Beruflich Dokumente

Kultur Dokumente

Catalogue PDF

Hochgeladen von

apurv bhartiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Catalogue PDF

Hochgeladen von

apurv bhartiCopyright:

Verfügbare Formate

2006

Measuring pin catalogue

Measuring pins

Measuring pin sets

Storage cases

Test Certificates

Magnetic measuring pins

PRECISION STANDARD TOOLS

PINNING SYSTEMS

DREI-S-technologies

3S_pruefstifte_engl_2008.indd 1 24.07.2008 14:54:11

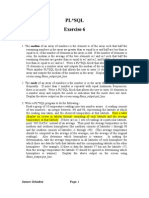

MEASURING PINS

Linearity of bore holes

DREI-S measuring pins are high-precision testing instruments with a

tolerance of ± 1μm in tolerance class I. Boasting excellent reliability and

hard-wearing qualities, they are ideal for use in quality assurance, in

stock receipt control and in manufacturing processes. They are simple to

use and very suitable for measurement tests on work pieces in manu-

facture, e.g. for testing bore holes on jig boring machines and/or on jig

milling machines.

Adjustment of Angularity of bore

dial gauges holes and bore hole Our many years of experience, continuous investment in complex

tolerances manufacturing plants and high-precision, PC-networked quality control

plants guarantee the quality of DREI-S measuring pins, which hold a

leading position in the European market.

DREI-S measuring pins are particularly suitable for the measurement

of even the smallest bore holes. In contrast to expensive internal measu-

ring instruments, their length offers a significant advantage: deep bore

holes can be measured not only for their dimensional accuracy but also

Groove measurements Micrometer divisions for their linearity and angularity.

DREI-S measuring pins can also be used for the measurement of an-

gularity, distances between holes, dovetail guides, profile depths, guide

surfaces and groove measurements.

In addition, they are suitable as adjustment controllers for a wide variety

of measuring instruments such as micrometers, dial gauges, as well as

go / no–go gauges.

DREI-S measuring pins are manufactured from gauge steel, hardness

Distance between holes Guide surfaces 60 – 64 HRC in accordance with DIN 2269, and tested at a tempera-

ture of 20° C ± 1° C.

DREI-S measuring pin holders allow the straightforward creation of

individual go / no–go gauges, whereby two measuring pins are placed

in the holder to serve as the upper and lower limit of a given tolerance

range.

Here you can see some illustrations of some of the applications already

Dovetail guides Profile depths and angles implemented.

02

3S_pruefstifte_engl_2008.indd Abs1:2 24.07.2008 14:54:24

MEASURING PINS

DREI-S measuring pins are ideal for use as calibrating pins, as well to

complement or expand incomplete pin sets.

Nominal diameter Standard dimensions from Chamfering:

Accuracy in accordance with DIN 2269 Ø 0.10 – 25.00 mm

Tolerance class I = ± 0.001 mm

Tolerance class II = ± 0.002 mm

Grading As standards, increasing by 0.01 mm

Customised grading available on request d= 0.10 - 0.99 mm

Pins with 1/1000 mm grading are only available

in tolerance class I (± 0.001 mm)

Material in accordance with DIN 2269 Calibrated steel with hardness of 60-64 HRC, aged

Longitudinal expansion coefficient (11.5 ±1) x 10 -6 x K -1

Reference temperature in accordance 20° C ±1° C

with DIN 102

Length including chamfer from Ø 0.10 – 0.99 mm: 40 mm d= 1.00 - 10.00 mm

from Ø 1.00 – 25.00 mm: 70 mm

Deviation

For pins between Ø 0.10 - 0.49 mm a 1/1000 mm grading is

also possible

Standard length l = 30 mm

Tolerance class 0 = ± 0.0005 mm

Chamfer (see following sketches) from Ø 0.10 – 0.99 mm both ends plain

from Ø 1.00 – 10.00 mm one end bevelled

from Ø 10.01 – 25.00 mm both ends bevelled

Size and shape of bevelling in accordance with DIN 2269;

