Beruflich Dokumente

Kultur Dokumente

IRC 37-2012 - BTech

Hochgeladen von

Vibhanshu MishraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IRC 37-2012 - BTech

Hochgeladen von

Vibhanshu MishraCopyright:

Verfügbare Formate

IRC: 37-2012

TENTATIVE GUIDELINES FOR THE DESIGN OF FLEXIBLE PAVEMENTS

Traffic consideration

1. Assessment of the present day average traffic is determined based on a seven-

day 24-hour count.

2. Traffic growth rate (r): Project traffic at the end of design life

• Past trends of traffic growth

• Macro-economic parameters (like GDP or SDP).

• Assume 5 percent in absence of data.

3. Design life:

1. National Highways and State Highways: minimum life of 15 years.

2. Expressways and Urban Roads: 20 years or higher.

3. Other categories of roads: 10 to 15 years

Pavement design as per IRC: 37-2012

4. Vehicle Damage Factor (VDF)

• Vehicles of different axle loads and axle configuration are converted to a

repetitions of standard axle load of magnitude 80 kN.

• Axle load survey is carried out to determine the VDF

𝑎𝑥𝑙𝑒 𝑙𝑜𝑎𝑑 𝑖𝑛 𝑘𝑁 4

• Single axle with single wheel on either side = ( )

65

𝑎𝑥𝑙𝑒 𝑙𝑜𝑎𝑑 𝑖𝑛 𝑘𝑁 4

• Single axle with dual wheel on either side = ( )

80

𝑎𝑥𝑙𝑒 𝑙𝑜𝑎𝑑 𝑖𝑛 𝑘𝑁 4

• Tandem axle with dual wheel on either side = ( )

148

𝑎𝑥𝑙𝑒 𝑙𝑜𝑎𝑑 𝑖𝑛 𝑘𝑁 4

• Tridem axles with dual wheel on either side = ( )

224

Pavement design as per IRC: 37-2012

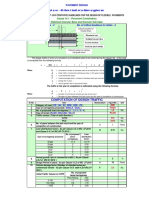

Example:

No. of No. of

Axle load, Kg Load equivalency factor (80kN)

axle vehicle

Total load

Vehicle

equivalency VDF

type

factor (EF)

Single

Single

axle

No. of No. of axle with 𝒂𝒙𝒍𝒆 𝒍𝒐𝒂𝒅 𝒊𝒏 𝒌𝑵 𝟒 𝒂𝒙𝒍𝒆 𝒍𝒐𝒂𝒅 𝒊𝒏 𝒌𝑵 𝟒

with ( ) ( )

axle vehicle dual 𝟔𝟓 𝟖𝟎

single

wheel

wheel

Buses 2 12 6080 6480 0.765 0.43 1.195

𝟏. 𝟏𝟗𝟓 × 𝟏𝟐 + (𝟏. 𝟎𝟕 × 𝟐𝟖𝟕𝟗)

= 𝟏. 𝟎𝟕

(𝟏𝟐 + 𝟐𝟖𝟕𝟗)

Truck 2 2879 5950 6250 0.702 0.37 1.07

Pavement design as per IRC: 37-2012

• In absence of sufficient information on axle loads and small project the following

indicative values of VDF can be used.

Initial Traffic Volume in Terms of Terrain

Commercial Vehicles Per Day Roiling/Plain Hilly

0-150 1.5 0.5

150-1500 3.5 1.5

More than 1500 4.5 2.5

Pavement design as per IRC: 37-2012

5. Lane Distribution Factor (LDF):

• Single-lane roads: total number of commercial vehicles in both directions.

• Two-lane single carriageway roads: 50 per cent of the total number of

commercial vehicles in both directions.

• Four-lane single carriageway roads: 40 per cent of the total number of

commercial vehicles in both directions.

• Dual carriageway roads: 75 per cent of the number of commercial vehicles

in each direction. For three-lane and four lane carriageway, the distribution

factor will be 60 per cent and 45 per cent respectively.

Pavement design as per IRC: 37-2012

Example:

• For Two-lane single carriageway roads with 4000 CVPD (Sum of both directions) the

design traffic will be?

