Beruflich Dokumente

Kultur Dokumente

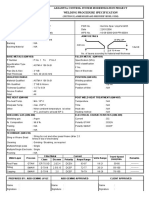

Welding Procedure Specifications

Hochgeladen von

IOT ISPRL0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

133 Ansichten2 SeitenWPS standard for Piping from toyo

Originaltitel

WELDING PROCEDURE SPECIFICATIONS

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWPS standard for Piping from toyo

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

133 Ansichten2 SeitenWelding Procedure Specifications

Hochgeladen von

IOT ISPRLWPS standard for Piping from toyo

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

FORMAT No.

: P- 001 1/2

NCU + AU (EPCC-01),IOCL Panipat

WELDING PROCEDURE SPECIFICATION (WPS)

CONSORTIUM OF TEC JOB No.:

EIL Job No.: 6556 Date: 22-12-2006

TOYO AND L&T BA/0718

DESCRIPTION TOYO EIL

Inspector’s Name KM Mathew S Ravindran

Signature

Date

WPS No: Corresponding PQR No:

B3-1-1-001 Rev.0 TOYO/ACEL/PQR-001 Rev 0

NAME OF APPLICABLE JOB : PLANT UG/AG PIPING

WELDING PROCESS : SMAW TYPE : MANUAL, AUTOMATIC, SEMI AUTOMATIC

JOINTS (QW-402) BASE METALS (QW-403)

GROOVE DESIGN

ASTM /ASME API 5L GR B, A106 Gr B , A53 Gr B , A105,

A516 Gr 70, 515 Gr 70, A234 WPB

SINGLE/DOUBLE’V’, SINGLE/DOUBLE BEVEL P NO. : 1 Gr No 1 to P No .Gr No 1&2

SKETCH ATTACHED THICKNESS RANGE : 1.50 to 19.05 mm

BACKING : WITH BACKING (Back chip and weld) OTHER : DIA METER RANGE : ALL

FILLET RANGE : ALL

FILLER METALS (QW-404) PREHEAT (QW-406)

WELD METAL ANALYSIS A No. : 1 PREHEAT TEMP. : 100 C (Min)

FILLER METAL F No. F4 INTER PASS TEMP. : 2500C (Max)

SPECIFICATION No. : SFA -5.1 PREHEAT MAINTENANCE: NA

AWS NO. : E 7018 POST HEATING : NA

SIZE OF ELECTRODES: 2.5mm, 3.2mm, 4mm, Dia POST WELD HEAT TREATMENT :(QW-407) NA

SIZE OF FILLER WIRE : NA

MANUFACTURER :

ESAB India Ltd , D&H Secheron , Advani Oerlikon:

FLUX COMPOSITION : NA

PARTICLE SIZE : NA GAS (QW-408)

CONSUMABLE INSERT : NA SHIELDING GAS : NA

DRYING TEMP. OF ELECTRODE & FLUX: NA PERCENT COMPOSITON : NA

POSITION : (QW-405) FLOW RATE : NA

POSITION OF GROOVE : ALL GAS BACKING :NA

WELDING PROGRESSION : UPHILL / DOWNHILL TRAILING SHIELDING GAS COMPOSITION: N.A.

OTHER : OTHER :

FORM: P- 001 2/2

NCU + AU (EPCC-01), Panipat

WELDING PROCEDURE SPECIFICATION (WPS)

CONSORTIUM OF

EIL Job No.: 6556 TEC JOB No.: BA/0718 Date: 22-12-2006

TOYO AND L&T

DESCRIPTION TOYO EIL

Inspector’s Name KM Mathew S . Ravindran

Signature

Date

WPS No: Corresponding PQR No:

B3-1-1-001 Rev.0 TOYO/ACEL/PQR-001 Rev 0

ELECTRICAL CHARACTERISTICS (QW-409) METHOD OF BACK GOUGING :

I & E range as given below Chipping & Grinding

CURRENT : DC POLARITY : DCEP MULTI PASS OR SINGLE PASS (PER SIDE) :

SMAW : Electrode Positive MULTI PASS

TUNGSTEN ELECTRODE SIZE & TYPE: NA SINGLE OR MULTIPLE ELECTRODES :

SINGLE

TECHNIQUE:(QW-410) : STRING OR WEAVE BEAD

Stringer bead for Root, Weave bead for others.

(weaving not more than 3 times the Electrode

Dia)

ORIFICE OR GAS CUP SIZE : NA OSCILLATION : NA

INITIAL & INTER PASS CLEANING:

OTHER :

BRUSHING , GRINDING,CHIPPING.

