Beruflich Dokumente

Kultur Dokumente

ASI Design Model For Light Bracing Cleat Connections PDF

Hochgeladen von

maheshbandhamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASI Design Model For Light Bracing Cleat Connections PDF

Hochgeladen von

maheshbandhamCopyright:

Verfügbare Formate

ASI SCJ Cleat Connection Cover 2Colour 9/03/10 9:57 AM Page 1

Steel Construction

Journal of the Australian Steel Institute

Volume 43 Number 2 – March 2010

Design Model for Light

Bracing Cleat Connection

ISSN 00049-2205 PRINT POST APPROVED PP255003/01614

STEEL CONSTRUCTION—EDITORIAL

Design Model for Light Bracing Cleat Connection

Two existing ASI publications on connections contain recommended design models for the bracing cleat

connection. Both these recommended design models are satisfactory for bracing members subject to

tension but the latest research indicates that these design models are unconservative for bracing members

subject to compression.

ASI has issued updated design models for a range of connections in Connections Design Series—Part 1–

2007 and Part 2–2009, which do not contain a design model for the bracing cleat connection. This

publication is intended to offer a recommended design model for review by interested parties before its

future inclusion in Connections Design Series—Part 1. The format of this publication is similar to the Design

Guides in the Connections Design Series.

For the purposes of this publication, light bracing cleat connections are defined as unstiffened cleats that

connect light bracing members to beams or columns. Typical applications include roof and wall bracing in

one-way rigid/one-way braced frames such as industrial building structures. This publication may also be

used to design unstiffened cleats which connect diagonal members in trusses to main chord members.

Bracing cleats for such applications may be cleats cut from plate or cut from square edge flat bar. Cleats

with only a single bracing member connected are the primary focus of the publication, but guidance is also

given for applications where multiple bracing members connect to the same gusset plate.

AUSTRALIAN STEEL INSTITUTE

The Australian Steel Institute (ASI) seeks to achieve industry Authors, Editors and Publishers of this publication: (a) will not

and professional development through regular technical be held liable or responsible in any way; and (b) expressly

seminars, publishing technical materials and making these disclaim any liability or responsibility for any loss or damage,

available through its bookshop and online, and providing costs or expenses incurred in connection with this Publication by

information through its web site www.steel.org.au. any person, whether that person is the purchaser of this

Publication or not. Without limitation, this includes loss, damage,

It operates for its members the largest steel technical library in costs and expenses incurred if any person wholly or partially

the Southern Hemisphere and provides lectures at colleges and relies on any part of this Publication, and loss, damage, costs

universities as well as hosting a range of committees providing and expenses incurred as a result of the negligence of the

direction and assistance to ASI outputs. Authors, Editors or Publishers.

Steel Construction is published by the ASI, Australia’s premier Warning: This Publication should not be used without the

technical marketing organisation representing companies and services of a competent professional person with expert

individuals involved in steel manufacture, distribution, knowledge in the relevant field, and under no circumstances

fabrication, design, detailing and construction. Its mission is to should this Publication be relied upon to replace any or all of the

promote the efficient and economical use of steel. Part of this knowledge and expertise of such a person.

work is to conduct technical seminars, educational lectures and

publish and market technical design aids. Its services are Contributions of original papers or reports on steel design,

available free of charge to financial corporate members. For research and allied technical matters are invited from readers

details regarding ASI services, readers may contact the for possible publication. The views expressed in these papers

Institute’s offices or visit the ASI website www.steel.org.au. are those of the authors and do not necessarily reflect the views

of ASI. Submissions should be in electronic format including all

Disclaimer: Every effort has been made and all reasonable care diagrams and equations in two columns, using Arial font (size

taken to ensure the accuracy of the material contained in this 10 point). A clean, camera-ready printout at 600 dpi should also

publication. However, to the extent permitted by law, the be forwarded.

Electronic copies of Steel Construction are available from the members’ section of the ASI website. These PDFs

may be freely downloaded by members for their personal use. Financial corporate members of the ASI may add

these PDFs to their company intranets but in the event of resignation from the ASI, the PDFs must be deleted. The

ASI permits members to quote excerpts from Steel Construction in their technical reports provided the journal is

referenced as the source.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 1

DESIGN MODEL FOR LIGHT BRACING CLEAT CONNECTIONS

Contents

Page No.

1 Introduction ...................................................................................................................................................... 3

2 Description of Connection ................................................................................................................................ 6

3 Typical Detailing and Detailing Considerations ................................................................................................ 7

4 Compliance with AS 4100 ................................................................................................................................ 9

5 Eccentricity on Bracing Cleat ..........................................................................................................................10

6 Design of End Connections to Bracing Members ............................................................................................12

7 Basis of Design Model for Bracing Cleat .........................................................................................................13

8 Recommended Design Models—Summary of Design Checks ........................................................................17

9 Recommended Design Model Part A Connected brace in tension ................................................................18

9.1 DESIGN CHECK No. 1—Design capacity of bolts in shear and bearing ...............................................18

9.2 DESIGN CHECK No. 2—Design capacity due to end plate tearout in bracing cleat..............................19

9.3 DESIGN CHECK No. 3—Design capacity of bracing cleat in block shear .............................................20

9.4 DESIGN CHECK No. 4—Design capacity of bracing cleat in axial tension ...........................................21

9.5 DESIGN CHECK No. 5—Design capacity of weld to support ................................................................22

9.6 DESIGN CHECK No. 6—Design capacity of supporting member locally at cleat location .....................23

10 Recommended Design Model Part B Connected brace in compression........................................................26

10.1 DESIGN CHECK No. 7—Design capacity of bolts in shear and bearing ...............................................26

10.2 DESIGN CHECK No. 8—Design capacity of bracing cleat under eccentric compression force.............27

10.3 DESIGN CHECK No. 9—Design capacity of weld to support ................................................................30

10.4 DESIGN CHECK No. 10—Design capacity of supporting member locally at cleat location ...................31

11 Multiple Bracing Members Connected to a Single Gusset Plate......................................................................34

12 Heavy Bracing Connections ............................................................................................................................38

13 Design Examples ............................................................................................................................................39

13.1 Design example No. 1—End connection to angle tension brace ...........................................................39

13.2 Design example No. 2—End connection to angle compression brace...................................................41

13.3 Design example No. 3—Bracing cleat to welded tee end connection to SHS brace in compression .....44

14 References......................................................................................................................................................46

Appendix A

Comparison of experimental results by Stock with design capacities from recommended

Design Model of Section 10 ............................................................................................................................48

Appendix B

Limcon outputs for design examples ...............................................................................................................49

Additional Corrigenda to Steel Construction Vol. 36 No. 2 September 2002

“Design Of Pinned Column Base Plates”.........................................................................................................57

2 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

DESIGN MODEL FOR LIGHT BRACING CLEAT CONNECTIONS

T.J. HOGAN

Consultant to Australian Steel Institute

R. T. COLLINS

Engineering Systems Pty Limited

1 INTRODUCTION

For the purposes of this publication, light bracing cleat connections are defined as unstiffened cleats that

connect light bracing members to beams or columns. Typical applications include roof and wall bracing in

one-way rigid/one-way braced frames such as industrial building structures. This publication may also be

used to design unstiffened cleats which connect diagonal members in trusses to main chord members.

The publication does not apply to heavy bracing members and their end connections (which are discussed

in Section 12) or to knee braces in portal frame buildings.

Light bracing members are deemed to include the following member types (see Table 1):

—flat bars

—rods

—angles (single or double)

—circular hollow section members up to 219 mm diameter

—square or rectangular hollow section members up to 200 mm maximum dimension

Bracing cleats for such applications may be cleats either cut from Grade 250 or Grade 350 plate to

AS/NZS 3678 (Ref. 9) or cut from square edge flat bar Grade 300 to AS/NZS 3679.1 (Ref. 10).

Light bracing cleats may be one of three forms shown in Figure 1 as follows:

—cleats with only one bracing member connected (Fig. 1(a))

—cleats with two bracing members connected (Fig. 1(b) or (c))

—cleats with three bracing members connected (Fig. 1(d))

Bracing cleats may be subject to tension or compression force applied through the connected brace

member.

FIGURE 1 LIGHT BRACING CLEATS

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 3

The main focus of this publication is the isolated bracing cleat for a single brace member of Fig 1(a) and

this publication provides a recommended design model for this arrangement. Methods of dealing with

bracing cleats with two or three bracing members attached are discussed in Section 11.

