Beruflich Dokumente

Kultur Dokumente

Apparel Considerations in Food-Processing Facilities

Hochgeladen von

jamil voraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Apparel Considerations in Food-Processing Facilities

Hochgeladen von

jamil voraCopyright:

Verfügbare Formate

Food Contamination

Apparel Considerations in

Food-Processing Facilities

By Jan Eudy

A comprehensive uniform program and personnel training can

reduce the incidence of food contamination in food plants.

T

he recent white paper concerning the modernization of tamination in the food industry is through a complete uniform

the GMPs addresses prevention of many contamination program and personnel training. A comprehensive uniform program

issues and emphasizes the control and training of operators is designed to provide:

working in manufacturing, packaging, or storage of human food.

One recommendation made is that, “No street clothing should be ● Contamination control

allowed unless protective outer garments are worn”. ● Security

The challenges of food safety and security and the impact of revised ● Safety

cGMPs in the food processing industry are evolving and, because of

this, constant quality assurance is required. This begins with having CONTAMINATION CONTROL Food processing apparel is designed

confidence in the garments and apparel service that supports food to capture particles shed from the human body and prevent these

processing operations. contaminants from being dispersed into the product or into the work

The food processing industry is acutely aware of the many possible environment. Such apparel protects from numerous contaminants

sources of contamination that threaten manufacturing, packaging that are generated from the human body, including:

and/or filling operations. The most significant threat is also the threat

that is easiest to control – employees working in the facility. HACCP ● Viable particles such as bacteria and yeasts.

“risk management” practices address all aspects of the operation ● Non-viable particles such as hair, dead skin cells and dandruff.

including personnel. ● Elements such as sodium, potassium, chloride and magnesium

One of the most significant methods for reducing human con- from sweat and saliva.

14 WINTER 2006 AIB QUARTERLY

It is important to note that because the human body produces Step 6

these contaminants in such large quantities, apparel must be worn Garments are ready for delivery to the customer. The linear process

and processed correctly. Additionally, dedicated food processing flow of production with line clearance between batches delineates

apparel protects the product and the process from contamination clear segregation of cleaned versus soiled garments.

brought into the plant on employees’ street clothes.

When choosing a uniform provider, one should consider the Step 7

importance of that provider’s ability to safeguard the food process- A comprehensive HACCP program and sanitation standard operat-

ing garments from cross-contamination from within the operation ing procedures assure that:

and from other customers, to maintain a constant level of aesthetic,

microbial, and particulate cleanliness, and to deliver uniforms in a ● Preventive and corrective maintenance is current on all equip-

timely and efficient manner. Uniform providers should follow a linear ment.

process of precision cleaning that includes the following steps: ● Personnel are trained and competent in their job discipline.

● Wash chemicals and water quality meets specifications.

Step 1 ● The laundry facility is pest free and clean at all times to protect

Clean garments are delivered and soiled garments are retrieved from a cleaned garments.

customer facility by a highly reliable service sales representative dedi-

cated to servicing this customer. All soiled food processing garments Step 8

are segregated before they are returned to the laundry, thereby reduc- The professionally trained service sales representative delivers cleaned

ing the potential cross-contamination with other soiled garments. garments and associated documentation to the customer.

The soiled garments are directly transported from the customer site

to the receiving area of the laundry. SAFETY. To assure continuity of service at all times, the uniform

provider should have a Disaster Prevention/Response/Recovery Plan

Step 2 that addresses the safety and security of personnel and property, in-

From receiving, garments are transported to the soil/sort area, where ternal and external equipment redundancy, procedures and policies

they are sorted by the customer and staged for laundering. Every and back-up facilities in various disaster scenarios.

load is weighed to assure the correct proportion of garments, wash

chemical, and water mixture. SECURITY. The provider should provide a variety of types and

colors of garment segregate operations, thus controlling potential

Step 3 cross contamination of product and easily identifying employees

A validated wash process that is specially formulated to address performing specialized operations.

