Beruflich Dokumente

Kultur Dokumente

Flamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James Luxford

Hochgeladen von

Efari BahcevanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Flamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James Luxford

Hochgeladen von

Efari BahcevanCopyright:

Verfügbare Formate

Proceedings of ASME Turbo Expo 2012

GT2012

June 11-15, 2012, Copenhagen, Denmark

GT2012-69536

FLAMABILITY OF HIGH FLASH POINT LIQUID FUELS

Peter J Kay, Andrew P. Crayford, Philip J. James Luxford

Bowen RWE npower

GTRC, Institute of Energy Swindon, Wiltshire, SN5 6PB, United Kingdom

Cardiff University, Cardiff, CF24 3TA, United

Kingdom

ABSTRACT Gas oil (flash point > 61 °C) ignited as a free jet at a

Current European Health and Safety Legislation was working pressure consistent with previous hypotheses.

implemented to limit the chance of a serious explosion However, when the jet impinged on a solid surface then the

occurring in the workplace by highlighting potentially resulting spray could be ignited at considerably lower delivery

explosive atmospheres and ensuring that ignition sources are pressures. Although the impingement process is complex, the

not present in these areas. Though hazardous area data will be discussed in light of contemporary models that

classification for gaseous and dust explosion hazards are well predict initial jet/spray characteristics along with post-

established, the same cannot be said for mists especially for impingement characteristics. This paper presents a first step

high flash point liquids. However, a recent literature review of towards consolidating previous studies and improving future

a range of (some fatal) incidents has shown that mist safety guidelines concerned with the risk posed by the

explosions are more common and the consequences more flammability of accidental releases of pressurised high

severe than previously anticipated. This work is, for example, flashpoint fuels.

applicable to the safe use of fuels and lubricants utilised in the

gas turbine power generation and propulsion industries. NOMENCLATURE

Previous studies of jet breakup regimes and idealised Symbol

flammability studies have indicated that low pressure releases Bst Spalding Transfer Number

(<10 bar) of low volatility fuels may still give rise to cp Specific Heat Capacity

combustion hazards. Impingement of accidental releases onto D Droplet Diameter

surfaces has been shown to exacerbate the potential hazard, or d Nozzle Diameter

broaden the range of hazardous release conditions. However, L Length of Nozzle

although a theoretical case can be made for generating La Laplace Number

flammable environments under moderate release conditions, Re Reynolds Number

very little evidence has been provided to bridge the gap Tst Flame Temperature

between ‘idealised’ studies and full-scale incidents. The aim of We Weber Number

this first programme of work is to start the process of bridging μ Viscosity

this gap, leading to well founded safety guidance. ρ Density

The test programme was conducted in a custom built σ Surface Tension

spray chamber located in the Gas Turbine Research Centre φ Equivalence Ratio

(GTRC) of Cardiff University. The fuel was released at a pre- Subscript

defined range of pressures of industrial relevance at a Air

atmospheric temperature. Igniters were positioned at three d Droplet

downstream locations and the continuous electrical discharge f Fuel

had an energy no greater than 4 mJ. Tests were conducted for l Liquid

‘free sprays’ where the spray was directed along the length of min Minimum

the chamber, and for impinging sprays where the spray was o Orifice

aligned to impinge normal to a flat un-heated surface. st Stoichiometric

1 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Water,stp Water at Standard Temperature and Pressure explosive mist atmosphere is important and can have a

Acronyms quantifiable impact.

ASR Atmospheric Spray Rig There is a significant amount of literature published

LFL Lower Flammability Limit examining the MIE of mists, atomization of liquid jets and

MIE Minimum Ignition Energy jet/spray impingement phenomena. For example the MIE for

SMD Sauter Mean Diameter various fuels has been studied in great detail under controlled

SWP Safe Working Pressure conditions (Bane et al, 2011; Shepard et al, 1990). Much

UFL Upper Flammability Limit literature has been published on the atomisation of sprays and

their related phenomena (Lefebvre, 1989). Also there are well

INTRODUCTION established models related to the impingement of drops and

The European ATEX directives (99/92/EC and 94/9/EC) which sprays on surfaces (Bai, et al, 2002; Mundo, et al, 1998).

are implemented in the UK under the Dangerous Substances This paper aims to begin to address the issues raised

and Explosive Atmospheres Regulations (DSEAR) 2002 and by the lack of guidance in the regulations – particularly for

the Equipment and Protective Systems Intended for Use in high flashpoint, involatile fuels - by developing knowledge of

Potentially Explosive Atmospheres Regulations 1996 (EPS spray/mist ignition for practical applications through an

Regulations) require employers to classify into zones areas experimental programme based on initial conditions pertinent

where explosion hazards may occur and utilise suitably to industry. The results generated are the complex combination

designed equipment within these zones accordingly limit the of the mechanisms governing spray formation, spray

chance of an accidental ignition. Though hazardous area impingement and spray ignition. However, the results observed

classification for gases and dust explosion hazards are well will be analysed and discussed in light of models published.

established (Eckhoff, 2006), the same cannot be said for mists Potentially flammable mists can be formed in a number of

especially for high flash point liquids, as first highlighted by ways – firstly mists can be created due to atomisation of liquid

Bowen and Shirvill (Bowen et al., 1994). jets. The simplest example is the break-up of a liquid jet from a

Very little progress has been made since this first plain orifice. A jet is formed as the pressurised fluid is forced

notification (Bowen, 2011), though a recent literature review though the exit orifice, the jet is ejected with a velocity