A recommended design model for light bracing cleats was published by the Australian Institute of Steel

Construction in 1994 (Sections 4.11 and 5.11 of Reference 1—known commonly as the ‘Green Book’). The

recommended design model in Reference 1 ignored the effect of eccentricity on the design of the cleat and

contained what subsequent research showed to be an unconservative assumption for the buckling strength

of a cleat subject to compression.

The Australian Institute of Steel Construction also published in 1996 a publication dealing with light bracing

cleats with hollow section bracing members connected to them (Sections 6 to 9 of Reference 2—known

commonly as the ‘Blue Book’). The bracing members explicitly considered were as follows (see Figure 2):

—flattened end circular hollow section bolted to the bracing cleat (Fig. 2(a));

—cleat welded to cap plate to form a tee, cap plate welded in turn to a hollow section brace member

(Fig 2(b));

—cleat fitted into a slot in a hollow section member and welded along the slot (Fig. 2(c)).

FIGURE 2 END CONNECTIONS TO HOLLOW SECTION BRACING MEMBERS

The basis of the design model for all member types in Reference 2 was the Kitipornchai, Al-Bermani and

Murray paper (Reference 3) which had recommended taking account of the eccentricity in such connections

of brace members to cleats through a specifically formulated yield line approach based on test results. An

effective length factor of 0.5 was used in the design method.

Subsequently, as more information became available, the Australian Steel Institute drew attention to the

fact that the design method based on Reference 3 may be unconservative (Ref. 4 of March 2004) and then

issued an Advisory Note (Ref. 5 of December 2005) regarding the bracing cleat connection. Engineering

Systems also issued similar cautionary advice (Ref. 17).

The Advisory Note made the following comments—see Reference 5:

‘… The problem arises because of the assumption that “the connection may be treated as two

eccentrically connected cleat components whose ends are fixed and prevented from sway”.

The connection types to which this advisory applies are the slotted tube, welded tee end and flattened

end connections. Unless restrained against sidesway, each of these connections deflects laterally as

it is loaded in compression, developing a plastic hinge in each plate at a fraction of the section

compression capacity. The real capacity of the connection is very much less than would be computed

assuming the presence of lateral restraint or the absence of eccentricity. The problem is exacerbated

4 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

for connections in short compression members and for compression members that are not exclusively

wind bracing.

The small eccentricity occurring when a stiff member is connected to a gusset plate (e.g. channel web

bolted to gusset plate) has traditionally been ignored in the design of simple bracing connections and

this is permissible in some cases because most of the eccentricity moment acts on the stiff bracing

member and only a small bending moment acts on the flexible cleat component. There is an important

difference between this situation and that with hollow section bracing connections. In these

connections there are two flexible components bolted together—“eccentrically connected cleats”. The

problem is that the eccentricity moment is shared between the two flexible plates and plastic hinges

develop at a very low load unless there is lateral restraint. The cleat assembly deflects sideways

during loading. Eccentrically connected cleats should not be designed as a concentric column even

when a large effective length factor is used. It is necessary to apply the existing design code rules for

combined bending and compression (AS 4100 Section 8—Members Subject to Combined Actions).

Software is available to perform the necessary code checks.

Recommendations

• Do not use an eccentric hollow section bracing connection for a short compression member

unless it is stiffened against sidesway. A concentric connection should be used if there is no

sidesway stiffening.

• Design eccentric hollow section bracing connections taking eccentricity into account by rigorous

application of design code rules for combined bending and compression—do not use the

method in ‘Design of Structural Steel Hollow Section Connections.’

This publication is intended to provide a revised recommended design model for the bracing cleat

connection that addresses the issue of eccentricity in cleats subject to both tension and compression and

also addresses the issue of the buckling capacity of the cleat when subject to compression. The

recommendations in this publication are formulated in terms of the provisions of AS 4100 (Ref. 6).

The issuing of this publication means that all Sections of Reference 1 will then have been updated (the

updating of the other sections of Reference 1 having been discussed in References 7 and 8) and means

that Sections 6 to 9 in Reference 2 can continue to be used provided the design of the bracing cleat is

modified using the recommendations of this publication.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 5

2 DESCRIPTION OF CONNECTION

The light bracing cleat comprises a plate (Grade 250 or Grade 350 to AS/NZS 3678—Ref. 9) or square edge

flat bar (Grade 300 to AS/NZS 3679.1—Ref. 10) fillet welded both sides to a supporting member with a

number of bolt holes provided so as to allow light bracing members such as shown in Table 1 to be bolted to

the bracing cleat using either M16/M20/M24 bolts in 8.8/S bolting category.

FIGURE 3 BRACING CLEAT DETAILS

TABLE 1

LIGHT BRACING MEMBERS—END CONNECTION DETAILS

Member Side elevation Section

Angle(s) and flat bar(s)

bolted directly to cleat

Rod—fin plate slotted

and welded to rod

Flattened end CHS—

bolted directly to cleat

Hollow sections—fitted

fin plate bolted to cleat

Hollow sections—

fabricated tee section

bolted to cleat

6 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

3 TYPICAL DETAILING AND DETAILING CONSIDERATIONS

Typical detailing of an isolated light bracing cleat is shown in Figure 4.

FIGURE 4 TYPICAL DETAILING TO BRACING CLEATS

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 7

DETAILING CONSIDERATIONS

1 Bracing cleats should be detailed as approximately rectangular shapes in order to reduce marking-off

and cutting times.

2 For single members, use a square edge flat bar as the cleat component wherever possible. Where

several bracing members connect to the same cleat (as in Fig. 1), use approximately rectangular

shaped plates wherever possible.

3 Welds to supporting members should be 6 or 8 mm fillet welds, both sides of bracing cleat, wherever

possible. Check the economics of using 10 mm fillet welds with the fabricator before using or else use

a full penetration butt weld.

4 Bolts should be M16/M20/M24 bolts in 8.8/S bolting category. 2 mm oversize holes should be used in

general. Where oversize or slotted holes are used, the provisions of AS 4100 Clause 14.3.5.2 in

respect of the use of the applicable bolt category and the use of plate washers need to be complied

with. See also References 11 and 12 for a discussion of the requirements of Clause 14.3.5.2 of

AS 4100 in respect of hole sizes.

5 Centreline of bolt group, centreline of bracing cleat and centre of weld should all coincide wherever

possible for the single member bracing cleat.

6 Members to which bracing is connected are often the first members erected in order to establish

stability for the overall frame. The bracing connections should hence be simple so as to allow rapid

installation of the bracing members.

7 Because bracing cleats project from supporting members, damage may occur during transport and

erection. For light bracing cleats, the cleats need to be able to be returned to their correct position if

damaged. If they cannot be easily returned to their original position, they should be removed and

replaced.

8 Minimum edge distances should be as follows—refer to Figure 4 and Table 9.6.2 of AS 4100

ae3 — Flat bar component M16 bolt 20 mm

M20 bolt 25 mm

M24 bolt 30 mm

since a square edge flat bar will have a rolled edge

— Plate component M16 bolt 28 mm

M20 bolt 35 mm

M24 bolt 42 mm

since it will not be known during the design phase whether the plate will be sheared, hand

flame cut, machine flame cut, sawn or planed along the cleat

ae1 — Flat bar or plate component M16 bolt 28 mm

M20 bolt 35 mm

M24 bolt 42 mm

since it will not be known during the design phase whether the flat bar or plate will be

sheared, hand flame cut, machine flame cut, sawn or planed when cut to length

NOTE: It is recommended that more than the minimum edge distance be used for bracing cleats to tension

members with only one row of bolts because the bolt tearout limit is associated with quite large deformations

and any accidental reduction of the edge distance during fabrication or erection could result in failure of the

connection.

9 Preferred bolt pitches (s p) and bolt gauge (s g) are as follows

M16 bolt 60 mm

M20 bolt 70 mm

M24 bolt 80 mm

8 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

4 COMPLIANCE WITH AS 4100

The bracing cleat connection should be designed to comply with Section 9 of AS 4100 (Ref. 6).

Clause 9.1.4 (b) (iii) of AS 4100 specifies that the minimum design action at the ends of axially loaded

tension or compression members shall be ‘0.30 times the member design capacity except that for threaded

rod acting as a bracing member with turnbuckles, the minimum tensile force shall be equal to the member

design capacity’. This requirement hence defines the minimum design force on a bracing cleat at the end of

a bracing member.

Clause 9.1.5 of AS 4100 states that :

‘Members or components meeting at a joint shall be arranged to transfer the design actions between

the parts and, wherever practicable, with their centroidal axes meeting at a point. Where there is

eccentricity at joints, the members and components shall be designed for the design bending

moments which result … Eccentricity between the centroidal axes of angle members and the gauge

lines for their bolted end connections may be neglected in statically loaded members, but must be

considered in members and connection components subject to fatigue loading.’

