Beruflich Dokumente

Kultur Dokumente

Muhammad Aqib: Inspection Technician

Hochgeladen von

usama666Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Muhammad Aqib: Inspection Technician

Hochgeladen von

usama666Copyright:

Verfügbare Formate

Muhammad Aqib

Inspection Technician

A-183 Gulshan e Hadeed Phase-2 Bin Qasim Karachi.

aqib.muhammad93@gmail.com

Contact Number: +92-3312429749

PROFESSIONAL CERTIFICATIONS:-

CSWIP 3.1(TWI)

RADIOGRAPHY LEVEL-1 (NCNDT)

RADIOGRAPHY LEVEL-2 (ASNT)

DPT LEVEL-2 (ASNT)

VISUAL INSPECTION LEVEL-2 (ASNT)

MAGNETIC PARTICAL TESTING LEVEL-2 (ASNT)

EMPLOYMENT HISTORY

DESIGN: - INSPECTION TECHNICIAN

CLIENT: - FAUJI FERTILIZER BIN QASIM LTD. KARACHI

DURATION: - JAN. 2017 – PRESENT

I HAVE PERFORMED THE FOLLOWING JOBS INDEPENDENTLY.

Perform Welding Qualification Test as per procedure To check the condition of consumables

Hydro testing of Exchanger, Vessel, Drum, Tank and Project Piping.

Leak Test (By SFT, Pneumatic Test, Hydro test)

Maintain the documentation work.

Pressure Vessels and Tanks Inspection as per API 510 and 653

Inspection of Exchangers.

Inspection of tubes of Furnace

Inspection of Rubber Lining of Tanks

Plant Process piping, Pipelines Inspections as per API 570

Knowledge of Material used at Fertilizer Plant

Welders Qualification Tests at all positions and Welding Inspection according to ASME Sec IX.

Data collection from Isometrics and P&ID’s

Witness of Welder Qualification as per ASME Sec IX.

Witness of welding Inspection of new fabricated tanks

PROFESSIONAL EXPERIENCE IN NDT WITH EQUIPMENT & REFERENCE

Visual Inspection, Videoscopy Inspection.

Dye penetrate Testing (solvent removal+ water washable+ and fluorescent

Magnetic Particle Testing ( With permanent and A.C&DC Yolk + Fluorescent and Visible)

Radiographic Test (with Ir.192)

Thickness Measurement and Ultrasonic Test (with 36DLPLUS, 38DL PLUS, DM4DL)

Hardness Test (with Equitip, Equitio 3)

Positive Material Identification (with Innovex XPD 2000 Analyzer)

In-service Piping Inspection / Thickness monitoring of critical piping using 36 DLPLUS, 38DL

PLUS, DM4DL) UT gauges to ensure safe containment as per Monitoring Plans.

Preparation of Thickness Monitoring reports

Preparation of Welding Procedure, considering repair or construction requirement.

Welding inspection of CS, SS, and Alloy Steel piping according to Procedure

CONDITION MONITORING

Routine and planned casing vibration monitoring of rotary equipment using TK-81 & Entek IRD’s

data PAC 1500, Dynamic 2500.

Keep historical record of all rotating machines including vibration, temperature and machine data.

DESIGN: - WELDING INSPECTOR

CLIENT: - ARAMCO (KSA)

DURATION: - OCT, 2016 TO NOV, 2017

To check approved WPS

Implement The ARAMCO Standards

To check the approved drawings

To check the condition of welding consumables.

To check the fit-up and welding inspection before, during and after.

To implement the ARAMCO standards. (SAES W12)

Perform cleaning inspection of pipe lines.

To check the approved JCC of welders as per client instruction.

Maintain the pre-heat temperature as per approved WPS.

Perform final inspection of welding joints with clients.

To maintain the Daily Welding Report on daily basis. (DWR)

DESIGN: - QA/QC INSPECTOR

CLIENT: - CHINA PETROLEUM CONSTRUCTION COMPANY (SOUTH SUDAN PROJECTS)

DURATION: - JUL. 2014 – SEP . 2016

Witness of welder qualification test as per approved WPS.

