Beruflich Dokumente

Kultur Dokumente

Vessel Drum Sew DWG

Hochgeladen von

SANGEETHAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vessel Drum Sew DWG

Hochgeladen von

SANGEETHACopyright:

Verfügbare Formate

REF.

STANDARDS & SPECIFICATION :

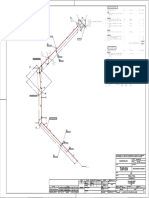

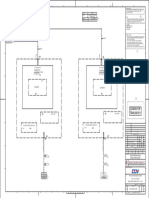

DESIGN DATA : BUFFER SOLUTION MAKE-UP DRUM

22 SL.NO DOCUMENT NO. DESCRIPTION

THK 200

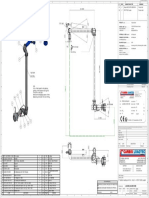

35 ITEM NO : PDO-V-100

TYP 01 KR.E&C.DE.28.(DE/VAM/157-18).2019 REV-0 SPECIAL NOTES FOR SUPPLY OF BUFFER

M SOLUTION MAKE-UP DRUM-PDO-V-100 Design/Construction code ASME SEC VIII DIV 1

02 03/DE/VAM/157-18 REV-0 VESSEL DATA SHEET Fluid composition Water with buffer salts

70

Ø65

N4 Operating Pressure Kg/cm²(a)

TYP

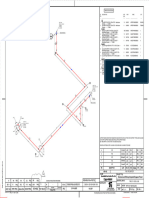

HOLE 03 KR-A4-PDO-03-7430 REV-0 VESSEL NOZZLE LAYOUT 1

35

45°

190

04 2437-PDO-D1-S1/0 REV-0 FABRICATED EQUIPMENT STANDARD DETAILS Design Pressure (process) Kg/cm²g) 3.5

300

T1 N6

05 KR.E&C.DE.19.EL AGITATOR MOTOR DATASHEET Design Vaccum (process) Kg/cm²g) FV

ECT.DATASHEET.ST.2019.03 REV-0 Operating Temperature(maximum) 65°c

444 355 Ø15

Maximum static Head (m) Full of liquid

THK

BAR 40 40 06 2347-PDO-W3-S2/0 REV-0 SELECTION OF SPECIAL MATERIALS AND

20

510

130

FINISHES FOR LP OXO ALCOHOL PLANTS Density of contents Kg/m³ 1100

N3 N7 07 6-12-0001 REV- 5 GENERAL SPECIFICATION FOR PRESSURE Material of construction 304L Stainless steel

5

VESSELS Material of internals 304L Stainless steel

R3

08 6-12-0006 REV- 5 SUPPLEMENTARY SPECIFICATION FOR Corrosion Allowance Shell Nill

190

615

AUSTENITIC STAINLESS STEEL VESSELS Corrosion Allowance fixed internals Nill

130

529

N3 09 6-12-0020 REV- 7 Corrosion Allowance removable internals Nill

STANDARD SPECIFICATION FOR STAINLESS

STEEL PLATES Heat treatment for process Reasons No

L2 N2 10 Insulation (IH/IC/IS/IT/IE/IJ/FP/None) None

1500

6-81-0001 REV- 2 STANDARD SPEC FOR PMI AT SUPPLIERS WORK

11 7-12-0038 REV- 0 ALLOWABLE NOZZLE LOADS Radiography Shell/Head Spot/Full

12 6-12-0014 REV- 1 ITP FOR STAINLESS STEEL PRESSURE Joint Efficiency Shell/Head 0.85/1