(Santon, 2009) of a range of incidents has shown that mist proportional to the upstream pressure. Small instabilities in the

explosions are more common and the consequences more jet form and grow until, at some distance downstream, the jet

severe than previously anticipated. The study identified 37 breaks up forming a spray and if confined – a mist.

incidents including 20 explosions, of which nine were Alternatively the jet, or spray, may impinge on a solid surface

collectively responsible for a total of 29 fatalities. and due to the fluid dynamics splash on the surface undergoing

For flammable gas hazards, the classification of hazardous further atomisation creating a finer mist (Maragkos et al,

areas into zones is based on an assessment of the frequency of 2002).

the occurrence and duration of the explosive atmosphere, as

follows: EXPERIMENTAL FACILITIES

• Zone 0: An area in which an explosive gas The experiments were conducted in the Atmospheric Spray Rig

atmosphere is present continuously or for long (ASR) located at the Gas Turbine Research Centre (GTRC)

periods. part of Cardiff University located in Port Talbot. The ASR is

• Zone 1: An area in which an explosive gas 2.2 x 1.2 x 0.7 m and has the release orifice located at the

atmosphere is likely to occur in normal operation. upstream end and a natural draft extraction at the other. Three

• Zone 2: An area in which an explosive gas NGK spark plugs, which are earthed via the rig, are located

atmosphere is not likely to occur in normal operation 0.5, 1.0 and 1.5 m downstream from the orifice respectively; as

and, if it occurs, will only exist for a short time. shown in Figure 1. Each igniter had a spark gap no greater

A similar system is applied to dust explosion hazards. than 3.8 mm and was connected to a Satronic ZT 870 ignition

Guidance on the classification of areas is provided in BS EN spark generator. The ignition spark generators are capable of

60079-10 (BSI, 2009) for application to gases, vapours and producing a continuous spark (50 Hz) with a voltage of 16 kV

liquids that are handled above their flashpoint, that could and spark energies of 4 mJ.

potentially give rise to an explosive atmosphere. However, this

standard does not cover mists.

Adhering to the guidelines and mitigating a mist

explosion risk thorough the use of appropriately rated

enclosures and safety systems can be costly. Therefore

understanding the parameters that affect the likelihood of an

2 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

(a)

Figure 1: Schematic representation of fuel delivery system.

The fuel was presurised in an accumulator with Nitrogen

affording a delivery pressure of up to 30 bar to be delivered at

the nozzle. A pneumatic valve just upstream of the final orifice

controls the timing and duration the release. The igniters and

final valve are controlled remotely. High definition videos of

the release events were simply recorded using a Cannon D60

SLR camera. The release orifice used throughout the

experimental program had a diameter of 1 mm and an aspect

ratio of unity.

The igniters were initiated prior to the fuel being released, (b)

and the fuel was sprayed until ignition was observed or a Figure 2: Video still of ignition of free spray at 2.5 SWP. (a)

maximum of 10 seconds, whichever came first. For the Pre-ignition and (b) Post-ignition

impingement tests the setup remained nominally identical with It is interesting to note that the spray was ignited by

the only modification being made to the location and igniter 3 which corresponds the location farthest downstream.

orientation of the nozzle. For the impingement studies the For comparison Figure 3 shows a video still of the free spray at

nozzle was located 60 mm from the impingement surface at a the SWP, which did not ignite during the 10 second delivery

perpendicular distance of 100 mm from the first igniter, the schedule.

fuel was sprayed vertically downwards normal to the flat

impingement surface.

The fuel used throughout all the tests was Gas-oil with a

quoted flash point of > 61 °C, which was released at

atmospheric temperature.

RESULTS

Due to the confidential nature of the research programme

the delivery pressures utilised for this study cannot be detailed

at this time consequently the results presented are non-

dimensionalised against a Safe Working Pressure (SWP). The

SWP is defined as the pressure at which there were no

recorded ignition events during the free spray experiments. Figure 3: Video still of ignition of free spray at 1.0 SWP

For the free spray experiments the release pressure was set Figure 4 presents two video stills showing pre and

at an initially high value and repeat experiments conducted at post-ignition of the impinging spray at 1.0 SWP. It is

decreasing delivery pressures until no ignition was observed interesting to note that the spray was ignited at Igniter 1

during the three repeated experiments. Figure 2 presents two corresponding to the closest downstream location (60mm)

video stills showing pre and post-ignition of the free spray at which is in contrast to the 1500 mm distance observed for

2.5 SWP. ignition of the free spray.

3 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

smaller droplets have a larger surface area to volume ratio

compared with larger drops for the same mass. This promotes

drop evaporation which in turn increases combustion

efficiency, which in turn can increase heat release rate and

over pressure significantly affecting the severity of the

incident. Figure 5 shows the number-under-size and mass

under size plots for the free sprays for the range of SWP’s

investigated. The mass-under-size plots were predicted from a

previously developed model by Kay et al, the data and

validation are discussed elsewhere (Kay et al, 2010). However

the correlation for predicting the mean spray diameter is

reproduced in Equation (1).

