keine Bewertungen

- Dual-Action Explosion-Proof Pressure SwitchesDokument1 SeiteDual-Action Explosion-Proof Pressure Switchesvishal.nithamNoch keine Bewertungen

- E 71 Multilingual ATEXDokument16 SeitenE 71 Multilingual ATEXJesus MirelesNoch keine Bewertungen

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputDokument3 SeitenIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputAsif BhatiNoch keine Bewertungen

- Series DA/DS-7000 Bourdon Tube Pressure Switches: Specifications - Installation and Operating InstructionsDokument4 SeitenSeries DA/DS-7000 Bourdon Tube Pressure Switches: Specifications - Installation and Operating InstructionsargaNoch keine Bewertungen

- Flotect Vane Operated Flow SwitchDokument2 SeitenFlotect Vane Operated Flow SwitchComercial FirenoNoch keine Bewertungen

- Specifications: DaikinDokument17 SeitenSpecifications: DaikinyoyokNoch keine Bewertungen

- Dwyer 626 13 GH P1 E4 S1 User Manual 0 300Dokument4 SeitenDwyer 626 13 GH P1 E4 S1 User Manual 0 300Anonymous QxmwZz4Noch keine Bewertungen

- Wet/Wet Differential Pressure Transmitter: Series 629CDokument2 SeitenWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNoch keine Bewertungen

- Product Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 TonsDokument26 SeitenProduct Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 Tonsalmig200Noch keine Bewertungen

- MANUAL (38 YCD) Condensing Unit Carrier.Dokument18 SeitenMANUAL (38 YCD) Condensing Unit Carrier.Carlos Manuel de la Hoz SerranoNoch keine Bewertungen

- Series 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument1 SeiteSeries 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsallaadeenNoch keine Bewertungen

- CDT Duct Mount ManualDokument4 SeitenCDT Duct Mount ManualHùng ĐỗNoch keine Bewertungen

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNoch keine Bewertungen

- SCD CatDokument1 SeiteSCD CatHussainAlkwitiNoch keine Bewertungen

- Mercoid pblt2 ManualDokument1 SeiteMercoid pblt2 ManualRudy HerreraNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Castel Check ValveDokument9 SeitenCastel Check Valveamin2shahinNoch keine Bewertungen

- Catalog Gp50 311 CryoDokument2 SeitenCatalog Gp50 311 CryoMAnhNoch keine Bewertungen

- Sensor de Presion Serie DM-2000Dokument1 SeiteSensor de Presion Serie DM-2000Giancarlo Reategui GuerraNoch keine Bewertungen

- ASCO - Pressure Switch - SA11DDokument7 SeitenASCO - Pressure Switch - SA11Djeffreyspeck7119Noch keine Bewertungen

- Aq CDT CDTRDokument4 SeitenAq CDT CDTRDon Roseller DumayaNoch keine Bewertungen

- Installsheet - 77 - 629c 01 CH p1 E1 s1Dokument4 SeitenInstallsheet - 77 - 629c 01 CH p1 E1 s1Mc EswaranNoch keine Bewertungen

- Photo Helic Ps PDFDokument4 SeitenPhoto Helic Ps PDFSoumen PaulNoch keine Bewertungen

- DP Sensor Tech Sheet (Dwyer Series 629)Dokument2 SeitenDP Sensor Tech Sheet (Dwyer Series 629)jed_poliNoch keine Bewertungen

- Series 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyDokument2 SeitenSeries 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyOperacao RDBrasilandiaNoch keine Bewertungen

- Fisher™ Type 1290 Vapor Recovery RegulatorDokument12 SeitenFisher™ Type 1290 Vapor Recovery RegulatorBEJOY KBNoch keine Bewertungen

- Series 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries 626 & 628 Pressure Transmitters: Specifications - Installation and Operating InstructionsMinh Nhut LuuNoch keine Bewertungen

- Valvula Diafragma Buschjost 82630Dokument2 SeitenValvula Diafragma Buschjost 82630Base SistemasNoch keine Bewertungen

- E.1.10.01 Pressure TripDokument2 SeitenE.1.10.01 Pressure TripEdgardo EscribanoNoch keine Bewertungen

- Series 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ADokument2 SeitenSeries 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ATrie IrsadNoch keine Bewertungen

- Manual de Operación V4-Ss2u PDFDokument16 SeitenManual de Operación V4-Ss2u PDFHeiner PalaciosNoch keine Bewertungen

- Electronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One PackageDokument1 SeiteElectronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One Packageluat1983Noch keine Bewertungen

- Series PFT Paddlewheel Flow Sensor: Specifications - Installation and Operating InstructionsDokument4 SeitenSeries PFT Paddlewheel Flow Sensor: Specifications - Installation and Operating InstructionsJoão AlvesNoch keine Bewertungen

- Product Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransfertDokument2 SeitenProduct Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransferteeeNoch keine Bewertungen

- OT Content Suite PlatformDokument6 SeitenOT Content Suite PlatformhnoamanNoch keine Bewertungen

- OT Content Suite PlatformDokument6 SeitenOT Content Suite PlatformhnoamanNoch keine Bewertungen

- 3256 FMDokument9 Seiten3256 FMeeeNoch keine Bewertungen

- CVDokument2 SeitenCVeeeNoch keine Bewertungen

- Delta Ia-Mds Vfd-E C en 20180301 WebDokument16 SeitenDelta Ia-Mds Vfd-E C en 20180301 WebeeeNoch keine Bewertungen

- TD 012019 enDokument24 SeitenTD 012019 enMikami TeruNoch keine Bewertungen

- Continuous Hinge With Clamps, Type 12Dokument4 SeitenContinuous Hinge With Clamps, Type 12eeeNoch keine Bewertungen

