Beruflich Dokumente

Kultur Dokumente

Reflux Plate Determinations For Batch Distillation: S. R. M. Ellis

Hochgeladen von

RajeshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reflux Plate Determinations For Batch Distillation: S. R. M. Ellis

Hochgeladen von

RajeshCopyright:

Verfügbare Formate

ENGINEERING AND PROCESS DEVELOPMENT

Reflux and Plate Determinations

for Batch Distillation

S. R. M. ELLIS

Chemical Engineering Department, The University o f Birmingham, Birmingham 15, England

I ?rT ASSESSING the number of plates in a binary distillation it

is usual to calculate the minimum reflux ratio and minimum

number of plates by using the Underwood (19) and Fenske (11)

The object of this paper is to re-examine Gilliland’s method and

to see if it can be extended to batch distillation. If this is pos-

sible, the method would also be of value in locating the feed plate

equations, and to calculate the operating reflux ratio and number in continuous distillation.

of plates by using the graphical McCabe-Thiele (16) construction.

When the relative volatility is less than 1.25 and the number of Procedure Includes Correlating Curves Based

theoretical plates in the column is high, the graphical hIcCabe- on Underwood, Fenske, and Smoker Equations

Thiele construction is difficult to apply. I n such cases the num- The procedure was to consider the systems, benzene-toluene,

ber of plates can be accurately determined using the Smoker (17) benzene-n-heptane, phenol-o-cresol, and ideal mixtures where

and Dodge and Huffman ( 7 ) equations. The use of such equa- the relative volatilities of the binary components or key com-

tions is time consuming and requires a high degree of arithmetical ponents in multicomponent distillation are 1.1, 1.05, 1.025, 1.01,

accuracy. and for a number of separations in each system to calculate mini-

As a rapid and reasonably accurate method for the preliminary mum and operating reflux and plate requirements.

determination of the number of theoretical plates in a column, For benzene-toluene the equilibrium data of Griswold, Andres,

Brown and Martin ( a ) and Gilliland ( l a )have proposed empirical

and Klein (IS)were selected, whereas for the system benzene-n-

correlating equations involving the number of plates, the minimum

heptane equilibrium data of Ellis (10) were used.

number of plates, the reflux ratio, and the minimum reflux ratio.

Underwood’s (19) equation was used to calculate all minimum

These equations apply to continuous distillation. Brown and reflux ratios. Except for benzene-n-heptane, the Fenske (11)

Martin and Gilliland allow for different feed conditions. The equation was used to determine minimum plate requirementa

correlating curves, although drawn through a band of points, give

The minimum number of plates for benzene-wheptane was evalu-

reasonably accurate results for continuous distillation. However, ated graphically.

when applied to batch distillation these correlations give inac-

curate results.

Cichelli ( 4 ) and Zuideiweg (21 ) have proposed correlations for

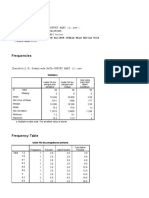

batch distillation between minimum requirements, the plate num- Table I. Calculation of Reflux and Plate Requirements

ber, and reflux ratio, where the difficulty of separation is defined S-Sm R- Rm

by the “pole height.,’ I n batch distillation it is desirable, how-

5* xw (lav. S Sm s+ 1 R Rm R + 1

ever, to be able to calculate rapidly the reflux ratio a t any stage in Benzene-Toluene

the distillation. The need for such calculations is emphasized in 10.2 4.24 0.53 2.27 2.25 0.01

8.3 4.24 0.44 2.45 2.25 0.06

the application of Bogart’s ( I ) equation to the separation of high 5.9 4.24 0.24 3.58 2.25 0.29

5.4 4.24 0.18 4.58 2.25 0.42

purity components from close boiling mixtures. 4.9 4.24 0.12 5.58 2.25 0.57

8.4 6.28 0.22 13.6 10.2 0.23

7.55 6.28 0.15 18.0 10.2 0.41

6.85 6.28 0.07 35.5 10.2 0.69

10.33 6 . 2 8 0.36 10.8 10.2 0.05

9.1 8.1 0.07 48.0 25.5 0.46

Dlstillatc 0.9 8 . 9 0 9 9.5 8.1 0.13 36.6 25.5 0.29

10.5 8.1 0.21 27.0 25.5 0.05

Bottoms 0.02 0.05 0.3

Benzene- n-Heptane

10.7 9.4 6.5

10.3 9.4 0.08 44.0 16.6 0.61

12.3 9.4 0.22 21.5 16.6 0.22

lX8 9.4 0.30 18.6 16.6 0.10

10.9 9.4 0.13 30.0 16 6 0.43

12.3 10.7 0.12 64.3 43 0 0 32

11.6 10.7 0.07 97.0 43. I) 0.56

12.9 10.7 0.16 50.0 43.0 0.14

14.0 6.5 0.5 3.5 3.1 0.09’

8 2 6.5 0.18 8.0 3.1 0 54

9,6 6.5 0.29 5.0 3.1 0.32

11.2 6.5 0.38 4.2 3.1 0.21

7.8 6.5 0.15 10.0 3 1 0.63

Phenol-o-Cresol

0.96 0.30 1.238 23.2 18.8 0.18 47.0 13.1 0.50

0.96 0.30 1.238 25.4 18.8 0.25 23.0 13.1 0.41

0.96 0.30 1.238 34.9 18.8 0.44 15.0 13.1 0.11

0.96 0.10 1.238 36.4 25.1 0.30 47.0 40. 1 0.14

0.96 0.10 1.238 27.8 25.1 0.09 96.0 40.1 0.58

0.96 0.10 1.238 30.6 25.1 0.16 67.0 40.1 0.40

0.96 0.04 1.238 33.6 29.8 0.11 200.0 100.6 0.49

0.96 0.04 1.238 35.8 29.8 0.16 150.0 100.6 0.33

Figure 1. Extrapolation of Curves Calculated for 0.96 0.04 1.238 39.4 29.8 0.24 120.0 100.6 0.16