0.97

(a) 𝐷𝑆𝑀𝐷 −0.85 0.44

𝐿 0.114 𝜇𝑙,𝑜 (1)

= 74𝑊𝑒𝑙,𝑜 𝑅𝑒𝑙,𝑜 � � � �

𝑑𝑜 𝑑𝑜 𝜇𝑤𝑎𝑡𝑒𝑟,𝑠𝑡𝑝

−0.37 −0.11

𝜎𝑙,𝑜 𝜌𝑙,𝑜

.� � � �

𝜎𝑤𝑎𝑡𝑒𝑟,𝑠𝑡𝑝 𝜌𝑤𝑎𝑡𝑒𝑟,𝑠𝑡𝑝

Figure 5 highlights the difference between

considering sprays by number or by mass. For example,

approximately 10 % of the mass is contained in droplets with a

diameter less than 400 microns for the 2.5 SWP case –

whereas 90 % of the droplets by number are contained within

this size range. This is simply because mass is proportional to

the diameter cubed, therefore if the diameter of a droplet is

(b) doubled then it will have 8 times the volume – effectively

Figure 4: Video still of ignition of impinging spray at 1.0 meaning that a significant proportion of the mass is contained

SWP. (a) Pre-ignition and (b) Post-ignition within a relatively few number of large droplets. In the context

of flammable risk hazards larger droplets not only reduce the

Table 1 presents a summary of the experimental results. evaporation rate but are less likely to be present in the spark

Table 1: Summary of test results gap at the time of a spark as, depending on the downstream

Test Number Pressure [SWP] Setup Ignition? location of the ignition source, the droplets are more likely to

1 2.5 Free Spray Yes have rained out.

2 2.0 Free Spray Yes

3 1.5 Free Spray Yes

4 1.0 Free Spray No

5 1.0 Impingement Yes

6 0.5 Impingement Yes

DISCUSSION

The first observation is that ignition occurred for releases

where the temperature of the fuel is below the flashpoint,

highlighting the fact that flashpoint cannot be used as a

measure for risk assessment relating to mist explosions.

The interesting observation from Table 1, is that

impingement of the spray results in an ignitable mixture at

delivery pressures half that of pressures previously considered

safe. There are still practical applications where fuel is

transported at this pressure, and consequently still a risk. The

thermo-fluid dynamics associated with this observation will be

analysed and discussed highlighting reasons for the differences Figure 5: Mass-under-size and number-under-size plots for

in ignitability. various SWP.

The size distribution in a spray has a significant The minimum ignition energy (MIE) required to

influence on its combustion characteristics. For example, ignite a droplet has been studied and quantified previously

4 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

(Ballal and Lefebvre, 1978) and is proportional to its diameter

(cubed). The model to predict the MIE for quiescent mists,

which was derived and subsequently validated experimentally

is given in Equation (2). This model relies on a number of

parameters including droplet diameter, equivalence ratio, gas

and liquid properties and evaporation constants.

1 𝜋𝑐𝑝,𝑎 ∆𝑇𝑠𝑡 𝐷3 𝜌𝑓 3/2 (2)

𝐸𝑚𝑖𝑛 = � � . � �

6 𝜌𝑎

1/2 𝜑𝑙𝑛(1 + 𝐵𝑠𝑡 )

The formula presented in Equation (2) is based on the

theory of the quenching distance between droplets in a

homogeneous quiescent mist. The MIE is then proposed as the

energy required to raise the temperature a sphere of air, with a

diameter equal to the quenching distance, from ambient to the

stoichiometric adiabatic flame temperature.

In this study the MIE model of Ballal and Lefebvre

has been combined with the droplet size model of Kay et al for Figure 7: Mass-under-size and number-under-size with MIE

2.5 SWP and 1.0 SWP and is presented in Figure 6 and Figure for 1.0 SWP.

7 respectively. These refer to the experimental data observed in It is now possible to get an idea of how the

Figure 2 and Figure 3 respectively. The MIE for the upper distribution of droplet sizes within the spray will affect its

flammability limit (UFL), stoichiometic and lower flammability. For example, Figure 6 shows that with an

flammability limit (LFL) conditions have been superimposed. ignition energy capped at 4 mJ, the largest droplet diameters

The scale for the secondary y-axis presenting the MIE has been for a flammable mist (based on Ballal and Lefebvre’s model) is

capped at 4 mJ, which is the anticipated spark energy utilised 63 microns - for stoichiometric mixtures. This can be related to

in this study (as stated in the spark generator datasheet). the number and mass under-size plots, as <0.1 % by-mass and

62 % by-number of the spray are below this theoretical

maximum diameter.

It was not possible to measure the true equivalence

ratio at the igniter prior to combustion and so results will be

discussed in a comparative sense. Figure 6 and Figure 7 show

that as the SWP is decreased from 2.5 to 1.0 then the

proportion of mass and number of droplets that could

theoretically be ignited decreases. This information is

presented in

Table 2 presents the maximum droplet diameter that

can be ignited by a 4 mJ spark and consequently the

percentage mass and number of droplets with a diameter below

this limit can be considered flammable.

Table 2: Summary of Ignition Spray Data

Condition UFL Stoich LFL

Diameter limit for a 4 mJ spark [µm] 48 63 177

Figure 6: Mass-under-size and number-under-size with MIE Mass-under-size for 2.5 SWP [%] <0.1 <0.1 1.6

for 2.5 SWP. Number-under-size for 2.5 SWP [%] 58 62 84

Mass-under-size for 1.0 SWP [%] <0.1 <0.1 <0.5

Number-under-size for 1.0 SWP [%] 38 48 74

The flammable percentage of the spray required for the spray

to combust is not easy to define, and further investigation

would be required to assess the affect of droplet size and

concentration on the MIE. Again the guidance in current

legislation is poor, for example in BS EN 60079-10-1 (BSI,

2009) it states that the flammable aerosol component of a spray

release may involve as little as 1% of the total mass released.