- SM150RDokument1 SeiteSM150ReeeNoch keine Bewertungen

- 10250T23GDokument2 Seiten10250T23GeeeNoch keine Bewertungen

- SM150RDokument1 SeiteSM150ReeeNoch keine Bewertungen

- SQL Server 2016 Editions Datasheet PDFDokument2 SeitenSQL Server 2016 Editions Datasheet PDFeeeNoch keine Bewertungen

- SiemensDokument10 SeitenSiemenseeeNoch keine Bewertungen

- Product Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransfertDokument2 SeitenProduct Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransferteeeNoch keine Bewertungen

- Tabla Awg A mm2Dokument1 SeiteTabla Awg A mm2Francisco HernandezNoch keine Bewertungen

- Product Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransfertDokument2 SeitenProduct Data Sheet: iPRD40r Modular Surge Arrester - 3P - IT - 460V - With Remote TransferteeeNoch keine Bewertungen

- Boiler Tubular Air Pre-Heater - TaphDokument18 SeitenBoiler Tubular Air Pre-Heater - TaphsbmmlaNoch keine Bewertungen

- Pulsar Extreme 3200CDokument28 SeitenPulsar Extreme 3200CGuillermoNoch keine Bewertungen

- Cobra's Messages Another Way of Explaining .Dokument18 SeitenCobra's Messages Another Way of Explaining .Dustin Thomas100% (1)

- Fan Arrangements Rotation Discharge and Motor Position Fe 3900Dokument8 SeitenFan Arrangements Rotation Discharge and Motor Position Fe 3900Adriano SantosNoch keine Bewertungen

- CCUS in Steel IndustryDokument52 SeitenCCUS in Steel IndustryJonson CaoNoch keine Bewertungen

- Furnace Safeguard and Supervisory SystemDokument36 SeitenFurnace Safeguard and Supervisory SystemNilesh Duryodhan100% (1)

- DC Motor Speed System Modeling (Final Report)Dokument41 SeitenDC Motor Speed System Modeling (Final Report)Khubaib Ahmed80% (5)

- Electrical Engineering Portal - Com Principles For Controlling HarmonicsDokument3 SeitenElectrical Engineering Portal - Com Principles For Controlling HarmonicsRobert GalarzaNoch keine Bewertungen

- Basic Science BASIC 8Dokument2 SeitenBasic Science BASIC 8Alexander ChristNoch keine Bewertungen

- MOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Dokument95 SeitenMOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Piyush KumarNoch keine Bewertungen

- Cutera GIS-HP Cooling FFA Data Capture - Rev ADokument3 SeitenCutera GIS-HP Cooling FFA Data Capture - Rev AMickey A CouvertierNoch keine Bewertungen

- Column Piping Stress AnalysisDokument6 SeitenColumn Piping Stress Analysissj22Noch keine Bewertungen

- Elctrical Safety PaperV3 1Dokument6 SeitenElctrical Safety PaperV3 120082012Noch keine Bewertungen

- Detroit S60 SpecsDokument2 SeitenDetroit S60 Specsgrgramm50% (2)

- Sector Bending Blurring Lines Between Non-Profit and For-ProfitDokument13 SeitenSector Bending Blurring Lines Between Non-Profit and For-ProfitKevNoch keine Bewertungen

- PS Range BrochureDokument16 SeitenPS Range BrochureJorge Alberto LTNoch keine Bewertungen

- Analisis Kertas 2 FizikDokument3 SeitenAnalisis Kertas 2 FizikAdrianaSafiyaNoch keine Bewertungen

- Batching PlantCP 30Dokument187 SeitenBatching PlantCP 30Anupam100% (2)

- GA-I (H) D 1000 Series ROBOTDokument1 SeiteGA-I (H) D 1000 Series ROBOTmfarrukhkNoch keine Bewertungen

- ECE 340 Lecture 26: Reverse Bias Breakdown: Class OutlineDokument20 SeitenECE 340 Lecture 26: Reverse Bias Breakdown: Class OutlineDao ZhangNoch keine Bewertungen

- ZTE Rectifier SettingsDokument4 SeitenZTE Rectifier SettingsRicardo Chavarria50% (2)

- General Physics 2 LAS Quarter 3Dokument450 SeitenGeneral Physics 2 LAS Quarter 3Eff100% (6)

- M M M M: Vinod Kumar.P.P Vinod Kumar.P.PDokument39 SeitenM M M M: Vinod Kumar.P.P Vinod Kumar.P.PHemanth ValsarajNoch keine Bewertungen

- AirPhoton Sampling Station Fact SheetDokument3 SeitenAirPhoton Sampling Station Fact Sheetnguyendacloc1986Noch keine Bewertungen

- 221 1 Engineering Work Suwpport by Excel Based ProgramDokument1 Seite221 1 Engineering Work Suwpport by Excel Based ProgramZoebairNoch keine Bewertungen

- Chemical Physical Properties of Bio CoalDokument18 SeitenChemical Physical Properties of Bio CoalYan Laksana100% (1)

- PB0101-2 Raymond HP BM Coal Pet CokeDokument2 SeitenPB0101-2 Raymond HP BM Coal Pet CokeswatkoolNoch keine Bewertungen

- 2010 Physiscs SolutionsDokument21 Seiten2010 Physiscs Solutionsjoebloggs_com100% (1)

- Research Paper On Magnetic Refrigeration Sourabh SInghDokument9 SeitenResearch Paper On Magnetic Refrigeration Sourabh SInghersourabh75% (4)