serves as protection against damage and makes insertion easier

d= 10.01 - 25.00 mm

Labelling from Ø 0.10 – 1.49 mm unlabelled

from Ø 1.50 – 2.99 mm labelling on centre of testing surface *)

from Ø 3.00 – 10.00 mm labelling on sharp-edged front surface

from Ø 10.01 – 25.00 mm labelling on a front surface

The tolerance class is not specified

Roundness Tolerance class I und II ≤ 1 μm

Surface roughness given in Rz, in Tolerance class I und II ≤ 1 μm

accordance with DIN 4768 Other surfaces in accordance with DIN 2269

*) CAUTION:

Because of possible enlargement in diameter, do not test above the marks!

03

3S_pruefstifte_engl_2008.indd Abs1:3 24.07.2008 14:54:39

MEASURING PIN SETS

DREI-S measuring pin sets are available in tolerance class I We supply 30 standard sets of measuring pins „from stock“.

= ± 0.001 mm or II = ± 0.002 mm in the diameter range Each set is available in two tolerance classes.

of 0.10 – 25.00 mm Ø, with a standard grading of 0.01 mm.

The measuring pins are supplied in high-quality storage cases. The storage cases are available in 3 sizes.

The appropriate size is determined by the content, i.e.

according to the number of items and their diameter.

Each pin is positioned individually in a high-quality plastic

plate by means of bore holes which are sized to fit the pin

diameter and labelled appropriately.

Customised gradings are also available by special order.

04

3S_pruefstifte_engl_2008.indd Abs1:4 24.07.2008 14:54:49

DREI-S STANDARD

MEASURING PIN SETS

Set Sets Storage Size Contents Diameter size Grading

No. cases (pcs.) in mm in mm

1 1 1 B 20 1.00 – 20.00 1.00

2 1 1 B 40 0.50 – 20.00 0.50

3 1 1 A 41 1.00 – 5.00 0.10

4 1 1 A 50 5.10 – 10.00 0.10

5 1 1 B 91 1.00 – 10.00 0.10

6 1 1 B 91 1.05 – 10.05 0.10

7 1 3 B 100 10.10 – 20.00 0.10

8 1 4 B 191 1.00 – 20.00 0.10

9 1 1 B 91 0.50 – 5.00 0.05

10 1 1 B 81 1.00 – 5.00 0.05

11 1 1 B 100 5.05 – 10.00 0.05

12 1 2 B 181 1.00 – 10.00 0.05

13 1 1 B 76 0.50 – 2.00 0.02

14 1 1 B 100 2.02 – 4.00 0.02

15 1 1 B 100 4.02 – 6.00 0.02

16 1 1 B 100 6.02 – 8.00 0.02

17 1 1 B 100 8.02 – 10.00 0.02

30 1 5 B 451 1.00 – 10.00 0.02

18 1 1 A 51 0.50 – 1.00 0.01

19 1 1 B 101 1.00 – 2.00 0.01

20 1 1 B 100 2.01 – 3.00 0.01

21 1 1 B 100 3.01 – 4.00 0.01

22 1 1 B 100 4.01 – 5.00 0.01

23 1 1 B 100 5.01 – 6.00 0.01

24 1 1 B 100 6.01 – 7.00 0.01

25 1 1 B 100 7.01 – 8.00 0.01

26 1 1 B 100 8.01 – 9.00 0.01

27 1 1 B 100 9.01 – 10.00 0.01

29* 1 1 C 273 1.00 – 10.00 0.10*

*in addition, for each no-

minal diameter, a test pin is

included with

+ 0.01 overdimension and

– 0.01 underdimension

05

3S_pruefstifte_engl_2008.indd Abs1:5 24.07.2008 14:54:57

STORAGE CASES

with bore holes for measuring pins

DREI-S storage cases protect the measuring pins and at the same time enable a clear storage system.