Perform Radiography of pipeline joints and also T joints of Tanks.

Review the approved WPS and WPQR.

Witness of NDT result as per ITP.

Field inspection of welding of flow line joints as per approved WPS.

Visual inspection of T joints of tanks and also interpretation of radio graphic films.

Witness of hydro test activities.

To inspect the fit up and welding joints of piping of well heads.

DESIGN: - QA/QC INSPECTOR

CLIENT: - ZEHENG HUAT ENGINEERING SERVICES. SOUTH SUDAN

DURATION: - JUN. 2016 – AUG. 2016

To conduct the welder performance qualification test and maintaining qualification list of welders.

Witness of NDE results.

Review the approved WPS and WPQR.

Interpretation of radiographic films.

To inspect the fit-up and weld joints of flow lines and piping as per WPS To maintain daily welding

report.

Witness of hydro test activities.

Responsible for welding inspection of flow line and above ground piping and with client for closing

punch items and release for box up.

DESIGN: - INSPECTION TECHNICIAN

CLIENT: - ENGRO POLYMER CHEMICAL LTD.

DURATION: - APR. 2016 – MAY. 2016 (TURN ARAOUND)

To perform inspection of WQT by visually and interpretations of RT films.

To perform welding inspection of heat exchanger tubes.

Witness of DPI and MPI inspection in pressure vessels.

To mark repairs and inspection of repairs as per client / ITP recommendations.

Witness of cleaning inspections of tube bundles, shells of heat exchangers and internal cleaning of

shell of pressure vessels, columns and release for box up.

To mark the repairs on weld joints regarding radiographic films

DESIGN: - QA/QC INSPECTOR (STATIC EQUIPMENT' S)

CLIENT: - DESCON ENGINEERING (ENOC REFINERY UAE)

DURATION: - JAN. 2016 – APR. 2016

PROFESSIONAL EXPERIENCE IN TURN AROUND:-

To check the JCC of welders and also check the environment of welding area as per procedure

To check the condition of welding consumables and inspections of piping joints in fabrication shop

as per approved WPS.

Shared the safety activities to welders during welding regarding good work man ship.

To perform pre cleaning inspection and post cleaning inspection of exchanger bundles of fin fan

cooler.

To perform pre and post cleaning inspection of columns.

To witness of result of NDE inspection after cleaning of T joints of columns, and tanks To marks

repairs and inspection of repairs as client.

To perform visual inspection before and after hydro jetting of tube bundles , shells of heat

exchangers and internal cleaning of shell pressure vessels column and release for box up.

To witness of pressure testing of heat exchangers as per approved ITP in all inspection stages.

DESIGN: - INSPECTION TECHNICIAN

CLIENT: - FAUJI FERTILIZER BIN QASIM LTD. KARACHI

DURATION: - 25 DAYS (2012, 2013, 2014, 2015)

PROFESSIONAL EXPERIENCE IN ANNUAL TURN AROUND:-

Perform NDT (DPT, MPI, UT, RT)

Ensuring that all piping work complies with contract and company health, safety, environmental and

quality policies and procedure.

Witness of hydro test activities of heat exchangers.

Visual and NDE inspection of burner nozzles.

Safety trainings specially Turnarounds.

To mark repair and inspection of repairs as per specifications.

To perform cleaning inspections and DPI inspection of plates of heat exchangers.

To perform welding inspection before, during and after and witness of pre heat, inter pass

temperature as per WPS

Perform DPI inspection of Plate type heat exchangers.