From this Clause, it is clear that any eccentricity between the bracing cleat and the bracing member must

be designed for when designing the member and the bracing cleat, irrespective of whether the member is in

tension or compression. However, the Clause allows that angle bracing members may be designed by

ignoring the eccentricity between the centroid of the member and the centroid of any bolt group at the end

connection. This is because generally the centroid is too close to the unconnected leg to allow bolts to fit.

Shear lag effects due to not all elements of the brace member being connected at the end connection are

allowed for in the case of tension members in Section 7 of AS 4100.

Note that eccentricity about both axes of the cleat may need to be considered—eccentricity about the minor

axis due to the bracing member or its end connection coming in on one side of the bracing cleat Fig. 5(b),

and eccentricity about the major axis due to the centroid of the bracing member or its end connection not

coinciding with the centreline of the bracing cleat—although usually the two coincide about the major axis,

see Figure 5(a).

FIGURE 5 ECCENTRICITIES AT CLEATS

Design for eccentricity is discussed in more detail in Section 5.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 9

5 ECCENTRICITY ON BRACING CLEAT

The assumption that will be made in this publication is that the centroidal axis of the bracing member and its

end connection will coincide (apart from angle members) in one plane—as in Figure 5(a)—so that there is

no eccentricity about the major axis of the bracing cleat. For single angle bracing members connected

directly to the bracing cleat, this assumption is not correct but AS 4100 Clause 9.1.5 permits any

eccentricity between the angle member centroidal axis and the centroid of the bolt group to be ignored (as

noted in Section 4).

For eccentricity about the minor axis of the bracing cleat, the following applies in terms of the requirements

of AS 4100 as discussed in Section 4 (refer to Table 1 for details of end connections to members):

concentric loading — double angles as bracing members, one each side of bracing cleat;

eccentric loading — single angle as a bracing member connected one side of bracing cleat;

— rod with fin plate connected to one side of bracing cleat;

— flat bar as bracing member connected to one side of bracing cleat;

— flattened end CHS bracing connected to one side of bracing cleat;

— fitted fin plate to hollow section bracing member connected to one side;

— tee plate end connection to hollow section bracing member with projecting

plate connected to one side of bracing cleat.

The notional eccentricity involved for the eccentrically loaded connections is taken to be that shown in

Figure 5 (b), being the distance from the centre of the bracing cleat to the centre of any connection plate to

the bracing member, except for the single angle bracing member where the eccentricity is taken as the

distance from the centroidal axis of the angle to the centre of the bracing cleat (see Figure 6). The angle

bracing member should be designed as eccentrically loaded in compression and designed for tension using

the k t term of Section 7 of AS 4100.

FIGURE 6 ECCENTRICITY FOR ANGLE BRACING MEMBER

Conventional practice has been to design the bracing cleats for no eccentricity when subject to either

tension or compression (see Reference 1). As noted in Section 4, this is not in accordance with AS 4100

Section 9.

A review of practice in other design sources results in the following observations:

(a) British practice as described in Section 9 of Reference 13 for angle, channel and tee brace members

subject to compression or tension is to ignore the theoretical eccentricity provided that the members

themselves are designed in accordance with BS 5950-1 Clause 4.7.10. For hollow section bracing

members, reference is made to CIDECT publications.

(b) American Institute of Steel Construction Specification (Reference 14) Clause J1.7 states that the

centre of gravity of bolt or weld groups should coincide with the centre of gravity of the member

unless provision is made for any eccentricity that would otherwise result. This is not required to be

10 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

observed for single angle, double angle or similar members. Reference to the Commentary suggests

that this really relates to eccentricity about the major axis of the member rather than the minor axis of

the member and is based on tests done in 1942. Other tests clearly indicate that eccentricity should

be allowed for in design (even for angle members) if fatigue is an issue.

(c) The AISC et al Hollow Section Connections Manual (Ref. 15) recommends that no eccentricity be

allowed for the welded tee and slotted plate connection in hollow section brace members if the brace

member is subject to tension. However, the same members when subject to compression are

recommended to be designed for any eccentricity between the centroids of the two plates involved, as

in Figure 5(b). This is the same approach as was used at Reference 2.

(d) More recent work on end connections to bracing members subject to compression (References 16 to

21), all recommend that bracing cleats subject to compression be designed for any eccentricity.

The approach taken in this publication is as follows:

(i) for bracing cleats subject to tension, no eccentricity is allowed for in design based primarily on

References 13 and 15 and past practice in Australia (Refs 1 and 2) and since any eccentricity present

does not cause a stability issue such as occurs in compression;

(ii) for bracing cleats subject to compression, the eccentricity suggested by Figure 5(b) and Figure 6 is

designed for, based on advice given in References 15 to 21.

(iii) the resulting design moment due to the eccentricity is divided between the bracing cleat and the

attaching cleat on the brace member or the brace member itself (if there is no cleat) on the basis of

the relative stiffness of each. If the bracing cleat and the attaching cleat on the brace member (as in

Figures 2(b) and (c)) are of similar length and thickness, this will result in a 50% assignment to each

cleat. In the case of angle brace members and flattened hollow section brace members, the stiffness

of the brace member is much greater than the stiffness of the bracing cleat and a minimum of 10% of

the design moment due to the eccentricity is recommended to be used, based on advice given in

Reference 17 (which is in turn based on modelling done using Microstran).

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 11

6 DESIGN OF END CONNECTIONS TO BRACING MEMBERS

The design of the end connections to the bracing members themselves is not part of the scope of this

publication. However, a brief coverage of the design of these end connections is include for completeness

and because some of the end connections have recommended design models in Reference 2 which have

one provision modified in Section 10 of this publication.

Flat Bars and Angles (see Table 1)

The end connections to both types of bracing members typically comprise bolts through the members

themselves into the bracing cleat. The design checks required are then:

—bearing capacity of bolts in the bracing member (tension and compression)

—end tearout capacity of the bracing member around the bolts (tension only)

—block shear capacity of the bracing member (tension only)

which all can be based on the guidance given in Sections 9 and 10 of this publication.

Rod with Fin Plate (see Table 1 and Figure 7)

The end connections to the rod type of bracing members typically comprise bolts through the fin plate at the

end of the rod into the bracing cleat. The design checks required are then:

—bearing capacity of the bolts in the fin plate to the bracing member (tension only)

—end tearout capacity of the fin plate to the bracing member (tension only)

—block shear capacity of the fin plate to the bracing member (tension only)

—design capacity in tension of the fin plate in terms of Section 7 of AS 4100

—design capacity of the fillet welds connecting the rod to the fin plate

The first four design checks can be based on the recommended design model of Sections 9 of this

publication. Rod members are only used in tension so that Section 10 of this publication does not apply to

these members.

FIGURE 7 END DETAIL FOR ROD BRACING MEMBER

Flattened End CHS (see Table 1 and Figure 2(a))

A recommended design model for this type of end connection is given in Section 7 of Reference 2. This

recommended design model may be used except for Section 7.3.1.3 for a member subject to compression

for which the recommended design model in Section 10 of this publication should be substituted.

Welded Tee Connection to Hollow Section (see Table 1 and Figure 2(b))

A recommended design model for this type of end connection is given in Section 8 of Reference 2. This

recommended design model may be used except for Section 8.3.2.3 for a member subject to compression

for which the recommended design model in Section 10 of this publication should be substituted.

Fin Plate to Slotted Hollow Section (see Table 1 and Figure 2(c))

A recommended design model for this type of end connection is given in Section 9 of Reference 2. This

recommended design model may be used except for Section 9.3.1.3 for a member subject to compression

for which the recommended design model in Section 10 of this publication should be substituted.

12 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

7 BASIS OF DESIGN MODEL FOR BRACING CLEAT

Most studies of bracing connections reviewed for this publication do not consider the simple isolated bracing

cleat connection dealt with in this publication, but deal with the more complex cases of several members

connected to the same gusset plate such as in Figure 1 (these gusset plate connections are discussed in

Sections 11 and 12).

However, the isolated bracing cleat forms a significant proportion of the overall number of bracing

connections in steel structures and a design model for this form of connection can form the basis for more

complex gusset plate connections, as will be discussed in Section 11.

Design for Tension

The recommended design model for a bracing cleat subject to a design tension force is primarily based on

the provisions contained in AS 4100 (Ref. 6) since suitable provisions are available.

