Beruflich Dokumente

Kultur Dokumente

Procurement in Manufacturing Organisatio PDF

Hochgeladen von

Manu GCOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Procurement in Manufacturing Organisatio PDF

Hochgeladen von

Manu GCCopyright:

Verfügbare Formate

PROCUREMENT IN MANUFACTURING ORGANISATION PORTFOLIO AND THE USE OF THE INTERNT (I Nyoman Pujawan)

PROCUREMENT IN MANUFACTURING ORGANISATION:

PORTFOLIO AND THE USE OF THE INTERNET

I Nyoman Pujawan

Department of Industrial Engineering, Sepuluh Nopember Institute of Technology, Surabaya

Manchester Business School, The University of Manchester, UK

ABSTRACT

Procurement function in manufacturing organisations has played significantly more critical

roles nowadays than in the past. The contribution of procurement function is much determined by

how well the procurement management system is designed. A critical aspect of managing

procurement function in order to optimise its contribution to the organisation is procurement

portfolio, i.e., categorisation of items and then differentiation of procurement focus for different

categories. This paper will discuss procurement portfolio as a basis for procurement manager to

optimise the contribution of his/her function in supporting the organisation’s objectives. The role

of electronic procurement in each category of the portfolio will also be discussed.

Keywords : procurement portfolio, manufacturing, electronic procurement.

1. INTRODUCTION

Traditionally, procurement has often been associated with clerical activities. People

working in a procurement function spent most of their time administering purchase

requisition from the units or departments needing a product or service, creating purchase

orders, delivering purchase orders to the suppliers, administering delivery schedule from

the suppliers, etc. When the items or service are purchased through a tendering or bidding

process, clerical activities such as drafting Request for Proposal (RFP) or Request for

Quotation (RFQ), administering submitted proposal or quotation, inviting prospective

candidates, and conducting bidding process are among activities that are heavily

associated with procurement function. Those activities were often considered to be less

strategic, short-term cost oriented, and hence, less effort was spent in digging more

strategic issues of procurement activities.

With the continuous pressure in the market competition, people are starting to widen

their perspective on what needs to be improved in the supply chain. The fact that all

manufacturing companies need heavy involvement of procurement function and that the

money spent by the procurement function by large is dominant in the organisation has

given manufacturing people critical understanding on how important and how strategic

procurement function is. When wider viewpoint is taken into account, procurement

function is not only critical to achieve cost advantage by obtaining low cost supply, but

also contributes substantially to the other dimensions of the organisation’s competitive

advantage. In addition to its role to obtain cost advantage, procurement also supports the

organisation in improving responsiveness, achieving better flexibility, and reducing risks

or improving reliability of the organisation. As suggested by Ellram and Liu (2002), “the

financial impact of purchasing and supply management goes well beyond cost reduction.

It extends to such critical performance areas as business growth, profitability, cash flow,

and asset utilization”.

Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra 13

http://puslit.petra.ac.id/journals/industrial

JURNAL TEKNIK INDUSTRI VOL. 5, NO. 1, JUNI 2003: 13 - 21

With the above things in mind, it is obvious that procurement people are held

responsible for much wider responsibility nowadays. Understanding the strategic

objective of the company and deploying this strategic objective into more specific

objectives, procedures, and standards in the procurement function requires a visionary

manager. He or she should be able to bring his or her staffs to support the organisation

strategic objective. In other words, procurement manager should be able to align the

organisation strategic objectives and the procurement objectives, procedures, and

standards. Figure 1 outlines several strategic roles in which the procurement function is

held accountable nowadays.

In order to optimise the strategic role of procurement function in a manufacturing

context, it is important to put an appropriate emphasis or focus in line with the

environmental characteristics facing the supply decisions. Classification of items based

on their environmental condition and then the alignment of the focus of the procurement

management for each of those categories or classifications is often known as procurement

portfolio. This paper will discuss procurement portfolio to provide procurement manager

with a framework that can be used in optimising the contribution of his/her function in

supporting the organisation’s objectives.

Strategic Roles of Procurement

1. Align strategic role of the organisation to procurement objectives

2. Actively monitoring procurement technology and adopt it when appropriate

3. Develop procurement portfolio to appropriately address different supply

characteristics

4. Manage supply risk

5. Develop healthy upstream competition

6. Maintain important information from which decision making can be made more

appropriately

7. Facilitate supplier involvement in new product development where appropriate

8. Develop supply base where appropriate

Figure 1. Outlines of Strategic Roles of Procurement Function

2. DEVELOPING PROCUREMENT PORTFOLIO

Most organisation normally deals with thousands of items to be purchased from

suppliers. Purchasing people are facing various characteristics of the items and different

consumption patterns. Characteristics of items may be associated with their physical

volumes and properties, design complexity, price, etc. On the other hand, it is usual that a

company manages various different demand patterns for the purchased items. Some items

are required at about the same quantity each week, some items are needed in one week of

each month, and many other items are only needed several units annually. Companies

dealing with fashion type products will observe evolving types of items in their database.

Even manufacturing companies which produce functional items like light bulbs, cereals,

cigarettes, etc. are facing significantly different consumption pattern of the purchases.

14 Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra

http://puslit.petra.ac.id/journals/industrial

PROCUREMENT IN MANUFACTURING ORGANISATION PORTFOLIO AND THE USE OF THE INTERNT (I Nyoman Pujawan)

Differences in the characteristics of items and in the pattern of consumption are two

out of many variables that make procurement activities difficult. Other variables, such as

the nature of market, i.e., whether many capable suppliers exist or the items can only be

supplied exclusively by one supplier, the unit price, the availability of local suppliers, and

the strategic importance of the item to the company are also important determinant in

procurement decisions. Literature on procurement portfolio suggested that in order to

design an optimal procurement model, an organisation should understand first the

characteristics of items to purchase, the demand pattern, maturity of the technology, and

the availability of supplier.