EDUCATION

Diploma of Associate Engineer (Mechanical)

(SINDH BOARD OF TECHNICAL EDUCATION KARACHI)

PERSONAL INFORMATION

Father Name: Wajid Ali Burki

CNIC: 42201-9324089-7

Date of Birth: 27/11/1993

Marital Status:Married

TOTAL NUMBER OF EXPERIENCE

7 Years’ Experience

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Resume An Welding InspectorDokument7 SeitenResume An Welding InspectorspearboraNoch keine Bewertungen

- Piping QC Inspector Resume 2020Dokument5 SeitenPiping QC Inspector Resume 2020Omprakash Yadav100% (1)

- APIINSPECTORDokument10 SeitenAPIINSPECTORdada khalandarNoch keine Bewertungen

- Veera CVDokument7 SeitenVeera CVPaul PhiliphsNoch keine Bewertungen

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Dokument7 SeitenResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinNoch keine Bewertungen

- Curriculum Vitae New 2017 MD Sajid AlamDokument6 SeitenCurriculum Vitae New 2017 MD Sajid AlamAlam MD SazidNoch keine Bewertungen

- QC CV SampleDokument11 SeitenQC CV SampleSikander NawazNoch keine Bewertungen

- CV SALAH JALLALI - English - Rev.01Dokument8 SeitenCV SALAH JALLALI - English - Rev.01salahjallaliNoch keine Bewertungen

- Muhammed Thanzeel QC Mechanical Inspector: ObjectivesDokument5 SeitenMuhammed Thanzeel QC Mechanical Inspector: ObjectivesMuhammed ThanzeelNoch keine Bewertungen

- Plant InspectorDokument7 SeitenPlant Inspectornaveed7861Noch keine Bewertungen

- CV & Certficate Merged.hDokument28 SeitenCV & Certficate Merged.hAjyal Union Ltd. Co.Noch keine Bewertungen

- K e y SK I L L S:: Experience HiglightsDokument5 SeitenK e y SK I L L S:: Experience Higlightswins zxcNoch keine Bewertungen

- QAQC Mechanical EngineerDokument6 SeitenQAQC Mechanical EngineerMohammed Anwaar ShaikhNoch keine Bewertungen

- CV - Sqa-UaeDokument13 SeitenCV - Sqa-UaeShanmuga Navaneethan100% (1)

- Resume of Qaqc Welding-Mechanical InspectorDokument5 SeitenResume of Qaqc Welding-Mechanical InspectorMohammed Illiasuddin100% (1)

- CV FormateDokument8 SeitenCV Formatetariq_hussain_20Noch keine Bewertungen

- Abdul Khaliq CV As A QC SupervisorDokument6 SeitenAbdul Khaliq CV As A QC SupervisorMNoch keine Bewertungen

- CV Salah Jallali - English New RevDokument8 SeitenCV Salah Jallali - English New RevSalah JallaliNoch keine Bewertungen

- Up Dated CV of D K Jena - DNV GLDokument15 SeitenUp Dated CV of D K Jena - DNV GLParag WadekarNoch keine Bewertungen

- Jawad+Ahsan + ResumeDokument3 SeitenJawad+Ahsan + ResumeAndiappan PillaiNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- New Updated Haider CVDokument5 SeitenNew Updated Haider CVFarhan haiderNoch keine Bewertungen

- Rashid CV (Equipment Inspector-SEP-2017)Dokument3 SeitenRashid CV (Equipment Inspector-SEP-2017)vajidqcNoch keine Bewertungen

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDokument7 SeitenInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarNoch keine Bewertungen

- L 1 Asad Ahmad Qaqc Piping Welding Ins PDFDokument9 SeitenL 1 Asad Ahmad Qaqc Piping Welding Ins PDFyasiriftikharNoch keine Bewertungen

- Qa/Qc Welding Inspector: Curriculum VitaeDokument5 SeitenQa/Qc Welding Inspector: Curriculum Vitaenaveed7861Noch keine Bewertungen

- Faizur Rahman CVDokument6 SeitenFaizur Rahman CVmuneeshwaraperumalNoch keine Bewertungen

- Mechanical Engineer: Mohd. Layeequr RahmanDokument7 SeitenMechanical Engineer: Mohd. Layeequr RahmanmdlayeequeNoch keine Bewertungen

- Mohammed Zeeshan API InspectorDokument8 SeitenMohammed Zeeshan API InspectorGulfam ShahzadNoch keine Bewertungen

- CV of Welding InspectorDokument4 SeitenCV of Welding Inspectorramesh77c100% (2)

- Rashid New CV (WI-SEP-2017)Dokument3 SeitenRashid New CV (WI-SEP-2017)vajidqcNoch keine Bewertungen