The design checks for bolts in shear, bolts bearing on the bracing cleat and plate tearout in the bracing

cleat are based on Clause 9.3.2.1 of AS 4100 and Section 3 of Handbook 1 (Ref. 11). The design of the

bracing cleat subject to axial tension is based on Clause 7.2 of AS 4100 and Section 5.4 of Handbook 1. As

noted in Section 5 of this publication, the bracing cleat is not designed for any eccentricity when subject to

tension force, and neither is the weld connecting the bracing cleat to the support.

The design check for block shear failure of the bracing cleat is based on the recommendations in

Section 5.4 of Handbook 1 (Ref 11), while the design check for the weld group is based on Section 11 of

Handbook 1.

The design check for local effects on the supporting member have been taken from the following sources :

(a) for a bracing cleat connected to the web of an I-section—the discussion in Section 5.11 of

Reference 1;

(b) for a bracing cleat connected to the face of a rectangular or square hollow section—the

recommendations in Section 6.2.1 of Reference 2.

Design for Compression

The recommended design model for a bracing cleat subject to a design compression force is also primarily

based on the provisions contained in AS 4100 (Ref. 6) where suitable provisions are available.

The major issues in designing the bracing cleat for combined bending and compression are:

1 the eccentricity to be used (Section 5 of this publication);

2 the effective length to be used;

3 whether moment amplification is used;

4 the method to be used to allow for combined bending and compression.

The recommended design model in Reference 1 did not allow for any eccentricity and used an effective

length of 0.70 × the distance from the bolt closest to the support, based on guidance in Reference 16. This

effective length was based on the assumption of fixed/fixed supports in Fig. 4.6.3.2 of AS 4100 (Ref 6).

Reference 2 adopted a design approach based on analytical and experimental work by Kitipornchai et al

(Ref. 3). Kitipornchai et al identified that the connection at the bracing cleat could fail in either a sway mode

or in a non-sway mode and concluded that for most practical connections, the connection at the bracing

cleat approximated a fixed-fixed connection. They derived six possible collapse mechanisms involving

plastic hinges which led to the formulation of the design model which was used in Reference 2. The

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 13

collapse mechanisms were verified by tests on isolated bracing cleats with assumed end conditions, not full-

scale tests.

Reference 2 stated for their design models to be valid that ‘the design of the bracing cleat eccentrically

loaded in compression assumes that both ends of the connections are fixed against sway’. The eccentricity

used in the design models was the distance between the centres of the two cleats and the effective length

used was 0.5 × the ‘distance between supports of the connection’ which was taken as the distance between

the face of the supporting member and the face of the in-coming bracing member.

Subsequently, some concern about the recommended design model of Reference 2 became evident,

particularly about whether the fixed-fixed/no sway assumption was correct. Advisory information was issued

by Engineering Systems (Ref. 17) and the Australian Steel Institute (Refs 4 and 5). Reference 5 also

suggested that Section 8 of AS 4100 be used to account for the effects of combined bending and

compression.

Following from these concerns, Clifton and el Sarraf (Ref. 18) proposed a design model for the bracing cleat

for combined bending and compression on the basis of a failure mode involving sway. The design model

was based on the provisions of NZ 3404 (Ref. 19) which has a number of sections common to those in

AS 4100, including Sections 6 and 8. This design model amplifies the design moment to allow for second-

order effects, increases the theoretical design eccentricity by 3 mm and uses an effective length factor of

1.0.

A relatively straightforward design method is given in Reference 15 (AISC et al method) which uses the

following assumptions:

(1) design allows for eccentric loading, the resulting bending moment being split equally between the

bracing cleat and the cleat attached to the bracing member;

(2) no moment amplification is applied to allow for second-order effects;

(3) an effective length factor of 1.2 is used;

(4) design for compression is based on the column curve for hollow sections used in Reference 23;

(5) design for combined bending and compression is based on a linear interaction equation taken from

Reference 23.

Recently, Stock (Ref. 20) carried out an experimental study of hollow section braces connected to bracing

cleats using fabricated tee-section end connections (Fig. 1(b)). Stock compared the experimental capacities

obtained from his testing with the design capacities obtained using the above AISC et al design model (Ref.

15) and reported that the ratio of experimental values to the predicted design capacities ranged from 1.05 to

1.39, with a mean of 1.20. This comparison was carried out with a capacity factor of 1.0 so that the mean

value increases to 1.33 for a capacity factor of 0.9. The AISC et al design method (Ref. 15) is hence

conservative based on this evidence.

In 2008, Khoo, Perera and Albermani (Ref. 21) conducted twelve (12) full-scale tests on hollow section

struts with eccentric and concentric end connections. They confirmed the sway collapse mechanism for

eccentric cleats and proposed a two-step design method. Their method was compared with other design

methods and results from finite element analysis and was found to be accurate. They concluded the

following:

(i) the Reference 2 design model grossly overestimated the connection capacity since it excludes the

sway mechanism;

(ii) the Reference 18 method was excessively conservative because it increased the theoretical

eccentricity by 3 mm and used the elastic section modulus rather than the plastic section modulus

when evaluating the design moment capacity of the bracing cleat due to concerns about bracing

cleats used in seismic applications;

14 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

(iii) the correlation between design capacities obtained using Limcon (Ref. 22) was very good. This

method uses Section 8 of AS 4100 for the combined bending and compression design condition,

moment amplification using Clause 4.4.2.3 of AS 4100 and an effective length factor of 1.0. The

Limcon method was found to represent a lower bound to the experimental results;

(iv) the two-step design method proposed by Khoo et al was found to give good agreement with the

experimental results.

Stock (Ref. 20) proposed a design method using Clause 8.4.2.2 of AS 4100 for combined bending and

compression, using eccentricity as discussed in Section 5 split equally between the two connected plates

and an effective length factor of 1.0 with no moment amplification for second-order effects. Using averaged

test results for each of four specimen types tested by him, he obtained a ratio of experimental results to

design capacity for this approach of 1.07—a slightly conservative result. This result was achieved with a

capacity factor of 0.9 .

Stock also proposed an advanced method for considering combined bending and compression using

AS 4100. This advanced method accounts for sway using a second-order moment amplification term based

on Clause 4.4.2 of AS 4100 and an effective length factor of 1.0. A closed form expression for the critical

compression force is then obtained by using Clauses 6.2 and 8.4.2.2 of AS 4100.

It should be noted that the moment amplification method given in Section 4 of AS 4100 is essentially for

frame-type beam and column structures and its application to small-scale problems such as the end

connection of a brace member has to be considered questionable.

The method adopted in the recommended design model in Section 10 of this publication has the following

features:

(a) a sway mode of failure is assumed;

(b) an effective length of 1.20x the distance between the supporting member and the end of the bracing

member is used based on one end being rotation fixed, translation fixed (supporting member) and one

end being rotation fixed, translation fixed (from Figure 4.6.3.2 of AS 4100);

(c) eccentricity is accounted for as set out in Section 5 of this publication;

(d) no amplification of the design moment is assumed;

(e) an αb of 0.5 is used to select the column curve for design for axial compression;

(f) Clause 8.4.4.1 of AS 4100 is used to determine the out-of-plane design capacity for the bracing cleat

subject to combined bending and compression.

The proposed method is believed to be sufficiently conservative and is similar to the AISC et al method

(Ref. 15), the Limcon method (Ref. 22) and the Stock simplified method (Ref. 20) in many respects. A

comparison of the results obtained from the proposed design model and the experimental results obtained

by Stock are contained in Appendix A of this publication.

The design checks for bolts in shear and bolts bearing on the bracing cleat are based on Clause 9.3.2.1 of

AS 4100 and Section 3 of Handbook 1 (Ref. 11). In the case of compression on the bracing cleat, only

tearout between bolt holes need be considered in terms of Clause 9.3.2.4 but no check is included as this is

considered an unlikely and non-critical failure possibility.

The design of the bracing cleat subject to axial compression is based on Clauses 6.2 and 6.3 of AS 4100

(using a value for αb of 0.5 for ‘other sections’ in Table 6.3.3(1) of AS 4100) and Section 5.4 of Handbook 1.

As noted above, the bracing cleat is designed for eccentricity when subject to compression force, resulting

in a bending moment about the minor axis of the bracing cleat. Clause 8.4.4.1 of AS 4100 is used for the

assessment of the out-of-plane design capacity of the bracing cleat subject to axial compression and

bending.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 15

There is no design check for block shear because this is a phenomenon that only occurs in connection

elements subject to tension.