With respect to the type of relationship with the supplier, Bensaou (1999) argued

that no one type of relationship, not even the strategic partnership, is inherently superior

to the others. This means that each company should develop and manage appropriately a

portfolio of relationship. The types of relationship may be determined based on item or

product characteristics, upstream market competition, and supplier conditions. For

example, highly standardised items with stable or declining demand, with mature

technology, and surrounded by many capable suppliers which the result in low switching

costs would be appropriately managed with market exchange style of relationship. A

market exchange relationship is characterised by limited information exchange, limited

time spent directly with supplier staffs, and virtually no joint efforts between the buyer

and supplier. On the other hand, complex items which require high level of customisation

and large capital investment and can only be supplied by limited number of suppliers may

be most suitably managed with a strategic partnership style. In a strategic partnership

model, both parties are willing to share data/information, extensively involve in joint

improvement initiatives and in new product design.

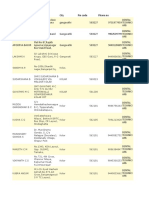

Handfield et al. (2000) developed a commodity portfolio matrix based on volume of

purchases and the degree of opportunity and risk resulting in four classes of commodities:

non-critical, bottleneck, leverage, and critical strategic supplies. The authors suggested

that strategic supplies are strategically important and difficult to substitute or to obtain

from alternative suppliers and are usually purchased in large volume. A similar portfolio

was also used in Olsen and Ellram (1997) who distinguished items based on the degree of

importance and the difficulty of managing the purchase situation. According to the

authors, the degree of importance is determined by three factors: competency, economic

value, and image. On the other hand, the difficulty of managing the purchase situation is

determined by product characteristics, supply market characteristics, and environment

conditions.

Figure 2 presents a general portfolio based on the degree of criticality and the

difficulty in obtaining the item. The degree of criticality is determined by whether or not

the item is a core component of the final product. An item has a high degree of criticality

if unavailability of the item means that the production process has to be stopped. This

type of item is normally required in almost all of the final products and no substitute is

available or possible. The degree of difficulty is reflected by the availability of capable

suppliers, flexibility in purchasing large or small quantity, and procurement lead time,

and delivery speed flexibility. An item is considered easy to obtain if many capable

suppliers are available with high volume and speed flexibility. Items which require

customised and complex design is likely to be uneasy to obtain because only limited

number of suppliers is likely to be capable of producing them.

Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra 15

http://puslit.petra.ac.id/journals/industrial

JURNAL TEKNIK INDUSTRI VOL. 5, NO. 1, JUNI 2003: 13 - 21

C

High volume flexibility, low Items are critical, maybe

r supply risk, critical to the expensive, not many suppliers

i organisation’s success. are able to supply, risk of

supply shortage, competing

t with other buyers.

i

c

a High volume flexibility, low Low volume flexibility, there is

l supply risk, not critical to the a risk of supply shortage, not so

l

organisation’s success. critical (not expensive and not

part of the core process)

y

D i f f i c u l t y t o O b t a i n

Figure 2. Segmentation of Purchases Based on Criticality and Difficulty to Obtain

3. ACHIEVING STRATEGIC COMPETITIVENESS BASED ON AN APPRO-

PRIATE PORTFOLIO

Creating a classification based on the above two dimensions is an important step in

procurement management. However, the strategic implication of this classification will

only be realised when it is further translated into differentiated focus. Logically, each cell,

which represents a unique set of characteristics, will have a different focus from other

cells. Figure 3 outlines the management focus that each cell should maintain.

Cell 1 is a cluster of items with low degree of importance and relatively easy to

obtain in the market. These items are normally simple and standardised, thus many

suppliers are capable of producing them. The technology required to produce the items is

mature and in many cases, with relatively low complexity or unsophisticated. Many other

buyers also normally need these items. In manufacturing companies, commodities items

such as bolt, nuts, and standardised paint are examples of cell 1 items. Most MRO

(maintenance, repair, and operations) items also belong to this classification. Office

supplies such as A4 papers are other examples. Since items are easily obtainable and the

design are normally simple and standardised, the buyer can focus on short-term

purchasing interest, i.e., looking at the price, comparing them, and then select the best

deal. Procuring these items does not need to be done by evaluating supplier technological

capability or their financial position. In other word, the buyer can design a very loose

relationship and can move from one supplier to another whenever appropriate and

investment to improve supplier capability is hardly ever justifiable in this situation. As far

as the procedure is concern, the buyer should strive to minimise bureaucracy of the

procurement process. Efforts should be spent to simplify procurement process and the

organisation should delegate purchasing decisions to lower level of authority.