decontamination, soil, and microbial removal from food processing

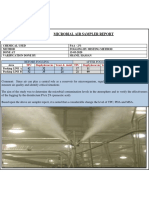

garments should be followed. The washer is pre-programmed with ENVIRONMENTAL MONITORING. FSIS “Microbial Sampling of

a computer controlled, ladder-logic wash formula that is interlinked RTE Products for the FSIS Verification Testing Program mandates

with the computer controlled wash chemical injection system and environmental sampling, including outer garments for workers, for

uses only fresh, processed water in all rinses and flushes. the presence of bacterial pathogens.” A comprehensive garment pro-

gram includes personnel certification that performs environmental

Step 4 sampling before and after working in the production process. Ad-

Garments are removed from the washer and immediately loaded in ditional environmental sampling should be performed before and

dryers. The computer controlled drying process inhibits microbial after sanitization of production surfaces.

bioburden by removing the moisture required for microbial rep-

lication. Additionally, garments never sit in washers or in a damp AUDITS FOR COMPLIANCE. Routine internal and external cus-

environment for an extended period of time, therefore eliminating tomer audits assure compliance to the customer’s specifications, the

potential for mildew. established HACCP program, and SSOPs.

Step 5 A BALANCED APPAREL PROGRAM. A balanced apparel program

From dryers, garments are transported to the final sort area, where for the food processing industry is a single source that specializes in

they are sorted, inspected, processed through a steam tunnel for apparel service, entrance mats, anti-fatigue mats, sanitary soaps and

final sanitization, and packaged. A 100% inspection of all garments supplies, first aid kits, and safety supplies.

is performed. Garments are segregated for repair or replacement,

if necessary. Experienced operators using advanced garment repair ABOUT CINTAS. Cintas Corporation provides specialized services to

technology control garment integrity. Bar coding and computerized various businesses in North America, including the food processing

inventory control provide garment history and efficient apparel industry. For more information, call 1-800-CINTAS1. AIB

management. Accurate customer-use records are generated for veri-

fication at delivery. The author is Corporate Quality Assurance Manager for Cintas Corporation.

AIB QUARTERLY WINTER 2006 15

Das könnte Ihnen auch gefallen

- SOP 3 Good Manufacturing Practices Sample of Employee Instructions - WMDokument31 SeitenSOP 3 Good Manufacturing Practices Sample of Employee Instructions - WMGeoff Erickson100% (1)

- Fish ProcessingDokument226 SeitenFish ProcessingReymond Saragena PapaNoch keine Bewertungen

- Sterility Assurance TrainingDokument28 SeitenSterility Assurance TrainingVasanthNoch keine Bewertungen

- Tip Sheet 24 CleaningDokument4 SeitenTip Sheet 24 Cleaningelflaquito80Noch keine Bewertungen

- Food Safety - Focused Facility and Equipment Hygienic Design StrategiesDokument6 SeitenFood Safety - Focused Facility and Equipment Hygienic Design StrategiesThẩm NguyễnNoch keine Bewertungen

- Cleaning Validation White PaperDokument7 SeitenCleaning Validation White PaperAngga PratamaNoch keine Bewertungen

- Minimizing Food Handling - A Secure Food Production Practice by Anant BhamkarDokument1 SeiteMinimizing Food Handling - A Secure Food Production Practice by Anant BhamkarEclatNoch keine Bewertungen

- The Listeria Control Program RecommendationsDokument26 SeitenThe Listeria Control Program Recommendationsnathbpm100% (1)

- Industrial Tour For Manufacturing Company SILVER SWANDokument5 SeitenIndustrial Tour For Manufacturing Company SILVER SWANjaredjoeNoch keine Bewertungen

- Whitepaper - Personal Hygiene Within The Food Industry - ENDokument12 SeitenWhitepaper - Personal Hygiene Within The Food Industry - ENos ozNoch keine Bewertungen

- Bioburden Considerations in Equipment-Cleaning Validation: Did Not Include Swab Sampling of The Transfer LinesDokument20 SeitenBioburden Considerations in Equipment-Cleaning Validation: Did Not Include Swab Sampling of The Transfer LinesWa Ode FasridaNoch keine Bewertungen

- 23 03 Po Annex1 EbookDokument23 Seiten23 03 Po Annex1 EbookDincer SELENNoch keine Bewertungen