It is noted that, at the conditions tested, the pressure

at which the free spray did not ignite is fixed at 1.0 SWP. This

5 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

suggests that the atomisation at this delivery pressure is

insufficient to provide small enough droplets at a high enough

droplet loading and consequently the percentage of droplets

within the flammable range was too low.

As discussed earlier; impingement exacerbated the

potential hazard. This is due to the re-atomisation of splashing

droplets, which reduces the mean droplet diameter whilst

increasing the droplet loading of the spray. Much effort has

been employed in understanding the impingement of single

and multiple droplet impacts on solid surfaces and developing

models that predict the post-impingement droplet

characteristics. Due to the two-phase thermofluid complexity

of the impingement process, previous analysis has resorted to

the development of non-dimensionalised correlations. A few of

these impingement models are employed in some of the more

widely used commercial CFD software. One of the most

commonly used correlations is the one proposed by Bai et al Figure 8: Mass-under-size and number-under-size for pre and

post-impingement sprays for 1.0 SWP.

and is discussed in detail elsewhere (Bai et al, 2002), but will

Figure 9 and Figure 10 show the post-impingement number

be described in brief here. The model, based on the impacting

and mass-under-size plots for 1.0 and 0.5 SWP. The LFL,

droplet Weber and Laplace number, first predicts whether the

stoichiometric and UFL have been superimposed as discussed

droplet will stick, spread, bounce or splash on the surface. The

earlier. Unlike the free spray data, presented in Figure 6 and

regime transition criteria are presented in Table 3 with the post

Figure 7, almost the entire spray is theoretically ignitable on a

impingement droplet characteristics based on separate

mass and number basis. These plots are a clear indication of

correlations depending on which regime the droplets are in.

how a hazard can be exacerbated due to impingement of a free

Table 3: Regime transition criteria (Bai et al, 2002)

spray.

Regime Transition Criteria

Stick Wed ≤ 2630.La −0.18 ( DRY ) ; Wed ≤ 2 (WET )

Rebound 2 < Wed ≤ 20 (WET )

Spread 20 < Wed ≤ 1320.La −0.18 (WET )

Wed > 2630.La −0.18 ( DRY )

Splash

Wed > 1320.La −0.18 (WET )

Based on the Sauter Mean Diameter (SMD) of the free spray,

the post impingement droplet characteristics were predicted

using the correlation of Bai et al. Figure 8 shows the mass and

number-under-size plots for both the pre and post-

impingement sprays. Figure 8 shows that the proportion of

mass contained within droplets with a diameter less than 200

microns has changed from less than 0.1 % for the pre-

impingement spray to greater than 90 % of the post- Figure 9: Mass-under-size and number-under-size with MIE

impingement spray. Significant changes are also observed for for 1.0 SWP.

the number-under-size plots.

6 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

• Impingent models from the literature demonstrated

how the droplet size distribution of the free spray is

significantly altered post-impingement, again in

qualitative agreement with current experimental

observations.

Whilst the contribution of this paper is generally

qualitative in nature, it provides a notable practical step

forward in developing understanding of this poorly studied

problem towards quantitative practical industrial

guidelines and standards. This is the focus of an ongoing

joint industry project.

ACKNOWLEDGMENTS

The authors would like to thank RWE for funding the

study and the efforts of Mr Steven Morris and Mr Terry

Figure 10: Mass-under-size and number-under-size with MIE

Treherne at the GTRC in helping conduct the experiments.

for 0.5 SWP.

Although outside of the scope of this study it worth

REFERENCES

considering the following. Solid surfaces in close proximity to

Bai, C.X., Rusche, H., Gosman, A.D., Modeling of

a potential release source may also, depending upon their size,

Gasoline Spray Impingement. Atomization and Sprays, 2002.

shape and number, result in confinement of the atomised spray

12: p. 1-27.

and acceleration of the resulting flame, therefore increasing

Ballal, D. R. & Lefebvre, A. H. (1978) Ignition and

not only the probability of ignition but also the consequences

flame quenching of quiescent fuel mists. Proc. R. Soc. Lond.,

of that event. The practical implication of this is that the

A364, p277-294.

environment surrounding such systems may have to be given

Bane, S.P.M., Ziegler, J.L, Boettcher, P.A, Coronel,

more detailed consideration in the risk assessment than has

S.A and Shepherd, J.E. (2011) Experimental investigation of

previously been thought necessary.

spark ignition energy in kerosene, hexane, and hydrogen.

Journal of Loss Prevention in the Process Industries. Article in

CONCLUSIONS

press.

This paper presents a study of hazards associated with

Bowen, P.J. and Shirvill, L.C. (1994). Combustion

high-flash point fuels and how the severity of the hazards can

hazards posed by the pressurized atomization of high-

be increased with spray impingement. The main conclusions

flashpoint liquids. Journal of Loss Prevention in Process

are:

Industries. V7 n3, pp 233-241.

• Unobstructed, ‘low-pressure’ liquid fuel releases

Bowen, P.J. (2011) Combustion Hazards Posed by

through plain orifices have been shown to ignite.

Hybrid Fuel Systems, Keynote Address at 5th European

• Sprays were ignited at temperatures significantly

Combustion Meeting, Scientific Programme, pg. 2, Cardiff

(circa 40K) below the flashpoint of the fuel.

28th June – 1st July 2011.

• A safe working pressure was determined

BSI (2009) Explosive atmospheres - Part 10-1:

experimentally for free spray conditions of a high-

Classification of areas - Explosive gas atmospheres. BS EN

flash point fuel.

60079-10-1:2009, British Standards Institution, London, UK.