50

Soln: ∗ 4000

100

• For four-lane single carriageway with 6000 CVPD (Sum of both directions) the design

traffic will be?

40

Soln: ∗ 6000

100

Pavement design as per IRC: 37-2012

6. Computation of Design Traffic

365 × [(1+𝑟)𝑛 −1]

𝑁= ×𝐴×𝐷×F

𝑟

Where,

N = Cumulative number of standard axles to be catered for in the design, msa

A = Initial traffic in the year of completion of construction, CVPD

D = Lane distribution factor

F = Vehicle Damage Factor

n = Design life in years

r = Annual growth rate of commercial vehicles in decimal.

Initial traffic in the year of completion, 𝐴 = 𝑃(1 + 𝑟)𝑋

Where,

P = Number of commercial vehicles as per last count

X = Number of years between the last count and the year of completion of construction

Pavement design as per IRC: 37-2012

Example: If Number of commercial vehicles as per last count is 2518 CVPD and

project will take 3 yr to complete and the annual growth rate of commercial

vehicles is 6.0%, calculate the design traffic for design traffic of 20 years considering

LDF as 0.5 and VDF as 4.8.

Soln: Initial traffic in the year of completion, 𝐴 = 𝑃(1 + 𝑟)𝑋

=2518(1 + 0.06)3

=3000 CVPD

365 × [(1+0.06)20 −1]

𝑁= × 3000 × 0.5 × 4.8

0.06

= 96672534 or 96 msa

Pavement design as per IRC: 37-2012

Requirement of subgrade

• Subgrade shall be compacted to a minimum of 97 percent of laboratory dry

density achieved with heavy compaction

• The select soil forming the subgrade should have a minimum CBR of 8 percent

for roads having traffic of 450 commercial vehicles per day or higher.

• 90th percentile of a minimum of six to eight average CBR values is used as

design CBR value for high volume roads such as Expressways, National Highways

and State Highways. For other categories of roads, design is based on 80th

percentile of laboratory CBR values.

• If the difference between the CBR of the select subgrade and embankment soils is

significantly different then effective CBR is used for design.

Pavement design as per IRC: 37-2012

Example: CBR values for a highway alignment are as follows:

3.5, 5.2, 8.0, 6.8, 8.8, 4.2, 6.4, 4.6, 9.0, 5.7, 8.4, 8.2, 7.3, 8.6, 8.9, 7.6

Calculate the design CBR?

Soln: After arranging: 3.5, 4.2, 4.6, 5.2, 5.7, 6.4, 6.8, 7.3, 7.6, 8.0, 8.2, 8.4, 8.6, 8.8, 8.9, 9.0

Percentile CBR

16

For CBR of 3.5, ∗ 100 = 100%

16

15

For CBR of 4.2, ∗ 100 = 93.75%;

16

14

For CBR of 4.6, ∗ 100 = 87.57%

16

From the plot of percentile values and CBR

The 90th percentile CBR value is 4.7

Pavement design as per IRC: 37-2012

Effective CBR of Subgrade

Pavement design as per IRC: 37-2012

Example: CBR of soil below the 500 mm of

the subgrade = 5 %

CBR of the 500 mm of the subgrade from

borrow pits = 8%

Calculate effective CBR of Subgrade?

7.5

Soln: 7.5%

Pavement design as per IRC: 37-2012

Determination of resilient modulus subgrade soil

The relation between resilient modulus and the effective CBR is given as:

𝑀𝑅 = 10 ∗ 𝐶𝐵𝑅, 𝑓𝑜𝑟 𝐶𝐵𝑅 5

𝑀𝑅 = 17.6 ∗ 𝐶𝐵𝑅 0.64 , for CBR > 5

Where, 𝑀𝑅 = Resilient modulus of subgrade soil, MPa.