- A Table Outlining The General Requirements To Be Considered For Each PrerequisiteDokument3 SeitenA Table Outlining The General Requirements To Be Considered For Each Prerequisiterea mae hamiladanNoch keine Bewertungen

- Good Hygiene and Manufacturing PracticesDokument15 SeitenGood Hygiene and Manufacturing PracticesMihai BejanNoch keine Bewertungen

- CTFA cGMPsDokument19 SeitenCTFA cGMPsAna Paula Santos GodoyNoch keine Bewertungen

- Risk Based Environmental Monitoring ProgrammeDokument51 SeitenRisk Based Environmental Monitoring ProgrammeAugustine KoomsonNoch keine Bewertungen

- Sanitary Design and Role of HACCP in SANITATION - HABUNGDokument13 SeitenSanitary Design and Role of HACCP in SANITATION - HABUNGBhupen Hajong100% (1)

- General Requirements To Be Considered For Each of The PrerequisiteDokument2 SeitenGeneral Requirements To Be Considered For Each of The PrerequisiteIan FredrickNoch keine Bewertungen

- PFI-QA-SOP-03 Integrated Pest ManagementDokument7 SeitenPFI-QA-SOP-03 Integrated Pest ManagementRugadya PaulNoch keine Bewertungen

- Sanitary Design and Role of HACCP in SanitationDokument12 SeitenSanitary Design and Role of HACCP in SanitationBhupen HajongNoch keine Bewertungen

- GMP GHP SopDokument64 SeitenGMP GHP SopPrasad MgNoch keine Bewertungen

- GMP GHP SopDokument64 SeitenGMP GHP SopPrasad Mg100% (2)

- HA CC P: Food Safety TrainingDokument18 SeitenHA CC P: Food Safety TrainingEngr Muhammad Zubair FarooqNoch keine Bewertungen

- Best Practices For Beef SlaughterDokument14 SeitenBest Practices For Beef SlaughteryemNoch keine Bewertungen

- IFS Food Checklist RequirementsDokument8 SeitenIFS Food Checklist RequirementsMarlon Rivas QuiñonezNoch keine Bewertungen

- Measures to ensure safety during COVID-19Dokument4 SeitenMeasures to ensure safety during COVID-19Rishap JindalNoch keine Bewertungen

- Mold Prevention SOPDokument30 SeitenMold Prevention SOPDebashishDolon100% (4)

- How To Establish An Aseptic Gowning Qualification ProgramDokument3 SeitenHow To Establish An Aseptic Gowning Qualification Programprakash deshmukhNoch keine Bewertungen

- HACCP System Lecture HandoutDokument17 SeitenHACCP System Lecture HandoutRichard Simon Kisitu100% (1)

- Tip Sheet 22 Personal Hygiene PlanDokument4 SeitenTip Sheet 22 Personal Hygiene Planelflaquito80Noch keine Bewertungen

- GMP Guidelines PDFDokument11 SeitenGMP Guidelines PDFMay EllaNoch keine Bewertungen

- SCC Innovasia FinalDokument16 SeitenSCC Innovasia FinalAnonymous 0zrCNQNoch keine Bewertungen

- GMP Guidelines For ManufacturersDokument23 SeitenGMP Guidelines For Manufacturerssiltanmuket88Noch keine Bewertungen

- Fundamentals of GMP & Their ApplicationDokument3 SeitenFundamentals of GMP & Their ApplicationKiran NiaziNoch keine Bewertungen

- Write Up PDFDokument17 SeitenWrite Up PDFFrancine Dawn MoloNoch keine Bewertungen

- Basic Elements of A Sanitation Program For Food ProcessingDokument5 SeitenBasic Elements of A Sanitation Program For Food ProcessingJohn Henry Wells100% (2)

- Food Processing Equipment Design and Cleanability: FLAIR-FLOW Technical Manual 377A/00Dokument35 SeitenFood Processing Equipment Design and Cleanability: FLAIR-FLOW Technical Manual 377A/00Bhavesh100% (1)

- Control MeasuresDokument9 SeitenControl MeasuresIvan Dave TorrecampoNoch keine Bewertungen