16 Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra

http://puslit.petra.ac.id/journals/industrial

PROCUREMENT IN MANUFACTURING ORGANISATION PORTFOLIO AND THE USE OF THE INTERNT (I Nyoman Pujawan)

C Keep multiple suppliers. Look at Focus on maintaining effective

other supply characteristics, partnerships: increase supplier

r choice need not predominantly reliability and buyer’s bargaining

i be based on cost. The use of power. Reduce long-term risk. Use

multi attribute e-auction is of on-line information exchange.

t

appropriate.

i 1 3

c

a Focus on obtaining low cost Focus on developing alternative

l suppliers and simplifying suppliers. Invest in technology and

procurement processes. The use knowledge to support supplier

i of e-auction is appropriate. capacity and capability. Develop

t purchasing consortium to justify the

investment.

y 2 4

D i f f i c u l t y t o O b t a i n

Figure 3. Procurement Management Portfolio: Differences in Management Focus

Cell 2 is a cluster of items which are not very critical but difficult to obtain. They are

non-core items, sometimes the price is not expensive, but only limited suppliers are

available to supply with a reasonable lead time. Olsen and Ellram (1997) and Handfield et

al. (2000) referred to this kind of items as bottleneck. Low supplier availability may be

due to the items are economically unattractive to produce or because the suppliers are

located far away so that it restrict speed flexibility. Quite often packaging items for

several manufacturing companies belong to this classification. Packaging items are not

core components and their price are normally not expensive, but quite often the

manufacturer change or improve the packaging designs to improve product appearance in

the market and thus more appealing to the customers. Facing with this situation, a

possible course of action the management may need to take is to develop new suppliers.

If the supplier is developed exclusively for the company, the volume of demand may not

guarantee the economies of scale of its production. Thus, whereas appropriate, initiating

what is called buying consortium may be a viable option. Supplier consortium is a group

of buying companies who aim to obtain a better bargaining power by pooling together

their demand. In this framework, the buying consortium is not primarily developed to

increase their bargaining power relative to the supplier, but to increase the availability of

the items or to increase both volume and speed flexibility of the items in question.

In contrast to cell 2, items classified to cell 3 are not difficult to obtain and these

items are critical to the company. Companies that use standardised items as their main

components or materials will often have cell 3 as dominant items in their purchases.

Small to medium cake producers rarely use specialised ingredients. Most of the

ingredients, including flour, sugar, and salt are standardised items that can be quite easily

obtained in the market. Because these items are easy to obtain but the company normally

Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra 17

http://puslit.petra.ac.id/journals/industrial

JURNAL TEKNIK INDUSTRI VOL. 5, NO. 1, JUNI 2003: 13 - 21

requires in large volume, the focus in procurement management could vary. One

company may need to keep more than one suppliers and the buying criteria need not be

predominantly based on cost. Other appropriate criteria may be prioritised. The price

offered by one supplier maybe about the same, but one supplier is willing to provide the

buyer with longer credit period. Or, the quoted price maybe the same, but one supplier is

willing to deliver twice a day but other suppliers are able to deliver no more than once a

day. In such a situation, the buyer should carefully choose what criteria to be used in

selecting the supplier.

Cell 4 is to accommodate strategic items, i.e., items which are highly critical to the

company and are not available as a commodity in the market. These items require special

capability or sophisticated technology and thus, only limited number of suppliers is

capable of producing/supplying those items. Limited availability of supply increases the

supplier’s bargaining power. Long-term risk of supply could be high if the current

supplier is not financially strong or if other buyers are competing with the company to

secure long-term supply availability. Due to these characteristics, the company should

spend substantial efforts to secure the supply and to improve long-term supplier

performance. Such a situation warrants the buyer to spend effort and money in initiating

long-term partnership with the supplier. Partnership normally involves commitment to

share risks and benefits and to pursue collaborative improvement. The buyer may need to

provide the supplier with technical, financial, and managerial supports whenever

appropriate. Supplier is often involved in the new product development process. Both

parties are also willing to share critical information and conserve partner’s trust by

keeping all of the shared information secure from other parties. Such a relationship

requires trust, commitment, and reliability from both parties. Automotive companies are

among the best examples showing supplier partnership model. For example, as pointed

out by Handfield et al. (2000), “BMW has sent maintenance engineers and procurement,

logistics, and quality personnel to suppliers –sometimes for several weeks at a time”.

4. THE USE OF ELECTRONIC PROCUREMENT

Recent development in supply chain management has been marked by a splendid

application of the Internet in purchasing activities. The traditional way of procuring goods

or services via manual and off line activities such as sending a Request for Quotation

(RFQ) by mail, conducting off line bidding process, typing purchase order in a stand

alone computer, sending it by fax or regular mail, and then pay the bills by using a

separate payment system is gradually replaced by electronics systems on the Internet.

Those manual processes are not only time consuming, but also costly. A purchase order

had to move step by step through costly staffs, from the administrative staff filling the

purchase order, to the purchasing manager checking and signing it, and then to the

accounting department for budget approval. Finally the purchase order should be sent via

a regular mail or a fax by a mail clerk. Presutti Jr. (2003) pointed out that the cost for

processing a purchase order is in the range of US$70 to 300. With the dramatic

development of the Internet, many of the procurement activities can now be done

electronically. Johnson and Whang (2002) provided a comprehensive review on the use

of the Internet in business, including in procurement.

18 Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra

http://puslit.petra.ac.id/journals/industrial

PROCUREMENT IN MANUFACTURING ORGANISATION PORTFOLIO AND THE USE OF THE INTERNT (I Nyoman Pujawan)

Software vendors have been persistently incorporating more and more capabilities

on their products so that the procurement processes can be done more easily with less

time and headcounts which ultimately promote higher efficiency and responsiveness.

PeopleSoft for example developed Supplier Relationship Management (SRM) software

which enables the user to seamlessly integrate the source to settle processes, from

determining the best supplier to receiving shipments, closing financial statements, and

then continually analysing suppliers’ performance. Procuri, another procurement software

provider, offers a sourcing tool that enables the user to conduct on-line negotiation with

different negotiation strategies such as one to one, sealed bid, and dynamic pricing

events. The tool is also equipped with features to do multi-attribute and multi line bidding

and to perform analyses on spending, supplier performance, and other relevant analysis.