Example : Calculate the 𝑀𝑅 for a subgrade soil with effective CBE of 12%

Soln: 𝑀𝑅 = 17.6 ∗ 12 0.64

= 86 MPa

Pavement design as per IRC: 37-2012

Determination of modulus of unbound granular (subbase+ base) layer

Unbound granular layer

𝑀𝑅_𝑔𝑟𝑎𝑛𝑢𝑙𝑎𝑟 = 0.2ℎ0.45 𝑀𝑅 𝑠𝑢𝑏𝑔𝑟𝑎𝑑𝑒

Where,

𝑀𝑅_𝑔𝑟𝑎𝑛𝑢𝑙𝑎𝑟 = Resilient modulus of the granular layer, MPa

h = thickness of granular layer, mm

Poisson's ratio = 0.35.

Example: calculate the modulus of 400 mm thick granular layer over a subgrade of 10

% CBR.

Soln: 227.7 MPa

Pavement design as per IRC: 37-2012

Determination of modulus of bituminous layer

Recommended resilient modulus values of the bituminous materials:

Pavement design as per IRC: 37-2012

PRINCIPLES OF PAVEMENT DESIGN

Flexible pavement is modelled as an elastic multilayer structure.

Stress and strains at two critical locations are calculated:

1. Tensile strain (∈𝑡 ) at the bottom of bituminous layer (fatigue failure)

2. Compressive strain (∈𝑉 ) at the top of subgrade (rutting failure)

Pavement design as per IRC: 37-2012

The limiting values of (∈𝑡 ) and (∈𝑣 ) for design traffic and layer configuration can

be calculated using the fatigue and rutting equations as follows

Fatigue Equation

1. 𝑁𝑓 = 2.21 × 10−4 ×[1 ∈𝑡]3.89 ×[1 𝑀𝑅]0.854 (80 percent reliability)

2. 𝑁𝑓 = 0.711 × 10−4 ×[1 ∈𝑡]3.89 ×[1 𝑀𝑅]0.854 (90 percent reliability)

Rutting Equation

1. 𝑁𝑟 = 4.1656 × 10−8 ×[1 ∈𝑉]4.5337 (80 percent reliability)

2. 𝑁𝑟 = 1.41 × 10−8 × [ 1 ∈𝑉]4.5337 (90 percent reliability)

Where,

𝑁𝑓 or 𝑁𝑟 = allowable number of standard axles, msa

∈𝑡 = Maximum tensile strain at the bottom of the bituminous layer, and

𝑀𝑅 = resilient modulus of the bituminous layer

∈𝑉 = Vertical strain in the subgrade

Pavement design as per IRC: 37-2012

Pavement design using design catalogue

For a given combinations of traffic, layer configuration and assumed material properties

the pavement composition can be adopted from design catalogue available in IRC: 37-2012

provided the assumed layer properties can be achieved in the field or CAN BE

COMPUTED USING LAYER PROGRAMS.

Pavement design as per IRC: 37-2012

Das könnte Ihnen auch gefallen

- On Regid PavementsDokument38 SeitenOn Regid PavementsramireddyNoch keine Bewertungen

- Automotive Wiring and Electrical SystemsVon EverandAutomotive Wiring and Electrical SystemsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- CE 353 Transportation Engineering II: Md. Rabiul IslamDokument25 SeitenCE 353 Transportation Engineering II: Md. Rabiul IslamMohamed Isak AliNoch keine Bewertungen

- PQC Design Tunnel PTLGDokument31 SeitenPQC Design Tunnel PTLGrao shoaibNoch keine Bewertungen

- Performance-Based Road Maintenance Contracts in the CAREC RegionVon EverandPerformance-Based Road Maintenance Contracts in the CAREC RegionNoch keine Bewertungen

- FlexibleDokument60 SeitenFlexibleSreekantha RNoch keine Bewertungen

- Lecture 1 - Introduction To Pavement Design and ESALDokument42 SeitenLecture 1 - Introduction To Pavement Design and ESALKAYE EVANGELISTANoch keine Bewertungen

- Classifying Roads and Calculating Pavement DesignDokument9 SeitenClassifying Roads and Calculating Pavement DesignLeo Albert MaputiNoch keine Bewertungen

- Asphalt Institute Method For Flexible Pavement DesignDokument30 SeitenAsphalt Institute Method For Flexible Pavement DesignHenra HalimNoch keine Bewertungen