- QA 6.1 Good Manufacturing PracticeDokument11 SeitenQA 6.1 Good Manufacturing PracticeangeldrandevNoch keine Bewertungen

- GMP ModulesDokument151 SeitenGMP ModulesHector SalcedoNoch keine Bewertungen

- Food Storage Warehouses GuidelinesDokument16 SeitenFood Storage Warehouses GuidelinesThuyền TháiNoch keine Bewertungen

- Cleanroom and Deionized WaterDokument100 SeitenCleanroom and Deionized WaterRubini Devi SelvarajooNoch keine Bewertungen

- Food Design 1Dokument4 SeitenFood Design 1neilradcliffeNoch keine Bewertungen

- 30 IM Sanitary DressingDokument15 Seiten30 IM Sanitary DressingNader SedighiNoch keine Bewertungen

- Prerequisite Programs (PRPS) Provide The Hygienic Foundations For Any Food Operation. The TermsDokument6 SeitenPrerequisite Programs (PRPS) Provide The Hygienic Foundations For Any Food Operation. The TermsMawee LastrellaNoch keine Bewertungen

- HACCP Analysis for Pineapple JamDokument33 SeitenHACCP Analysis for Pineapple JamWadie ChafikiNoch keine Bewertungen

- Module 5: Implement Good Manufacturing Practice ProcedureDokument7 SeitenModule 5: Implement Good Manufacturing Practice ProcedureStevenNoch keine Bewertungen

- Iso22000 Training GuidelineDokument11 SeitenIso22000 Training GuidelineGidion Jeffri PoerbaNoch keine Bewertungen

- C GMPDokument12 SeitenC GMPAbid Ali KhanNoch keine Bewertungen

- Food Safety Program (Risk Management) PDFDokument11 SeitenFood Safety Program (Risk Management) PDFMichael Dej Pablo100% (1)

- Food Safety PDFDokument11 SeitenFood Safety PDFMaria AnnieskaNoch keine Bewertungen

- Good Manufacturing Practices.Dokument123 SeitenGood Manufacturing Practices.anandhra2010100% (2)

- Food Safety and SanitationDokument1 SeiteFood Safety and SanitationJoddie LoplopNoch keine Bewertungen

- BRC Training Guide SampleDokument22 SeitenBRC Training Guide SampleOsman AitaNoch keine Bewertungen

- COVID 19 Management Guidance BWBDokument23 SeitenCOVID 19 Management Guidance BWBEmrul SobhanNoch keine Bewertungen

- COVID-19 Management Guidance for RMG FactoriesDokument23 SeitenCOVID-19 Management Guidance for RMG FactoriesMd. Yousuf Ebna AbedinNoch keine Bewertungen

- 2013.10.23 COP For Milk Producers Oct 2013Dokument139 Seiten2013.10.23 COP For Milk Producers Oct 2013FLed NguyenNoch keine Bewertungen

- GMPDokument123 SeitenGMPmoshejamNoch keine Bewertungen

- Cleaning and disinfection of food factories: a practical guideVon EverandCleaning and disinfection of food factories: a practical guideNoch keine Bewertungen

- Effective microbiological sampling of food processing environments (1999)Von EverandEffective microbiological sampling of food processing environments (1999)Noch keine Bewertungen

- Astm D1894-14Dokument7 SeitenAstm D1894-14Huỳnh Phúc NguyễnNoch keine Bewertungen

- M.S. and high tensile nuts bolts productionDokument5 SeitenM.S. and high tensile nuts bolts productionscribddaduNoch keine Bewertungen

- Design Manufacture and Simulation of BalDokument82 SeitenDesign Manufacture and Simulation of BalMEER MUSTAFA ALINoch keine Bewertungen

- Annex 1 Essential Safety RequirementDokument12 SeitenAnnex 1 Essential Safety Requirementjamil voraNoch keine Bewertungen

- Guide to competent bodies for material quality certificationDokument13 SeitenGuide to competent bodies for material quality certificationJAFFERNoch keine Bewertungen

- Fasteners - Stainless SteelDokument10 SeitenFasteners - Stainless Steeljamil voraNoch keine Bewertungen