Benzene-n-Heptane

February 1954 INDUSTRIAL AND ENGINEERING CHEMISTRY 279

ENGINEERING AND PROCESS DEVELOPMENT

suspecting that the relative volatility would influence their

Table II. Calculation of Reflux and Plate Requirements correlations, found no e\Tidence for this effect,. Figure 2 shows

R - Rm s - Sm s - As?,

that when the intercept value, __- , is plotted against R,,, a

XU ZIP R Rm R + 1 S S7n Sfl S-tl

a = 1.1

series of curves are obtained, each of which is related to the

34 5 0 16 61.7 34.5 0 44

relat'ive volatility of the system. For relative volatilities less

0.90 0.25 $1.2

0.90 0.25 00.0 34 5 0 36 48.7 34.5 0 28 than 1.25, the slope of the linear plots of Figure 3 can be corrc-

0.90 0.25 80.0 34 5 0 56 42.6 34.5 0 18

0.90 0,2;2 37.5 34 5 0 078 71.5 34.5 0 51 lated by plotting against the relative vo1atilit)-.

0.90 0.50 19.0 15 8 0.16 48.2 23.0 0 51 Calculation of Reflux Ratio and Number of Plates. From

0.90 0.50 23.0 13 8 0 30 38.4 23.0 0 39

0.90 0.50 30.0 15 8 0 46 32.7 23.0 0 28 Tables I and 11, the resulting curves of the type illustrated in

0.90 0.10 100.0 88 8 0 11 73.0 46.1 0 36

0.90 0.10 120.0 88 8 0 26 62.8 46.1 0 26 Figure 1 have been grouped together into a family of curvcs, as

0.90 0.10 200.0 88 8 0 49 53.5 46.1 0 14 shown in Figure 4.

a = 1.05 I n the application of Figure 4, t'he first' step is to decide nhich

0.83 0.40 83.3 37.3 0.55 57.3 43.8 0 23 correlating curve is to be used for the calculation. From R,,, or

0.85

0.85

0.40

0.40

48.3

40 6

37.3

37.3

0.23

0.078

75.3

107.4

43.8

43.8

0

0

42

58 S , the extrapolated intercept,

s--

- s,

at zero value of

-

R -- R ,

0.96 0.06 500.0 378.9 0 24 169.8 120.6 0 23 SS.1' R i l

0.95 0.05 428,O 378.9 0.11 174.2 120 6 0 30

0.95 0.05 800.0 378.9 0.53 136.1 120.6 0 11 can be evaluated froin &her Figure 2 or 3. This intercept on

0.80 0.50 28 0 23.6 O,l5 63.9 28.4 0 35 Figure 4 gives the appropriate correlating curve and, if R,, and

0.80 0.50 36 8 23.6 0.35 47.0 28.4 0 39

0.80 0.50 50.0 23.6 0.52 38.5 28.4 0 27 S , are known, either R or S can be calculated. The application

0.80 0.10 175 0 155.3 0.11 127.2 73.4 0 42

0.80 0.10 200,o 155.3 0.22 110.8 73.4 0 34 of the above method can be illustrated by the three following es-

Q.80 0 10 230.0 155.3 0.32 100.4 73.4 0 27 amples.

0.80 0.10 315.0 155 3 0.50 88.6 73 4 0 17

a = 1.022

SEPARATIOS O F CHLOROBESZEKE AXD H R O l f O B . Young

(20) gives the relative volatility of chloro- and bromobenzrne as

, O . 80 0.50 56.0 47.6 0.13 128 0 56.3 0 5s

,O. 80 0.50 60.0 47.6 0 20 110.2 56.3 0 48 1.889. Consider a batch distillation in a 10-theoretical-plate

0.80 0.50 95.0 47.6 0.49 75.4 56.3 0 25 column, where it is desired to calculate the necessary reflux ratio

0.80 0.30 125.0 94.9 0.24 151.7 90.6 0 39

,O. 80 0.30 150.0 94.9 0.36 122.8 90.6 0 26 to give an overhead product containing 98.0% chlorobenzene arid

0.80 0.30 182.0 94.9 0.48 112.0 90.6 0 19

a bottoms product containing 11.'7yo of chlorobenxenc.

d = 1.01 The Underwood equation gives a R,, v:ilue of 9.4 and the Ii'enske

0.80 0 50 130 6 119 6 0.20 278 6 140 0 0 47 equation gives a S , value of 9.3. If the I?,, value of (3.1 is

0.80 0.50 180 0 119.6 0.33 219 3 140 0 0 36

0.80 0.50 230.0 119.6 0.47 189 5 110 0 0 26 taken, from Figure 2 by- interpolating betmen the curvefi, the

0.80 0.60 95.5 82.8 0.13 226 3 99 0 0 56

0.80 0 60 120 3 82.8 0.31 173 9 99 0 0 40 raluc of the intercept for 01 = 1.88!1 is 0.4'7. Prom the

0.80 0.60 170 0 82.8 0.51 132 3 99 0 0 23 ST1

correlating curve in Figure 4 correspontliiig t,o intercept value

0.4; and for

R - Ren s -t-s,,,18. 0.14. For

R + 1 = 0.52, the value of ___-

For benzene-toluene and benicne n-heptane, operating reflux S,,= 9.3 this gives a reflux ratio of 20.5, Edge\~orth-Johnslonc

and plate requirements n ere determined froin graphical 3Ic- ( 8 ) ,using a XcCai,e-Thiclc coristruct,ion, calculated a reflux ratio

Cabe-Thiele constructions. In all other cases calculations n ere of 20.0. A comparison is made in Table I11 of the reflux ratios

made using the Smoker equation calculated by li:tlgcir-orth-Johnstone (8).using a i\IcC~"ahc-Thiele

Calculations a l e eunimari/cci in Tnblcs I and 11.