VESSELS/ COLUMNS Hydrotest Pressure Kg/cm² Fill With Water At ambient temp

13 6-81-0007 REV-1 ITP FOR BOLTING MATERIAL Stress Relief Nill

L1A

300X300X16THK

14 6-81-0005 REV-3 ITP FOR FORGED , SEAMLESS AND WELDED Insulation Nill

L1B FITTINGS Painting As per specification

400

15 7-12-0001 REV-5 VESSEL TOLERANCES

16 7-12-0015 REV-5 STANDARD BOLT HOLE ORIENTATION

17 7-12-0006 REV-5P ANGLE LEG SUPPORT

18 7-12-0010 REV-6 MANHOLE WITH DAVIT

19 7-12-0026 REV-5 EARTHING LEG

N5

75

20 7-12-0028 REV-5 MANUFACTURER NAME PLATE

21 7-12-0029 REV-5 BRACKET FOR NAME PLATE

25 22 7-12-0018 REV-5 STANDARD SPECIFICATION FOR INTERNAL

60

60

FLANGE

60

23 6-51-0064 REV-0 SPECIFICATION FOR ENERGY EFFICIENT

30

0

N5 MEDIUM VOLTAGE INDUCTION MOTORS

100 24 6-26-0001 REV-3 STANDARD SPECIFICATION FOR MECHANICAL

N3 N4 AGITATORS

NOZZLE SCHEDULE :

623

522

FLANGES

NOZZLE

50 S.F

SERVICE QTY SIZE SCH TYPE/ PROJ. RF/PAID

MARK

INCH /THK RATING FACE FINISH REF. W/THK

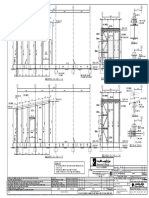

N1 Liquid Outlet 1 2" 160 300# WNRF 623

N2 Liquid inlet 1 3" 160 300# WNRF 1100 190ODX115IDX10THK

N2 L1A 81

N3 Solid Inlet 1 8" 80 S 150 # WNRF 522 360ODX265IDX10THK

N4 Gas vent 1 2" 160 300 # WNRF 493

125 AARH

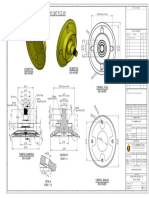

N5 Agitator 1 14" 160 150 # SORF 624

150

N6 Utility Connection 1 2" 160 150 # WNRF 1100

N7 Sample Point 1 2" 160 150 # WNRF 1100

L1 A Level 1 3" 160 150 # WNRF 1100 190ODX115IDX10THK

ID 1900 X 10THK

L1 B Level 1 3" 160 150 # WNRF 1100 190ODX115IDX10THK

L2 Level 1 2" 160 300 # WNRF 1100

T1 Temperature 1 2" 160 150 # 1100

WNRF

2400 T.L TO T.L

Tapping

250

M1 Man Hole 1 24" 160 150 # SORF 1091 300WX10THK

250

150

150

M

150

150

N6

N7 L1B L2 T1

DDDDDDDDDDDDD

250 250

119 HANDLES 02 Ø20 x 320 LG SS 304L

118 PIPE M1 01 OD 616X 10THK X 195LG SA 240 GR 304L

1500

117 R.F PAD M1 01 360WIDTH X10THK SA 240 GR 304L

N1

116 STUD WITH NUTS M1 20+2

115 GASKET M1 1+2 600NB X 150# STD. SPWD

114 BLIND FLANGE MI 01 600NB X 150# BLRF. SA 182 GR 304L

113 FLANGE M1 01 600NB X 150# SORF. SA 182 GR 304L

112 EARTHING LUG 02 100 X 75 X 10THK. SS 304L

400

111 SUPPORT PLATE 02 22THK. X 30 X 190LG. SA 182 GR 304L

110 BAR 02 Ø15 X120 LG. SA 182 GR 304L

109 LIFTING LUG 02 22THK. X 200 X 510LG. SS 304L

108 FLUSH BOTTOM VALVE 01

107 BAFFLE 04 170 WIDTH X 2400LG. SA 240 GR 304L

106 COVER PLATE 04 150X150X6THK SS 304L

105 RF PAD FOR LUG 04 300W X 10THK X 325LG SS 304L

104 BASE PLATE 04 300X300X16THK SS 304L

103 ANGLE LEG SUPPORT 04 150 X 150 X 12THK SS 304L

70° 102 DISH END 02 10THK. X 1920 OD. SA 240 GR 304L

FPW 101 SHELL 01 10THK.X1920OD.X2400LG. SA 240 GR 304L

SL DESCRIPTION QTY. SIZE MATERIAL WT.

MATERIAL SPECIFICATION

2/3

1/3

1.6

2

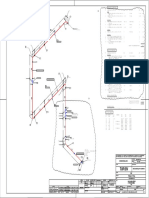

SANGEETHA ENGINEERING WORKS (P)LTD.