The design check for the weld group is based on Section 11 of Handbook 1 for a fillet weld group subject to

a compressive axial force and bending moment due to the eccentricity on the bracing cleat which is

assumed to also apply to the weld.

The design check for local effects on the supporting member are based as follows:

(a) for a bracing cleat connected to the web of an I-section—the discussion in Section 5.11 of

Reference 1;

(b) for a bracing cleat connected to the face of a rectangular or square hollow section—the

recommendations in Section 6.2.1 of Reference 2.

The recommended design model in this publication meets the requirements of Clause 9.1.4 of AS 4100 that

any design method be based on a recognised method and experimental evidence. The philosophy adopted

in this publication is the same as that espoused in Handbook 1 (Ref. 11) being as follows:

(i) take into account overall connection behaviour, carry out an appropriate analysis in order to

determine a realistic distribution of forces within the connection;

(ii) ensure that each component or fastener in each action path has sufficient capacity to transmit

the applied action;

(iii) recognise that this procedure can only give a connection where equilibrium is capable of being

achieved but where compatibility is unlikely to be satisfied, and therefore ensure that the

connection elements are capable of ductile behaviour.

16 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

8 RECOMMENDED DESIGN MODELS—SUMMARY OF DESIGN CHECKS

PART A CONNECTED BRACE IN TENSION

Design is based on determining N des (the design capacity of the bracing cleat) which is the minimum of the

design capacities N a, N b, N c, N d, N e, N f obtained from DESIGN CHECK Nos 1 to 6 inclusive.

The design requirement is then N des ≥ N t* (design tension force)

Minimum design tension force should be as stated in Section 4.

Connection geometry is as shown in Section 3, Figure 4.

9.1 DESIGN CHECK NO 1—Design capacity of bolts in shear and bearing (N a)

9.2 DESIGN CHECK NO 2—Design capacity due to end plate tearout (N b)

9.3 DESIGN CHECK NO 3—Design capacity of bracing cleat in block shear (N c)

9.4 DESIGN CHECK NO 4—Design capacity of bracing cleat in axial tension (N d)

9.6 DESIGN CHECK NO 5—Design capacity of weld to support (N e)

9.6 DESIGN CHECK NO 6—Design capacity of supporting member locally at cleat location (N f)

PART B CONNECTED BRACE IN COMPRESSION

Design is based on determining N des (the design capacity of the bracing cleat) which is the minimum of the

design capacities N g, N h, N i , N j obtained from DESIGN CHECK No.s 7 to 10 inclusive.

The design requirement is then N des > N c* (design compression force)

Minimum design compression force should be as stated in Section 4.

Connection geometry is as shown in Section 3, Figure 4.

10.1 DESIGN CHECK NO 7—Design capacity of bolts in shear and bearing (N g)

10.2 DESIGN CHECK NO 8—Design capacity of bracing cleat under eccentric axial compression

(N h)

10.3 DESIGN CHECK NO 9—Design capacity of weld to support (N i )

10.4 DESIGN CHECK NO 10—Design capacity of supporting member locally at cleat location (N j)

NOTE: The design checks of both Part A and B do not take account of the parameters of the connected bracing

member (if a flat bar or angle) or of the end connection to the bracing member. The design of the member or its end

connection must consider a number of aspects which may affect the overall design capacity of the total connection

(see Section 6).

The design models contained within this publication are considered to be applicable only to connections

which are essentially statically loaded. Connections subject to dynamic loads, earthquake loads or fatigue

applications may require additional considerations.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 17

9 RECOMMENDED DESIGN MODEL 9.1 DESIGN CHECK No. 1—Design

PART A CONNECTED BRACE IN capacity of bolts in shear and

TENSION bearing

Design capacity of bolts in shear and bearing, N a

where

Na = nbkr(φVdf)

nb = total number of bolts in bracing cleat

kr = reduction factor to account for the length of a bolted lap splice connection—given in Table 11 of

Handbook 1 (Ref. 11) but generally 1.0 for normal connections for light bracing members

φVdf = design capacity of a single bolt in shear or bearing on the bracing cleat

= [φVfn or φV fx; 0.9 × 3.2tidffui]min

fui = tensile strength of cleat component (see Table 2)

ti = thickness of cleat component

df = bolt diameter

φVfn = design capacity in shear for bolt with threads included in the shear plane

= 59.3 kN for M16 bolt, 8.8/S category

92.6 kN for M20 bolt, 8.8/S category

133 kN for M24 bolt, 8.8/S category

φVfx = design capacity in shear for bolt with threads excluded from shear plane

= 82.7 kN for M16 bolt, 8.8/S category

129 kN for M20 bolt, 8.8/S category

186 kN for M24 bolt, 8.8/S category

NOTE: Threads are normally assumed to be included in the shear plane unless specifically detailed so that they can

be considered excluded (refer to Design Guide 1—Ref. 12). Design capacities of bolts in shear taken from Table 10

of Handbook 1 (Ref. 11).

18 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

9 RECOMMENDED DESIGN MODEL 9.2 DESIGN CHECK No. 2—Design

PART A CONNECTED BRACE IN capacity due to end plate

TENSION tearout in bracing cleat

Design capacity due to end plate tearout in bracing cleat, N b

where

Nb = nbk r(φVen)

nb = total number of bolts in bracing cleat

kr = reduction factor to account for the length of a bolted lap splice connection—given in Table 11 of

Handbook 1 (Ref. 11) but generally 1.0 for normal connections

φVen = 0.9aetifui

fui = tensile strength of cleat component (see Table 2)

ti = thickness of cleat component

ae = minimum distance from edge of a hole to the edge of the cleat measured in the direction of the

axial tension force plus half the bolt diameter (d f)

= [ae1; ae2 ]min

= ae1

ae1 = (ae – 1) (Figures 8(a), 8(b), 8(c))

ae2 = (s p – 0.5dh – 1) (Figures 8(a), 8(c))

dh = hole diameter s p = bolt pitch

ae = distance from centre-line of hole to edge (Figures 8(a), 8(b), 8(c))

FIGURE 8 DETAILING OF BOLT HOLES IN BRACING CLEAT

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 19

9 RECOMMENDED DESIGN MODEL 9.3 DESIGN CHECK No. 3—Design

PART A CONNECTED BRACE IN capacity of bracing cleat in

TENSION block shear

Design capacity of bracing cleat in block shear, N c

where

Nc = φ[A ntfui + 0.6Agvf yi] Based on discussion in Section 5.4 of Handbook 1 (Ref. 11)

φ = 0.75 (see Handbook 1—Reference 11)

fui = tensile strength of cleat component (see Table 2)

fyi = yield stress of cleat component (see Table 2)

Agv = gross area subject to shear (see Figure 10)

Agt = gross area subject to tension

Ant = net area subject to tension = Agt – allowance for holes (diameter = dh) (see Figure 10)

ti = thickness of cleat component

The general definitions of areas Ant, A gv are shown in Figure 9 (taken from Figure 50 in Handbook 1).

A nt = (l t – (n h – 1)d h )t i

A gv = l vt i

n h = no. of holes in vertical line

d h = hole diameter

FIGURE 9 BLOCK SHEAR FAILURE AREA

Specific formulae for Ant, Agv for typical bracing cleat configurations are shown in Figure 10.

A nt = (a e3 – 0.5d h )t i A nt = (a e3 – 0.5d h )t i

A gv = (a e + s p )t i A gv = (a e + 2s p )t i

A nt = (s g – d h )t i A nt = (s g – d h )t i

A gv = (a e + s p )t i A gv = (a e + 2s p )t i

FIGURE 10 DEFINITIONS OF GROSS SHEAR AREA AND NET TENSION AREA

20 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

9 RECOMMENDED DESIGN MODEL 9.4 DESIGN CHECK No. 4—Design

PART A CONNECTED BRACE IN capacity of bracing cleat in

TENSION axial tension

Design capacity of bracing cleat in axial tension, Nd

where

Nd = [Ndy; Ndf]min

Ndy = design capacity in axial tension – yield check

= 0.9bitifyi

Ndf = design capacity in axial tension – fracture check

= 0.9 × 0.85 × 1.0 × (bi – ngdh)tifui

bi = width of component

fyi = yield stress of component (Table 2)

ti = thickness of component

fui = tensile strength of component (Table 2)

ng = number of holes of diameter dh across component at gauge sg (either 1 or 2 in Figure 10)

dh = hole diameter

Bracing cleats may be cut from Grade 250 plate or may be cut from a Grade 300 flat bar. Yield stress (fyi )

and tensile strength (fui ) for usual cleat thickness (ti ) are as set out in Table 2.