They are available in 3 sizes with a bore hole depth corresponding to the length of DREI-S measuring pins.

Design:

Wooden frame in black enamel.

Black plastic retaining panel with bore holes.

Labelling on all bore holes to show diameter sizes.

Tolerance class is specified on the plate.

06

3S_pruefstifte_engl_2008.indd Abs1:6 24.07.2008 14:54:57

External dimensions/capacity

Size A Small storage case

L approx. 175 mm, W approx. 155 mm, H approx. 84 mm

Capacity

55 measuring pins 0.10 – 0.99 mm Ø

50 measuring pins 1.00 – 6.99 mm Ø

25 measuring pins 7.00 – 13.00 mm Ø

Size B Standard storage case

L approx. 325 mm, W approx. 155 mm, H approx. 84 mm

Capacity

100 measuring pins 0.10 – 10.00 mm Ø

55 measuring pins 10.01 – 14.99 mm Ø

36 measuring pins 15.00 – 19.99 mm Ø

21 measuring pins 20.00 – 25.00 mm Ø

Size C Large storage case

With special dimensions, L approx. 415 mm, W approx. 325 mm, H approx. 84 mm

Capacity

according to diameter,

up to 300 measuring pins

07

3S_pruefstifte_engl_2008.indd Abs1:7 24.07.2008 14:55:06

Replaceable

PLASTIC HANDLES and

METAL HOLDERS

for measuring pins

Metal pin holders made of zinc die casting Plastic handles

DREI-S measuring pin holders allow the straightfor- The use of thin measuring pins may result in the pins hea-

ward creation of individual goods/spoilage calibres, ting up. Under these circumstances, the rated dimensions can

whereby two measuring pins are placed in the holder to no longer be guaranteed.

serve as the upper and lower limit of a given tolerance Measuring pins with a diameter range of Ø 0.40 to 5.30 mm

range. The measuring pin holders are available in maybe supplied with replaceable plastic handles

5 sizes.

Size of Span Length of Length Handle Span range Diameter Length

holder range holder of span length of handle of handle

approx. approx. approx. approx.

Size 1 1 - 2 mm Ø Size 1 0.40 – 0.80 mm Ø

60 mm 26 mm 8 mm 14 mm

approx. approx. approx. approx.

Size 2 2 - 4 mm Ø Size 2 0.80 – 1.30 mm Ø

68 mm 30 mm 8 mm 14 mm

approx. approx. approx. approx.

Size 3 4 - 6 mm Ø Size 3 1.30 – 1.80 mm Ø

76 mm 33 mm 8 mm 14 mm

approx. approx. approx. approx.

Size 4 6 - 8 mm Ø Size 4 1.80 – 2.30 mm Ø

84 mm 35 mm 8 mm 14 mm

approx. approx. approx. approx.

Size 5 8 - 10 mm Ø Size 5 2.30 – 2.80 mm Ø

92 mm 37 mm 8 mm 14 mm

approx. approx.

Size 6 2.80 – 3.30 mm Ø

8 mm 14 mm

approx. approx.

Size 7 3.30 – 3.80 mm Ø

8 mm 14 mm

approx. approx.

Size 8 3.80 – 4.30 mm Ø

8 mm 14 mm

approx. approx.

Size 9 4.30 – 4.80 mm Ø

8 mm 14 mm

approx. approx.

Size 10 4.80 – 5.30 mm Ø

8 mm 14 mm

08

3S_pruefstifte_engl_2008.indd Abs1:8 24.07.2008 14:55:06

CERTIFICATES OF

ACCURACY

The following certificates of accuracy

can be issued for measuring pins

Certificate of accuracy no.1 (free of charge)

General confirmation that the diameters of the measuring pins are in accordance with tolerance class I or II of DIN 2269.

Surface roughness and roundness ≤ 1 μm.