- Nuts and BoltsDokument42 SeitenNuts and Boltsjamil voraNoch keine Bewertungen

- MOdule H RequirementDokument8 SeitenMOdule H Requirementjamil voraNoch keine Bewertungen

- StdoutDokument1 SeiteStdoutMohammed NourNoch keine Bewertungen

- Full Quality Assurance Certificate: L&T Valves LimitedDokument5 SeitenFull Quality Assurance Certificate: L&T Valves Limitedjamil voraNoch keine Bewertungen

- Annex Iv Eu Declaration of Conformity (No XXXX)Dokument1 SeiteAnnex Iv Eu Declaration of Conformity (No XXXX)jamil voraNoch keine Bewertungen

- Readme 1Dokument1 SeiteReadme 1Jogn DebNoch keine Bewertungen

- 2014 68 Eu PDFDokument96 Seiten2014 68 Eu PDFAlienshow100% (1)

- New PED - tcm37-17564Dokument3 SeitenNew PED - tcm37-17564jamil voraNoch keine Bewertungen

- Crawley Borough Council: Food ComplaintsDokument5 SeitenCrawley Borough Council: Food Complaintsjamil voraNoch keine Bewertungen

- Food Safety Culture Module BrochureDokument8 SeitenFood Safety Culture Module Brochurejamil voraNoch keine Bewertungen

- A Study of Microbial Air Sample by PAA As DisinfectantDokument1 SeiteA Study of Microbial Air Sample by PAA As Disinfectantjamil voraNoch keine Bewertungen

- StdoutDokument1 SeiteStdoutMohammed NourNoch keine Bewertungen

- OCA - 095 Equipment Information Sheet-Handler - 181119Dokument1 SeiteOCA - 095 Equipment Information Sheet-Handler - 181119jamil voraNoch keine Bewertungen

- Data - of Best KindDokument4 SeitenData - of Best Kindkt1996Noch keine Bewertungen

- Guidelines For Certification of Grower Groups: 5.1 SCOPEDokument27 SeitenGuidelines For Certification of Grower Groups: 5.1 SCOPEjamil voraNoch keine Bewertungen

- Project Plan Template: Project Conception and InitiationDokument5 SeitenProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZNoch keine Bewertungen

- ASME VIII Div 1 Thickness FormulaDokument2 SeitenASME VIII Div 1 Thickness Formulajamil voraNoch keine Bewertungen

- Accreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationDokument39 SeitenAccreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationdemiNoch keine Bewertungen

- Food Safety Culture ExcellenceDokument5 SeitenFood Safety Culture Excellencejamil voraNoch keine Bewertungen

- Thick Walled Cylinders (Corrected)Dokument17 SeitenThick Walled Cylinders (Corrected)John Larry CorpuzNoch keine Bewertungen

- OCA - 115c - Initial Application (Processing & Trading) - 181119Dokument4 SeitenOCA - 115c - Initial Application (Processing & Trading) - 181119jamil voraNoch keine Bewertungen

- Product Launch Marketing PlanDokument17 SeitenProduct Launch Marketing Planjamil voraNoch keine Bewertungen

- OCA - 097 Product Flowinformation Sheet-Handler - 181119Dokument2 SeitenOCA - 097 Product Flowinformation Sheet-Handler - 181119jamil voraNoch keine Bewertungen

- Project Plan Template: Project Conception and InitiationDokument5 SeitenProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZNoch keine Bewertungen

- Bra Fit BookDokument40 SeitenBra Fit Booke-mir100% (7)

- Buksh IndustriesDokument3 SeitenBuksh IndustriesM Yasir AliNoch keine Bewertungen

- Oscar The Pug Puppy Aidie and Jellybean Chie Powles Comp VDokument15 SeitenOscar The Pug Puppy Aidie and Jellybean Chie Powles Comp VJheix Diniz100% (2)

- My Sails 3 New Prirocnik Za Ucitelje TestiDokument12 SeitenMy Sails 3 New Prirocnik Za Ucitelje TestiTjaša KrajncNoch keine Bewertungen