WELDING SEQUENCE & PROCEDURE

ELECTRODE TRAVEL

BEAD DIA

WELD SEQUENCE classificatio AMPS VOLTS SPEED

No. mm

n cm / min

Root Pass -SMAW 1 E-7018 2.5,3.15 80-110 18-24 4-8

2nd pass -SMAW 2 E-7018 3.15,4.0 110-180 20-26 5 - 10

Balance Passes-SMAW 4 - ALL E-7018 4.0 140-220 22-28 6- 12

2nd side-SMAW ALL E-7018 4.0 140-220 22-28 6- 12

COMMENTS :

Das könnte Ihnen auch gefallen

- WPS-2 InchDokument2 SeitenWPS-2 InchKarthikeyan MpNoch keine Bewertungen

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDokument1 SeiteWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNoch keine Bewertungen

- WPS GF170 As 1554.6Dokument1 SeiteWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- WPS PQR 12 PDFDokument9 SeitenWPS PQR 12 PDFVinay YadavNoch keine Bewertungen

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDokument20 SeitenA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNoch keine Bewertungen

- BOHLER E71T-1C - 1M 1.2mm F71TA08173Dokument1 SeiteBOHLER E71T-1C - 1M 1.2mm F71TA08173ALexander HuancahuireNoch keine Bewertungen

- Sarma Tub Inox Certificat PDFDokument1 SeiteSarma Tub Inox Certificat PDFJacob HarrisNoch keine Bewertungen

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Dokument5 SeitenA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNoch keine Bewertungen

- Weld Repair ProcedureDokument51 SeitenWeld Repair Proceduremohd as shahiddin jafriNoch keine Bewertungen

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Dokument1 SeiteZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNoch keine Bewertungen

- AWWCE Unit Rates For Pipe Work - LegaDokument24 SeitenAWWCE Unit Rates For Pipe Work - LegaMiko Abi0% (1)

- STEEL Structures in GeneralDokument11 SeitenSTEEL Structures in GeneralsbunNoch keine Bewertungen

- Eil WPSDokument28 SeitenEil WPSRanjan Kumar0% (1)

- Manpower Ogawa (5 Jan - 31 Jan 2015)Dokument1 SeiteManpower Ogawa (5 Jan - 31 Jan 2015)Alin Ziyanti PanjaitanNoch keine Bewertungen

- Tungsten ElectrodesDokument2 SeitenTungsten ElectrodesSyed Furqan Rehmani0% (2)

- Fit-Up TC-2Dokument1 SeiteFit-Up TC-2Muhammad Fitransyah Syamsuar Putra100% (2)

- Product Information: Inspection Certificate No. 161095 Rev1Dokument1 SeiteProduct Information: Inspection Certificate No. 161095 Rev1nwoforNoch keine Bewertungen

- Oil Pantriting ProcedureDokument5 SeitenOil Pantriting ProcedureSERT-QA/QC- BUZNoch keine Bewertungen

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokument8 SeitenStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERNoch keine Bewertungen

- Products Presentation MajorDokument47 SeitenProducts Presentation MajorJuanita AndrewsNoch keine Bewertungen

- Catalogue Revolloy Welding ConsumablesDokument30 SeitenCatalogue Revolloy Welding ConsumablesAdi SutardiNoch keine Bewertungen

- Saudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetDokument3 SeitenSaudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetabdullaNoch keine Bewertungen

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDokument13 SeitenFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuNoch keine Bewertungen

- PRES TIG Hot Wire Narrow Gap Welding enDokument25 SeitenPRES TIG Hot Wire Narrow Gap Welding enRavishankarNoch keine Bewertungen

- COOLING TOWER FAN Erection Quality ChecklistsDokument1 SeiteCOOLING TOWER FAN Erection Quality ChecklistsBudoy SmithNoch keine Bewertungen

- 5D Bends Combine RFQDokument376 Seiten5D Bends Combine RFQMuhammad Ghufran KhanNoch keine Bewertungen

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDokument9 SeitenTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNoch keine Bewertungen

- dpvc-09 Petrobras PDFDokument47 Seitendpvc-09 Petrobras PDFBilly TanNoch keine Bewertungen

- Hust WPS Gtaw - Smaw 6GDokument4 SeitenHust WPS Gtaw - Smaw 6GtruongtrungplhdNoch keine Bewertungen

- Daily Report: 653 03 YG 00400 14-May-2017 Sunday DPR-347Dokument8 SeitenDaily Report: 653 03 YG 00400 14-May-2017 Sunday DPR-347mcgNoch keine Bewertungen

- Control Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedDokument1 SeiteControl Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedSiddiqui Abdul KhaliqNoch keine Bewertungen

- Hyundai Electrode CATALOG - 7thDokument134 SeitenHyundai Electrode CATALOG - 7tharianaseri100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Pressure Test Execution Plan Mar 24 Rev.cDokument12 SeitenPressure Test Execution Plan Mar 24 Rev.cAbdullah Al JubayerNoch keine Bewertungen