Certificate of accuracy no. 2* (at extra charge)

Each measuring pin is listed and classified in a table showing rated and actual diameter.

e.g. rated Ø 2.30 act. Ø 2.2998 Tol. I

rated Ø 2.35 act. Ø 2.3502 Tol. I

Surface roughness and roundness ≤ 1μm.

Certificate of accuracy no. 3* (at extra charge)

Each measuring pin is listed in a table showing both rated and actual diameter, and measured roughness and roundness.

e.g. rated Ø 2.30 act. Ø 2.2998 rgh. 0.65 rd. 0.75

rated Ø 2.35 act. Ø 2.350 rgh. 0.50 rd. 0.60

Surface roughness and roundness ≤ 1μm

In all our certificates of accuracy you can find directions to DKD (German Calibration Laboratory) or PTB (Physical-Technical Institute

of Germany) for the return of the measuring tools

e.g.:

Certificate of accuracy

Issued on: 20.08.03

Certificate no.: 3020/9/ „Year“ case no.: 037/02/“Year“

Order no.: 402008

For: Smith & Co KG

91126 Schwabach

Test item: Measuring pin set rated 0.500 – 5.000 mm

Tolerance class: II = ± 0.002 mm Reference temperature according to

DIN 102 = 20° C ±1° C

Test instrument length: KLM – 60.01 DKD Calibration no. 0526/01/03 and 0527/01/03

Measuring deviation: (± 0.2 + 2 x L/100) μm, L given in mm

Reference pins: No. 2989 PTB 99

No.: 0733 DKD-K-00303-04-03

Roundness no.: 87707 DKD 12653-99

Roughness no.: 0427 RNDH 2 n. EN 814 003 PTB 03

Certificate of accuracy no. 4 (price according to scope of test)

If required, all measuring pins can be certified by an external, DKD-approved test laboratory.

*) for measuring pins of less than 0.50 mm, only certificate no.1 can be issued.

09

3S_pruefstifte_engl_2008.indd Abs1:9 24.07.2008 14:55:19

MAGNETIC

MEASURING PINS

Magnetic measuring pins facilitate the testing procedures. Specially suitable for rational

gear wheel measurement. Additional possible implementations include testing procedures

on work items where conventional measuring pins either roll away or fall down due to posi-

tion (e.g. measurement of diagonal surfaces).

In the case of steel work items, the pins are self-adhesive, thus facilitating the test procedure.

The magnetic strength of the magnetic measuring pins is both significantly higher than in the

case of magnetic measuring pins made of steel, and does not deteriorate over time.

Nominal diameter 1.00 1.25 1.50 1.524 1.60

1.65 1.75 2.00 2.032 2.25

2.50 2.75 3.00 3.25 3.50

4.00 4.25 4.50 5.00 5.25

6.00 7.00 8.00 9.00

Accuracy Tolerance I = ± 0.001 mm

Length 35 mm

Customised items can also be supplied by special order.

10

3S_pruefstifte_engl_2008.indd Abs1:10 24.07.2008 14:55:19

Example:

Use of magnetic

measuring pins

11

3S_pruefstifte_engl_2008.indd Abs1:11 24.07.2008 14:55:31

Additional high-precision standard parts available from our product range:

• Ejector pins DIN ISO 6751 / DIN ISO 8694 / DIN ISO 8693 / DIN ISO 1530

• Ejector sleeves DIN ISO 8405

• Core pins / centre sleeves

• Ejector pins: customized models

• Piercing punches DIN 9861 / DIN 9840 / DIN 9844 / DIN 9843 / DIN ISO 8020

• Piercing punches with trombone neck

• Perforation pins

• Pull-through punches according to DIN 7952

• Rectangular and square piercing punches DIN 9846

• Piercing punches: customized models

• Preforge-/ upsetting ejector pins • Dowel pins DIN ISO 8734 (similar to previous std. DIN 6325)

• Hexagonal punches / extrusion punches • Dowel pins DIN ISO 8735 (similar to previous std. DIN 7979)