1.0

Correlations Provide Rapid and Accurate

Calculation of Reflux and Plate Requirements

I

The results for the benzene-n-heptane system (Table I ) have

been expressed graphically in Figure 1. For benzcue-n-heptane

separate curves are obtained for varyiii.s tlrgrtw of separation.

Similar graphs (riot shown) for the other tahles result in curves

having a sixiilar trend.

R - Xnz

For values of ___- less than 0.05 the cu

s - s,, value of+unity

I I2 - R,,, approaches zero. 13y es- I I I I I

an

S+1

as

R + l

s - s, are obtained

0 20 40

- R, - 60 80

trapolation of the curves, intercept values of -

Si-1 Figure 2 . Correlation with Minimum Reflux Ratio

which can be correlated by plotting against t h e

ratio of the volatile conmonent in the overheads

and bottoms, or against the minimum reflux

ratio, R,,,, or the minimum number of plates,

S,n. The use of these extrapolated curves

does limit the correlation to those values of

R greatei than 1.05 E,. Such correlations are

shon-n in I'iyuies 2 and 3. When the relatire

volatility is greater than 1.25 the correlation of

the s

s -' Sm

inteicept n-ith R,, is probably the

7-1

most convenient. If the relative volatility is

less than 1.25, the linear correlation mith S, is - sm'

the most valuable.

Gilliland ( I d ) and Zuiderneg ( Z l ) , although Figure 3. Correlation with Minimum Number of Theoretical Plates

280 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 46,No. 2

ENGINEERING AND PROCESS DEVELOPMENT

07.5 1 I I I These examples show that this graphical method for calculating

the reflux ratio or the number of plates approaches the accuracy

of the Smoker and Dodge and Huffman equations. Although the

correlating curves are based on the Underwood, Fenske, and

Smoker equations, the method might not have been expected to

give such accurate results in view of the ease with which it may

be applied. The method can be equally well applied to the sep-

aration of key components in an ideal multicomponent mixture

\\\ i I

I I if the correct minimum reflux ratio is used.

Continuous Distillation and Feed Plate Location. To deter-

mine the total number of plates in the distillation column for

a given reflux ratio, it is necessary to use the correlating curves

of Gilliland ( l a ) or Brown and Martin ( 8 ) .

If the total number of plates is known, numerous methods have

I ” ’ 1 # 1 1 1 1

-1

been proposed for locating the feed plate-Le., hlcCabe-Thiele

construction, plate-to-plate analysis, the Smoker equation, and

0 025 0.5 075

the empirical correlation of Kirkbride (14).

It was considered feasible that Figure 4 should be applicable to

s - sm the location of the number of trays above the feed plate. The

Figure 4. Correlation of ____ Intercept with Reflux feed composition entering the column a t ita boiling point is con-

S+ 1 sidered to be the equivalent of a composition in a reboiler in a

and Plate Requirements

batch distillation. This is probably best illustrated by the follow-

ing examples.

SEPARATION OF BENZSNE AND TOLUEXE. Consider a continu-

method, those calculated by Gilliland’s correlation, and by the ous still fractionating a mixture of 40.0y0 benzene and 60.0y0

method proposed in this paper. toluene a t a reflux ratio of 3 to 1, so that each product is 99.0%

Gilliland’s correlation does not apply to batch distillation. pure. The Smoker and RlcCabe-Thiele methods give 7.9 plates

This is not a criticism of the method, since it was developed for above the feed plate. The total number of theoretical plates is

continuous distillation. 15.7.

The relative volatility a t the feed point is 2.45 and the average

value between the feed and overhead compositions is 2.40, R , =

1.65, and S , = 5.6.

Table 111. Comparison of Methods of Calculating Reflux From Figure 2 the

s - s,

intercept is taken as 0.52 and from

Si-1

Ratio R - R,

Figure 4, with -___ as0.34, -

s

-+8, = 0.25. S , the number of

R +

Distillate Bottoms a MoCabe-Thielea Ellis Gilliland

plates above the feed, is 7.8, which is in close agreement with the

0 98 0.26 1 889 7 0 7.0 8.1 above result.

0 98 0 175 1 889 12 0 12 0 19 0

0 98 0 117 1 889 20 0 20 5 31.0 SEPARATION OF 0-, m- and p-MONONITROTOLUENE. In the

a Edgeworth-Johnstone ( 8 ) . srparation of this ternary mixture, Coulson and Warner (6) have

shown by plate-to-plate analysis that a reflux ratio of 5 to 1 re-

quires 21 theoretical plates for the specified overhead and bot-

toms compositions. The number of plates above the feed is 11.0.

For the key components, 0- and p-nitrotoluene, the relative vola-

I O OXYGEV

S C P ~ R ~ T OF N ISOTOPES. For the separation of oxy- tility is 1.7, R, = 2.23, and S , between the feed plate and over-

gen isotopes, Dodge and Huffman ( 7 ) give a relative volatility of

01 = 1.006. For a distillate composition of 2.54%, a bottoms head compositions is 7.9. From Figure 2 the ; ‘ ;%

-___ intercept is

product of 0.20%, and a reflus ratio of 3920, Dodge and Huffmaq 0.58, which locates the appropriate curve on Figure 4. From

(1)and Smoker ( I ? ) calculated the number of theoretical trays as R - R, S - S,

Figure 4 for = 0.46, ~- + = 0.22, such that S = 10.5.