TABLE 2

BRACING CLEAT MATERIAL STRENGTHS

Strength of plate to Strength of flat bars to

AS/NZS 3678 (Ref. 9) AS/NZS 3679.1 (Ref. 10)

Grade 250 Grade 300

Thickness of Yield Tensile Thickness Yield Tensile

plate stress strength of bar stress strength

mm MPa MPa mm MPa MPa

≤8 280 410 < 11 320 440

> 8, ≤ 12 260 410 ≥ 11, ≤ 17 300 440

> 12, < 40 250 410 > 17 280 440

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 21

9 RECOMMENDED DESIGN MODEL 9.5 DESIGN CHECK No. 5—Design

PART A CONNECTED BRACE IN capacity of weld to support

TENSION

FILLET WELDS

Design capacity of weld to support, Ne

where

Ne = 2Lwφvw (fillet welds both sides of cleat)

Lw = length of weld to support (Figure 4 = bi/cosθ, bi = component width)

φvw = design capacity of fillet weld per unit length of weld (Table 23 of Handbook 1, also see

below)

Expression for N e based on formula derived in Section 11 of Handbook 1 (Ref. 11).

Welds are fillet welds and, for economy, should be sized to be single pass welds if possible—this generally

means 6 mm or 8 mm fillet welds, although some welding procedures will allow 10 mm single pass fillet

welds to be deposited. Check individual situations using 10 mm fillet welds with fabricator before specifying.

Welds would normally be weld category SP.

For weld category SP, φv w = 0.835 kN/mm E41/W40X electrodes, 6 mm fillet

= 0.978 kN/mm E48/W50X electrodes, 6 mm fillet

= 1.11 kN/mm E41/W40X electrodes, 8 mm fillet

= 1.30 kN/mm E48/W50X electrodes, 8 mm fillet

BUTT WELDS

No design check is necessary provided weld complies with AS 4100 (Ref. 6) and AS/NZS 1554.1 (Ref. 24)

and weld is SP category. Compliance with these two Standards ensures that weld metal strength matches

or exceeds the strength of bracing cleat. Supporting member should be Grade 300 for Grade 250/300

bracing cleat and Grade 350 for Grade 350 bracing cleat for assumption to be valid.

22 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

9 RECOMMENDED DESIGN MODEL 9.6 DESIGN CHECK No. 6—Design

PART A CONNECTED BRACE IN capacity of supporting member

TENSION locally at cleat location

9.6.1 Connection to column flange in line with web

FIGURE 11 SUPPORTING COLUMN LOCAL CAPACITY

—CONNECTION IN LINE WITH WEB

No assessment necessary.

9.6.2 Connection to web of I-section column from one side or web of I-section beam from one side

FIGURE 12 BRACING CLEAT CONNECTED TO ONE SIDE OF I-SECTION WEB

Design capacity of web of I-section, Nf

where

f yc t c2 [bi + 12t c ]

Nf = 0. 9

d1 cos θ

d1 = clear depth between flanges of I-section

tc = web thickness of I-section

fyc = yield stress of I-section web

bi = width of component

ti = thickness of component

θ = angle of inclination defined in Figure 4

Based on discussion in Section 5.11 of Reference 1, which is in turn based on simplified elastic analysis in

Blodgett (Ref. 25).

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 23

9.6.3 Connection to both sides of web of I-section column or beam

Design capacity of web as given in Section 9.6.2.

Design force is any out-of-balance tension force on the two bracing cleats assuming both cleats come in at

same location and are approximately of equal lengths.

9.6.4 Connection to face of rectangular hollow section

FIGURE 13 BRACING CLEAT CONNECTED TO

FACE OF RECTANGULAR HOLLOW SECTION

Design capacity of face of hollow section, N f

where

Nf = [Nf1; Nf2]min

Nf1 = design capacity due to face shear capacity

= 0.9 × 2 × (0.6fycbvtc)/sinθ

Nf2 = design capacity due to face yielding capacity

=

(

f yc t c2 2η + 4 1 − β ) for

bc

≤ 30

1− β cos θ tc

fyc = yield stress of hollow section face

bc = width of hollow section face to which bracing cleat is attached

bv = width of projection of bracing cleat to face

= bi / cosθ (Fig. 13)

tc = thickness of face of hollow section

θ = angle of inclination (Fig. 13)

β = ti/bc

η = bv/bc

ti = thickness of bracing cleat

bi = width of bracing cleat

Based on Section 6.2.1 of Reference 2.

24 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

9.6.5 Connection to face of circular hollow section

FIGURE 14 BRACING CLEAT CONNECTED TO

FACE OF CIRCULAR HOLLOW SECTION

Design capacity of face of hollow section, N f

where

Nf = [Nf1; Nf2]min

Nf1 = design capacity due to shear capacity

= 0.9 × 2 × (0.6fycbvtc)/sinθ

Nf2 = design capacity due to yielding capacity

2 (1 + 0.25η)f (n′) provided η ≤ 4.0

= 5.0fyc t c

cos θ

fyc = yield stress of circular hollow section

bv = width of projection of bracing cleat

= bi / cosθ (Fig. 14)

tc = thickness of circular hollow section

θ = angle of inclination (Fig. 14)

do = diameter of CHS section

η = bv / d o

f (η′) = 1.0 (CHS column unloaded or in axial tension)

= 1 + 0.3n ′ − 0.3n ′ 2 for n ′ < 0 (CHS column in axial compression)

⎛ N 0* p M 0* ⎞

n′ = ⎜⎜

− + ⎟

⎝ N s′ M s′ ⎟⎠

N 0* p = design preload (i.e. additional axial compression in CHS column at connection other than that

required to maintain equilibrium with bracing cleat expressed as an absolute value)

N s′ = fyAg (for CHS column)

M 0* = design bending moment in CHS column at bracing cleat location

M s′ = fyZ0 (for CHS column)

Ag = gross area of cross-section of CHS column

Z0 = elastic section modulus of CHS column

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 25

10 RECOMMENDED DESIGN MODEL 10.1 DESIGN CHECK No. 7—Design

PART B CONNECTED BRACE IN capacity of bolts in shear and

COMPRESSION bearing

Design capacity of bolts in shear and bearing, N g

where

Ng = nbkr(φVdf)

nb = total number of bolts in bracing cleat

kr = reduction factor to account for the length of a bolted lap splice connection—given in Table 11 of

Handbook 1 (Ref. 11) but generally 1.0 for normal connections for light bracing members

φVdf = design capacity of a single bolt in shear or bearing in the bracing cleat

= [φVfn or φVfx; 0.9 × 3.2tidffui]min

fui = tensile strength of cleat component (see Table 2)

ti = thickness of cleat component

df = bolt diameter

φVfn = design capacity in shear for bolt with threads included in the shear plane

= 59.3 kN for M16 bolt, 8.8/S category

92.6 kN for M20 bolt, 8.8/S category

133 kN for M24 bolt, 8.8/S category

φVfx = design capacity in shear for bolt with threads excluded from shear plane

= 82.7 kN for M16 bolt, 8.8/S category

129 kN for M20 bolt, 8.8/S category

186 kN for M24 bolt, 8.8/S category

NOTE: Threads are normally assumed to be included in the shear plane unless specifically detailed so that they can

be considered excluded (refer to Design Guide 1—Ref. 12). Design capacities of bolts in shear taken from Table 10

of Handbook 1 (Ref. 11).