- CV of Engineer MD Sazid Alam1Dokument8 SeitenCV of Engineer MD Sazid Alam1Alam MD SazidNoch keine Bewertungen

- Ramdas P R Resume: QA/QC Inspector/ Supervisor (Welding& Piping)Dokument9 SeitenRamdas P R Resume: QA/QC Inspector/ Supervisor (Welding& Piping)Myak Okuoku100% (2)

- Welding InspectorDokument5 SeitenWelding InspectorqaqcnaviNoch keine Bewertungen

- Rashid New CV (Feb-2017)Dokument3 SeitenRashid New CV (Feb-2017)vajidqcNoch keine Bewertungen

- CV 2023Dokument5 SeitenCV 2023AmitNoch keine Bewertungen

- Cengiz Karaköse: 05.2019, Now, NDT Coordinator - Responsible For All NDT Works in ProjectDokument4 SeitenCengiz Karaköse: 05.2019, Now, NDT Coordinator - Responsible For All NDT Works in ProjectCengiz KARAKOSENoch keine Bewertungen

- Edison Aliagan Walit: Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailDokument8 SeitenEdison Aliagan Walit: Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailEdison WalitNoch keine Bewertungen

- CV Aravind API InspectorDokument12 SeitenCV Aravind API Inspectorநான் மகான் அல்லNoch keine Bewertungen

- Yavar Shadab CVDokument4 SeitenYavar Shadab CVMuhammed ThanzeelNoch keine Bewertungen

- Shaik Yousufuddin (Welding Inspector)Dokument3 SeitenShaik Yousufuddin (Welding Inspector)Mohamed AdelNoch keine Bewertungen

- Lijo Johnson - Api Inspector - 510 - CVDokument5 SeitenLijo Johnson - Api Inspector - 510 - CVonline M100% (1)

- Edison Aliagan Walit: Registered Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailDokument8 SeitenEdison Aliagan Walit: Registered Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailEdison WalitNoch keine Bewertungen

- Abdul Qadir Welding Inspector CVDokument6 SeitenAbdul Qadir Welding Inspector CVSani TipareNoch keine Bewertungen

- Devi Vara PrasadDokument8 SeitenDevi Vara PrasadPaul PhiliphsNoch keine Bewertungen

- QAQC Welding Painting InspectorDokument6 SeitenQAQC Welding Painting InspectorPramod Gr100% (1)

- Resume of Qaqc Mech InspectorDokument5 SeitenResume of Qaqc Mech InspectorMohammed IlliasuddinNoch keine Bewertungen

- Anoop.S. P: (Qa/Qc Welding/Piping)Dokument10 SeitenAnoop.S. P: (Qa/Qc Welding/Piping)Hanuman RaoNoch keine Bewertungen

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDokument9 SeitenTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNoch keine Bewertungen

- Mohamed Ashim: Mechanical InspectorDokument5 SeitenMohamed Ashim: Mechanical InspectorMad TahaNoch keine Bewertungen

- First Name: Majdi Last Name: Jerbi Birth Date and Place: 28/02/1985 (Sfax)Dokument6 SeitenFirst Name: Majdi Last Name: Jerbi Birth Date and Place: 28/02/1985 (Sfax)Dali MhiriNoch keine Bewertungen

- Tenveer Hussain CV 29124Dokument7 SeitenTenveer Hussain CV 29124Tanveerhussain Q.ANoch keine Bewertungen

- Shahbaz Ahmad CVDokument8 SeitenShahbaz Ahmad CVShahbaz AhmadNoch keine Bewertungen

- BgasDokument8 SeitenBgassudhakar rajendranNoch keine Bewertungen

- CV of Raj (Dec'23)Dokument3 SeitenCV of Raj (Dec'23)ahiadarshNoch keine Bewertungen

- CSWIP-3.2.2 & API 570 - BiswajitDokument5 SeitenCSWIP-3.2.2 & API 570 - BiswajitmanojNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsVon EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNoch keine Bewertungen

- Analysis of Roller BearingDokument15 SeitenAnalysis of Roller Bearingusama666Noch keine Bewertungen