Ariba Spend Management provides capabilities to obtain enterprise-wide visibility and

operational control. This application enables the user to use finer criteria in selecting

suppliers. Oracle, with its Oracle Sourcing feature, allows users to integrate the

procurement activities with the back end applications. Many other procurement

software/tools providers, such as Epicor and Covigna, are well equipped with various

sophisticated capabilities.

The role of third parties, such as independent electronic market exchanges, in

boosting e-procurement practice has also been fantastic. Companies are now able to find

a wide range of items easily and quickly via virtual markets. With the power of the

Internet, various items can be easily bought electronically via virtual markets such as

assetline.com for construction equipment and machinery, ironplanet.com for heavy

equipment, steelauction.com for steel products like beams, rods, ingots, and pipes,

chemicalnet.com for chemical items, theplasticsexchane.com for plastics materials, and

many others. Such virtual markets are also developing progressively in countries such as

China (for example Chemchine.com, echinachem.com), India (such as Chemvalue.com,

Indiamarkets.com Indiachemicalportal.com), Korea (cyberdisty.com), Middle East (such

as MEsteel.com), and Latin America (ActiMart.com). Those virtual markets enable the

buying companies to more proactively seek potential suppliers, conduct bidding processes

on-line, and obtain up to date analysis on price trends and other information on market

development from experts.

Traditionally, items belong to cell 3 are appropriate to purchase via a tendering

process. Unlike item in cell 1, the large volume of purchases in this category warrants the

expensive and time consuming tendering process. With the advent of the Internet,

tendering process has become more popular in procurement, and items in other category,

especially in cell 1 are also candidates for tendering. The use of the Internet as a media

for tendering has made this mode much cheaper and faster unlike the traditional tendering

process which was normally very expensive and time consuming. Buyers can do a

tendering process in their own on-line facilities, if there is any, but can also use third

party providers such as the ones mentioned above. A popular means of selecting the

cheapest offer from the competing suppliers through the Internet is recently well known

as electronics reverse auction or abbreviated as e-auction (see for example, Emiliani,

2000; Emiliani and Stec, 2002; Smart and Harrison, 2003; Smeltzer and Carr, 2003). In

this case, the buyer invites several potential suppliers to bid for price electronically and

the one with the lowest bid will win.

E-procurement has not been extensively applied for procurement of items in

categories 2 and 4. Although limited number of manufacturing companies may have

Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra 19

http://puslit.petra.ac.id/journals/industrial

JURNAL TEKNIK INDUSTRI VOL. 5, NO. 1, JUNI 2003: 13 - 21

applied e-procurement for strategic items, the nature of e-procurement would be different

from those in categories 1 and 3. Here, buying companies are hardly ever possible to use

e-auction due to the limited availability of potential suppliers and due to specific designs

are often needed for items in cell 4. Electronic procurement in this case should be able to

integrate internal business processes of the two parties so that the buyer can easily

monitor supplier’s stock and capacity availability and the supplier can also monitor

buyer’s stock, demand, and production plan/schedule.

5. CONCLUDING REMARK

This paper discusses procurement portfolio and the role of e-procurement in

supporting the strategic role of procurement. In many organisations, a large number of

different types of items are usually purchased. Treating all items equally does not create

an effective procurement system. A portfolio is a model that procurement manager can

use to distinguish items based on their characteristics and then differentiate procurement

focus for each category in order to optimise the contribution of procurement function to

the company’s strategic objectives. Furthermore, the use of electronics procurement

system should take into account the above classification. Electronics reverse auction

which is very popular recently and has been proven to provide very high rate on

investment (ROI) is only suitable if many suppliers are capable of supplying the items in

question. Understanding the characteristics of items, supply availability and the

associated risks, the demand patterns, and the appropriateness of each e-procurement

system is critical to creating an effective procurement management system.

REFERENCES

Bensaou, M., 1999. “Portfolio of Buyer–Supplier Relationships”, Sloan Management

Review, Summer, pp. 35 – 44.

Ellram, L. R., and B. Liu, 2000. “The Financial Impact of Supply Management”, Supply

Chain Management Review, Nov/Dec.

Emiliani, M. L., 2000. “Business-to-Business Online Auctions: Key Issues for Purchasing

Process Management”, Supply Chain Management: An International Journal,

vol. 5 (4), pp. 176 – 186.

Emiliani, M. L., and D. J. Stec, 2002. “Realizing savings from online reverse auctions”,

Supply Chain Management: An International Journal, vol. 7(1), pp. 12 – 23.

Handfield, R. B., D. R. Krause, T. V. Scannel, and R. M. Monczka, 2000. “Avoid the

Pitfall in Supplier Development”, Sloan Management Review, Winter, pp. 37 – 49.

Johnson, M. E., and S. Whang, 2002. “E-business and Supply Chain Management: An

Overview and Framework”, Production and Operations Management, vol. 11 (4),

pp. 413 – 423.

20 Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra

http://puslit.petra.ac.id/journals/industrial

PROCUREMENT IN MANUFACTURING ORGANISATION PORTFOLIO AND THE USE OF THE INTERNT (I Nyoman Pujawan)

Olsen, R. F., and L. E. Ellram, 1997. ”A portfolio approach to supplier relationships”,

Industrial Marketing Management, vol. 26 (2), pp. 101 -113.

Presutti Jr., W. D., 2003. “Supply Management and e-procurement: Creating Value

Added in the Supply Chain”, Industrial Marketing Management, vol. 32, pp. 219 –

226.