521. If R, is taken as 1960 and S, is taken as 430, then from

~

R + l

Figure 3, by interpolation and extrapolation, the intercept value Multicomponent Systems. I n continuous multicomponent

distillation the presence of other components influences the

- Sm is 0.58. Csing the appropriate curve of Figure 4,for

of ___

R

S + l

_ _R_

-

R +1

m -

- 0.5> ___ ’s + 1

- sm has a value of 0.19. The number of

separation of the key components and the evaluation of their

minimum reflux ratio. Figures 3 and 4 can be rapidly applied

to the location of the feed plate with a reasonable degree of

plates obtained by this procedure is 529, which is in close agree- accuracy if the following procedure is adopted:

ment with the above calculated result.

SEPI R ~ T I O N OF ~L-HEPTAKE AND ~IETHYLCYCLOHEXANE. In 1. R, is determined using the equation of Underwood (18)

the separation of n-heptane and methylcpclohexane (with a rel- between the overhead composition and the composition of the

ative volatility of 1.07) to give an overhead and bottoms product liquid fraction of the feed. The Colburn (6) equation can be

of 06.0 and 3.33%, respectively, and using a reflux ratio of 1000, similarly used for evaluating R,.

2. For a liquid feed, S, is determined between the ratio of key

Dodge and Huffinan ( 7 ) calculated that 105 theoretical plates components in the overhead composition and the ratio in the feed

were required. Since R,, = 415 and S, = 97.0, for S, = 97.0 and by using the Fenske (11) equation. I n the case of flash vaporiea-

a: = 1.07 from Figure 3 the intercept value of -

S -+S, is 0.35. tion of the feed, S, is determined between the ratio of key com-

ponents in the overhead composition and the ratio in the liquid

R - Rm fraction of the feed.

This locates the cun’e on Figure 4, and from

R f l

-

= 0.59 the 3. For a liquid feed, S = n 1 and S,, n, +

1 are equal

to the theoretical and minimum number of theoretical trays above

+ +

value of is 0.09. This gives the number of plates as the feed plate. I n the application of Figures 3 and 4 to feed plate

S + l location the assumption is made that the ratio of key components

105.6, which again is in good agreement with the calculation of in the feed entering the feed tray is the same as that in the liquid

Dodge and Huffman. leaving the tray above the feed plate.

February 1954 I N D U S T R I A L A N D E N G I N E E R I N G CHEMISTRY 281

ENGINEERING AND PROCESS DEVELOPMENT

propriate curve is iocltteci in

Table IV. Calculations for Continuous Multicomponent Systems terms of the minimum reflux