10 t

10 t

1.6 KUREEKKAD, ERNAKULAM-682305.

2

2/3

1/3

TITLE:

DATE: --/--/-- --/--/--

60°

60°

BUFFER SOLUTION MAKE UP DRUM DRAWN. MANEESH SEW:

CLIENT:

M/S.BPCL-KOCHI REFINERY CHKD. RR RATHEESH

P.O.NO:4507279410 DATE:06/06/2019 APPRD. CLIENT. BPCL.

PROJ: SHEET-A1

DRG.NO: SEW / 18-19 /18 REV:01 SCALE : AS NOTED

1 OF 2

REF.DRG.NO: ALL DIMENSIONS ARE IN mm

R6

35

Ø6

R3

3(TYP.)

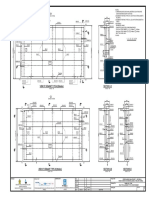

SANGEETHA ENGINEERING WORKS (P) LTD.

R8

80

200NB

62

110

62 30 50

6 2

18 52 30 50 30 18

50NB

80NB

80NB

200

230

5 15

R3

20

142

THK.

TYP.

5

10

16

50NB

tn tn

45°

35°

2 15

tp

2

1.6 SANGEETHA ENGINEERING WORKS (P)LTD.

2

R3 R3

KUREEKKAD, ERNAKULAM-682305.

1.6

TITLE:

DATE: --/--/-- --/--/--

5

30° BUFFER SOLUTION MAKE UP DRUM DRAWN. MANEESH SEW:

2

CLIENT:

M/S.BPCL-KOCHI REFINERY CHKD. RR RATHEESH

P.O.NO:4507279410 DATE:06/06/2019 APPRD. CLIENT. BPCL.

PROJ: SHEET-A1

DRG.NO: SEW / 18-19 /18 REV:01 SCALE : AS NOTED

2 OF2

REF.DRG.NO: ALL DIMENSIONS ARE IN mm

Das könnte Ihnen auch gefallen

- Clarifier Tank Layout - 250 CMH PDFDokument1 SeiteClarifier Tank Layout - 250 CMH PDFepe civil1Noch keine Bewertungen

- Tupi BV: Cosco (Dalian)Dokument2 SeitenTupi BV: Cosco (Dalian)Robles DreschNoch keine Bewertungen

- Punj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Dokument1 SeitePunj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Saptarshi MandalNoch keine Bewertungen

- Tank Datasheet - CS-8000KL - RADokument1 SeiteTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNoch keine Bewertungen

- La253x.ca100v-008 R02Dokument2 SeitenLa253x.ca100v-008 R02Ricardo TurinNoch keine Bewertungen

- Acc 5100 00012 01Dokument1 SeiteAcc 5100 00012 01Saptarshi MandalNoch keine Bewertungen

- 4139M06017 Default 000Dokument1 Seite4139M06017 Default 000gopi krishnaNoch keine Bewertungen

- Piping Isometric - 4Dokument1 SeitePiping Isometric - 4CosminMarianNoch keine Bewertungen

- Filtered Water Piping Supports - VERIFDokument14 SeitenFiltered Water Piping Supports - VERIFBMWGNoch keine Bewertungen

- Tupi BV: Cosco (Dalian)Dokument2 SeitenTupi BV: Cosco (Dalian)Robles DreschNoch keine Bewertungen

- BBS BorpileDokument1 SeiteBBS BorpileSurya Bintang RamadhanaNoch keine Bewertungen

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Dokument1 Seite10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanNoch keine Bewertungen

- Training-1: 01 Issued For Training RK RK RKDokument4 SeitenTraining-1: 01 Issued For Training RK RK RKJuan Luis FerretNoch keine Bewertungen

- 2023-01-24 - GROUND FLOOR - CENTERLINE-ModelDokument1 Seite2023-01-24 - GROUND FLOOR - CENTERLINE-ModelPranay GandhiNoch keine Bewertungen

- 8460cb20-40h Drawing 1Dokument1 Seite8460cb20-40h Drawing 1Janos HallaNoch keine Bewertungen

- 066504u58271 004 004-ADokument1 Seite066504u58271 004 004-ADINESH VNoch keine Bewertungen

