Beruflich Dokumente

Kultur Dokumente

8 13wafercleaningprocess

Hochgeladen von

BINOY BERAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

8 13wafercleaningprocess

Hochgeladen von

BINOY BERACopyright:

Verfügbare Formate

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/334596751

Silicon Wafer Cleaning: A Fundamental and Critical Step in Semiconductor

Fabrication Process

Article · July 2019

CITATIONS

1 author:

Binoy Bera

20 PUBLICATIONS 51 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Acnt and MoS2 Nanosheets View project

Material Synthesis View project

All content following this page was uploaded by Binoy Bera on 23 July 2019.

The user has requested enhancement of the downloaded file.

International Journal of

Applied Nanotechnology

eISSN: 2455-8524 (Online)

Vol. 5: Issue 1

www.journalspub.com

Silicon Wafer Cleaning: A Fundamental and Critical Step in

Semiconductor Fabrication Process

Binoy Bera

1

Department of computer science and engineering, West Bengal University of Technology,

Kolkata – 700064, India

ABSTRACT

Silicon is the most interesting and useful semiconductor material in fabrication of numerous

semiconductor devices. In semiconductor device fabrication, the various processing steps fall

into four general categories i.e. deposition, removal, patterning and modification of

electrical properties. In every step, wafer cleaning is the primary and principle step for

developing semiconductor based electronic devices. Cleaning process is the removal of

chemical and particle impurities without altering or damaging the wafer surface or substrate.

Here in this paper, silicon wafer cleaning procedures has been reviewed in sort. Some basic

concepts about clean room were also described in brief.

Keywords: Semiconductor fabrication, silicon wafer, wafer cleaning, clean room.

*Corresponding Author: berabinoy17@gmail.com

INTRODUCTION grows, coats, otherwise transfers a material

Semiconductor is a solid substance that onto the wafer. Removal is any process

has an electrical conductivity between that like etching and chemical mechanical

of an insulator and conductor. The planarization (CMP) that removes material

defining property of a semiconductor from wafer. Patterning is about shaping or

material is that it can be doped with altering of deposited materials and is

impurities that alter its electronic generally referred to as lithography.

properties in a controllable way. silicon is Finally, modification of electrical

most popular semiconductor material used properties is done by doping impurities in

in developing microelectronics devices. semiconductor material. The objective of

Semiconductor device fabrication is the the wafer cleaning process [1-10] is the

process used to create the integrated removal of chemical and particle

circuits that are present in everyday impurities without altering or damaging

electrical and electronic devices. In the wafer surface or substrate (fig. 1).

semiconductor device fabrication, the Wafer cleaning is done for pre diffusion

various processing steps fall into four clean means which creates a surface that is

general categories such as deposition, free from metallic, particulate and organic

removal, patterning and modification of contaminants, metallic ion removal clean

electrical properties. Deposition is any i.e. remove metallic ion which can have

process like physical vapour deposition detrimental effect on semiconductor [11-

and chemical vapour deposition that 17] device operation, particle removal

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 8

Silicon Wafer Cleaning: A Fundamental and Critical Step Binoy Bera

clean that means in which particle removal solution for 10 minutes and a high pH is

from surface using chemical or mechanical maintained. This methods oxidize organic

scrubbing using megasonic cleaning and contamination (form carbon di-oxide,

post etch clean which remove photo resist water etc ) and form complex such as

and polymers left after etching process. Cu(NH3)4+2 with metals (Au, Ag, Cu, Ni,

Here in this paper, for silicon wafer Zn, Cd, Co, Cr). In this process, Slowly,

cleaning, different procedures such as native oxide is dissolving and grow back

RCA (radio corporation of America) new oxide, which removes particles on

cleaning, SC (standard cleaning) cleaning, oxide. NH4OH is used less because it

ohmi cleaning, megasonic cleaning, etches Si and makes its surface rough. In

ultrasonic cleaning has been discussed in SC-2 method, hydrochloric acid (73%),

brief. hydrogen peroxide (73%) and water is

taken in the ratio of 1:1:6 with temperature

SILICON WAFER CLEANING of 70-800C. The silicon wafer is kept

PROCEDURES immersed in this solution for 10 minutes

RCA cleaning and a low pH is maintained. This method

RCA clean is “standard process” used to is used to remove alkali ions and cations

remove organics, heavy metals and alkali like Al+3, Fe+3 and Mg+2 that form NH4OH

ions from silicon wafer. Here ultrasonic insoluble hydroxide is in basic solutions

agitation is used to dislodge particles. like SC-1. These metals are precipitate

RCA is stands for Radio Corporation of onto wafer surface in the SC-1 solution,

America which now makes TV, stereos while they form soluble complexes in SC-

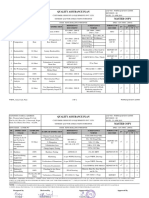

etc. In figure 2, RCA cleaning method is 2 solution. SC-2 is also complete the

discussed. In first step, sulfuric acid and removal of metallic contaminates such as

Au that may not have been completely

hydrogen peroxide is taken in the ratio of

removed by SC-1 step.