Stages abol e 01'mininirim number of plates

__ Feed Plate and the relative volatility oi

~~~~~~l~ ~ ~N ~ t. ~Above

l Feed Plate plate Ihwres the system. Tho correlatioii

No. of Stages R RTn S,& andlysi- 3 and 4 Iteieience can aim he applied to the

1 8.8 9.0 2.0 5.G 6.0 6.2 Brown and Soudera ( 3 ) ,column 2 . locatiori -if the feed plarc ill

T ~ W 7, p. 1 . ~ ~ 8

2 17.0 3.0 1.35 6.5 6.0 6.1 Brown and Rouders ( 3 ) , coliinin 5 , continuouu dist'illatioit .

Table 7 , p. 1568

3 16.0 1.6 0.93 3.3 6.0 6.2 ICdinister (G), exaniple 27 !flash The method is of particular

vaporization of feed)

4 11.0 2.0 0.9 2.3 3.0 3.1 Robinson and Gilliland ( 1 5 ) ,p. 261 value in the separation ot

5 26.0 10.0 B.1 9.5 13.0 13.6 Robinson and Billiland ( 2 6 ' ) , p. 237 clofie h o i l i n g c ornpo 1 i ~ ' iti8 I

6 29.8 32.3 .>.S 22.0 24.2n 23.2 Brown and Martin (11.n. 696.

CaSP Id since it C D I ~be rapidly ripplied

a By absorption factor method.

with an uecuracy of the orciuv

of the Hnioker equation

4. \Vith flash vaporization of the feed the number of theo- Nomenclature

retical trays and nlinimum number of theoretical trays above

the feed plate are taken to be n and ntrL. The ratio of key com- :ELI, ZIT = distillate and still composition

ponents in the liquid fraction of the feed is assumed t o be the 01 = rt:liitive volatili1,y

composition of the liqcid leaving the feed plate. 12 = number of t,heoret,icwl phtel; in column

5. If the optimum ratio of key components o n the feed plate n,,, = minimum number of theoretical plates in colurriri

is calculated, then, as in step 4,n and nmare the number of theo- s = n + 1

retical and minimum number of theoretical trays above the feed SV,

R

= n,,,+ I

reflux ratio = O / l >

plate, The results given in T:rl,lP T V indicate the accur,ic.y of =

the method. R,,, = minimum reflux ratio

The calculatioii for e.wmple 3 in Table I V is given a s follows: Literature Cited

Minimum number of trays abovc the feed plate:

(1) I3ogar.r, M . J . P., Tmns. ,in,. rt7sl. (,'hem, Engrs., 33, 139 (193;]~

( 2 ) Brown. C. G., a n d X n r t i n , TI. Z.,

Ibi'd., 35, 579 (1939).

( 3 ) 13r.ou-n, C. G., a n d Houders, 31.. "Science of Petroleum," 1.01~

9Zm +2 = 5.3

2, p. 1544, London, Oxford U n i ~ e m i t yPress, 1938.

111this instance, with flash vaporization ot the feed snd p:titiaI

condensation, the minimum number of t l a n above the ircd plittr

is 3.3. In the application of Figures 3 and 1,S,, = 3.3 London. 1949,

From Figwe 3 for S, 3.3 and CY = 2.35, (7) Dodge, B. F.,nnd Iluft'nixn, ,J. It., Is[).I~NI:.CHRM.,29, 14:%

(1937).

(8) Edgeirorth-Johiistonc, R., Ibid., 3 6 , 1068 (1944).

(9) Edmistor, W.C., P e i d e t ~ nEng?.,

~ 19, 74 (June 1948).

(10) &Xis, Y. I?. AI., T~uras.I n a l . (,'hem. Rngr.c, ( L o n d o n ) , 30, ,jri

For R = 1.5 and R , = 0.95, then, from Figure 4.

1. R., IND. I h c . C(H€:?,I., 24, 482 (19;32)~

E. Ti.,Ibid.. 32, 1220 (1940).

J., Andres, D., and Klein, V , A, Trans, .1m. I N S [ .

Chena. Erzgrs., 37, 228 (1943).

(11) Kirkhiide, C . G., Petiok:um, Refi7?w,23,

(15) MrCahe, W.I,..and Thiele, E . W., I,

(1925).

Thus the number of plates above the feed tray is 6.2. (16) Robinson, C. S., a n d Gilliland, E. I<.. "Elements of E'mctiond

It would appear that the main advantage for this method of Distillation," 4th o d . . Yew Yoi k, IIcGraw-Hill Book Co.,

1950.

feed plate lowtion is the rapidity with which it can be applied in (17) Smolcer, E. H., Tram. A m . I l l & C'herri. Enurs., 34, 165 (10:3X).

the preliminary iissessment of ti problem. (18) Underwood, -4. 6. T'., C ng. Pmgr.. 44, 603 (1948).

(19) Underwood, A. ,J. V., . I n s f . Chsm. Bngrs. (London). 10,

131 (1932).

Summary (20) Y o u n g , S., T r a m . Chrwt. Soc., 81, 7G8 (1902).

(21) Zuiderwog, F. J., Chem. EUQ.S e i . , 1 , 8 (1951)*

Gillilaud's empirical reflux a i d plate correlation has been ex-

tended to batch distillation by using a family of curves. The ap- Rr:caivmu for review Mar011 20, 1853. ACCFPTED

October 43, 1 ! ) 3 3 ~

END OF ENGINEERING A N D PROCESS DEVELOPMENT SECTION

282 INDUSTRIAL AND ENGINEERING CHEMISTRY Vol. 46,No. 2

Das könnte Ihnen auch gefallen

- Chem 26.1 ProbSet1 1stSemAY1920Dokument3 SeitenChem 26.1 ProbSet1 1stSemAY1920LoeyNoch keine Bewertungen

- Process and Equipment Experiment: Fluid CircuitDokument25 SeitenProcess and Equipment Experiment: Fluid CircuitNguyễn ThuNoch keine Bewertungen

- Themultipleregressionmodel: I I1 I2 I3Dokument16 SeitenThemultipleregressionmodel: I I1 I2 I3Mon LuffyNoch keine Bewertungen

- 1991 - Prediction of Thermodynamic Properties of Oil and Gas Condensate MixturesDokument7 Seiten1991 - Prediction of Thermodynamic Properties of Oil and Gas Condensate MixturesRosendo Monroy LoperenaNoch keine Bewertungen

- Problem set 6Dokument2 SeitenProblem set 6Omar TamerNoch keine Bewertungen

- SOIL Laboratory REPORTDokument16 SeitenSOIL Laboratory REPORTMekuannint DemekeNoch keine Bewertungen