Smart, A., and A. Harrison, 2002. “Reverse Auctions as a Support Mechanism in Flexible

Supply Chains”, International Journal of Logistics: Research and Applications,

vol. 5 (3), pp. 275 – 284.

Smeltzer, L. R., and A. S. Carr, 2003. “Electronics Reverse Auctions: Promises, Risks,

and Conditions for Success”, Industrial Marketing Management, vol. 32, pp. 481 –

488.

Jurusan Teknik Industri, Fakultas Teknologi Industri, Universitas Kristen Petra 21

http://puslit.petra.ac.id/journals/industrial

Das könnte Ihnen auch gefallen

- Quantity Purchase 22234Dokument7 SeitenQuantity Purchase 22234Mohammad FaizuNoch keine Bewertungen

- Michael Porter's Value Chain: Unlock your company's competitive advantageVon EverandMichael Porter's Value Chain: Unlock your company's competitive advantageBewertung: 4 von 5 Sternen4/5 (1)

- Chapter 5 Sourcing Materials and Services - Version 1.2Dokument37 SeitenChapter 5 Sourcing Materials and Services - Version 1.2Zin Mar OoNoch keine Bewertungen

- Vendor DevelopmentDokument17 SeitenVendor DevelopmentAashish Bachlash0% (1)

- Benchmarking Study of Strategic Sourcing PracticesDokument2 SeitenBenchmarking Study of Strategic Sourcing PracticesPepe CMNoch keine Bewertungen

- Purchasing Notes GeneralDokument101 SeitenPurchasing Notes GeneralPhilip K BiegoNoch keine Bewertungen

- Strategic Procurement Management Lecture Notes by Bagaya Ramathan PDFDokument11 SeitenStrategic Procurement Management Lecture Notes by Bagaya Ramathan PDFFatmata Sheriff KamaraNoch keine Bewertungen

- Table of Content: PurchasingDokument9 SeitenTable of Content: PurchasingLilCent MmanuelNoch keine Bewertungen

- Procurement 4Dokument38 SeitenProcurement 4Shabnam ShahNoch keine Bewertungen

- Porters Research PaperDokument8 SeitenPorters Research Paperrfxlaerif100% (1)

- Supply Chain Management in The Textile IndustryDokument10 SeitenSupply Chain Management in The Textile Industryimroz_ali90Noch keine Bewertungen

- CHDokument5 SeitenCHZafwaan RoobleNoch keine Bewertungen

- Quản trị vận hànhDokument7 SeitenQuản trị vận hànhNhi LêNoch keine Bewertungen

- 6 Procurement Logistics and Supply Chain MGT PDFDokument85 Seiten6 Procurement Logistics and Supply Chain MGT PDFhoussem eddine75% (4)

- Insights Into The Strategic Sourcing Decision - Understanding BuyeDokument23 SeitenInsights Into The Strategic Sourcing Decision - Understanding BuyeLuisa Fernanda SolanoNoch keine Bewertungen

- 02 Handout 1Dokument4 Seiten02 Handout 1Abbegail CalinaoNoch keine Bewertungen

- Lecture Three: Organisational Buying Structures and The Impact of Issues Such As Brand Strength and Customer Service ContentDokument13 SeitenLecture Three: Organisational Buying Structures and The Impact of Issues Such As Brand Strength and Customer Service Contentharismasood90Noch keine Bewertungen

- Rich Text Editor FileDokument5 SeitenRich Text Editor FileRonnald WanzusiNoch keine Bewertungen

- SourcingDokument82 SeitenSourcinglomefNoch keine Bewertungen

- Purchasing and Materials Management PDFDokument210 SeitenPurchasing and Materials Management PDFShueab Mujawar100% (1)

- Strategic Purchasing Control of The Industrial Enterprise: Digitalization and Logistics ApproachDokument10 SeitenStrategic Purchasing Control of The Industrial Enterprise: Digitalization and Logistics ApproachXdASDNoch keine Bewertungen

- Compare and Contrast The Industrial Organisation Approach To The ResourceDokument3 SeitenCompare and Contrast The Industrial Organisation Approach To The ResourceMarvin AlleyneNoch keine Bewertungen

- Research Paper On Purchasing and Supply ManagementDokument8 SeitenResearch Paper On Purchasing and Supply ManagementudmwfrundNoch keine Bewertungen

- SCLM Cia 3Dokument28 SeitenSCLM Cia 3Mohd Yousuf MasoodNoch keine Bewertungen

- Procurement ManagementDokument32 SeitenProcurement ManagementmemeNoch keine Bewertungen

- The Procurement Process PDFDokument7 SeitenThe Procurement Process PDFsuadistanNoch keine Bewertungen

- Chap 1Dokument23 SeitenChap 1Mohamed NorNoch keine Bewertungen

- Capturing The Risk-Pooling Effect Through Inventory Planning and Demand SwitchingDokument14 SeitenCapturing The Risk-Pooling Effect Through Inventory Planning and Demand SwitchingManhNoch keine Bewertungen

- CHAPTER 3-Purchasing MMDokument25 SeitenCHAPTER 3-Purchasing MMhailegebreselassie24Noch keine Bewertungen

- Chapter-2 TQMDokument13 SeitenChapter-2 TQMeyna delos santosNoch keine Bewertungen

- Competitive Advantage of Information Systems (Porter'S Wheel)Dokument6 SeitenCompetitive Advantage of Information Systems (Porter'S Wheel)JimshegsNoch keine Bewertungen

- Balancing MarqueringDokument11 SeitenBalancing Marqueringlucia zegarraNoch keine Bewertungen