- Asphalt Institute Method FOR Flexible Pavement Design: Dr. Padma Bahadur ShahiDokument30 SeitenAsphalt Institute Method FOR Flexible Pavement Design: Dr. Padma Bahadur ShahiPadma ShahiNoch keine Bewertungen

- Locked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019Dokument5 SeitenLocked DESIGN SHEET FINAL ARUN-SATYENDRA 11.06.2019ajay_430Noch keine Bewertungen

- Pavement Design PresentationDokument206 SeitenPavement Design PresentationQAQCNoch keine Bewertungen

- Pavement Deisgn 2012Dokument59 SeitenPavement Deisgn 2012WillowcrestNoch keine Bewertungen

- Equivalent Single Axle Load Group 2Dokument17 SeitenEquivalent Single Axle Load Group 2Cheryl Lou SantiagoNoch keine Bewertungen

- Water Bound Macadam RoadsDokument22 SeitenWater Bound Macadam RoadsArslan ButtNoch keine Bewertungen

- Design TrafficDokument29 SeitenDesign TrafficSeanam DM80% (5)

- Assignment Highway Week 5Dokument6 SeitenAssignment Highway Week 5Farell TanNoch keine Bewertungen

- Article RdsoDokument18 SeitenArticle Rdsoabhimanyutiwari1234Noch keine Bewertungen

- PAVEMENT DESIGN GUIDELINESDokument2 SeitenPAVEMENT DESIGN GUIDELINESRam Samujh SharmaNoch keine Bewertungen

- Low Volume Road Traffic DesignDokument3 SeitenLow Volume Road Traffic DesignSatish BhairanattiNoch keine Bewertungen

- Rollover Calculation System October 17, 2003 1Dokument21 SeitenRollover Calculation System October 17, 2003 1GilbertoNoch keine Bewertungen

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Dokument38 SeitenStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi50% (2)

- NDDOT AASHTO Pavement Design InputsDokument33 SeitenNDDOT AASHTO Pavement Design InputsEng Abdikarim WalhadNoch keine Bewertungen

- Venkat FlexiblePavement DesignDokument86 SeitenVenkat FlexiblePavement DesignV Venkata Narayana100% (5)

- Aashto DesignDokument28 SeitenAashto DesignJalal Habib KhanNoch keine Bewertungen

- 89BDokument2 Seiten89BJamie SchultzNoch keine Bewertungen

- Flexible Pavement Design As Per IRC: 37-2012: Jheel A. Patel Prof. Amit A. Amin Dr. L. B. Zala Mr. Hardik SukhadiyaDokument5 SeitenFlexible Pavement Design As Per IRC: 37-2012: Jheel A. Patel Prof. Amit A. Amin Dr. L. B. Zala Mr. Hardik Sukhadiyasuneet kuma meenaNoch keine Bewertungen

- Flexible Pavement Design IRC37 2001 2Dokument4 SeitenFlexible Pavement Design IRC37 2001 2Chatnoir NoirNoch keine Bewertungen

- ESWL FlexibleDokument25 SeitenESWL FlexibleFiras BarrajNoch keine Bewertungen

- Topic - Design of Flexible Pavements: Karma Mahavidyalaya Engg. CollegeDokument58 SeitenTopic - Design of Flexible Pavements: Karma Mahavidyalaya Engg. Collegesohail irfanNoch keine Bewertungen

- Pavement Calculation SheetDokument7 SeitenPavement Calculation SheetSuchitra PandaNoch keine Bewertungen

- Question Bank On LHB Design Coaches PDFDokument100 SeitenQuestion Bank On LHB Design Coaches PDF155374% (43)

- Flexible Pavement Design PMGSY As Per IRC 72Dokument2 SeitenFlexible Pavement Design PMGSY As Per IRC 72Mayuri ShahNoch keine Bewertungen

- Traffic AnalysisDokument31 SeitenTraffic AnalysisEmad Elhussieny100% (1)

- Airport Pavement Design and EvaluationDokument104 SeitenAirport Pavement Design and Evaluationwanjailani91% (11)

- Guide to Roads, Bridges, and Highway InfrastructureDokument66 SeitenGuide to Roads, Bridges, and Highway InfrastructurecometNoch keine Bewertungen