- Disc Holder CMT FCD 45Dokument1 SeiteDisc Holder CMT FCD 45ILHAMNoch keine Bewertungen

- 153015.11 - R0 - Water Tank (DT) 7,500L - AssyDokument1 Seite153015.11 - R0 - Water Tank (DT) 7,500L - AssyLucky PradanaNoch keine Bewertungen

- 4327d Wistron DMB40 (BMW-Z4-DIS) 11289-1 Dell Inspiron 14z-5423Dokument105 Seiten4327d Wistron DMB40 (BMW-Z4-DIS) 11289-1 Dell Inspiron 14z-5423Fausto DavidNoch keine Bewertungen

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Dokument1 SeiteR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNoch keine Bewertungen

- 03 Structural 1538212476908Dokument14 Seiten03 Structural 1538212476908Fadi AlatrashNoch keine Bewertungen

- Tupi BV: Cosco (Dalian)Dokument1 SeiteTupi BV: Cosco (Dalian)Robles DreschNoch keine Bewertungen

- Cable M12-Picospox 0.5MDokument1 SeiteCable M12-Picospox 0.5MBoxerpower GasNoch keine Bewertungen

- xDED HARDWARE MANADO REV 03-LGPDokument1 SeitexDED HARDWARE MANADO REV 03-LGPRyan WijayaNoch keine Bewertungen

- La233r1.ca100v-000 R03Dokument1 SeiteLa233r1.ca100v-000 R03Ricardo TurinNoch keine Bewertungen

- (Trafo Katk-85-190-205)Dokument1 Seite(Trafo Katk-85-190-205)Laura Sofía VélezNoch keine Bewertungen

- Ifc - Issued For Construction: AngloamericanDokument2 SeitenIfc - Issued For Construction: AngloamericanJOSE LUIS TENORIO ARENASNoch keine Bewertungen

- Fw-211-1001-U-06 Ems-A1-20100-Axxx-1001 10160-Ewp-Dau-Ug-000-20101Dokument1 SeiteFw-211-1001-U-06 Ems-A1-20100-Axxx-1001 10160-Ewp-Dau-Ug-000-20101BADDY BADDYNoch keine Bewertungen

- Annexure-10 GAD of DelCEN2500HvDokument6 SeitenAnnexure-10 GAD of DelCEN2500HvSAEL SOLARNoch keine Bewertungen

- Dew-Point Evaporative Comfort Cooling: Jesse DeanDokument39 SeitenDew-Point Evaporative Comfort Cooling: Jesse DeanNaziman AzlyeNoch keine Bewertungen

- La213x.ca100v-111 R01-CLGDokument1 SeiteLa213x.ca100v-111 R01-CLGRicardo TurinNoch keine Bewertungen

- Foundation of Bore Pile T.08 AA6 +9 Up To +15 Class 6 - Rev-0 (NEN)Dokument1 SeiteFoundation of Bore Pile T.08 AA6 +9 Up To +15 Class 6 - Rev-0 (NEN)RikiNoch keine Bewertungen

- Ist Floor Punch Layout With Beam-Layout1Dokument1 SeiteIst Floor Punch Layout With Beam-Layout1A.K.M Shafiq MondolNoch keine Bewertungen

- Hug 98 104071 CS 2358 00001 0003 01Dokument1 SeiteHug 98 104071 CS 2358 00001 0003 01anandNoch keine Bewertungen

- Detail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermoDokument1 SeiteDetail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermosilviNoch keine Bewertungen

- 13L00501A - 7P-A: General NotesDokument7 Seiten13L00501A - 7P-A: General NotesCLS AKNoch keine Bewertungen

- 13L00501A - 7P-A: General NotesDokument7 Seiten13L00501A - 7P-A: General NotesCLS AKNoch keine Bewertungen

- 239 Albert Replacement Cladding PanelsDokument4 Seiten239 Albert Replacement Cladding PanelsmeghadurganNoch keine Bewertungen

- CM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NoteDokument2 SeitenCM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NotemarklaforestNoch keine Bewertungen

- 2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Dokument1 Seite2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Hassan KhanNoch keine Bewertungen