• Special punches

• Machining tools and equipment

• Parts manufactured according to drawing • Cutting-off and surface grinding machine

• Paid work • External grinding machine

DIN EN ISO 9001:2000

Certificate: 01 100 80420

Always one step ahead

DREI-S was the first manufacturer of ejector pins

in Europe and a pioneer in the introduction of 150 years of successful industrial manufacturing

the previous DIN 1530 standard. We therefore speaks for our experience and innovative

have a long tradition of active involvement in DIN approach. Initiative, responsibility, lateral thinking,

standards. DREI-S-WERK was also a pioneer in and the desire to continually improve and extend

the implementation of new nitriding technologies, our range with new products are the driving forces

which are now standard on the market. behind our company and its employees.

DREI-S-WERK Präzisionswerkzeuge GmbH & Co. Fertigungs KG

Postal address: Office location:

PO Box 20 Schmauser-Str. 3 Phone +49 (0) 98 74/50 42 150 www.drei-s-werk.com

D-91561 Neuendettelsau D-91564 Neuendettelsau Fax +49 (0) 98 74/50 42 151 precision@drei-s-werk.de

3S_pruefstifte_engl_2008.indd Abs1:12 24.07.2008 14:56:19

Das könnte Ihnen auch gefallen

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsVon EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- BMD Plug Gauges: Technical GuideDokument52 SeitenBMD Plug Gauges: Technical Guidekunalkp88Noch keine Bewertungen

- The User-Computer Interface in Process Control: A Human Factors Engineering HandbookVon EverandThe User-Computer Interface in Process Control: A Human Factors Engineering HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Diatest 9Dokument86 SeitenDiatest 9tungNoch keine Bewertungen

- BMD Plug Gauge Technical Guide enDokument52 SeitenBMD Plug Gauge Technical Guide enRobertShenNoch keine Bewertungen

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- Rambold - Katalog 2004 ENDokument53 SeitenRambold - Katalog 2004 END.T.Noch keine Bewertungen

- Heidenhain General CatalogDokument64 SeitenHeidenhain General CatalogJair ArmandoNoch keine Bewertungen

- Length ProdDokument47 SeitenLength ProdFranc CindNoch keine Bewertungen

- Kafer Messuhrenfabrik - Katalog 2018 ENDokument148 SeitenKafer Messuhrenfabrik - Katalog 2018 END.T.Noch keine Bewertungen

- Automobile Manufacturing Technology 05 04 2020Dokument2 SeitenAutomobile Manufacturing Technology 05 04 202031 Sameer SinhaNoch keine Bewertungen

- Standard GageDokument104 SeitenStandard GageOleh SmolovyiNoch keine Bewertungen

- Jual - Coating Thickness CEM DT-156 #Harga #082217294199Dokument3 SeitenJual - Coating Thickness CEM DT-156 #Harga #082217294199Tantan Teknik IndonesiaNoch keine Bewertungen

- Starrett 33Dokument612 SeitenStarrett 33calidadcdokep100% (1)

- Bareiss Broschüre Englisch 11 11 12.inddDokument6 SeitenBareiss Broschüre Englisch 11 11 12.inddLOGANATHAN VNoch keine Bewertungen

- Rohini 67207682273Dokument19 SeitenRohini 67207682273Cobra BabaNoch keine Bewertungen

- Product Information Clip-On Extensometer 5025-1, 8040-1 and 7537-1Dokument3 SeitenProduct Information Clip-On Extensometer 5025-1, 8040-1 and 7537-1Diego AvendañoNoch keine Bewertungen

- 08 925 Clip On Extensometer 5025 1 PI enDokument3 Seiten08 925 Clip On Extensometer 5025 1 PI enDiego AvendañoNoch keine Bewertungen

- Co35Non-Destructive Testing of Hardened Concrete 35Dokument4 SeitenCo35Non-Destructive Testing of Hardened Concrete 35Moncef Thabet100% (1)