- SMDokument192 SeitenSMHeather MyleNoch keine Bewertungen

- Operations Strategy - Sbaa7027: Unit - IDokument117 SeitenOperations Strategy - Sbaa7027: Unit - Ijugraj randhawaNoch keine Bewertungen

- Porter's Five TheoryDokument6 SeitenPorter's Five TheoryPrity chhetryNoch keine Bewertungen

- Purchasing Chessboard - EnglishDokument0 SeitenPurchasing Chessboard - EnglishErika Lopes CiprianoNoch keine Bewertungen

- Purpose F 2016Dokument5 SeitenPurpose F 2016samuel tilahunNoch keine Bewertungen

- Introduction For The StudyDokument7 SeitenIntroduction For The StudyKarthik DeeviNoch keine Bewertungen

- What Is Industrial PurchasingDokument5 SeitenWhat Is Industrial Purchasingkeyur100% (1)

- SMSG NotesDokument17 SeitenSMSG NotesSanskar wadhwaNoch keine Bewertungen

- Supply Chain Strategies Which One Hits The MarkDokument11 SeitenSupply Chain Strategies Which One Hits The MarkFaried Putra SandiantoNoch keine Bewertungen

- ch-3mm EditedDokument17 Seitench-3mm EditedmelkecoopNoch keine Bewertungen

- Insurance Industry Value Chain BY Professor Festus M. Epetimehin Joseph Ayo Babalola University, Ikeji - ArakejiDokument13 SeitenInsurance Industry Value Chain BY Professor Festus M. Epetimehin Joseph Ayo Babalola University, Ikeji - ArakejiA-17 Akash AgravatNoch keine Bewertungen

- Accounting Purchasing and Supply Chain ManagementDokument6 SeitenAccounting Purchasing and Supply Chain ManagementSwetha ParthiNoch keine Bewertungen

- Alexandre Campos CompetinovDokument37 SeitenAlexandre Campos CompetinovAlexandre Campos100% (1)

- Logistic and Value PRESENTATIONDokument8 SeitenLogistic and Value PRESENTATIONSaio M S KamaraNoch keine Bewertungen

- Procurement ManagementDokument12 SeitenProcurement ManagementRochak SinglaNoch keine Bewertungen

- Blackbook LogisticsDokument28 SeitenBlackbook LogisticsSean Tapiwa KaberaNoch keine Bewertungen

- Strategic SourcingDokument4 SeitenStrategic SourcingХристинаГулева100% (1)

- Airline ProcurementDokument7 SeitenAirline ProcurementPTS Ground SupportNoch keine Bewertungen

- Claudious Gwaze AssignmentDokument14 SeitenClaudious Gwaze AssignmentStandrick MuchiniNoch keine Bewertungen

- SCM - Strategic SourcingDokument4 SeitenSCM - Strategic SourcingGajendra Singh RaghavNoch keine Bewertungen

- Tactical vs. Strategic Purchasing PDFDokument9 SeitenTactical vs. Strategic Purchasing PDFmihai simionescuNoch keine Bewertungen

- Supply ChainDokument38 SeitenSupply ChainJames Euler Villar EstradaNoch keine Bewertungen

- Reporting ManagmentDokument12 SeitenReporting ManagmentTuseef AhmedNoch keine Bewertungen

- M S B S: Aterial Ourcing and Uying TrategiesDokument10 SeitenM S B S: Aterial Ourcing and Uying TrategiesRiwii MahqNoch keine Bewertungen

- Supply Chain and Logistics Management Trimester - 4 CIA-3 Research Based Assignment Automobile IndustryDokument30 SeitenSupply Chain and Logistics Management Trimester - 4 CIA-3 Research Based Assignment Automobile Industrytanvi kamaniNoch keine Bewertungen

- Explain The Importance of Purchasing in A Manufacturing OrganizationDokument14 SeitenExplain The Importance of Purchasing in A Manufacturing OrganizationHRish BhimberNoch keine Bewertungen

- Order-Winning and Order-Qualifying CriteriaDokument3 SeitenOrder-Winning and Order-Qualifying CriteriaJesica MaryNoch keine Bewertungen

- MARKETING ENVIRONMENT - Unit 2Dokument19 SeitenMARKETING ENVIRONMENT - Unit 2Manu GCNoch keine Bewertungen

- Ignou Proposal PP No 112834Dokument16 SeitenIgnou Proposal PP No 112834Manu GCNoch keine Bewertungen

- Industry Analysis TemplateDokument9 SeitenIndustry Analysis TemplateManu GCNoch keine Bewertungen

- INDUS TMT Case StudyDokument6 SeitenINDUS TMT Case StudyManu GCNoch keine Bewertungen

- Indian Steel Strategy To AmbitionDokument14 SeitenIndian Steel Strategy To AmbitionManu GCNoch keine Bewertungen

- Comparative Analysis of Indian Private and Public Sectors With Special Reference To TATA Steel and SAILDokument53 SeitenComparative Analysis of Indian Private and Public Sectors With Special Reference To TATA Steel and SAILManu GCNoch keine Bewertungen

- 1 s2.0 S0970389618304609 MainDokument33 Seiten1 s2.0 S0970389618304609 MainManu GC100% (1)

- Indian Steel Strategy To AmbitionDokument14 SeitenIndian Steel Strategy To AmbitionManu GCNoch keine Bewertungen

- EY Indian Steel Strategy To Ambition PDFDokument21 SeitenEY Indian Steel Strategy To Ambition PDFManu GCNoch keine Bewertungen