- (JPL GGL GCCPL WP ML 17) Under Ground Hydro TestingDokument21 Seiten(JPL GGL GCCPL WP ML 17) Under Ground Hydro TestingParas JaniNoch keine Bewertungen

- Course Module 4Dokument6 SeitenCourse Module 4Makise AghataNoch keine Bewertungen

- Wps Mma PipeDokument2 SeitenWps Mma PipeDimitris NikouNoch keine Bewertungen

- Cracks in WeldsDokument19 SeitenCracks in Weldsjesycuban100% (1)

- How To Weld T-1 SteelDokument21 SeitenHow To Weld T-1 SteelMuthu Barathi ParamasivamNoch keine Bewertungen

- Duplex Stainless Steel - Part 2 - TWIDokument6 SeitenDuplex Stainless Steel - Part 2 - TWItuanNoch keine Bewertungen

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDokument5 SeitenQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Noch keine Bewertungen

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Dokument2 SeitenSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNoch keine Bewertungen

- Submerged Arc Welding: by L D PoyyaraDokument29 SeitenSubmerged Arc Welding: by L D PoyyararajeshNoch keine Bewertungen

- Welding Electrodes For Petrochemical IndustryG PDFDokument44 SeitenWelding Electrodes For Petrochemical IndustryG PDFerogonNoch keine Bewertungen

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDokument11 SeitenCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNoch keine Bewertungen

- Cladding Clad Pipes 625a-Seminar 2010Dokument37 SeitenCladding Clad Pipes 625a-Seminar 2010ssNoch keine Bewertungen

- Welded Joint Design and ProductionDokument116 SeitenWelded Joint Design and ProductionGilbertoUGONoch keine Bewertungen

- S-8018 B2Dokument5 SeitenS-8018 B2Abhishek AnandNoch keine Bewertungen

- Check For Weld Between 50dia & Rainforcement PadDokument8 SeitenCheck For Weld Between 50dia & Rainforcement PadUmer AziqNoch keine Bewertungen

- WPS PQR PDFDokument23 SeitenWPS PQR PDFAhmad Daniel100% (1)

- Fir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFDokument3 SeitenFir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFgaladrialNoch keine Bewertungen

- Report On Industrial Training AT Dee Piping Systems Prithla (Palwal)Dokument20 SeitenReport On Industrial Training AT Dee Piping Systems Prithla (Palwal)Amit PatelNoch keine Bewertungen

- IVR-8117994011-01 - Rev.00Dokument6 SeitenIVR-8117994011-01 - Rev.00Abhay KarandeNoch keine Bewertungen

- MQP - 1 PDFDokument15 SeitenMQP - 1 PDFDoita Dutta ChoudhuryNoch keine Bewertungen

- Cold Bending of 3LPP-Flowline PipesDokument2 SeitenCold Bending of 3LPP-Flowline PipesShanmuga NavaneethanNoch keine Bewertungen

- Specification FOR Piping Fabrication and InstallationDokument27 SeitenSpecification FOR Piping Fabrication and Installationgc_panchaNoch keine Bewertungen

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDokument3 SeitenDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNoch keine Bewertungen

- WPS 03 GtawDokument3 SeitenWPS 03 GtawBiswajit DeyNoch keine Bewertungen

- WPS For Different Materail by BhelDokument176 SeitenWPS For Different Materail by Bhelsaisssms911691% (46)

- Final WPS - ItdcDokument2 SeitenFinal WPS - ItdcsarancivilrajNoch keine Bewertungen

- (L5) - (NEET 2.0) - Solutions - 24th AprilDokument76 Seiten(L5) - (NEET 2.0) - Solutions - 24th AprilMustafa AliNoch keine Bewertungen

- NORSOK Structural Steel Fabrication M-101Dokument67 SeitenNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- Fundamentals of Thermodynamics and Heat Transfer: March 2019Dokument9 SeitenFundamentals of Thermodynamics and Heat Transfer: March 2019Vinay SawantNoch keine Bewertungen

- Unit 4Dokument68 SeitenUnit 4priyata debNoch keine Bewertungen

- Turner Spectrophotometer: Operating Manual MODEL SP-830Dokument20 SeitenTurner Spectrophotometer: Operating Manual MODEL SP-830eka_setyowati0Noch keine Bewertungen

- SG Test3MCQ 64ac8bc86f1720.64ac8bcaa19898.54250131Dokument34 SeitenSG Test3MCQ 64ac8bc86f1720.64ac8bcaa19898.54250131390108263Noch keine Bewertungen

