Beruflich Dokumente

Kultur Dokumente

Re useofPlasticWasteasPalletizedAggregatesforConcreteInfrastructure PDF

Hochgeladen von

Stephany AguilarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Re useofPlasticWasteasPalletizedAggregatesforConcreteInfrastructure PDF

Hochgeladen von

Stephany AguilarCopyright:

Verfügbare Formate

Re-use of Plastic Waste as Palletized Aggregates for Concrete Infrastructure

Abstract

Solid waste management is one of the big issues in Pakistan. Disposal of the solid waste is a major problem for the industry which is increasing day by day throughout the world . However, these wastes can be used in

concrete in the form of coarse aggregate. This research demonstrates the feasibility of beneficial effects that can be achieved by using recycled plastic as replacement of coarse aggregates in concrete. Performance of

concrete mixtures having 5%, 10%, 15% ,20%, 25% & 30% of plastic waste as pelletized coarse aggregate has been investigated. Standard procedures were adopted to determine various strengths and durability tests of

the concrete. The results showed that the replacement of pelletized aggregate beyond 10% affected the properties significantly where as the replacement of pelletized aggregate up to 10% caused no major changes in the

characteristics of concrete.

Introduction

The quantity of solid waste is expanding rapidly. It is estimated that the rate of expansion is doubled every 10 years. This is due to the rapid growth of the population as well as the industrial sector (Phaiboon and Mallika,

2007). In a report, the National Council on Public Works Improvement identified the solid-waste crisis as an area of the infrastructure with great needs for improvement (Rebeiz et al., 1993). The solid-waste crisis is important

from an environmental and economical point of view. As landfill areas are rapidly depleting, the cost of solid-waste disposal is rapidly increasing. The cost for solid-waste management was, on an average, $2.7-3.6/t in 1979.

The cost is now more than $18/t and, in many localities; the cost exceeds $90/t ("Our" 1989, http://5gyres.org/global_research/).

Among the solid-waste materials, plastics have received a lot of attention because they are generally not biodegradable. On a weight basis, there are about 10 billion kg of plastic wastes in the U.S. per year, which

represents about 7% by weight of the total solid wastes (Thayer, 1989). However, plastic wastes are very visible, since they constitute about 30% by volume of the total solid wastes (Kline 1989). (Karim et al., 1992). The

various types of plastics in municipal wastes are Polyethylene terephthalate (PET), High density polyethylene (HDPE), Low density polyethylene (LDPE), Polypropylene(PP), Polystyrene (PS) etc.

The major users of plastic are the packaging industries, consuming about 41%, 20% in building and construction, 15% in distribution and large industries, 9% in electrical and electronic, 7% in automotive, 2% in agriculture

and 6% in other uses. (Zoorob and Suparma, 2000).

Among the various types of plastics, the largest component of the plastic waste is low density polyethylene/linear low density polyethylene (LDPE) at about 23%, followed by 17.3% of high density polyethylene, 18.5% of

polypropylene, 12.3% of polystyrene (PS/extended PS), 10.7% polyvinyl chloride, 8.5% polyethylene terephthalate and 9.7% of other types. (Zoorob and Suparma, 2000).

The use of recycled plastics in concrete is relatively a new development in the world of concrete technology and lot of research must go in before this material is actively used in concrete construction. The use of plastics in

concrete lowered the strength of resultant concrete, therefore, the research must be oriented towards ternary systems that helps in overcoming this drawback of use of plastics in concrete.

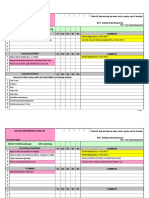

Temperature Variation w.r.t Plastic Waste In

Percentage

Replaced Plastic Waste in Percentage

Rate of

change of 0 % 5% 10 % 15 % 20 % 25 % 30 %

Conducting Split Tensile Test on Cylinders Failure pattern of Control Concrete Failure pattern of Plastic Concrete

temperature

59-34 55-32 55-34 56-36 54-35 52-34 50-33

(T2 - T1)

25 23 21 20 19 18 17

Difference

Total 8 8 8 8 8 8 8

time(hrs)

Plastic Aggregate Thermal Resistivity Apparatus ∆= (T2- T1) / t

3.125 2.875 2.625 2.5 2.375 2.25 2.12

Bulk Density vs Plastic Aggregate

CONCLUSIONS and RECOMMENDATIONS:

1. It is obvious from the results that recycled plastic aggregates may be used as replacement in concrete for

regular aggregates.

2. Although the addition of plastic aggregate decreases the strength of concrete therefore it can only be used

as non-load bearing structural components, such as, partition walls, side walks lean concrete etc.

3. Replacement of pelletized aggregate in concrete increases its ductility.

4. The presence of plastic aggregates in the concrete increases its insulating ability therefore it can be used

in extreme weather conditions.