- 10/1/06 List of Niosh Standard Protections, Cautions and Limitations For Approval LabelsDokument4 Seiten10/1/06 List of Niosh Standard Protections, Cautions and Limitations For Approval Labelsusama666Noch keine Bewertungen

- MCQ and Short QuestionDokument3 SeitenMCQ and Short Questionusama666Noch keine Bewertungen

- Beyblade: Jump To Navigationjump To SearchDokument4 SeitenBeyblade: Jump To Navigationjump To Searchusama666Noch keine Bewertungen

- Chapter 7: Quiz: Mohammed Alfaraj - May 23, 2021 7:05:43 PMDokument8 SeitenChapter 7: Quiz: Mohammed Alfaraj - May 23, 2021 7:05:43 PMusama666Noch keine Bewertungen

- Usama Ijaz Internship LetterDokument1 SeiteUsama Ijaz Internship Letterusama666Noch keine Bewertungen

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Dokument2 SeitenDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666Noch keine Bewertungen

- % Gravitation Acceleration % Length of Pendulum % Damping Co-Efficient % Default Max. Step Size % Step Size % Time Interval % Total Number of StepsDokument1 Seite% Gravitation Acceleration % Length of Pendulum % Damping Co-Efficient % Default Max. Step Size % Step Size % Time Interval % Total Number of Stepsusama666Noch keine Bewertungen

- Due: July 22: Mini Project IV ME373Dokument3 SeitenDue: July 22: Mini Project IV ME373usama666Noch keine Bewertungen

- TSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life EstimationDokument11 SeitenTSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life Estimationusama666Noch keine Bewertungen

- Latent Thermal Energy Storage: Usama Ijaz 2014-ME-126Dokument10 SeitenLatent Thermal Energy Storage: Usama Ijaz 2014-ME-126usama666Noch keine Bewertungen

- Tahir Cv.Dokument1 SeiteTahir Cv.usama666Noch keine Bewertungen

- Manual LiftingDokument1 SeiteManual Liftingusama666100% (1)

- Usama Ijaz 1Dokument1 SeiteUsama Ijaz 1usama666Noch keine Bewertungen

- Nominal Thickness (MM) Minimum Measured Thickness (MM)Dokument2 SeitenNominal Thickness (MM) Minimum Measured Thickness (MM)usama666Noch keine Bewertungen

- Aasim Shahzad Alam 1Dokument1 SeiteAasim Shahzad Alam 1usama666Noch keine Bewertungen

- Valve Lift DiagramDokument2 SeitenValve Lift Diagramusama666Noch keine Bewertungen

- Careem ReceiptDokument2 SeitenCareem Receiptusama666Noch keine Bewertungen

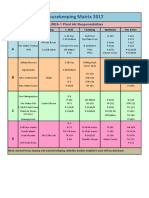

- Housekeeping Matrix 2017: UREA-1 Plant HK ResponsibilitiesDokument3 SeitenHousekeeping Matrix 2017: UREA-1 Plant HK Responsibilitiesusama666Noch keine Bewertungen

- Engro Project ReportDokument16 SeitenEngro Project Reportusama66650% (2)

- Housekeeping Matrix 2017: UREA-1 Plant HK ResponsibilitiesDokument3 SeitenHousekeeping Matrix 2017: UREA-1 Plant HK Responsibilitiesusama666Noch keine Bewertungen

- Application Form For CSWIP 5 Year Renewal (Overseas)Dokument7 SeitenApplication Form For CSWIP 5 Year Renewal (Overseas)prabuNoch keine Bewertungen

- ADANI Security Brochure A4 ENG 100119Dokument12 SeitenADANI Security Brochure A4 ENG 100119Nassima BELILNoch keine Bewertungen

- List of Technical Report To Be UploadedDokument6 SeitenList of Technical Report To Be UploadedSAGAR BAGDENoch keine Bewertungen

- Quality Requirements For Welding Fusion Welding of Metallic MaterialsDokument12 SeitenQuality Requirements For Welding Fusion Welding of Metallic Materialspalani.djpNoch keine Bewertungen