- Assignment 3, 2010 - HYSYSDokument6 SeitenAssignment 3, 2010 - HYSYSZhiyong Huang0% (1)

- Libro de FosfatosDokument34 SeitenLibro de Fosfatosaramis21trisha23Noch keine Bewertungen

- SorptionDokument19 SeitenSorptionROMELIE GABALLO ALBIANoch keine Bewertungen

- Frequencies: JawabDokument8 SeitenFrequencies: JawabBerlianna CintaNoch keine Bewertungen

- Hess and Dingwell 1996Dokument4 SeitenHess and Dingwell 1996GUIDO EDGARD SALAS ALVAREZNoch keine Bewertungen

- DATE:-2019.12.31 Experiment No: - 07 Experiment Name: - Determination of Alaklinity and Koh Number of Latex. TheoryDokument8 SeitenDATE:-2019.12.31 Experiment No: - 07 Experiment Name: - Determination of Alaklinity and Koh Number of Latex. TheoryChalani KuruneruNoch keine Bewertungen

- Entrance Region Length and Mass Transfer in Bubble ColumnsDokument20 SeitenEntrance Region Length and Mass Transfer in Bubble Columnsmouhcine maouhoubNoch keine Bewertungen

- Pap AyuDokument6 SeitenPap AyuFadli Maulana FikriNoch keine Bewertungen

- Quantification of The M1 and M3 Polymorphs of Alite in OPC ClinkerDokument2 SeitenQuantification of The M1 and M3 Polymorphs of Alite in OPC ClinkerDerekNoch keine Bewertungen

- Titanic Passenger Data Is Available For 1310 Individuals For 14 Variables, Though NotDokument9 SeitenTitanic Passenger Data Is Available For 1310 Individuals For 14 Variables, Though NotHabibNoch keine Bewertungen

- Distilation Egs PDFDokument8 SeitenDistilation Egs PDFJoão SegattoNoch keine Bewertungen

- Assg + Ans BookDokument3 SeitenAssg + Ans BookAnonymous OqslzfFDYNoch keine Bewertungen

- Magnetic Susceptibility Organic CompoundsDokument6 SeitenMagnetic Susceptibility Organic CompoundsGazali DolkenNoch keine Bewertungen

- 5.2.basic Concepts of Quality Management: Om-Unit VDokument37 Seiten5.2.basic Concepts of Quality Management: Om-Unit VTummala Akhil DattaNoch keine Bewertungen

- Flotation collector testing results for xanthate and derivativesDokument11 SeitenFlotation collector testing results for xanthate and derivativesgerardo orrantiaNoch keine Bewertungen

- Group 1_ALEJANO_DEZOLLER_GRATIS_BATCH REACTORDokument8 SeitenGroup 1_ALEJANO_DEZOLLER_GRATIS_BATCH REACTORJohn Frix AlejanoNoch keine Bewertungen

- Rohan Shelke Div-J 1966Dokument4 SeitenRohan Shelke Div-J 1966Shriansh KulkarniNoch keine Bewertungen

- Large Strain Consolidation: TitleDokument41 SeitenLarge Strain Consolidation: Titlerelu59Noch keine Bewertungen

- Experimental Study of CH4/O2/CO2 Mixtures FlammabilityDokument7 SeitenExperimental Study of CH4/O2/CO2 Mixtures FlammabilityBabuNoch keine Bewertungen

- Case Study 01Dokument12 SeitenCase Study 01Tanvir ShawonNoch keine Bewertungen

- 1997 Gioncu & Petcu - Available Rotation Capacity of Wide-Flange Beams and Beam-Columns Part 2. Experimental and Numerical TestsDokument26 Seiten1997 Gioncu & Petcu - Available Rotation Capacity of Wide-Flange Beams and Beam-Columns Part 2. Experimental and Numerical TestsAKNoch keine Bewertungen

- FrequenciesDokument2 SeitenFrequenciesSri WahyuniNoch keine Bewertungen

- BT 301 Biophysics Tutorial Sheet-IVDokument2 SeitenBT 301 Biophysics Tutorial Sheet-IVShivaani EswaranNoch keine Bewertungen

- 41.1.30 AOAC of Fi Cial Method 991.39 Fatty Acids in en Cap Su Lated Fish Oils and Fish Oil Methyl and Ethyl Es TersDokument2 Seiten41.1.30 AOAC of Fi Cial Method 991.39 Fatty Acids in en Cap Su Lated Fish Oils and Fish Oil Methyl and Ethyl Es TersAlex SaenzNoch keine Bewertungen

- INVISCID FLOW SIMULATION ARROUND NACA 641-212 - Fillipe OliveiraDokument17 SeitenINVISCID FLOW SIMULATION ARROUND NACA 641-212 - Fillipe OliveiraFillipe OliveiraNoch keine Bewertungen

- Sieve Analysis-: Kabul University Engineering Faculty Civil DepartmentDokument5 SeitenSieve Analysis-: Kabul University Engineering Faculty Civil DepartmentAssad YaqubiNoch keine Bewertungen

- Esterification of Ethanol in A Batch Reactor in Presence of H2SO4Dokument17 SeitenEsterification of Ethanol in A Batch Reactor in Presence of H2SO4MD.Khairul EducationNoch keine Bewertungen

- Prevent Condensation with Insulation ThicknessDokument5 SeitenPrevent Condensation with Insulation ThicknessAbhijeet SahuNoch keine Bewertungen

- Mullen - 1983Dokument21 SeitenMullen - 1983Astri AzairaNoch keine Bewertungen

- Direct Shear 26112018Dokument24 SeitenDirect Shear 26112018O'cond DioraNoch keine Bewertungen

- Direct Shear TestDokument10 SeitenDirect Shear TestRuzengulalebih ZEta's-ListikNoch keine Bewertungen

- Batch Sedimentation Process Lab ReportDokument5 SeitenBatch Sedimentation Process Lab ReportsdjdsfNoch keine Bewertungen

- Batch Distillation Report AnalysisDokument14 SeitenBatch Distillation Report AnalysisMahmoud HendawyNoch keine Bewertungen

- Analisis Respon Surface Design Box Behnken: "Optimasi Adsorpsi Kitosan Bertaut Silang Glutaraldehidaterhadap Ion Fe (Iii) "Dokument5 SeitenAnalisis Respon Surface Design Box Behnken: "Optimasi Adsorpsi Kitosan Bertaut Silang Glutaraldehidaterhadap Ion Fe (Iii) "Zahra saharaNoch keine Bewertungen

