Beruflich Dokumente

Kultur Dokumente

Stainless Series S6500 (Globe) S61500 (Angle) Specification Sheet

Hochgeladen von

WattsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stainless Series S6500 (Globe) S61500 (Angle) Specification Sheet

Hochgeladen von

WattsCopyright:

Verfügbare Formate

R

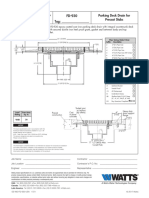

Stainless Series

Standard Materials

Coating: Body & Cover: Ductile Iron ASTM A536 NSF Listed Fusion Bonded Epoxy Lined

C

S6500 (Globe) S61500 (Angle)

01/05

Globe

I H

Angle

Standard Materials

Body & Cover: Ductile Iron ASTM A536 Coating: NSF Listed Fusion Bonded Epoxy Lined and Coated 316 Stainless Steel Buna-N (standard) EPDM (optional) Viton (optional)

A VALVE SIZE 6 8 10 12 16 18 20 24 GLOBE 150# 17-3/4 21-3/8 26 30 35 48 48 48 B GLOBE 300# 18-5/8 22-3/8 27-3/8 31-1/2 36-5/8 49-5/8 49-5/8 49-3/4 C COVER TO CENTER 11-5/8 15 17-7/8 21 25-3/4 31 31 31 D ANGLE 150# 8-7/8 10-11/16 E ANGLE 300# 9-3/8 11-3/16 F ANGLE 150# 6-3/4 7-1/4 G ANGLE 300# 7-1/4 7-3/4 H PORT SIZE 3/4 1 1 1 1 1 1 1

H

F G

A B

Trim: Elastomers:

D E

Dimensions

I PORT SIZE 3/4 3/4 1 1-1/4 1-1/4 1-1/2 1-1/2 1-1/2 SHIPPING WEIGHTS* 77 168 225 376 450 850 860 870

Description

*Estimated in lbs.

The Watts ACV Models S6500 and S61500 are reduced port, dual chamber basic valves that incorporate a one-piece disc and diaphragm assembly. This assembly is the only moving part within the valve, allowing it to open or close as commanded by the pilot control system. When pressure is applied to the upper diaphragm chamber and released from the lower diaphragm chamber, the valve travels to a closed position. When pressure is applied to the lower diaphragm chamber and released from the upper diaphragm chamber the valve travels to a full open position. When pressure is balanced between the upper and lower diaphragm chambers, the valve will hold an intermediate position until commanded to modulate open or closed by the pilot control system. The Stainless Steel design offers superior corrosion resistance, as well as a lightweight alternative to conventional heavy iron valves. Stainless Steel construction provides extended, diaphragm life and reduces the frequency and labor costs associated with traditional maintenance repairs. Model S6500: Globe Pattern Dual Chamber Basic Valve Model S61500: Angle Pattern Dual Chamber Basic Valve

Operating Pressure

150 Flanged = 250 psi / 300 Flanged = 400 psi

Operating Temperature

Buna-N: 160F Maximum EPDM: 300F Maximum Viton: 250F Maximum

8550 Hansen Road Houston, Texas 77075 (Ph) 713.943.0688 (Fx) 713.944.9445 www.wattsacv.com

Flow Flow Data Data - ACV S6500 (Globe) / S61500(Angle)

Valve Size - Inches Maximum Continuous Flow Rate Gpm (Water) Maximum Intermittent Flow Rate Gpm (Water) CV Factor GPM (Globe) CV Factor GPM (Angle) 6 800 1000 224 237 8 1850 2300 489 534 10 3100 4000 932 12 5000 6250 1428 16 7000 8900 2067 18 11100 14100 2881 20 11100 14100 2881 24 11100 14100 2881

Maximum continuous flow based on velocity of 20 ft. per second. Maximum intermittent flow based on velocity of 25 ft. per second. The CV factor of a valve is the flow rate in US GPM at 60 F that will cause a 1 psi drop in pressure. The factors stated are based upon a fully open valve. CV factor can be used in the following equations to determine Flow (Q) and Pressure Drop (r P): Q (Flow) = CV r P rP (Pressure Drop) = (Q/CV)2

12

100 80 60 40

Pressure Drop (p.s.i.)