- Vci CalculationDokument12 SeitenVci CalculationHitarth SarvaiyaNoch keine Bewertungen

- VDFDokument1 SeiteVDFNaqvi ANoch keine Bewertungen

- Designing Flexible Pavement for Rural RoadDokument2 SeitenDesigning Flexible Pavement for Rural RoadRam Samujh SharmaNoch keine Bewertungen

- Design of Flexible Pavements For Low Volume Rural Roads - FinalDokument31 SeitenDesign of Flexible Pavements For Low Volume Rural Roads - FinalAsit MohantyNoch keine Bewertungen

- Cairo University Highway Pavement DesignDokument2 SeitenCairo University Highway Pavement DesignBosy Roshdy0% (1)

- Traffic Concepts and Load Equivalency FactorsDokument20 SeitenTraffic Concepts and Load Equivalency FactorsDallas HubbardNoch keine Bewertungen

- Tute 07 Traffic Loading & Pavement DesignDokument2 SeitenTute 07 Traffic Loading & Pavement Designyu yanNoch keine Bewertungen

- Pavement Thickness Design ProcedureDokument29 SeitenPavement Thickness Design Proceduremustafurade1Noch keine Bewertungen

- Ce-441 Class Presentation-1f of 4-1Dokument16 SeitenCe-441 Class Presentation-1f of 4-1স্মরন জিৎNoch keine Bewertungen

- Real Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDokument47 SeitenReal Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDebra JacksonNoch keine Bewertungen

- Transportation Plaining SesignDokument17 SeitenTransportation Plaining Sesignkushaljp8989Noch keine Bewertungen

- Pavement Design ManualDokument25 SeitenPavement Design Manualjean willieNoch keine Bewertungen

- PP1-Design of Flexible PavementDokument37 SeitenPP1-Design of Flexible PavementSrinivas PNoch keine Bewertungen

- CE 318 ESAL Tutorial 1Dokument3 SeitenCE 318 ESAL Tutorial 1shehalan nilumindaNoch keine Bewertungen

- Pavement DesignDokument75 SeitenPavement DesignJMSorianoNoch keine Bewertungen

- Topic 4 - Traffic CharacterizationDokument11 SeitenTopic 4 - Traffic CharacterizationdanielNoch keine Bewertungen

- Government of Madhyapradesh: Pench Diversion Project ChhindwaraDokument37 SeitenGovernment of Madhyapradesh: Pench Diversion Project ChhindwaraManish PatelNoch keine Bewertungen

- Traffic and pavement design dataDokument5 SeitenTraffic and pavement design dataShashi kumarNoch keine Bewertungen

- Design Flexible ATJ 5I85 2013 2022Dokument33 SeitenDesign Flexible ATJ 5I85 2013 2022Leediya AfrinaNoch keine Bewertungen

- Design Traffic LoadDokument16 SeitenDesign Traffic LoadMarc MathieuNoch keine Bewertungen

- Pavement FlexibleDokument74 SeitenPavement FlexibleNishant KumarNoch keine Bewertungen

- Lecture Notes On IRC 37Dokument8 SeitenLecture Notes On IRC 37AdhirajNoch keine Bewertungen

- CohesiveInteraction PDFDokument9 SeitenCohesiveInteraction PDFVibhanshu MishraNoch keine Bewertungen

- Highway Engineering by S.K.khanna and C.E.GDokument301 SeitenHighway Engineering by S.K.khanna and C.E.GVibhanshu MishraNoch keine Bewertungen

- 09 - Chapter 5 PDFDokument54 Seiten09 - Chapter 5 PDFVishal RaiNoch keine Bewertungen

- 'Operation Bluestar' The Untold StoryDokument42 Seiten'Operation Bluestar' The Untold StorySikh TextsNoch keine Bewertungen

- L2 Geometric Design IntroductionDokument28 SeitenL2 Geometric Design IntroductionVibhanshu Mishra0% (1)

- EE424M IntroductionDokument31 SeitenEE424M IntroductionVibhanshu MishraNoch keine Bewertungen

- Stiffness Methods For Systematic Analysis of StructuresDokument35 SeitenStiffness Methods For Systematic Analysis of Structuresjtek01100% (1)