• Sprays that impinged on a normal surface ignited at Eckhoff, R.K (2006) Differences and similarities of

0.5 the safe working pressure determined for the free gas and dust explosions: A critical evaluation of the European

jet releases highlighting a significant outstanding ‘ATEX’ directives in relation to dusts. Journal of Loss

issue concerning ‘area classification’ Prevention in the Process Industries, V19, pp 553-560.

• Current models in the literature have been used to EI (2005) Area classification code for installations

indicate the likelihood of flammable sprays, and handling flammable fluids. Part 15 of the IP model code of safe

emphasise the importance of both droplet size and practice in the petroleum industry, Energy Institute, London,

concentration on the MIE required. UK.

• Published models from the literature showed that at Kay, P.J., Bowen, P.J., Witlox, H.W.M. (2010) Sub-

the conditions tested the proportion of the spray cooled and flashing liquid jets and droplet dispersion II.

considered flammable at the SWP was shown to be Scaled experiments and derivation of droplet size correlations.

significantly less compared to a spray at 2.5 SWP,

consistent with our obseverations.

7 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Journal of Loss Prevention in the Process Industries, Volume

23, Issue 6, Pages 849-856

Lefebvre, A.H. (1989) Atomization and Sprays,

Hemisphere Publishing Corporation. ISBN 0-89116-603-3

Maragkos, A., Bowen, P.J., (2002) Combustion

hazards due to impingement of pressurised releases of high

flashpoint liquid fuels, The Proceedings of the Combustion

Institute, 29 305-311 ISSN 1540-7489

Mundo, C., Sommerfeld, M., and Tropea, C, On the

Modeling of Liquid Sprays Impinging on Surfaces. Atomization

and Sprays, 1998. 8: p. 625-652.

Santon, R.C. (2009) Mist fires and explosions - an

incident survey. Proc. IChemE Hazards XXI Symposium &

Workshop, Manchester, UK.

Shepherd, J. E., Lee, J. J., & Krok, J. C. (1999). Spark

ignition energy measurements in Jet A. GALCIT report FM97-

9. Graduate Aerospace Laboratories, California Institute of

Technology

8 Copyright © 2012 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 06/12/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Das könnte Ihnen auch gefallen

- 1 s2.0 S0957582097706530 MainDokument9 Seiten1 s2.0 S0957582097706530 MainBac Ho VanNoch keine Bewertungen

- 10 1021@ef700545jDokument9 Seiten10 1021@ef700545jHangie Cristina Montoya PeñalozaNoch keine Bewertungen

- MegDokument14 SeitenMegnabillah arsya100% (1)

- Combustion and Radiation Modeling PDFDokument10 SeitenCombustion and Radiation Modeling PDFlfgmarcantoniNoch keine Bewertungen

- 1 s2.0 S0950423023001948 MainDokument12 Seiten1 s2.0 S0950423023001948 MainManish DhimanNoch keine Bewertungen

- Fuel Volume 185 Issue 2016 (Doi 10.1016 - J.fuel.2016.07.126) Bao, Qi Fang, Qin Yang, Shigang Zhang, Yadong Xiang, Hengbo - Experimental InvDokument12 SeitenFuel Volume 185 Issue 2016 (Doi 10.1016 - J.fuel.2016.07.126) Bao, Qi Fang, Qin Yang, Shigang Zhang, Yadong Xiang, Hengbo - Experimental Invigor VladimirovichNoch keine Bewertungen

- Payri 2016 Applied-EnergyDokument10 SeitenPayri 2016 Applied-Energypepitoperez235Noch keine Bewertungen

- An Experimental Study On The Interaction of Water Mist With Vertical or Horizontal Spray FlameDokument10 SeitenAn Experimental Study On The Interaction of Water Mist With Vertical or Horizontal Spray FlameS BNoch keine Bewertungen

- Zarei-Ezadi2020 Article StudyOnTheFlareTipOfAGasRefineDokument10 SeitenZarei-Ezadi2020 Article StudyOnTheFlareTipOfAGasRefineiJordanScribdNoch keine Bewertungen

- Flare Radiation PredictionDokument30 SeitenFlare Radiation PredictionSmith ChhatrabhutiNoch keine Bewertungen

- SPE Paper 69679Dokument11 SeitenSPE Paper 69679Nicholas Garrett100% (2)

- Shsan Foolafgar - 2019 - C&F - Characterization of Flameless Combustion in A Model Gas Turbine Combustor Using A Novel Post Processing ToolDokument12 SeitenShsan Foolafgar - 2019 - C&F - Characterization of Flameless Combustion in A Model Gas Turbine Combustor Using A Novel Post Processing TooljayakrishnatejaNoch keine Bewertungen

- 2-Airblast AtomizationDokument29 Seiten2-Airblast AtomizationNojus DekerisNoch keine Bewertungen

- Reed Laboratory Evaluation of Bicarbonate Powders As Fire SuppressantsDokument10 SeitenReed Laboratory Evaluation of Bicarbonate Powders As Fire SuppressantsMohamed DEZIRINoch keine Bewertungen

- Proper application of flammability dataDokument10 SeitenProper application of flammability dataparsmessengerNoch keine Bewertungen

- Skjold Et Al. 2006 - Simulation of Dust Explosions in Complex Geometries With Experimental Input From StandardizedDokument8 SeitenSkjold Et Al. 2006 - Simulation of Dust Explosions in Complex Geometries With Experimental Input From StandardizedMario VargasNoch keine Bewertungen