30 20

10 8 6 4 3 2

2 100,000

6 8 10

20

40 60 80 100

200

500

1000

2000

5000 10000 20000

Flow Rate - Gallons per minute (Water)

Valve Cover Valve CoverChamber Cham- Capacity

Valve Size (in) .oz. U.S. Gal 6 22 8 70 1-1/4 2-1/2 4 9-1/2 9-1/2 9-1/2 10 12 16 18 20 24

Valve Valve Travel Travel

Valve Size (in) (in) 6 1 8 1-1/2 10 2 12 2-1/2 16 3 18 4 20 4 24 4

8550 Hansen Road Houston, Texas 77075 (Ph) 713.943.0688 (Fx) 713.944.9445 www.wattsacv.com

16

18 /

Angle Globe

6

10

20 /

24

Headloss

Das könnte Ihnen auch gefallen

- Es WD TD 300 UsaDokument1 SeiteEs WD TD 300 UsaWattsNoch keine Bewertungen

- Es WQ PWSRDokument2 SeitenEs WQ PWSRWattsNoch keine Bewertungen

- Es WD Li 12 LT UsaDokument1 SeiteEs WD Li 12 LT UsaWattsNoch keine Bewertungen

- Es OfpsysDokument2 SeitenEs OfpsysWattsNoch keine Bewertungen

- Es WQ PwfgacDokument2 SeitenEs WQ PwfgacWattsNoch keine Bewertungen

- Es WQ PwfcalDokument2 SeitenEs WQ PwfcalWattsNoch keine Bewertungen

- Es Oftwh CDokument2 SeitenEs Oftwh CWattsNoch keine Bewertungen

- Series 97FB-FSFE Specification SheetDokument2 SeitenSeries 97FB-FSFE Specification SheetWattsNoch keine Bewertungen

- Series LFFHB Specification SheetDokument2 SeitenSeries LFFHB Specification SheetWattsNoch keine Bewertungen

- Es FHBDokument1 SeiteEs FHBWattsNoch keine Bewertungen

- Es WQ PwsrtaDokument2 SeitenEs WQ PwsrtaWattsNoch keine Bewertungen

- Es WQ PWFMZDokument2 SeitenEs WQ PWFMZWattsNoch keine Bewertungen

- ES PW SmartStream ADokument4 SeitenES PW SmartStream AWattsNoch keine Bewertungen

- Is WD DLSZ InstallationDokument1 SeiteIs WD DLSZ InstallationWattsNoch keine Bewertungen

- Es BD1156FDokument2 SeitenEs BD1156FWattsNoch keine Bewertungen

- Es WD Hy 800 CanDokument1 SeiteEs WD Hy 800 CanWattsNoch keine Bewertungen

- Es 757isrDokument2 SeitenEs 757isrWattsNoch keine Bewertungen

- Is WD DLSZ InstallationDokument1 SeiteIs WD DLSZ InstallationWattsNoch keine Bewertungen

- Es Lfemvii 6400SSDokument4 SeitenEs Lfemvii 6400SSWattsNoch keine Bewertungen

- Es 957isrDokument2 SeitenEs 957isrWattsNoch keine Bewertungen

- Es Lf474aDokument2 SeitenEs Lf474aWattsNoch keine Bewertungen

- Es BD911Dokument2 SeitenEs BD911WattsNoch keine Bewertungen

- Es Lf474aDokument2 SeitenEs Lf474aWattsNoch keine Bewertungen

- ES WD DeadLevel S USADokument1 SeiteES WD DeadLevel S USAWattsNoch keine Bewertungen

- Es-Of1465tm 1665TMDokument3 SeitenEs-Of1465tm 1665TMWattsNoch keine Bewertungen

- ES WD DeadLevel Z USADokument1 SeiteES WD DeadLevel Z USAWattsNoch keine Bewertungen

- Basic Construction Operation Troubleshooting: WarningDokument2 SeitenBasic Construction Operation Troubleshooting: WarningWattsNoch keine Bewertungen

- Es WD FD 930 UsaDokument1 SeiteEs WD FD 930 UsaWattsNoch keine Bewertungen

- Es LFRC105Dokument2 SeitenEs LFRC105WattsNoch keine Bewertungen

- Es LFMMV HTKDokument2 SeitenEs LFMMV HTKWattsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Zhang Et Al. 2010Dokument6 SeitenZhang Et Al. 2010Aizat HawariNoch keine Bewertungen

- NSTM 262 OilsDokument110 SeitenNSTM 262 OilsMaria Gabriela BusteloNoch keine Bewertungen