26 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

10 RECOMMENDED DESIGN MODEL 10.2 DESIGN CHECK No. 8—Design

PART B CONNECTED BRACE IN capacity of bracing cleat under

COMPRESSION eccentric compression force

Design capacity of bracing cleat under eccentric compression force, N h

where

φM syi

Nh =

[e d + φM syi / N cc ]

Based on Clause 8.4.4.1 of AS 4100 for bracing cleat subject to compression force and bending moment

about minor axis.

where

φM syi = 0.9f yi bi t i2 / 4

ed = eccentricity applicable to bracing cleat for design purposes (see below)

Ncc = design capacity of bracing cleat in axial compression (see below)

fyi = yield stress of cleat component (see Table 2)

bi = width of cleat component

ti = thickness of cleat component

The design eccentricity (e d) is defined as follows:

(a) Double angle brace member ed = 0

(b) Single angle brace member (Figure 15)

FIGURE 15 ECCENTRICITY FOR SINGLE ANGLE BRACE MEMBER

ed = kee

(I / L )cleat ≥ 0.10

ke =

(I / L )cleat + (I / L )angle + (I / L )cleat at other end

Icleat = bi t i3 / 12

Lcleat = di in Figure 15

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 27

(c) Flattened end to CHS brace member (Figure 16)

FIGURE 16 END DETAIL FOR FLATTENED END TO CHS BRACE MEMBER

ed = kee

(I / L )cleat

≥ 0.10

ke =

(I / L )cleat + (I / L )chs + (I / L )cleat at other end

Icleat = bi t i3 / 12

Lcleat = di in Figure 16

(d) Fabricated tee or fitted fin plate end connection to hollow section brace member (Figure 17)

FIGURE 17 END DETAILING FOR FABRICATED TEE AND FITTED FIN PLATE

END CONNECTIONS TO HOLLOW SECTION BRACE MEMBERS

ed = 0.5e

e = (ti + tj) / 2

Design capacity of bracing cleat under axial compression, N cc

where

Ncc = 0.9αcNs ≤ 0.9 Ns (AS 4100 Clause 6.3.3)

Ns = nominal section capacity in axial compression

= bitifyi (AS 4100 Clause 6.2 taking kf = 1.0 and

assuming all holes are filled with bolts)

bi = width of cleat component

ti = thickness of cleat component

fyi = yield stress of cleat component (see Table 2)

28 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

αc = the member slenderness reduction factor (AS 4100, Clause 6.3.3)

⎧ ⎡ ⎛ 90 ⎞ 2 ⎤ ⎫⎪

⎪

= ⎨1 −

ξ ⎢1 − ⎜⎜ ⎟⎟ ⎥ ⎬

⎪ ⎢⎣ ⎝ ξλ ⎠ ⎥⎦ ⎪

⎩ ⎭

⎛ λ ⎞2

⎜ ⎟ +1 + η

⎝ 90 ⎠

ξ = 2

⎛ λ ⎞

2⎜ ⎟

⎝ 90 ⎠

λ = λn + αaαb

η = 0.00326(λ– 13.5) ≥ 0

⎛ le ⎞ ⎛ f yi ⎞

λn = ⎜⎜ ⎟⎟ ⎜ ⎟ since k f = 1.0

⎜ 250 ⎟

⎝r ⎠ ⎝ ⎠

2100(λ n − 13.5 )

αa =

λ2n − 15.3λ n + 2050

αb = the appropriate member section constant given in Table 6.3.3(1) of AS 4100

= 0.5 (other sections)

r = t i2 / 12

le = effective length defined in Figure 18, based on Figure 4.6.3.2 of AS 4100

(a) Angle as bracing member

(b) Hollow section as bracing member. End connection either type shown in Figure 2

—flattened end circular hollow section

—tee section welded to cap plate

—fin plate fitted to slot in hollow section

Assumption is that both ends are fixed and can sway laterally

FIGURE 18 EFFECTIVE LENGTH OF CLEAT

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 29

10 RECOMMENDED DESIGN MODEL 10.3 DESIGN CHECK No. 9—Design

PART B CONNECTED BRACE IN capacity of weld to support

COMPRESSION

FILLET WELDS

Design capacity of weld to support, N i

where

2Lw φv w

Ni = ⎡ 2ed ⎤

⎢1 + ⎥

⎣ ti ⎦

Lw = length of weld to support (Figure 4 = bi/cosθ, bi = component width)

ed = eccentricity defined in DESIGN CHECK NO. 8

ti = thickness of cleat component

φvw = design capacity of fillet weld per unit length of weld (Table 23 of Handbook 1, also see below)

Expression for N i based on formula derived in Section 11 of Handbook 1 (Ref. 11).

Welds are fillet welds and, for economy, should be sized to be single pass welds if possible—this generally

means 6 mm or 8 mm fillet welds, although some welding procedures will allow 10 mm single pass fillet

welds to be deposited. Check individual situations using 10 mm fillet welds with fabricators before

specifying. Welds would normally be weld category SP.

For weld category SP, φv w = 0.835 kN/mm E41/W40X electrodes, 6 mm fillet

= 0.978 kN/mm E48/W50X electrodes, 6 mm fillet

= 1.11 kN/mm E41/W40X electrodes, 8 mm fillet

= 1.30 kN/mm E48/W50X electrodes, 8 mm fillet

= 1.39 kN/mm E41/W40X electrodes, 10 mm fillet

= 1.63 kN/mm E48/W50X electrodes, 10 mm fillet

BUTT WELDS

No design check is necessary provided weld complies with AS 4100 (Ref. 6) and AS/NZS 1554.1 (Ref. 24)

and weld is SP category. Compliance with these two Standards ensures that weld metal strength matches

or exceeds the strength of bracing cleat. Supporting member should be Grade 300 for Grade 250/300

bracing cleat and Grade 350 for Grade 350 bracing cleat for assumption to be valid.

30 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

10 RECOMMENDED DESIGN MODEL 10.4 DESIGN CHECK No. 10—Design

PART B CONNECTED BRACE IN capacity of supporting member

COMPRESSION locally at cleat location

10.4.1 Connection to column flange in line with web

FIGURE 19 SUPPORTING COLUMN LOCAL CAPACITY—

CONNECTION IN LINE WITH WEB

No assessment necessary.

10.4.2 Connection to web of I-section column from one side or web of I-section beam from one side

FIGURE 20 BRACING CLEAT CONNECTED TO ONE SIDE OF I -SECTION WEB

Design capacity of web of I -section, Nj

where

f yc t c2 [bi + 12t c ]

Nj = 0. 9

d1 cos θ

d1 = clear depth between flanges of I-section

tc = web thickness of I-section

fyc = yield stress of I-section web

bi = width of component

ti = thickness of component

θ = angle of inclination defined in Figure 4

Based on discussion in Section 5.11 of Reference 1, which is in turn based on simplified elastic analysis in

Blodgett (Ref. 25).

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 31

10.4.3 Connection to both sides of web of I-section column or beam

Design capacity of web as given in Section 10.4.2.

Design force is any out-of-balance compression force on the two bracing cleats assuming both cleats come

in at same location and are approximately of equal lengths.

10.4.4 Connection to face of rectangular hollow section

FIGURE 21 BRACING CLEAT CONNECTED TO

FACE OF RECTANGULAR HOLLOW SECTION

Design capacity of face of hollow section, N j

where

Nj = [Nj1; Nj2]min

Nj1 = design capacity due to face shear capacity

= 0.9 × 2 × (0.6fycbvtc)/sinθ

Nj2 = design capacity due to face yielding capacity

=

(

f yc t c2 2η + 4 1 − β ) for

bc

≤ 30

1− β cos θ tc

fyc = yield stress of hollow section face

bc = width of hollow section face to which bracing cleat is attached

bv = width of projection of bracing cleat to face

= bi/ cosθ (Fig. 21)

tc = thickness of face of hollow section

θ = angle of inclination (Fig. 21)

β = ti/bc

η = bv/bc

ti = thickness of bracing cleat

bi = width of bracing cleat

Based on Section 6.2.1 of Reference 2.

32 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

10.4.5 Connection to face of circular hollow section

FIGURE 22 BRACING CLEAT CONNECTED TO

FACE OF CIRCULAR HOLLOW SECTION

Design capacity of face of hollow section, N j

where

Nj = [Nj1; Nj2]min

Nj1 = design capacity due to shear capacity

= 0.9 × 2 × (0.6fycbvtc)/sinθ

Nj2 = design capacity due to face yielding

2 (1 + 0.25η)f (n ′) provided η ≤ 4.0

= 5.0f yc t c

cos θ

fyc = yield stress of circular hollow section

bv = width of projection of bracing cleat to face

= bi / cosθ (Fig. 22)

tc = thickness of circular hollow section

θ = angle of inclination (Fig. 22)

do = diameter of CHS section

η = bv/do

f (η′) = 1.0 (CHS column unloaded or in axial tension)

= 1 + 0 . 3n ′ − 0 . 3n ′ 2 for n ′ < 0 (CHS column in axial compression)

⎛ N 0* p M 0* ⎞

n′ = − ⎜⎜ + ⎟

⎟

⎝ N s

′ M ′

s ⎠

N 0* p = design preload (i.e. additional axial compression in CHS column at connection other than that

required to maintain equilibrium with bracing cleat expressed as an absolute value)

N s′ = fyAg (for CHS column)

M 0* = design bending moment in CHS column at bracing cleat location

M s′ = fyZ0 (for CHS column)

Ag = gross area of cross-section of CHS column

Z0 = elastic section modulus of CHS column

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 33

11 MULTIPLE BRACING MEMBERS CONNECTED TO A SINGLE GUSSET PLATE

The common method for the design of cleats/gussets with multiple bracing members connected—as in

Figure 1(b), (c) and (d)—is based on treating each bracing member as being connected to an individual

bracing cleat whose width is defined by the ‘Whitmore section’.