- Abaqus TutsDokument1 SeiteAbaqus TutsVibhanshu MishraNoch keine Bewertungen

- Damage PlasticityDokument12 SeitenDamage PlasticityVibhanshu Mishra100% (1)

- Greene's Tention Stiffening Model PDFDokument8 SeitenGreene's Tention Stiffening Model PDFVibhanshu MishraNoch keine Bewertungen

- Teaching and Learning Structural Engineering Analysis With MatlabDokument19 SeitenTeaching and Learning Structural Engineering Analysis With MatlabArnold ApostolNoch keine Bewertungen

- Transportation Engineering I CE 304Dokument37 SeitenTransportation Engineering I CE 304Vibhanshu MishraNoch keine Bewertungen

- Learn Abaqus script in one hourDokument12 SeitenLearn Abaqus script in one hourbaspopNoch keine Bewertungen

- Utilization of Matlab in Structural AnalysisDokument16 SeitenUtilization of Matlab in Structural AnalysisclaudioNoch keine Bewertungen

- Abaqus TutsDokument1 SeiteAbaqus TutsVibhanshu MishraNoch keine Bewertungen

- Finite Element Programming With MATLABDokument58 SeitenFinite Element Programming With MATLABbharathjoda100% (8)

- Lecture Notes On Construction Project ManagementDokument7 SeitenLecture Notes On Construction Project Managementqwertyui123321Noch keine Bewertungen

- Aggregates ENCI579 Lecture4Dokument57 SeitenAggregates ENCI579 Lecture4Vibhanshu MishraNoch keine Bewertungen

- For Lane 1-: Headway in SecDokument4 SeitenFor Lane 1-: Headway in SecVibhanshu MishraNoch keine Bewertungen

- Seismic-Resistant Design: SpectrumDokument53 SeitenSeismic-Resistant Design: Spectrummohd sumerNoch keine Bewertungen

- CamScanner App Scans Documents EasilyDokument2 SeitenCamScanner App Scans Documents EasilyVibhanshu MishraNoch keine Bewertungen

- Relative Frequency Distribution Curve (Right Lane)Dokument8 SeitenRelative Frequency Distribution Curve (Right Lane)Vibhanshu MishraNoch keine Bewertungen

- Is 800:2007Dokument150 SeitenIs 800:2007crajtry100% (2)

- Top10schlumbergerfieldengineerinterviewquestionsandanswers 150602023812 Lva1 App6892Dokument77 SeitenTop10schlumbergerfieldengineerinterviewquestionsandanswers 150602023812 Lva1 App6892Vibhanshu MishraNoch keine Bewertungen

- (A Very Short Overview) : SeismologyDokument66 Seiten(A Very Short Overview) : SeismologyHaider ShahNoch keine Bewertungen

- Construction Technology Series FoundationDokument116 SeitenConstruction Technology Series Foundationgbola96% (25)

- Piled Raft References and BooksDokument3 SeitenPiled Raft References and BooksIancu-Bogdan TeodoruNoch keine Bewertungen

- Design and Construction of Concrete Gravity DamsDokument69 SeitenDesign and Construction of Concrete Gravity Damshenybam83% (6)

- Pile FoundationsDokument106 SeitenPile Foundationsyennamsri04100% (3)

- UEMX 3813 Highway and Transportation: Lecture 3: Highway Capacity and Level-of-Service Analysis Ir - Dr. Khoo Hooi LingDokument60 SeitenUEMX 3813 Highway and Transportation: Lecture 3: Highway Capacity and Level-of-Service Analysis Ir - Dr. Khoo Hooi LingMOBA UNINoch keine Bewertungen

- AS 1742.5-1997 Traffic Control DevicesDokument29 SeitenAS 1742.5-1997 Traffic Control DevicesBenNoch keine Bewertungen

- CE122 2 GW02 Narrative ReportDokument3 SeitenCE122 2 GW02 Narrative ReportSean RiveroNoch keine Bewertungen

- Economic Impact of Traffic SignalsDokument6 SeitenEconomic Impact of Traffic SignalsJohn Siraut100% (1)