- 3 CH 6Dokument149 Seiten3 CH 6eeesolomon2124Noch keine Bewertungen

- A Refinery Pan BatchDokument5 SeitenA Refinery Pan Batchmuhammad alaik nailal HudaNoch keine Bewertungen

- Norma MAT2004Dokument12 SeitenNorma MAT2004Marcelo Carvalho100% (1)

- Focus Stacking in LinuxDokument7 SeitenFocus Stacking in LinuxklladoNoch keine Bewertungen

- DLP #: 1 Learning Area: SCIENCE - MATTER Grade Level: Grade 8 Quarter: 3 Time Frame: 70 Minutes Teacher: CLAUDINE S. TUL-IDDokument8 SeitenDLP #: 1 Learning Area: SCIENCE - MATTER Grade Level: Grade 8 Quarter: 3 Time Frame: 70 Minutes Teacher: CLAUDINE S. TUL-IDElvin VillaNoch keine Bewertungen

- Header&pipe Sizes - 00361Dokument9 SeitenHeader&pipe Sizes - 00361JKKNoch keine Bewertungen

- Nov 21st 2014 Friday: Products DetailsDokument1 SeiteNov 21st 2014 Friday: Products DetailsXuân Giang NguyễnNoch keine Bewertungen

- Gazil, Jerico June C. Module 3 With AnswerDokument2 SeitenGazil, Jerico June C. Module 3 With AnswerJunior PayatotNoch keine Bewertungen

- Spray-Type Deaerating Heaters: TABLE 12.2Dokument2 SeitenSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiNoch keine Bewertungen

- Modern Pulley AnalysisDokument16 SeitenModern Pulley AnalysisMariappan ArumugamNoch keine Bewertungen

- ACTIVITY - Periodic Trends Properties WebQuest 2017 PDFDokument3 SeitenACTIVITY - Periodic Trends Properties WebQuest 2017 PDFVasudev Pandey0% (1)

- PYQs Mechanical Operation 1990 2021 1660247465560Dokument115 SeitenPYQs Mechanical Operation 1990 2021 1660247465560durgesh patelNoch keine Bewertungen

- Emg 2508 Notes Set 3Dokument27 SeitenEmg 2508 Notes Set 3Njuguna FredrickNoch keine Bewertungen

- Introduction To Highway Pavement-1Dokument60 SeitenIntroduction To Highway Pavement-1Sagni Oo ChambNoch keine Bewertungen

- Almansoori Inspection Services: Travelling Block AssemblyDokument2 SeitenAlmansoori Inspection Services: Travelling Block AssemblyRanjithNoch keine Bewertungen

- Flexural Design of Reinforced Concrete Beam SectionsDokument15 SeitenFlexural Design of Reinforced Concrete Beam SectionsAamir HaideriNoch keine Bewertungen

- 01-Mi-Dti Cut Sheet 0715Dokument2 Seiten01-Mi-Dti Cut Sheet 0715Marvin EstradaNoch keine Bewertungen

- Final Tower Analysis Report SST 65 M - SoeDokument99 SeitenFinal Tower Analysis Report SST 65 M - SoeErpanBeanTarpoNoch keine Bewertungen

- 5.2 CLIVET Air Cooled Inv-Screw ChillerDokument17 Seiten5.2 CLIVET Air Cooled Inv-Screw Chillerremigius yudhiNoch keine Bewertungen

- Lec 22 PDFDokument2 SeitenLec 22 PDFabdulzahraNoch keine Bewertungen

- Into 2 Mems ClocksDokument42 SeitenInto 2 Mems ClocksjonwangNoch keine Bewertungen

- 420118-Hydraulic Pump SettimaDokument9 Seiten420118-Hydraulic Pump SettimaAndreyOsyaninNoch keine Bewertungen

- Nadca - Overview of Defets in Die CastingDokument197 SeitenNadca - Overview of Defets in Die CastingJayabharath Rajadurai100% (8)

- ME463 Plate3 CapulDokument9 SeitenME463 Plate3 CapulJuvy Lyka CapulNoch keine Bewertungen

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsVon EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsBewertung: 4 von 5 Sternen4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableVon EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (5)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolVon EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNoch keine Bewertungen

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireVon EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireBewertung: 4 von 5 Sternen4/5 (129)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNoch keine Bewertungen

- Bioplastics: A Home Inventors HandbookVon EverandBioplastics: A Home Inventors HandbookBewertung: 4 von 5 Sternen4/5 (2)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsVon EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Chemistry: a QuickStudy Laminated Reference GuideVon EverandChemistry: a QuickStudy Laminated Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNoch keine Bewertungen

- Transformer: The Deep Chemistry of Life and DeathVon EverandTransformer: The Deep Chemistry of Life and DeathBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilVon EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilBewertung: 5 von 5 Sternen5/5 (1)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)Von EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)Noch keine Bewertungen