Whitmore (Ref. 26) investigated the stress distribution in gusset plates and concluded that an effective

section obtained by a dispersion of 30 degrees from the first to the last line of bolts (as in Fig. 23) could be

used. Stresses in the gusset plate can be calculated by dividing the axial force in the bracing member by

the Whitmore effective cross-sectional area. Support for the Whitmore approach may be found in

References 27 to 29, as reviewed in Reference 1.

FIGURE 23 WHITMORE SECTION

The design approach recommended by Whitmore fits easily into the recommended design models of

Sections 9 and 10, since each brace member can be considered as being connected to a bracing cleat

whose area is equal to the ‘Whitmore section’ multiplied by the cleat thickness. For the case of three

members attached to a single gusset plate, each with at least two rows of bolts in the end connection—as in

Figure 24—the Whitmore sections are readily determined using Figure 23. If there is any overlap resulting

from the projection at 30 degrees, the Whitmore sections so obtained should be reduced to avoid any such

overlap.

Note that the Whitmore recommendation of a 30 degree spread cannot be applied directly to the common

two bolt end connections used at the ends of many light bracing members, but the Whitmore section would

still be defined as the distance between the bolt columns in such cases.

Figure 25 shows some typical end connections where two or three bracing members connect to the same

gusset plate. A suggested assignment of effective areas is made so that for each bracing member, part of

the gusset plate is assigned to allow the use of the Recommended Design Models of Sections 9 and 10 of

this publication.

Another alternative is to carry out a finite element analysis of the gusset plate—a far more involved

procedure.

34 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

FIGURE 24 APPLICATION OF WHITMORE SECTION

TO MULTIPLE MEMBER GUSSET PLATES

FIGURE 25 ASSIGNMENT OF AREAS ON GUSSET PLATE

FOR 2-BOLT END CONNECTIONS

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 35

The effective area concept is suited to all the DESIGN CHECKS in Sections 9 and 10 except for DESIGN

CHECKS 5 and 9 for the weld group and DESIGN CHECKS 6 and 10 for the supporting member, because

for these checks the resultant of the all the brace forces should be designed for when multiple brace

members connect to the same gusset plate.

For the weld group to the supporting member, the brace member forces need to be resolved into six (6)

possible design actions as shown in Figure 26 so that the weld group and the supporting member are

subject to:

—a resultant shear force Fx*

—a resultant axial force Fz*

—a resultant moment M y* due to eccentricity of Fx* and Fz* force components relative to weld group

centroid.

—normally zero values for Fy* , M z* , M x*

Revised DESIGN CHECKS 5 and 9 can then be derived from Section 4.10 of Handbook 1 (Ref. 11) as

follows:

FIGURE 26 DESIGN ACTIONS ON GUSSET PLATE WELD

Governing design equation

(v ) + (v ) + (v )

*

≤ φv w = φ(0.6fuw t t )

v res = * 2 * 2 * 2

x y z

v y* = 0 since Fy* = 0, M z* = 0

v x* = Fx* / (2Lw ) since M z* = 0

Fz* M y* (± 0.5L w )

v z* = − since M x* = 0

2L w I wy

where: I wy = L3w / 6

36 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

Typical configurations showing how forces from bracing members can be resolved are shown in Figure 27,

where e = eccentricity of Fx* and Fz* force components relative to the weld group centroid.

Fx* = Fx1* + Fx2 Fx* = Fx4* − Fx5*

*

Fx* *

= Fx3

Fz* = Fz2* − Fz1* Fz* = Fz4* − Fz3* Fz* = Fz6* + Fz7* − Fz5*

M y* = Fz1* e1 − Fz2* e 2 M y* = Fz3* e3 − Fz 4 e 4 M y* = – Fz6* e 6 + Fz7* e7

*

(assuming Fz5 goes through

weld group centroid)

FIGURE 27 DESIGN ACTIONS FOR MULTIPLE BRACING MEMBERS CONNECTED

TO SINGLE GUSSET PLATE

Existing DESIGN CHECKS 6 and 10 can be used for the supporting member by using the resultant value of

Fz* from Figure 27.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 37

12 HEAVY BRACING CONNECTIONS

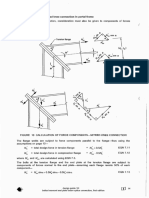

FIGURE 28 BRACING CONNECTIONS WITH MULTIPLE BRACE MEMBERS

USING END PLATE CONNECTION (after Ref. 13)

Heavy bracing connections using I-sections as part of the bracing system (as in Fig. 28) do not fall within

the scope of this publication.

The American Institute of Steel Construction sponsored extensive research into this type of connection,

which included that reported at Reference 29, and recommend the use of the Uniform Force Method (see

Refs 30, 31). The essence of the Uniform Force Method is to select the geometry of the connection such

that bending moments do not exist at three connection interfaces:

—gusset to beam interface

—gusset to column interface

—beam to column interface

The connection can then be designed for shear force and tension or compression as appropriate. Full

details of the method may be found at Reference 30.

38 STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010

13 DESIGN EXAMPLES 13.1 Design example No. 1—End

connection to angle tension

brace

NOTE: Same design example as Section 4.11.3 of Reference 1.

FIGURE 29 END CONNECTION TO ANGLE TENSION BRACE

Design parameters

Design action N t* = 120 kN

Angle brace 100 × 75 × 10UA Grade 300

b1 = 100 mm b 2 = 75 mm tb = 9.5 mm fyb = 320 MPa

Ag = 1580 mm2 An = 1580 – 1 × 22 × 9.5 = 1370 mm 2 fub = 440 MPa

a e2 = 70 – 22/2 –1= 58 mm a e1 = 35 – 1 = 34 mm

Bracing cleat 90 × 10 square edge flat bar, Grade 300

bi = 90 mm ti = 10 mm fyi = 320 MPa fui = 440 MPa

θ = 30° L w = 90/cos 30° = 104 mm

a e2 = 70 – 22/2 –1= 58 mm a e1 = 35 – 1 = 34 mm a e3 = 45 mm

Bolts 3 × M20 bolts, 8.8/S category, threads included in shear plane

df = 20 mm d h = 22 mm s p = 70 mm

φV fn = 92.6 kN k r = 1.0 nb = 3

Welds 6 mm fillet weld, both sides of cleat, L w = 104 mm

weld category SP, E48XX weld metal

φv w = 0.978 kN/mm

Support connected to column flange in line with web as Figure 11.

STEEL CONSTRUCTION VOLUME 43 NUMBER 2 – MARCH 2010 39

Minimum design action

Member design capacity = minimum of: (AS 4100, Clause 7.2 k t = 0.85)

0.9 × 1580 × 320/10 3 = 455 kN

0.9 × 0.85 × 0.85 × 1370 × 440/10 3 = 392 kN

= 392 kN

Minimum design action = 0.3 × 392 = 118 kN < N t* = 120 kN

Adopt N t* = 120 kN

DESIGN CHECK NO. 1

φVdf = minimum of 92.6 kN

0.9 × 3.2 × 10 × 20 × 440 / 103 = 253 kN

Na = 3 × 1.0 × 92.6 = 278 kN

Also check bearing of bolt in angle bracing member

φVdf = minimum of 92.6 kN

0.9 × 3.2 × 9.5 × 20 × 440 / 103 = 241 kN

Na = 3 × 1.0 × 92.6 = 278 kN

DESIGN CHECK NO. 2

min ae = [58, 34]min = 34 mm

φVen = 0.9 × 34 × 10 × 440 / 103 = 135 kN

Nb = 3 × 1.0 × 135 = 404 kN

Also check end plate tearout in angle bracing member

φVen = 0.9 × 34 × 9.5 × 440 / 103 = 128 kN

Nb = 3 × 1.0 × 128 = 384 kN

DESIGN CHECK NO. 3

From Figure 10, Ant = (45 – 0.5 × 22) × 10 = 340 mm2

Agv = (35 + 2 × 70) × 10 = 1750 mm2

Nc = 0.75 × [340 × 440 + 0.6 × 1750 × 320] / 103

= 364 kN

DESIGN CHECK NO. 4

Ndy = 0.9 × 90 × 10 × 320 / 103 = 259 kN

Ndf = 0.9 × 0.85 × 1.0 × (90 – 1.0 × 22) × 10 × 440 / 103 = 229 kN

Nd = [259; 229]min = 229 kN

DESIGN CHECK NO. 5