- Sem I 2020-2021 Software Quiz (Chapters 2, 3 5)Dokument5 SeitenSem I 2020-2021 Software Quiz (Chapters 2, 3 5)Syahema SalehNoch keine Bewertungen

- PETSOC-09-07-18 Gas Condensate Reservoir Performance PDFDokument7 SeitenPETSOC-09-07-18 Gas Condensate Reservoir Performance PDFEduardo UstarezNoch keine Bewertungen

- PETSOC-09-07-18 Gas Condensate Reservoir Performance PDFDokument7 SeitenPETSOC-09-07-18 Gas Condensate Reservoir Performance PDFMiguel Angel GonzalesNoch keine Bewertungen

- C19a Rio's SpreadsheetDokument8 SeitenC19a Rio's SpreadsheetaluiscgNoch keine Bewertungen

- FsconsDokument36 SeitenFsconsMuhammad Abdul Wajid RaiNoch keine Bewertungen

- Potentiometric Determination of The Ionization Constant of A Pure Unknown Weak AcidDokument3 SeitenPotentiometric Determination of The Ionization Constant of A Pure Unknown Weak AcidDozdi100% (3)

- Soil Ex3Dokument5 SeitenSoil Ex3Azeezan AlessaNoch keine Bewertungen

- Bliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil160043Dokument11 SeitenBliquid-Liquid Ternary Equilibrium in Water (A) - Butyl Acetate (B) - Acetic Acid (C) System Mow Wei Keat Kil160043Jian LiangNoch keine Bewertungen

- Sedimentation Finalrepz1 100604195822 Phpapp02Dokument6 SeitenSedimentation Finalrepz1 100604195822 Phpapp02Michelle MenciasNoch keine Bewertungen

- Analyte, % Analyte Ratio Unit 0.5 Cvhorwitz 0.67 Cvhorwitz 2 C (-0.1505)Dokument4 SeitenAnalyte, % Analyte Ratio Unit 0.5 Cvhorwitz 0.67 Cvhorwitz 2 C (-0.1505)Abu WildanNoch keine Bewertungen

- Assignment 2Dokument2 SeitenAssignment 2Gia Janella SemillaNoch keine Bewertungen

- Difusividad de Gases en Vapores PDFDokument4 SeitenDifusividad de Gases en Vapores PDFJunior Alexander Lazo ZeladaNoch keine Bewertungen

- Exfiltration Trench (French Drain) ManualDokument83 SeitenExfiltration Trench (French Drain) ManualFrancis MitchellNoch keine Bewertungen

- Reynolds Experiment ENSC3003Dokument6 SeitenReynolds Experiment ENSC3003Jodi LynchNoch keine Bewertungen

- Fundamental Concepts and Computations in Chemical Engineering 1st Edition Utgikar Solutions ManualDokument21 SeitenFundamental Concepts and Computations in Chemical Engineering 1st Edition Utgikar Solutions Manualalicenhan5bzm2z100% (26)

- Distillation Column Design With MatlabDokument10 SeitenDistillation Column Design With MatlabTheødřøš ÄbNoch keine Bewertungen

- Theory of Particulate Processes: Analysis and Techniques of Continuous CrystallizationVon EverandTheory of Particulate Processes: Analysis and Techniques of Continuous CrystallizationNoch keine Bewertungen

- Government Publications: Key PapersVon EverandGovernment Publications: Key PapersBernard M. FryNoch keine Bewertungen

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageVon EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNoch keine Bewertungen

- Target Metal TestDokument1 SeiteTarget Metal TestRajeshNoch keine Bewertungen

- STEAM BLOWING AND BOILER SAFETYDokument30 SeitenSTEAM BLOWING AND BOILER SAFETYSaravana KumarNoch keine Bewertungen

- Thermosiphon OperationDokument63 SeitenThermosiphon OperationRajesh100% (1)

- Training Your BrainDokument17 SeitenTraining Your BrainRajeshNoch keine Bewertungen

- Compressed Air SystemDokument29 SeitenCompressed Air SystemPrathmesh GujaratiNoch keine Bewertungen

- Design Evaluation of Particulate Wet Scrubbing Systems FactorsDokument48 SeitenDesign Evaluation of Particulate Wet Scrubbing Systems FactorsAnonymous MVHQ97KEoP100% (4)

- IC Workshop Materials 09 - Construction Drawing PracticesDokument43 SeitenIC Workshop Materials 09 - Construction Drawing PracticesooiNoch keine Bewertungen

- PA-PAC Eutectic MixturesDokument4 SeitenPA-PAC Eutectic MixturesRajeshNoch keine Bewertungen

- Production of Maleic Anhydride From Benzene: BackgroundDokument2 SeitenProduction of Maleic Anhydride From Benzene: BackgroundRajeshNoch keine Bewertungen

- Thermal StressesDokument3 SeitenThermal StressesRajeshNoch keine Bewertungen

- Steam EjectorsDokument6 SeitenSteam EjectorsmayurjannuNoch keine Bewertungen

- Project Management For Chemical EngineersDokument6 SeitenProject Management For Chemical EngineersJuan Antonio Jimenez Velazquez100% (1)

- Pre CommissioningDokument10 SeitenPre CommissioningRajesh100% (2)

- Benzoic Acid Vapor PressureDokument5 SeitenBenzoic Acid Vapor PressureRajeshNoch keine Bewertungen

- Understand Real World Problems in EjectorDokument8 SeitenUnderstand Real World Problems in EjectorEdgar Enrique Diaz Marquina100% (1)

- 11-Flues and ChimneysDokument97 Seiten11-Flues and ChimneysValiNoch keine Bewertungen

- Energy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, UDokument18 SeitenEnergy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, USATISH PAWARNoch keine Bewertungen

- NOx formation thresholds and reduction methodsDokument1 SeiteNOx formation thresholds and reduction methodsS SanchitNoch keine Bewertungen