- Fundamental Value of A Physical Quantity Established by National & International Organizations It Must BeDokument66 SeitenFundamental Value of A Physical Quantity Established by National & International Organizations It Must Bemohd zeeshanNoch keine Bewertungen

- 04 MarTestDokument67 Seiten04 MarTesttheboogiemanNoch keine Bewertungen

- Mitutoyo ID-N-B IndicatorsDokument6 SeitenMitutoyo ID-N-B IndicatorsAmrane AkramNoch keine Bewertungen

- Kroeplin - Katalog 2010 ENDokument24 SeitenKroeplin - Katalog 2010 END.T.Noch keine Bewertungen

- 350457-2L General-Catalog en PDFDokument72 Seiten350457-2L General-Catalog en PDFPavan AryaNoch keine Bewertungen

- m0097 Tension Meter Tester A4Dokument2 Seitenm0097 Tension Meter Tester A4Julian de faveriNoch keine Bewertungen

- Gauges Engineering Supplies CatalogDokument16 SeitenGauges Engineering Supplies CatalogNabeel AliNoch keine Bewertungen

- Schwenk - Katalog 2014 ENDokument38 SeitenSchwenk - Katalog 2014 END.T.Noch keine Bewertungen

- Helios Preisser 2021Dokument290 SeitenHelios Preisser 2021Valentin IonescuNoch keine Bewertungen

- Density Measurement: Reliable Measurement Even Under Extreme ConditionsDokument5 SeitenDensity Measurement: Reliable Measurement Even Under Extreme Conditionshugo rinconNoch keine Bewertungen

- Measuring Pin Catalogue: Measuring Pins Measuring Pin Sets Storage Cases Test Certificates Magnetic Measuring PinsDokument12 SeitenMeasuring Pin Catalogue: Measuring Pins Measuring Pin Sets Storage Cases Test Certificates Magnetic Measuring PinsManh PhamNoch keine Bewertungen

- Lab ManualDokument19 SeitenLab ManualAjij Mujawar100% (1)

- Production Dual Caliper (X-Y) : DescriptionDokument1 SeiteProduction Dual Caliper (X-Y) : DescriptionKarim IsmailNoch keine Bewertungen

- Testing and Measuring Instruments: For Vehicle WheelsDokument16 SeitenTesting and Measuring Instruments: For Vehicle Wheelsaizaz65Noch keine Bewertungen

- Linear MeasurementDokument79 SeitenLinear MeasurementRht BrdNoch keine Bewertungen

- 208945-2F - Length - Gauges - 01 2Dokument52 Seiten208945-2F - Length - Gauges - 01 2rcaletaNoch keine Bewertungen

- Din 862Dokument4 SeitenDin 862068999100% (1)

- 18-MCE-49 Lab Session 01Dokument5 Seiten18-MCE-49 Lab Session 01Waqar IbrahimNoch keine Bewertungen

- 2019 Summer Model Answer Paper (Msbte Study Resources)Dokument12 Seiten2019 Summer Model Answer Paper (Msbte Study Resources)Prajwal gamerNoch keine Bewertungen

- Apaupadores 208 - 945-26Dokument43 SeitenApaupadores 208 - 945-26MarcosNoch keine Bewertungen

- Laboratory Report 1 DellosaDokument11 SeitenLaboratory Report 1 DellosaAgent PNoch keine Bewertungen

- Mitutoyo - Twardościomierze Shore'a HH-300 - E4137-811 - 2009 ENDokument6 SeitenMitutoyo - Twardościomierze Shore'a HH-300 - E4137-811 - 2009 END.T.Noch keine Bewertungen

- Koba - Step Precision Step Gauge: Our Quality Assures Highest PrecisionDokument8 SeitenKoba - Step Precision Step Gauge: Our Quality Assures Highest Precisioncmm5477Noch keine Bewertungen

- Tolerances and Fits: Min MaxDokument24 SeitenTolerances and Fits: Min MaxIrfan MuhammadNoch keine Bewertungen