- Supply Chain ManagementDokument9 SeitenSupply Chain ManagementManu GCNoch keine Bewertungen

- Indian Steel Industry 28.6.19Dokument22 SeitenIndian Steel Industry 28.6.19Manu GCNoch keine Bewertungen

- FM - Amreli Nagrik Bank - 2Dokument84 SeitenFM - Amreli Nagrik Bank - 2jagrutisolanki01Noch keine Bewertungen

- Juarez, Jenny Brozas - Activity 2 MidtermDokument4 SeitenJuarez, Jenny Brozas - Activity 2 MidtermJenny Brozas JuarezNoch keine Bewertungen

- The Second Oracle at DelphiDokument14 SeitenThe Second Oracle at Delphiapi-302698865Noch keine Bewertungen

- 4 Marine Insurance 10-8-6Dokument53 Seiten4 Marine Insurance 10-8-6Eunice Saavedra100% (1)

- SMART Goal Worksheet (Action Plan)Dokument2 SeitenSMART Goal Worksheet (Action Plan)Tiaan de Jager100% (1)

- Littérature Russe I Cours 1-3PDFDokument45 SeitenLittérature Russe I Cours 1-3PDFSarah DendievelNoch keine Bewertungen

- PMP Mock Exams 1, 200 Q&ADokument29 SeitenPMP Mock Exams 1, 200 Q&Asfdfdf dfdfdf100% (1)

- Utilitarianism and The Ethical Foundations of Cost-Effectiveness Analysis in Resource Allocation For Global HealthDokument7 SeitenUtilitarianism and The Ethical Foundations of Cost-Effectiveness Analysis in Resource Allocation For Global HealthZainab AbbasNoch keine Bewertungen

- CentipedeDokument2 SeitenCentipedeMaeNoch keine Bewertungen

- Intermarket AnaDokument7 SeitenIntermarket Anamanjunathaug3Noch keine Bewertungen

- Micro PPT FinalDokument39 SeitenMicro PPT FinalRyan Christopher PascualNoch keine Bewertungen

- GAAR Slide Deck 13072019Dokument38 SeitenGAAR Slide Deck 13072019Sandeep GolaniNoch keine Bewertungen

- English (202) Tutor Marked Assignment: NoteDokument3 SeitenEnglish (202) Tutor Marked Assignment: NoteLubabath IsmailNoch keine Bewertungen

- FINAL Haiti Electricity Report March 2018Dokument44 SeitenFINAL Haiti Electricity Report March 2018Djorkaeff FrancoisNoch keine Bewertungen

- Abi AyodhyaDokument4 SeitenAbi AyodhyaHarshdeep SinghNoch keine Bewertungen

- Quotation 017-2019 - 01-07-2019Dokument8 SeitenQuotation 017-2019 - 01-07-2019Venkatesan ManikandanNoch keine Bewertungen

- IIM Kashipur Master of Business Administration (MBA) Microeconomics, Term I, Academic Year 2021-2022 Syllabus I. Instructor DetailDokument20 SeitenIIM Kashipur Master of Business Administration (MBA) Microeconomics, Term I, Academic Year 2021-2022 Syllabus I. Instructor DetailSai Teja MekalaNoch keine Bewertungen

- The A To Z Guide To Afghanistan Assistance 2012Dokument365 SeitenThe A To Z Guide To Afghanistan Assistance 2012Khan MohammadNoch keine Bewertungen

- Modern Advanced Accounting in Canada Canadian 8th Edition Hilton Solutions Manual PDFDokument106 SeitenModern Advanced Accounting in Canada Canadian 8th Edition Hilton Solutions Manual PDFa748358425Noch keine Bewertungen

- Strategy Output Activity (Ppa) : Activities (Ppas) For The Social Sector Activities (Ppas) For The Education Sub-SectorDokument3 SeitenStrategy Output Activity (Ppa) : Activities (Ppas) For The Social Sector Activities (Ppas) For The Education Sub-Sectorstella marizNoch keine Bewertungen

- Course Code: EDU15104DCE Course Title: Population Education: Unit 1Dokument7 SeitenCourse Code: EDU15104DCE Course Title: Population Education: Unit 1Danielle Joyce NaesaNoch keine Bewertungen

- Bond ValuationDokument49 SeitenBond Valuationmehnaz kNoch keine Bewertungen

- FO NCR.13thEditionDokument639 SeitenFO NCR.13thEditionBryan KadusaleNoch keine Bewertungen

- Quizlet - SOM 122 Chapter 5 - ManagementDokument3 SeitenQuizlet - SOM 122 Chapter 5 - ManagementBob KaneNoch keine Bewertungen

- Program Notes, Texts, and Translations For The Senior Recital of M. Evan Meisser, BartioneDokument10 SeitenProgram Notes, Texts, and Translations For The Senior Recital of M. Evan Meisser, Bartione123Noch keine Bewertungen

- Unconstituted Praxis PDFDokument115 SeitenUnconstituted Praxis PDFGerardo AlbatrosNoch keine Bewertungen

- Dentapdf-Free1 1-524 1-200Dokument200 SeitenDentapdf-Free1 1-524 1-200Shivam SNoch keine Bewertungen

- IBA High Frequency Words PDFDokument18 SeitenIBA High Frequency Words PDFReduanul Chowdhury NitulNoch keine Bewertungen

- Hymns by John Henry NewmanDokument286 SeitenHymns by John Henry Newmanthepillquill100% (1)

- Summary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisVon EverandSummary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisBewertung: 5 von 5 Sternen5/5 (15)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedVon EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedBewertung: 5 von 5 Sternen5/5 (81)