- Journal of Loss Prevention in The Process Industries: Dong LV, Wei Tan, Liyan Liu, Guorui Zhu, Lei PengDokument9 SeitenJournal of Loss Prevention in The Process Industries: Dong LV, Wei Tan, Liyan Liu, Guorui Zhu, Lei Pengigor VladimirovichNoch keine Bewertungen

- Bayat2012 PDFDokument7 SeitenBayat2012 PDFarun aryaNoch keine Bewertungen

- UV-VIS technique for measuring fuel vapor distributionDokument9 SeitenUV-VIS technique for measuring fuel vapor distributionAngel IsidoroNoch keine Bewertungen

- Shapa Venting Paper 10Dokument10 SeitenShapa Venting Paper 10nshsharma7475Noch keine Bewertungen

- Analysis of Air Blast Effect For Explosives in A Large Scale DetonationDokument7 SeitenAnalysis of Air Blast Effect For Explosives in A Large Scale DetonationnguyenhNoch keine Bewertungen

- CFD Study of NO Emissions in A Model Commercial Aircraft Engine CombustorDokument10 SeitenCFD Study of NO Emissions in A Model Commercial Aircraft Engine CombustorstepanovatvNoch keine Bewertungen

- Impacts On Blowoff by A VarietyDokument4 SeitenImpacts On Blowoff by A VarietyDr.Hesham BaejNoch keine Bewertungen

- A Non-Premixed Combustion Model Based On Flame STRDokument59 SeitenA Non-Premixed Combustion Model Based On Flame STRCarlos AlarconNoch keine Bewertungen

- XXV Poster 11Dokument11 SeitenXXV Poster 11silambarasan PNoch keine Bewertungen

- Advances in dust explosion vent sizing methodsDokument12 SeitenAdvances in dust explosion vent sizing methodsjosethompsonNoch keine Bewertungen

- Simulation Research On Interaction Rules Between Superfine - 2014 - Procedia enDokument8 SeitenSimulation Research On Interaction Rules Between Superfine - 2014 - Procedia enjanainaNoch keine Bewertungen

- Application of CFD On The Sensitivity Analyses of Some Parameters of The Modified Hartmann TubeDokument12 SeitenApplication of CFD On The Sensitivity Analyses of Some Parameters of The Modified Hartmann TubeAnas SafwanNoch keine Bewertungen

- Developments in and Implementation of Gas Generators For Fire SuppressionDokument16 SeitenDevelopments in and Implementation of Gas Generators For Fire SuppressionSharat ChandraNoch keine Bewertungen

- 1 s2.0 S0306261921017177 MainDokument13 Seiten1 s2.0 S0306261921017177 MainDaniel MesaNoch keine Bewertungen

- Spe 101422 MS P PDFDokument5 SeitenSpe 101422 MS P PDFmsmsoft90Noch keine Bewertungen

- 1 s2.0 S0029549315002290 Main - NED - FourtharticleDokument13 Seiten1 s2.0 S0029549315002290 Main - NED - FourtharticlePratap SathiahNoch keine Bewertungen

- Computational Evaluation of Emissions For Non-Premixed Natural Gas CombustionDokument3 SeitenComputational Evaluation of Emissions For Non-Premixed Natural Gas CombustionijsretNoch keine Bewertungen

- Approximation of Flammability Region For Natural Gas-Air-Diluent MixtureDokument6 SeitenApproximation of Flammability Region For Natural Gas-Air-Diluent Mixtureg_marianiNoch keine Bewertungen

- ANSUL - Fire Protection Solutions For LNGDokument29 SeitenANSUL - Fire Protection Solutions For LNGErwinNoch keine Bewertungen

- Chemical Hazards in RefineryDokument11 SeitenChemical Hazards in RefineryRuqiyya Israfilova100% (1)

- Vess FireDokument21 SeitenVess FirecsNoch keine Bewertungen

- 1 s2.0 S0894177721000625 MainDokument27 Seiten1 s2.0 S0894177721000625 MainShelly BiswasNoch keine Bewertungen

- Dust Testing For DSEAR and ATEX Complian PDFDokument16 SeitenDust Testing For DSEAR and ATEX Complian PDFSawita LertsupochavanichNoch keine Bewertungen

- LFL EthaneDokument4 SeitenLFL EthaneMaysa YovandaNoch keine Bewertungen

- Carbon Balack Asme2006 revised12-DrSoltaniehrevised-20augDokument10 SeitenCarbon Balack Asme2006 revised12-DrSoltaniehrevised-20augShivangi GargNoch keine Bewertungen

- Turbulent combustion modelling of a confined premixed methane/air jet flameDokument20 SeitenTurbulent combustion modelling of a confined premixed methane/air jet flameeafz111Noch keine Bewertungen

- Large Eddy Simulation of Ethanol-Gasoline Fire: SciencedirectDokument6 SeitenLarge Eddy Simulation of Ethanol-Gasoline Fire: SciencedirectjanainaNoch keine Bewertungen

- Pool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Dokument14 SeitenPool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Torero02Noch keine Bewertungen

- Energies: Burning Behaviour of High-Pressure CH - H - Air MixturesDokument20 SeitenEnergies: Burning Behaviour of High-Pressure CH - H - Air MixturesNguyen Minh TienNoch keine Bewertungen

- TroaeDokument17 SeitenTroaeKUMAR KAUSHIKNoch keine Bewertungen

- Improved Coward Explosive Triangle For Determining Explosibility of Mixture GasDokument7 SeitenImproved Coward Explosive Triangle For Determining Explosibility of Mixture GassunilsinghmNoch keine Bewertungen

- Dust Explosion VeDokument10 SeitenDust Explosion VeSalva McNoch keine Bewertungen