5. Recycled plastic aggregates (R.P.A) results in light weight concrete

6. Pelletized aggregate can be a solution to reduce the plastic waste.

Principal Investigator: Dr. Khan Shahzada Funding Agency

Co-Principal Investigator: Dr. Gencturk Bora (USA) & Dr. Muhammad Fahad

MSc. Scholar: Engr. Tariq Ali

Research Assistants: Engr. Ahmad Zeb

Engr. M. Umer Khalil

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- List of Thai Exporter MDF and Plywood Products: Medium Density Fibreboard (MDF) HardboardDokument3 SeitenList of Thai Exporter MDF and Plywood Products: Medium Density Fibreboard (MDF) HardboardVlas BogdănNoch keine Bewertungen

- BodyDokument128 SeitenBodyaddisNoch keine Bewertungen

- Technical Data: HST M10, M12, M16Dokument5 SeitenTechnical Data: HST M10, M12, M16Benjaminhuynh08Noch keine Bewertungen

- Building Construction - Viii: Large Span Roof Plan 1 Large Span Roof Isometric 3Dokument1 SeiteBuilding Construction - Viii: Large Span Roof Plan 1 Large Span Roof Isometric 3Vinita KumariNoch keine Bewertungen

- Case 9 ImDokument4 SeitenCase 9 ImPaula Castro BermúdezNoch keine Bewertungen

- Case Study Design of G 4 RCC StructureDokument20 SeitenCase Study Design of G 4 RCC StructureKrishna MurariNoch keine Bewertungen

- History of Shoemaking From Ancient Craft to Mechanized IndustryDokument3 SeitenHistory of Shoemaking From Ancient Craft to Mechanized IndustryJuan Jose100% (1)

- Damp ProofingDokument15 SeitenDamp ProofingKhushboo PriyaNoch keine Bewertungen

- Unified BSR Rural Road PMGSY Rajasthan 20 December 2019Dokument103 SeitenUnified BSR Rural Road PMGSY Rajasthan 20 December 2019Roopesh ChaudharyNoch keine Bewertungen

- BSRIA - Underfloor Heating GuideDokument49 SeitenBSRIA - Underfloor Heating GuidetienlamNoch keine Bewertungen

- Steel Truss Design Eurocode PDFDokument24 SeitenSteel Truss Design Eurocode PDFCarlos Eduardo RodriguezNoch keine Bewertungen

- Ch02 - Manufacturing OperationsDokument55 SeitenCh02 - Manufacturing OperationsHassan MughalNoch keine Bewertungen

- Minor Project 3 Krishna KriplaniDokument78 SeitenMinor Project 3 Krishna KriplaniKriplani KrishnaNoch keine Bewertungen

- Oracle Case StudyDokument12 SeitenOracle Case StudyKalAsh KumarNoch keine Bewertungen

- Koerner - 32 Terzaghi LectureDokument16 SeitenKoerner - 32 Terzaghi LectureJanaki RamNoch keine Bewertungen

- Issues in Managing Manufacturing Flexibility: A ReviewDokument19 SeitenIssues in Managing Manufacturing Flexibility: A Reviewanil kumarNoch keine Bewertungen

- Nalla Crosing PDFDokument1 SeiteNalla Crosing PDFameygandhiNoch keine Bewertungen

- Procurement Monitoring MV HechanovaDokument36 SeitenProcurement Monitoring MV HechanovaHammerman Construction0% (1)

- Midas Gen: Project TitleDokument11 SeitenMidas Gen: Project TitleShadin Asari ArabaniNoch keine Bewertungen

- 8.WMS For Concrete RepairDokument8 Seiten8.WMS For Concrete Repairamol100% (1)

- 27-06-2021 - Money Requisition - Comilla (Jangalia) ProjectDokument1 Seite27-06-2021 - Money Requisition - Comilla (Jangalia) ProjectRupam DebnathNoch keine Bewertungen

- Construction materials standardsDokument9 SeitenConstruction materials standardsHILAL ALSAMANoch keine Bewertungen

- Steel Calculator Brick and Mortar CalculatorDokument12 SeitenSteel Calculator Brick and Mortar CalculatorGopal SudhirNoch keine Bewertungen

- Final Exam CarpentryDokument1 SeiteFinal Exam CarpentryLuis John Villamagno100% (2)

- ASTM C331-2010 Light Weight Aggregates For MasonryDokument4 SeitenASTM C331-2010 Light Weight Aggregates For MasonryHaniAminNoch keine Bewertungen

- Commissioning Process: Presented By: Rodelito "Dodo" J. OcampoDokument24 SeitenCommissioning Process: Presented By: Rodelito "Dodo" J. OcampoMark Barcelona100% (1)

- Qualification and Experience of Key Personnel Proposed For Administration and Executed of The ContractDokument2 SeitenQualification and Experience of Key Personnel Proposed For Administration and Executed of The ContractARSENoch keine Bewertungen

- Design and TechnologyDokument12 SeitenDesign and TechnologyDavid MwapeNoch keine Bewertungen

- Building Maintenance Check ListDokument38 SeitenBuilding Maintenance Check ListMa Soledad Gonzales Bundac100% (1)

- Methodology ShaliPatchDokument6 SeitenMethodology ShaliPatchArun SinghNoch keine Bewertungen