- Product Catalogue - Shijiazhuang Huanyang Textile Co.,Ltd.Dokument1 SeiteProduct Catalogue - Shijiazhuang Huanyang Textile Co.,Ltd.a27gabrNoch keine Bewertungen

- Unit 3: American BeautyDokument42 SeitenUnit 3: American BeautyEnglish TimeNoch keine Bewertungen

- GROUP 5 - Final Exam MKT302.1 S1.P1. 2021 - 2022Dokument19 SeitenGROUP 5 - Final Exam MKT302.1 S1.P1. 2021 - 2022Nguyễn Bá HiếnNoch keine Bewertungen

- Eevee Plushie Sewing Pattern by TeacupLionDokument15 SeitenEevee Plushie Sewing Pattern by TeacupLionStefy Shor100% (1)

- Expression 3 5 4 2 Manual enDokument48 SeitenExpression 3 5 4 2 Manual enCleber AugustoNoch keine Bewertungen

- Leather and Garment Goods Level 1Dokument110 SeitenLeather and Garment Goods Level 1Online plateNoch keine Bewertungen

- Erp For Knit, Dye, GMT IndDokument1 SeiteErp For Knit, Dye, GMT IndSaif RahmanNoch keine Bewertungen

- Notes On RenaissanceDokument11 SeitenNotes On RenaissanceCrystal ChuaNoch keine Bewertungen

- Levi's Vintage Clothing 2015Dokument65 SeitenLevi's Vintage Clothing 2015Luca dallas100% (1)

- Berroco Linus: Skill Level: Finished MeasurementsDokument4 SeitenBerroco Linus: Skill Level: Finished MeasurementsrobinmckoNoch keine Bewertungen

- Where are my keysDokument68 SeitenWhere are my keysSena YılmazerNoch keine Bewertungen

- Interchange4thEd Level1 Unit03 Vocabulary WorksheetDokument1 SeiteInterchange4thEd Level1 Unit03 Vocabulary WorksheetFlux MillsNoch keine Bewertungen

- ArbolesDokument27 SeitenArbolesIsis KuriNoch keine Bewertungen

- Store Visit Report at Superdry, MidvalleyDokument17 SeitenStore Visit Report at Superdry, MidvalleygslSuetLinNoch keine Bewertungen

- Free Knitted Vest PatternsDokument22 SeitenFree Knitted Vest PatternsDarbost1Noch keine Bewertungen

- Ethics and Aesthetic Appearance of Kebaya Indonesia: SuciatiDokument4 SeitenEthics and Aesthetic Appearance of Kebaya Indonesia: Suciatifarida budiNoch keine Bewertungen

- English KnottyDokument2 SeitenEnglish Knottynehiltas2013Noch keine Bewertungen

- Grade 1 Unit 5 - Lesson 1: Worksheet Global Stage 1Dokument10 SeitenGrade 1 Unit 5 - Lesson 1: Worksheet Global Stage 1Hong Phuong GiangNoch keine Bewertungen

- Elna Serger Instruction Manual 624dse 614de 604eDokument28 SeitenElna Serger Instruction Manual 624dse 614de 604eDana Savu67% (9)

- Small Rhinoceros: Kristi Tullus, Http://sidrun - Spire.eeDokument10 SeitenSmall Rhinoceros: Kristi Tullus, Http://sidrun - Spire.eeEurydice Suz100% (6)

- Dressing For The Occasion: The Dress Code Guide of The Western WorldDokument14 SeitenDressing For The Occasion: The Dress Code Guide of The Western WorldmcesairNoch keine Bewertungen

- Chapter 3 Basic WardrobeDokument51 SeitenChapter 3 Basic WardrobeSherry Avena100% (4)

- FSDokument54 SeitenFSDorothy Leonardo ObriqueNoch keine Bewertungen

- SOP-QC-005-R01 Generic Defect Classification List For ApparelDokument18 SeitenSOP-QC-005-R01 Generic Defect Classification List For ApparelBếp Rơm Của MẹNoch keine Bewertungen

- Lion MikeDokument14 SeitenLion MikeWandice Vânia Cruz100% (11)

- AccessoriesDokument69 SeitenAccessoriesAilyn PoliranNoch keine Bewertungen