- Numerical Investigation Towards Hitac Conditions in Laboratory Scale Ethanol Spray CombustionDokument15 SeitenNumerical Investigation Towards Hitac Conditions in Laboratory Scale Ethanol Spray Combustionchandan k akellaNoch keine Bewertungen

- Research Sponsored by: I D Power Branch - Office of Naval Research j;u Department of the NavyDokument250 SeitenResearch Sponsored by: I D Power Branch - Office of Naval Research j;u Department of the NavyAlperen BozdemirNoch keine Bewertungen

- Explosibility TestingDokument3 SeitenExplosibility Testingfawmer61Noch keine Bewertungen

- Fire and Explosion Characteristics of Powders: Vahid Ebadat, PH.DDokument7 SeitenFire and Explosion Characteristics of Powders: Vahid Ebadat, PH.Dsiruslara6491Noch keine Bewertungen

- An Attempt at Large Eddy Simulation For Combustor Modeling: Leiyong Jiang and Ian CampbellDokument10 SeitenAn Attempt at Large Eddy Simulation For Combustor Modeling: Leiyong Jiang and Ian CampbellWVNicholsonNoch keine Bewertungen

- 2022 - d1 02 Mcgrattan PaperDokument8 Seiten2022 - d1 02 Mcgrattan PaperAnoopNoch keine Bewertungen

- Sdmyers Fluid Testing EbookDokument18 SeitenSdmyers Fluid Testing EbookJesus TzianNoch keine Bewertungen

- 7-Numerical Simulation of Thermal Radiation DistribuDokument12 Seiten7-Numerical Simulation of Thermal Radiation DistribuAhmed SolimanNoch keine Bewertungen

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionVon EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionNoch keine Bewertungen

- Corrosion and Fouling Control in Desalination IndustryVon EverandCorrosion and Fouling Control in Desalination IndustryNoch keine Bewertungen

- Sevim ÖztürkDokument5 SeitenSevim ÖztürkEfari BahcevanNoch keine Bewertungen

- Oil & Gas Industry Standards for Corrosion TestingDokument7 SeitenOil & Gas Industry Standards for Corrosion TestingrajikhannaNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 19Dokument1 SeiteISC Process Safety Competency - Sayfa - 19Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 24Dokument1 SeiteISC Process Safety Competency - Sayfa - 24Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 32Dokument1 SeiteISC Process Safety Competency - Sayfa - 32Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 27Dokument1 SeiteISC Process Safety Competency - Sayfa - 27Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 29Dokument1 SeiteISC Process Safety Competency - Sayfa - 29Efari BahcevanNoch keine Bewertungen

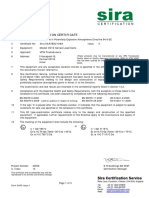

- 3510 - Sira 0asdDokument4 Seiten3510 - Sira 0asdEfari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 20Dokument1 SeiteISC Process Safety Competency - Sayfa - 20Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 25Dokument1 SeiteISC Process Safety Competency - Sayfa - 25Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 31Dokument1 SeiteISC Process Safety Competency - Sayfa - 31Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 04 PDFDokument1 SeiteISC Process Safety Competency - Sayfa - 04 PDFEfari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 26Dokument1 SeiteISC Process Safety Competency - Sayfa - 26Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 30Dokument1 SeiteISC Process Safety Competency - Sayfa - 30Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency - Sayfa - 28Dokument1 SeiteISC Process Safety Competency - Sayfa - 28Efari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency Sayfa 02Dokument1 SeiteISC Process Safety Competency Sayfa 02Efari BahcevanNoch keine Bewertungen

- Journal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengDokument11 SeitenJournal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengEfari BahcevanNoch keine Bewertungen

- ISC Process Safety Competency Sayfa 05Dokument1 SeiteISC Process Safety Competency Sayfa 05Efari BahcevanNoch keine Bewertungen

- Sil Poster Eng PDFDokument1 SeiteSil Poster Eng PDFEfari BahcevanNoch keine Bewertungen

- Asset Integrity Management for Ageing AssetsDokument4 SeitenAsset Integrity Management for Ageing AssetsEfari BahcevanNoch keine Bewertungen

- Journal of Cleaner Production: Vasco Bolis, Elisabet Cap On-García, Oliver Weder, Konrad HungerbühlerDokument13 SeitenJournal of Cleaner Production: Vasco Bolis, Elisabet Cap On-García, Oliver Weder, Konrad HungerbühlerEfari BahcevanNoch keine Bewertungen

- ccc10-1 2018 222Dokument10 Seitenccc10-1 2018 222Efari BahcevanNoch keine Bewertungen

- Sil AtexDokument6 SeitenSil AtexEfari BahcevanNoch keine Bewertungen

- Journal of Loss Prevention in The Process Industries: Renato BenintendiDokument6 SeitenJournal of Loss Prevention in The Process Industries: Renato BenintendiEfari BahcevanNoch keine Bewertungen

- Journal of Cleaner Production: Vasco Bolis, Elisabet Cap On-García, Oliver Weder, Konrad HungerbühlerDokument13 SeitenJournal of Cleaner Production: Vasco Bolis, Elisabet Cap On-García, Oliver Weder, Konrad HungerbühlerEfari BahcevanNoch keine Bewertungen

- Journal of Loss Prevention in The Process Industries: Fang Yan, Kaili Xu, Zhikai Cui, Xiwen YaoDokument7 SeitenJournal of Loss Prevention in The Process Industries: Fang Yan, Kaili Xu, Zhikai Cui, Xiwen YaoEfari BahcevanNoch keine Bewertungen