- PRUEFTECHNIK PortableSaw Brochure ENDokument2 SeitenPRUEFTECHNIK PortableSaw Brochure ENvanloc tranNoch keine Bewertungen

- Precision Test Sieves - Sieve ShakersDokument28 SeitenPrecision Test Sieves - Sieve ShakersSupriyo PNoch keine Bewertungen

- Data Sheet: EnglishDokument2 SeitenData Sheet: EnglishAazam KhanNoch keine Bewertungen

- Metrology Uniit IIDokument53 SeitenMetrology Uniit IIrramesh2k8712Noch keine Bewertungen

- Customized Bearings and Racks - Product Catalog ENDokument8 SeitenCustomized Bearings and Racks - Product Catalog ENbekirrrrNoch keine Bewertungen

- Fits and TolerancesDokument115 SeitenFits and TolerancesSachidhanandam MNoch keine Bewertungen

- Catalogue 2021 Pied A Coulisse B ENDokument44 SeitenCatalogue 2021 Pied A Coulisse B ENRudolf OppermannNoch keine Bewertungen

- Tiger Steel Erw Pipes SubmittalDokument47 SeitenTiger Steel Erw Pipes Submittalshabanashabana065Noch keine Bewertungen

- Case Study 3Dokument38 SeitenCase Study 3ramtwinsmeNoch keine Bewertungen

- Metrology and MeasurementsDokument58 SeitenMetrology and MeasurementsShishir Fawade75% (4)

- SilverSchmidt - Sales Flyer - English - HighDokument4 SeitenSilverSchmidt - Sales Flyer - English - HighJabranYounasNoch keine Bewertungen

- SilverSchmidt - Sales Flyer - English - HighDokument4 SeitenSilverSchmidt - Sales Flyer - English - HighAhmed AbuoelnagaNoch keine Bewertungen

- Labmaster Universal 1000MDokument6 SeitenLabmaster Universal 1000MVallik TadNoch keine Bewertungen

- Grade Data Sheet: Heat ResistanceDokument2 SeitenGrade Data Sheet: Heat Resistanceapurv bhartiNoch keine Bewertungen

- Hy-Tuf - AMS 6425 PDFDokument2 SeitenHy-Tuf - AMS 6425 PDFapurv bhartiNoch keine Bewertungen

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDokument1 SeiteAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNoch keine Bewertungen

- Special Metals UDIMET® Alloy 520 SuperalloyDokument2 SeitenSpecial Metals UDIMET® Alloy 520 Superalloyapurv bhartiNoch keine Bewertungen

- Stainless Steel - HY-TUF / AMS 6425: Chemical CompositionDokument1 SeiteStainless Steel - HY-TUF / AMS 6425: Chemical Compositionapurv bhartiNoch keine Bewertungen

- Hy-Tuf - AMS 6425 PDFDokument2 SeitenHy-Tuf - AMS 6425 PDFapurv bhartiNoch keine Bewertungen

- Hy-Tuf - AMS 6425 PDFDokument2 SeitenHy-Tuf - AMS 6425 PDFapurv bhartiNoch keine Bewertungen

- HY-80 SteelDokument1 SeiteHY-80 Steelapurv bhartiNoch keine Bewertungen

- Hy-Tuf / AMS 6425: Additional InformationDokument2 SeitenHy-Tuf / AMS 6425: Additional Informationapurv bhartiNoch keine Bewertungen

- Other Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979Dokument1 SeiteOther Alloys Other Alloys: Udimet Alloy L-605 Udimet Alloy 520 Udimet Alloy 720 Udimet Alloy D-979apurv bhartiNoch keine Bewertungen

- Paper 5Dokument4 SeitenPaper 5hbyhNoch keine Bewertungen

- Ahriman's Prophecy Walk ThroughDokument106 SeitenAhriman's Prophecy Walk ThroughAngga Nata100% (1)