- 65 93 PR Pid 01090 - 0001 - BDokument1 Seite65 93 PR Pid 01090 - 0001 - BgeocaustasNoch keine Bewertungen

- For Approval: Ceiling Space To Be Airtight by OthersDokument1 SeiteFor Approval: Ceiling Space To Be Airtight by Othersavinash3479Noch keine Bewertungen

- SD.20 Structural Concrete Standards Anchor Bolt DetailsDokument1 SeiteSD.20 Structural Concrete Standards Anchor Bolt DetailsajmainNoch keine Bewertungen

- Comments - Isometric Drawing (Biological Tank)Dokument1 SeiteComments - Isometric Drawing (Biological Tank)Julius ContrerasNoch keine Bewertungen

- Conectores-de-Borna TRAFODokument4 SeitenConectores-de-Borna TRAFOJunior MartinezNoch keine Bewertungen

- Rawabi Project: Design CriteriaDokument1 SeiteRawabi Project: Design CriteriaaliiiiiiiiiiNoch keine Bewertungen

- View of Segmant Type A1 (Extrados) Section C-C: R1k R3k R4k R1k R3k R4kDokument13 SeitenView of Segmant Type A1 (Extrados) Section C-C: R1k R3k R4k R1k R3k R4kChiranjaya HulangamuwaNoch keine Bewertungen

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Dokument11 SeitenEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariNoch keine Bewertungen

- Mackie Big Knob PS SchematicDokument1 SeiteMackie Big Knob PS SchematicPedro CiminiNoch keine Bewertungen

- AD790-A-700-Coordination Drawing - GF 12.12-A700 Part-1Dokument1 SeiteAD790-A-700-Coordination Drawing - GF 12.12-A700 Part-1noufal rafiNoch keine Bewertungen

- PLAN at (-) 4.170 LVL (STAIRCASE-1) PLAN at (-) 8.070 LVL (STAIRCASE-1) Roof Plan (Staircase-1)Dokument1 SeitePLAN at (-) 4.170 LVL (STAIRCASE-1) PLAN at (-) 8.070 LVL (STAIRCASE-1) Roof Plan (Staircase-1)Gavriel NgNoch keine Bewertungen

- Butterfly Valves: B. D. K. Engineering Industries LimitedDokument6 SeitenButterfly Valves: B. D. K. Engineering Industries LimitedRajesh KanalaNoch keine Bewertungen

- Tupi BV: Cosco (Dalian)Dokument3 SeitenTupi BV: Cosco (Dalian)Robles DreschNoch keine Bewertungen

- Detail 2Dokument1 SeiteDetail 2Widad RusdiNoch keine Bewertungen

- Material List - Fabrication: - / - A1ZA-1 2 PMDokument2 SeitenMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNoch keine Bewertungen

- MSI Confidential 00205363 RD (C) 2020112402 劉巍 (00208453) : Dp + Dp + Dp + Hdmi/Dp PG142-B00Dokument54 SeitenMSI Confidential 00205363 RD (C) 2020112402 劉巍 (00208453) : Dp + Dp + Dp + Hdmi/Dp PG142-B00hiệp nguyễn văn (văn-hiệp-pc)Noch keine Bewertungen

- 0417 - 118T3293 Cooling Sealing AirDokument6 Seiten0417 - 118T3293 Cooling Sealing AirfaisalnadimNoch keine Bewertungen

- 312 BDokument2 Seiten312 BДрагиша Небитни Трифуновић50% (2)

- LAY OUT PLAN-Ware House-Structure-RL-1-ModelDokument1 SeiteLAY OUT PLAN-Ware House-Structure-RL-1-ModelAbid AyubNoch keine Bewertungen

- BMMV1013 Lab 2 20212022 2Dokument17 SeitenBMMV1013 Lab 2 20212022 2Blue BeatleNoch keine Bewertungen

- Acid Base Titration-1Dokument18 SeitenAcid Base Titration-1Adia MasooraNoch keine Bewertungen

- O X I D A T Ive Stability of Biodiesel: Gerhard KnotheDokument5 SeitenO X I D A T Ive Stability of Biodiesel: Gerhard KnotheIAMANDU COSTANoch keine Bewertungen