- Enjoy English Grade 7 Revision Sample.Dokument24 SeitenEnjoy English Grade 7 Revision Sample.margaretgombahNoch keine Bewertungen

- Traffic Loads On Road BridgesDokument47 SeitenTraffic Loads On Road BridgespabloNoch keine Bewertungen

- Review of Literature: 2.1 Risk PerceptionDokument31 SeitenReview of Literature: 2.1 Risk PerceptionTrixNoch keine Bewertungen

- Small Scale Creative Solutions For Better City Living PDFDokument224 SeitenSmall Scale Creative Solutions For Better City Living PDFPragya BharatiNoch keine Bewertungen

- 187-199 West End Lane Camden Planning ReportDokument73 Seiten187-199 West End Lane Camden Planning ReportWHampsteadNoch keine Bewertungen

- Firefighters' Pocket BookDokument115 SeitenFirefighters' Pocket BookajefniNoch keine Bewertungen

- Traffic Congestion in Metro Manila Due to Numerous VehiclesDokument2 SeitenTraffic Congestion in Metro Manila Due to Numerous Vehiclesdaniela aquinoNoch keine Bewertungen

- Urban Roads & Road SectionsDokument26 SeitenUrban Roads & Road SectionsKandarp RajyaguruNoch keine Bewertungen

- Reboke 6000 Tsi: Farming Wagon Instruction ManualDokument69 SeitenReboke 6000 Tsi: Farming Wagon Instruction ManualMarcio BólicoNoch keine Bewertungen

- iGO8 User Manual English USDokument88 SeiteniGO8 User Manual English USl6ginNoch keine Bewertungen

- Irc 67 2012Dokument20 SeitenIrc 67 2012Md Manower AlamNoch keine Bewertungen

- Talking Heads February 2017Dokument28 SeitenTalking Heads February 2017Barwon Heads Marketing0% (1)

- RFP For Selection of Transaction Advisor For Development of Multi-Level Car Parking at Sadar Bazar, Gurugram, HaryanaDokument54 SeitenRFP For Selection of Transaction Advisor For Development of Multi-Level Car Parking at Sadar Bazar, Gurugram, HaryanabhartiNoch keine Bewertungen

- Construction Traffic Management Plan 1Dokument23 SeitenConstruction Traffic Management Plan 1engasjayawardhanaNoch keine Bewertungen

- Jaypee Infrateach Limited-4Dokument124 SeitenJaypee Infrateach Limited-4sabul1276100% (1)

- Company Car Policy SampleDokument4 SeitenCompany Car Policy SampleASHWINI PATADENoch keine Bewertungen

- CDP AsansolDokument0 SeitenCDP Asansolani29archiNoch keine Bewertungen

- Solutions To Reduce Traffic CongestionDokument38 SeitenSolutions To Reduce Traffic CongestionedgarabrahamNoch keine Bewertungen

- Bicycle Lane Proposal QuestionedDokument1 SeiteBicycle Lane Proposal QuestionedChandan BhattaraiNoch keine Bewertungen

- Dangerous RoadDokument8 SeitenDangerous RoadWALDO RUIZ LOPEZNoch keine Bewertungen

- Topic 7. Salient Provisions of R.A. 4136Dokument6 SeitenTopic 7. Salient Provisions of R.A. 4136alliahnahNoch keine Bewertungen

- JSA FOR ROAD LAYING WORK (Asphalt Paving)Dokument10 SeitenJSA FOR ROAD LAYING WORK (Asphalt Paving)wahyu nugroho86% (7)

- Campey - Dakota Turf Tender - Operators Manual 2006aDokument44 SeitenCampey - Dakota Turf Tender - Operators Manual 2006aCampey Turf Care SystemsNoch keine Bewertungen

- Aptitude Questions and AnswersDokument116 SeitenAptitude Questions and Answerssanando_it12100% (1)

- Caribe - Michel CamiloDokument18 SeitenCaribe - Michel CamiloJonathan FonsecaNoch keine Bewertungen

- Roadmarking 2020Dokument5 SeitenRoadmarking 2020Mae EugenioNoch keine Bewertungen