- BCA Protocol PDFDokument7 SeitenBCA Protocol PDFAlyssa236Noch keine Bewertungen

- Abs 0678Dokument11 SeitenAbs 0678Jorge OrtegaNoch keine Bewertungen

- Check Valve (Swagelok) MS-01-176 PDFDokument16 SeitenCheck Valve (Swagelok) MS-01-176 PDFIsmailIbrahimNoch keine Bewertungen

- TeslaDokument13 SeitenTeslaAmal ShajiNoch keine Bewertungen

- Nano Coating Application For Corrosion Reduction in Oil and Gas Transmission Pipe: A Case Study in South of IranDokument7 SeitenNano Coating Application For Corrosion Reduction in Oil and Gas Transmission Pipe: A Case Study in South of IranInternational Journal of Science and Engineering InvestigationsNoch keine Bewertungen

- 13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureDokument2 Seiten13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureAlyssaRamosNoch keine Bewertungen

- Chromatographyvolume 1Dokument99 SeitenChromatographyvolume 1JOSE R. LEALNoch keine Bewertungen

- Piper Moisture Equilibrium Between - Gas - Space - A Secado de Transformadores PDFDokument7 SeitenPiper Moisture Equilibrium Between - Gas - Space - A Secado de Transformadores PDFarmandoa71565Noch keine Bewertungen

- Electrostatics PDFDokument17 SeitenElectrostatics PDFcolorado wildernessNoch keine Bewertungen

- TFP330 10 2013Dokument4 SeitenTFP330 10 2013Mihai CatalinNoch keine Bewertungen

- Astm f136 Rev ADokument4 SeitenAstm f136 Rev AAhmad BrianNoch keine Bewertungen

- Acid Mist Generation in Copper Electrowinning (Hydrometallurgy Publication)Dokument6 SeitenAcid Mist Generation in Copper Electrowinning (Hydrometallurgy Publication)aweloongaNoch keine Bewertungen

- Computational Evaluate Self-Reactivity HazardsDokument8 SeitenComputational Evaluate Self-Reactivity Hazardspolaris44100% (1)

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDokument32 SeitenAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanNoch keine Bewertungen

- Robustness of The QAL2 Calibration EN14181 UncertaDokument10 SeitenRobustness of The QAL2 Calibration EN14181 UncertaAnaibar TarikNoch keine Bewertungen

- Che 511 HW Set #5 Due Nov 12: Additional InformationDokument2 SeitenChe 511 HW Set #5 Due Nov 12: Additional InformationAshish KotwalNoch keine Bewertungen

- Introduction To The Problems Surrounding Garment TextilesDokument30 SeitenIntroduction To The Problems Surrounding Garment TextilesFathi Mustafa100% (1)

- MSDS Benzene PDFDokument6 SeitenMSDS Benzene PDFPiyu SyahputraNoch keine Bewertungen

- Yi Jian ElementBuilderSEDokument6 SeitenYi Jian ElementBuilderSEYi Jian80% (5)

- Hollow Bricks Manufacturing StepsDokument3 SeitenHollow Bricks Manufacturing StepsClark G. BennettNoch keine Bewertungen

- Chemical Food SafetyDokument297 SeitenChemical Food SafetyqtrystNoch keine Bewertungen

- Synthesis of UiO 66 OH Zirconium Metal Organic FrameworkDokument7 SeitenSynthesis of UiO 66 OH Zirconium Metal Organic FrameworkFilozofijaPaleNoch keine Bewertungen

- TPXData SheetDokument4 SeitenTPXData Sheetrameshkarthik810Noch keine Bewertungen

- Cyberware AlternityDokument25 SeitenCyberware Alternitycymru devourer100% (1)

- Characterization of Iron Oxide Thin Film Prepared by The Sol-Gel MethodDokument2 SeitenCharacterization of Iron Oxide Thin Film Prepared by The Sol-Gel MethodBryan Anders AguilarNoch keine Bewertungen

- Cost Unit Februri 2017dddddddddddgDokument563 SeitenCost Unit Februri 2017dddddddddddgHatlan RizalNoch keine Bewertungen

- PDS Hempathane HS 55610 en-GBDokument3 SeitenPDS Hempathane HS 55610 en-GBalouisNoch keine Bewertungen

- Implementing Claim, Evidence, ReasoningDokument12 SeitenImplementing Claim, Evidence, ReasoningGreeshma ColumbusNoch keine Bewertungen