- Journal of Loss Prevention in The Process Industries: Xuanya Liu, Jingjing Li, Xinwei LiDokument6 SeitenJournal of Loss Prevention in The Process Industries: Xuanya Liu, Jingjing Li, Xinwei LiEfari BahcevanNoch keine Bewertungen

- Journal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengDokument11 SeitenJournal of Natural Gas Science and Engineering: Ke Shan, Jian Shuai, Kui Xu, Wei ZhengEfari BahcevanNoch keine Bewertungen

- Introduction To Layers of Protection Analysis: Angela E. SummersDokument6 SeitenIntroduction To Layers of Protection Analysis: Angela E. SummersEfari BahcevanNoch keine Bewertungen

- The Use of Vaportight Barriers As A Basis For Hazardous Area Classification DesignDokument8 SeitenThe Use of Vaportight Barriers As A Basis For Hazardous Area Classification DesignEfari BahcevanNoch keine Bewertungen

- Apostila Inglês - Ensino Fundamental - T1 Student S BookDokument65 SeitenApostila Inglês - Ensino Fundamental - T1 Student S BookEnsino Fundamental100% (6)

- EP820 User Guide (V100R003C00 - 05) (PDF) - ENDokument47 SeitenEP820 User Guide (V100R003C00 - 05) (PDF) - ENchineaNoch keine Bewertungen

- Event Service AgreementDokument5 SeitenEvent Service AgreementPNC ChoraleNoch keine Bewertungen

- Liveability Index 2022Dokument13 SeitenLiveability Index 2022Jigga mannNoch keine Bewertungen

- Diversity QuotasDokument7 SeitenDiversity Quotasapi-609564626Noch keine Bewertungen

- Yuken pvr50 FF 45 Raa 3180 Hydraulic Vane PumpDokument4 SeitenYuken pvr50 FF 45 Raa 3180 Hydraulic Vane Pumpnelson nadarNoch keine Bewertungen

- C9880046 Signed OfferLetterDokument8 SeitenC9880046 Signed OfferLetterẞhûpâthi RëddyNoch keine Bewertungen

- LPT22Dokument3 SeitenLPT22Leonardo Vinicio Olarte CarrilloNoch keine Bewertungen

- Notes Micro FinanceDokument9 SeitenNotes Micro Financesofty1980Noch keine Bewertungen

- Sustainable City PDFDokument361 SeitenSustainable City PDFagusbudiyonoNoch keine Bewertungen

- Elo TecDokument2 SeitenElo TecMimi MimiNoch keine Bewertungen

- M M M V V V N N N δ δ: Client: Date: Author: Job #: Project: Subject: B1 ReferencesDokument12 SeitenM M M V V V N N N δ δ: Client: Date: Author: Job #: Project: Subject: B1 ReferencesAndrew ArahaNoch keine Bewertungen

- CHEMIST LICENSURE EXAM TABLEDokument8 SeitenCHEMIST LICENSURE EXAM TABLEJasmin NewNoch keine Bewertungen

- Rotex Brochure PDFDokument4 SeitenRotex Brochure PDFestramilsolutionNoch keine Bewertungen

- FP02BDokument3 SeitenFP02BRazak JeyNoch keine Bewertungen

- Civil Engineering Final Year Projects Topic List - HTMLDokument4 SeitenCivil Engineering Final Year Projects Topic List - HTMLJohn Meverick E EdralinNoch keine Bewertungen

- Thermocold AWC PROZONE Tech PDFDokument44 SeitenThermocold AWC PROZONE Tech PDFAlexNoch keine Bewertungen

- SWOT Analysis AuchanDokument2 SeitenSWOT Analysis AuchanDaniela DogaruNoch keine Bewertungen

- Hawaii Hotel Performance by WeekDokument1 SeiteHawaii Hotel Performance by WeekHonolulu Star-AdvertiserNoch keine Bewertungen

- Zara Restaurant and Lounge Business PlanDokument54 SeitenZara Restaurant and Lounge Business Plankira572992% (12)

- Regulatory Updates on Japan's MO169 Medical Device Quality Management OrdinanceDokument7 SeitenRegulatory Updates on Japan's MO169 Medical Device Quality Management OrdinanceHong XuyenNoch keine Bewertungen

- Practice Test Answer Sheets AnswersDokument85 SeitenPractice Test Answer Sheets AnswersDon't Make Me AngryNoch keine Bewertungen

- Rock CycleDokument30 SeitenRock CycleDenny PrawiraNoch keine Bewertungen

- Hydro TestDokument35 SeitenHydro TestSumedh SinghNoch keine Bewertungen

- The Political Ecology of Food and AgricultureDokument15 SeitenThe Political Ecology of Food and AgricultureMitchNoch keine Bewertungen

- CCUS technologies activities in France: Focus on industriesDokument21 SeitenCCUS technologies activities in France: Focus on industriesGaurav MishraNoch keine Bewertungen

- Basics of Petroleum Physical PropertiesDokument4 SeitenBasics of Petroleum Physical PropertiesBharatiyulamNoch keine Bewertungen

- SSC DWDokument4 SeitenSSC DWsanketpavi21Noch keine Bewertungen

- 3G3EV Installation ManualDokument55 Seiten3G3EV Installation ManualHajrudin SinanovićNoch keine Bewertungen

- Understanding Themes Worksheet CN 1-20Dokument2 SeitenUnderstanding Themes Worksheet CN 1-20Sean DarvinNoch keine Bewertungen