- The Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeVon EverandThe Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- Broken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterVon EverandBroken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterBewertung: 5 von 5 Sternen5/5 (3)

- I Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Von EverandI Will Teach You to Be Rich: No Guilt. No Excuses. No B.S. Just a 6-Week Program That Works (Second Edition)Bewertung: 4.5 von 5 Sternen4.5/5 (13)

- The Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeVon EverandThe Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Bitter Brew: The Rise and Fall of Anheuser-Busch and America's Kings of BeerVon EverandBitter Brew: The Rise and Fall of Anheuser-Busch and America's Kings of BeerBewertung: 4 von 5 Sternen4/5 (52)

- A History of the United States in Five Crashes: Stock Market Meltdowns That Defined a NationVon EverandA History of the United States in Five Crashes: Stock Market Meltdowns That Defined a NationBewertung: 4 von 5 Sternen4/5 (11)

- Summary of 10x Is Easier than 2x: How World-Class Entrepreneurs Achieve More by Doing Less by Dan Sullivan & Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisVon EverandSummary of 10x Is Easier than 2x: How World-Class Entrepreneurs Achieve More by Doing Less by Dan Sullivan & Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (24)

- Rich Dad Poor Dad: What the Rich Teach Their Kids About Money That the Poor and Middle Class Do NotVon EverandRich Dad Poor Dad: What the Rich Teach Their Kids About Money That the Poor and Middle Class Do NotNoch keine Bewertungen

- Summary: The Gap and the Gain: The High Achievers' Guide to Happiness, Confidence, and Success by Dan Sullivan and Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisVon EverandSummary: The Gap and the Gain: The High Achievers' Guide to Happiness, Confidence, and Success by Dan Sullivan and Dr. Benjamin Hardy: Key Takeaways, Summary & AnalysisBewertung: 5 von 5 Sternen5/5 (4)

- The Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindVon EverandThe Science of Prosperity: How to Attract Wealth, Health, and Happiness Through the Power of Your MindBewertung: 5 von 5 Sternen5/5 (231)

- Financial Intelligence: How to To Be Smart with Your Money and Your LifeVon EverandFinancial Intelligence: How to To Be Smart with Your Money and Your LifeBewertung: 4.5 von 5 Sternen4.5/5 (540)

- Sleep And Grow Rich: Guided Sleep Meditation with Affirmations For Wealth & AbundanceVon EverandSleep And Grow Rich: Guided Sleep Meditation with Affirmations For Wealth & AbundanceBewertung: 4.5 von 5 Sternen4.5/5 (105)

- A Happy Pocket Full of Money: Your Quantum Leap Into The Understanding, Having And Enjoying Of Immense Abundance And HappinessVon EverandA Happy Pocket Full of Money: Your Quantum Leap Into The Understanding, Having And Enjoying Of Immense Abundance And HappinessBewertung: 5 von 5 Sternen5/5 (159)

- Summary of I Will Teach You to Be Rich: No Guilt. No Excuses. Just a 6-Week Program That Works by Ramit SethiVon EverandSummary of I Will Teach You to Be Rich: No Guilt. No Excuses. Just a 6-Week Program That Works by Ramit SethiBewertung: 4.5 von 5 Sternen4.5/5 (23)

- Quotex Success Blueprint: The Ultimate Guide to Forex and QuotexVon EverandQuotex Success Blueprint: The Ultimate Guide to Forex and QuotexNoch keine Bewertungen

- Meet the Frugalwoods: Achieving Financial Independence Through Simple LivingVon EverandMeet the Frugalwoods: Achieving Financial Independence Through Simple LivingBewertung: 3.5 von 5 Sternen3.5/5 (67)

- Baby Steps Millionaires: How Ordinary People Built Extraordinary Wealth--and How You Can TooVon EverandBaby Steps Millionaires: How Ordinary People Built Extraordinary Wealth--and How You Can TooBewertung: 5 von 5 Sternen5/5 (323)

- Fluke: Chance, Chaos, and Why Everything We Do MattersVon EverandFluke: Chance, Chaos, and Why Everything We Do MattersBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Secrets of the Millionaire Mind: Mastering the Inner Game of WealthVon EverandSecrets of the Millionaire Mind: Mastering the Inner Game of WealthBewertung: 4.5 von 5 Sternen4.5/5 (1026)

- The Holy Grail of Investing: The World's Greatest Investors Reveal Their Ultimate Strategies for Financial FreedomVon EverandThe Holy Grail of Investing: The World's Greatest Investors Reveal Their Ultimate Strategies for Financial FreedomBewertung: 5 von 5 Sternen5/5 (7)

- Rich Bitch: A Simple 12-Step Plan for Getting Your Financial Life Together . . . FinallyVon EverandRich Bitch: A Simple 12-Step Plan for Getting Your Financial Life Together . . . FinallyBewertung: 4 von 5 Sternen4/5 (8)

- The Millionaire Next Door: The Surprising Secrets Of Americas WealthyVon EverandThe Millionaire Next Door: The Surprising Secrets Of Americas WealthyBewertung: 4.5 von 5 Sternen4.5/5 (948)

- Rich Dad's Cashflow Quadrant: Guide to Financial FreedomVon EverandRich Dad's Cashflow Quadrant: Guide to Financial FreedomBewertung: 4.5 von 5 Sternen4.5/5 (1387)

- The Wyckoff Methodology in Depth: How to trade financial markets logicallyVon EverandThe Wyckoff Methodology in Depth: How to trade financial markets logicallyBewertung: 5 von 5 Sternen5/5 (28)