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDokument782 Seiten2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- GMN RodamientosDokument51 SeitenGMN RodamientosJayNoch keine Bewertungen

- Anilkumar Surendran 3-AdDokument4 SeitenAnilkumar Surendran 3-AdAnil AmbalapuzhaNoch keine Bewertungen

- MMG 302Dokument164 SeitenMMG 302piyush patilNoch keine Bewertungen

- Stonecoal v3 Guidelines 2023-03-22Dokument71 SeitenStonecoal v3 Guidelines 2023-03-22Esha RamaswamiNoch keine Bewertungen

- AI LabDokument17 SeitenAI LabTripti JainNoch keine Bewertungen

- Curtis Mathes CM25020S by Samsung - Owner's ManualDokument49 SeitenCurtis Mathes CM25020S by Samsung - Owner's ManualpadawerNoch keine Bewertungen

- IRDM Assignment-I PDFDokument4 SeitenIRDM Assignment-I PDFPiyush AggarwalNoch keine Bewertungen

- NBPME Part II 2008 Practice Tests 1-3Dokument49 SeitenNBPME Part II 2008 Practice Tests 1-3Vinay Matai50% (2)

- Islami Bank Bangladesh Limited: Ibbl Ibanking ServiceDokument2 SeitenIslami Bank Bangladesh Limited: Ibbl Ibanking ServiceShaikat AlamNoch keine Bewertungen

- PCI20107, Overview of Boiler Commissioning and Startup PDFDokument17 SeitenPCI20107, Overview of Boiler Commissioning and Startup PDFMarc AnmellaNoch keine Bewertungen

- Exercises: Use The Correct Form of Verbs in BracketsDokument3 SeitenExercises: Use The Correct Form of Verbs in BracketsThủy NguyễnNoch keine Bewertungen

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Dokument1 SeiteCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaNoch keine Bewertungen

- Agro Tech Foods LTDDokument17 SeitenAgro Tech Foods LTDAlmas KhanNoch keine Bewertungen

- Comparative ApproachDokument12 SeitenComparative ApproachSara WongNoch keine Bewertungen

- E. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarDokument3 SeitenE. What Was The Chinese POW Death Rate in WW2 and The Second Sino-Japanese WarPamela SantosNoch keine Bewertungen

- Ed508-5e-Lesson-Plan-Severe Weather EventsDokument3 SeitenEd508-5e-Lesson-Plan-Severe Weather Eventsapi-526575993Noch keine Bewertungen

- Nestle IndiaDokument74 SeitenNestle IndiaKiranNoch keine Bewertungen

- Public Economics - All Lecture Note PDFDokument884 SeitenPublic Economics - All Lecture Note PDFAllister HodgeNoch keine Bewertungen

- PL SQL Exercise6Dokument2 SeitenPL SQL Exercise6Nishant AndhaleNoch keine Bewertungen

- Swot Ananlysis of Fintech CompaniesDokument7 SeitenSwot Ananlysis of Fintech CompaniesUyen Le VuNoch keine Bewertungen

- 9.LearnEnglish Writing A2 Instructions For A Colleague PDFDokument5 Seiten9.LearnEnglish Writing A2 Instructions For A Colleague PDFوديع القباطيNoch keine Bewertungen

- O RTIZDokument2 SeitenO RTIZKhimberly Xylem OrtizNoch keine Bewertungen

- Eimco Elecon Initiating Coverage 04072016Dokument19 SeitenEimco Elecon Initiating Coverage 04072016greyistariNoch keine Bewertungen

- Electrochemistry DPP-1Dokument2 SeitenElectrochemistry DPP-1tarunNoch keine Bewertungen

- Fin 320 - Individual AssignmentDokument14 SeitenFin 320 - Individual AssignmentAnis Umaira Mohd LutpiNoch keine Bewertungen

- Board of DirectorsDokument2 SeitenBoard of DirectorsjonahsalvadorNoch keine Bewertungen