- Supplier Evaluation - 27.06Dokument27 SeitenSupplier Evaluation - 27.06sharanNoch keine Bewertungen

- Elite Precast Concrete Limited: Risk Assessment & Method StatementDokument6 SeitenElite Precast Concrete Limited: Risk Assessment & Method StatementblahblahNoch keine Bewertungen

- University of Rizal System: Republic of The Philippines Antipolo City A.Y. 2019 - 2020Dokument20 SeitenUniversity of Rizal System: Republic of The Philippines Antipolo City A.Y. 2019 - 2020Czelsi Carlos NavarroNoch keine Bewertungen

- ITP For Raised Access FlooingDokument2 SeitenITP For Raised Access FlooingDeepak MewadaNoch keine Bewertungen

- FqwaecsDokument2 SeitenFqwaecsMohamed SelimNoch keine Bewertungen

- Vineesh - Store KeeperDokument3 SeitenVineesh - Store KeeperAnonymous JJLEwONoch keine Bewertungen

- Food Safety Audit ReportDokument27 SeitenFood Safety Audit ReportafmishNoch keine Bewertungen

- Adwea Standard Quality Control Plan (SQCP) : For Ductile Iron FittingsDokument17 SeitenAdwea Standard Quality Control Plan (SQCP) : For Ductile Iron FittingsAmro HarasisNoch keine Bewertungen

- Operating Instruction ASL 94Dokument291 SeitenOperating Instruction ASL 94Bayanaka Tehnik100% (1)

- UV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Dokument20 SeitenUV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Fairuz Luthfa100% (1)

- TubeDokument126 SeitenTubeONESTAR111100% (1)

- Quality Manual - Free FormDokument21 SeitenQuality Manual - Free Formshyam100% (1)

- Jig 4 SmallerAirportsJIG4 - CHECK LISTDokument26 SeitenJig 4 SmallerAirportsJIG4 - CHECK LISTgulfpipinggmailcom100% (5)

- Quality in Construction ProjectsDokument179 SeitenQuality in Construction ProjectsJaydeepDas100% (2)

- Method Statement For Internal Painting Rev 2Dokument20 SeitenMethod Statement For Internal Painting Rev 2Ngô Trung NghĩaNoch keine Bewertungen

- MS Site and FenceDokument11 SeitenMS Site and FenceSahabzada AamirNoch keine Bewertungen

- XBLR3103 SG PDFDokument67 SeitenXBLR3103 SG PDFNur Faizuddin AmanNoch keine Bewertungen

- Pa 020 0028 - PSSRDokument18 SeitenPa 020 0028 - PSSRrizqi widodo100% (1)

- SAEP-379 Quality Issues NotificationDokument4 SeitenSAEP-379 Quality Issues NotificationMusic And FunNoch keine Bewertungen

- Peri Up Flex Shoring Tower Instructions For Assembly and UseDokument80 SeitenPeri Up Flex Shoring Tower Instructions For Assembly and UsedzuklevskiNoch keine Bewertungen

- Itp For Structural Steel Work 4 PDF FreeDokument12 SeitenItp For Structural Steel Work 4 PDF FreemahmoudNoch keine Bewertungen

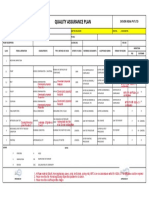

- Quality Assurance Plan: Dover India PVT LTDDokument1 SeiteQuality Assurance Plan: Dover India PVT LTDDeepak UpadhyayNoch keine Bewertungen

- 1781 - 001 - Fire ProtectionDokument21 Seiten1781 - 001 - Fire ProtectionabdulNoch keine Bewertungen

- ANSI-ASIS - Audiiting Management Systems - SPC2 - Exec Summary PDFDokument19 SeitenANSI-ASIS - Audiiting Management Systems - SPC2 - Exec Summary PDFslusaf100% (1)

- RISK IN FidicDokument53 SeitenRISK IN FidicANASNoch keine Bewertungen

- Inside302 PDFDokument46 SeitenInside302 PDFaarigonNoch keine Bewertungen