- Quiz MolarmassavogadromoleratiomassempiricalmolecularformulacollaborativeDokument8 SeitenQuiz Molarmassavogadromoleratiomassempiricalmolecularformulacollaborativeapi-233552637Noch keine Bewertungen

- Silicaflex™ Blanket AB PDFDokument4 SeitenSilicaflex™ Blanket AB PDFShaikhRizwanNoch keine Bewertungen

- Bismuth To GoldDokument20 SeitenBismuth To GoldTony Gary67% (3)

- Biogenic Amines by HPLCDokument7 SeitenBiogenic Amines by HPLCNeidys SanchezNoch keine Bewertungen

- G11 Phy CH-8 Study MaterialDokument29 SeitenG11 Phy CH-8 Study MaterialPrasanna VijayakumarNoch keine Bewertungen

- Material BalanceDokument78 SeitenMaterial Balanceusman0553100% (4)

- Thermodynamic Analysis & Enhancement of Cogeneration PlantDokument17 SeitenThermodynamic Analysis & Enhancement of Cogeneration PlantSheri KhosoNoch keine Bewertungen

- Homework 2 SolutionDokument9 SeitenHomework 2 Solutionmohammed el erianNoch keine Bewertungen

- Effect of PH On GFP DenaturationDokument10 SeitenEffect of PH On GFP DenaturationDominic YapNoch keine Bewertungen

- Know Your Cooling SystemDokument103 SeitenKnow Your Cooling SystemgustavoNoch keine Bewertungen

- AQA Chemistry (P 1) June 2018 QPDokument32 SeitenAQA Chemistry (P 1) June 2018 QPNCC Non-Copyright ContentNoch keine Bewertungen

- BCS WHO Classification QAS04 109rev1 Waive Invivo BioequivDokument45 SeitenBCS WHO Classification QAS04 109rev1 Waive Invivo BioequivjjmuruzaNoch keine Bewertungen

- Analysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerDokument7 SeitenAnalysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerSyahriRomadhoniNoch keine Bewertungen

- 3-Ikoku - Natural Gas Production EngineeringDokument271 Seiten3-Ikoku - Natural Gas Production EngineeringIshani GuptaNoch keine Bewertungen

- Cellular EnergyDokument3 SeitenCellular EnergyEvelyn KimNoch keine Bewertungen

- Applications of Fluid Mechanics To Industrial ProblemsDokument55 SeitenApplications of Fluid Mechanics To Industrial ProblemssatyaseshadriNoch keine Bewertungen

- AMV Presentation PDFDokument72 SeitenAMV Presentation PDFAhmad ZaidiNoch keine Bewertungen

- Ammonium Nitrate ExplosivesDokument24 SeitenAmmonium Nitrate ExplosivesManh Loc PhanNoch keine Bewertungen

- 2007 02 16 Valero Refinery Propane FireDokument9 Seiten2007 02 16 Valero Refinery Propane FirePimol SuriyaprasitNoch keine Bewertungen

- Ganesan Book Imp ChapterDokument40 SeitenGanesan Book Imp ChapterParas ChahalNoch keine Bewertungen

- ReferenceDokument2 SeitenReferenceraj_klnceNoch keine Bewertungen

- A Review On Green Hydrogen Future of Green Hydrogen in IndiaDokument7 SeitenA Review On Green Hydrogen Future of Green Hydrogen in IndiaSPE Baghdad sectionNoch keine Bewertungen

- 2 Chemistry of Carbohydrates 2023Dokument80 Seiten2 Chemistry of Carbohydrates 2023Moses MutsikwiNoch keine Bewertungen

- Xu Princeton 0181D 10615Dokument175 SeitenXu Princeton 0181D 10615Sailendra MeherNoch keine Bewertungen

- Chemistry Education and Contributions From History and Philosophy of ScienceDokument260 SeitenChemistry Education and Contributions From History and Philosophy of ScienceEflin WulanNoch keine Bewertungen

- Transcript of IB Chemistry Mind MapDokument8 SeitenTranscript of IB Chemistry Mind MapJayakumar SankaranNoch keine Bewertungen

- Errors in Chemical Analysis - Lecture 3Dokument20 SeitenErrors in Chemical Analysis - Lecture 3Acidri AbdulkarimNoch keine Bewertungen