- Preparing Process Unit for Initial StartupDokument7 SeitenPreparing Process Unit for Initial StartupTan JieShengNoch keine Bewertungen

- Checklist For Mechanical CompletionDokument8 SeitenChecklist For Mechanical CompletionAnand PatelNoch keine Bewertungen

- Restriction Orifice Diamater CalculationDokument1 SeiteRestriction Orifice Diamater CalculationRajeshNoch keine Bewertungen

- DCS TestingDokument5 SeitenDCS TestingRajeshNoch keine Bewertungen

- Steam BlowingDokument28 SeitenSteam BlowingRajeshNoch keine Bewertungen

- 11-Flues and ChimneysDokument97 Seiten11-Flues and ChimneysRajeshNoch keine Bewertungen

- Checklist For Mechanical CompletionDokument8 SeitenChecklist For Mechanical CompletionAnand PatelNoch keine Bewertungen

- Fuels and Combustion OverviewDokument28 SeitenFuels and Combustion OverviewDrupad PatelNoch keine Bewertungen

- Pump selection and head calculation exampleDokument37 SeitenPump selection and head calculation exampleIhsan Wiratama100% (1)

- Pid Legend PDFDokument1 SeitePid Legend PDFSocMed Dtk UI0% (1)

- Dry Saturated Steam TablesDokument2 SeitenDry Saturated Steam TablesNadia NadhilahNoch keine Bewertungen

- Why Johnny Can't Clone: Common Pitfalls and Not So Common SolutionsDokument10 SeitenWhy Johnny Can't Clone: Common Pitfalls and Not So Common SolutionsGanesh KumarNoch keine Bewertungen

- Analysis of Anionic Surfactants - LC100020 - EDokument1 SeiteAnalysis of Anionic Surfactants - LC100020 - EjcencicNoch keine Bewertungen

- Activity On MicroscopeDokument8 SeitenActivity On MicroscopeMeg MaxilomNoch keine Bewertungen

- Scallop and Finfish Concentration Extraction Detection NoV HAV Mar2019Dokument37 SeitenScallop and Finfish Concentration Extraction Detection NoV HAV Mar2019Thiago Haeitmann da FonsecaNoch keine Bewertungen

- KromatografiDokument51 SeitenKromatografiNadia Ulfa BurhanuddinNoch keine Bewertungen

- Microscopy and StainingDokument7 SeitenMicroscopy and StainingDenmark ManlusocNoch keine Bewertungen

- Erythroid PrecursorsDokument1 SeiteErythroid PrecursorsMezouar AbdennacerNoch keine Bewertungen

- Analysis of Lubricant Oil Samples in Compliance With ASTM D7500 Using The Shimadzu Simulated Distillation Gas Chromatograph SystemDokument2 SeitenAnalysis of Lubricant Oil Samples in Compliance With ASTM D7500 Using The Shimadzu Simulated Distillation Gas Chromatograph SystemMaikel Perez NavarroNoch keine Bewertungen

- Edvotek S-51 ManualDokument33 SeitenEdvotek S-51 Manualjellyfish27100% (1)

- G11 Bio WS5 Cell TypesDokument1 SeiteG11 Bio WS5 Cell TypesArlance Sandra Marie MedinaNoch keine Bewertungen

- D-Dimer Rapid Quantitative Test COA-F21117507ADDokument1 SeiteD-Dimer Rapid Quantitative Test COA-F21117507ADg64bt8rqdwNoch keine Bewertungen

- AN525 400-Pesticides TSQ MAXDokument16 SeitenAN525 400-Pesticides TSQ MAXАлександр100% (1)

- 308-1127 - Nucleic Acid-Based Techniques-AmplificationDokument11 Seiten308-1127 - Nucleic Acid-Based Techniques-AmplificationmeiNoch keine Bewertungen

- Analysis of Raw Meats and Fats of Pigs Using PolymeraseDokument6 SeitenAnalysis of Raw Meats and Fats of Pigs Using PolymeraseMet RizalNoch keine Bewertungen

- LC Columns (Pages 350-545) PDFDokument373 SeitenLC Columns (Pages 350-545) PDFHayro De La CruzNoch keine Bewertungen

- UNIT 1: Bacteria: Course: B.Sc. Biotechnology Semester IiiDokument24 SeitenUNIT 1: Bacteria: Course: B.Sc. Biotechnology Semester IiiPriya PankajNoch keine Bewertungen

- Lecture 3 - 2023 - DNA SequencingDokument67 SeitenLecture 3 - 2023 - DNA SequencingChen ZhonghaoNoch keine Bewertungen

- Omed0104 2022 MayDokument4 SeitenOmed0104 2022 MayIffa NooramNoch keine Bewertungen

- Halla 1 3 4Dokument4 SeitenHalla 1 3 4Rizka YulianawatiNoch keine Bewertungen

- Lecture 7-Introduction To ChromatographyDokument58 SeitenLecture 7-Introduction To ChromatographyLeo Pis100% (1)

- Worksheet No. 1 Paper Chromatography: ObservationsDokument1 SeiteWorksheet No. 1 Paper Chromatography: ObservationsNeil PenetranteNoch keine Bewertungen

- Lab 01 - Streaking For Isolation and Interpreting Primary Culture ResultsDokument18 SeitenLab 01 - Streaking For Isolation and Interpreting Primary Culture ResultsVincent ReyesNoch keine Bewertungen

- Cromatografia ArticuloDokument8 SeitenCromatografia Articuloazure_azureNoch keine Bewertungen

- Fundamentals of Gas Chromatography and Carrier GasDokument7 SeitenFundamentals of Gas Chromatography and Carrier GasRoco neluNoch keine Bewertungen

- ViroDokument4 SeitenVirolctorres7462antNoch keine Bewertungen

- 01 Fundamentals of GCMS PDFDokument41 Seiten01 Fundamentals of GCMS PDFKakaDewi75% (4)

- HPLC Lab ManualDokument7 SeitenHPLC Lab ManualRakesh Kumar ChaudharyNoch keine Bewertungen

- A Lamar BlueDokument10 SeitenA Lamar BlueRuan JinglinNoch keine Bewertungen

- 2 Mic125Dokument7 Seiten2 Mic125nadiazkiNoch keine Bewertungen

- Difference of Rush Frozen Section and Routine HistopathologyDokument2 SeitenDifference of Rush Frozen Section and Routine HistopathologyCatherine MerillenoNoch keine Bewertungen