1:1 - 1:4. The wafer is kept immersed in

that solutions for 10 minutes with

Ohmi cleaning

temperature of 100-1500C. This process is

Ohmi cleaning is happened in fewer steps

also referred as pirhana cleaning. After

and low temperature condition. Detail

that the wafer is dipped for 1 minute in a

steps of ohmi cleaning process is described

hydrofluoric acid (HF) solutions where in figure 3.

ratio of HF and H2O is 1:10. Finally the

wafer is rinsed with de-ionized water for Megasonic and Ultrasonic cleaning

some fixed time at room temperature. The In megasonic cleaning process,

other two process i.e. SC-1 and SC-2 Mechanical agitation of cleaning fluid by

method is also included in RCA cleaning high-frequency vibrations (between 20 and

process. In every step, the wafer is rinsed 45 kHz) are used to cause cavitation -

with de-ionized water to clean it properly. formation of low-pressure vapor bubbles

that scrub the surface. Higher frequencies

Standard cleaning (>45kHz) form smaller bubbles on the

Standard cleaning is consisting of two surface of silicon wafer, thus it is less

steps i.e. SC-1 and SC-2. In SC-1 method, effective. However, megasonic (1MHz)

ammonium hydroxide (28%), hydrogen cleaning is also found effective in particle

peroxide (30%) and water are taken in the removal. These two processes are highly

ratio of 1:1:5 with temperature of 70-800C. effective for removing surface

The silicon wafer is kept immersed in this contaminants from silicon wafer.

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 9

International Journal of Applied Nanotechnology

eISSN: 2455-8524 (Online)

Vol. 5: Issue 1

www.journalspub.com

Fig. 1. Different types of contaminants, their origin and effects on silicon wafer.

Chemicals Conditions Results

H2SO4/H 2O2 120 - 150ÞC Strips organics

1:1 to 4:1 10 min especially photoresist

HF/H 2O Room T Strips chemical

1:10 to 1:50 1 min oxide

DI H 2O Rinse Room T

NH4OH/H 2O2/H 2O 80 - 90ÞC Strips organics,

1:1:5 to 0.05:1:5 10 min metals and particles

SC-1

DI H 2O Rinse Room T

HCl/H 2O2/H 2O 80 - 90ÞC Strips alkali ions

1:1:6 10 min and metals

SC-2

DI H 2O Rinse Room T

Fig. 2. Detail process of RCA cleaning.

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 10

Silicon Wafer Cleaning: A Fundamental and Critical Step Binoy Bera

Chemicals Conditions Results

Fig. 3. Detail steps involved in ohmi cleaning process.

Fig. 4. ISO equivalent clean room classes.

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 11

International Journal of Applied Nanotechnology

eISSN: 2455-8524 (Online)

Vol. 5: Issue 1

www.journalspub.com

Fig. 5. FED STD 209E equivalent clean room classes.

Clean Room organics present in the silicon wafer.

Clean room is a place where all these Cleaning is comprising roughly one fourth

cleaning process happened and where (1/4) of any integrated circuit fabrication

provisions are made to reduce particulate process. Here in this paper, some standard

contamination. All the parameters such as clean room classifications [20] were also

temperature, humidity and pressure are described in brief.

controlled in a clean room by using some

key components i.e. high efficiency REFERENCES

particulate air (HEPA) filter and ultra-low [1] T. Takahagi, I. Nagai, A. Ishitani, H.

particulate air (ULPA) filter. Clean room Kuroda, and Y. Nagasawa, J. Appl.

is classified according to two standards Phys., 64(7), 3516, 1988.

(fig. 4-5) i.e. ISO equivalent and FED [2] S. Verhaverbeke, J. Alay, P. Mertens,

STD 209E equivalent. This classification M. Meuris, M. Heyns, W.

is done according to the number of Vandervorst, M. Murrell, and C.

particles permitted per volume of air. Sofield, Mat. Res. Soc. Symp. Proc.,

259, 391, 1992.

CONCLUSION [3] J. S. Jeon, S. Raghavan, H. G. Parks,

Contaminants [18-19] happens during the J. K. Lowell, and I. Ali, J.

microelectronics integrated circuit Electrochem. Soc, 143, 2870, 1996.

fabrication process. Cleaning is one of the [4] G. Li, E. Kneer, B. Vermeire, H. Parks,

most desired process to remove J. S. Jeon and S. Raghavan, submitted

contaminants from wafer. All the cleaning to J, Electrochem. Soc, 1997.

process happened in a clean room. [5] B. Bera. Literature Review on

Particles are largely removed by ultrasonic Electrospinning Process (A

agitation during cleaning.Organics Fascinating Fiber Fabrication

(photoresist) are removed in O2 plasma or Technique). Imperial Journal of

in sulfuric acid (H2SO4)/hydrogen Interdisciplinary Research (IJIR).

peroxide (H2O2) solutions which is named Vol-2, Issue-8, 2016.

as piranha cleaning. The “RCA clean” is [6] B. Bera, Madhumita.Das Sarkar.

used to remove metals and any remaining Piezoelectricity in PVDF and PVDF

Based Piezoelectric Nanogenerator:

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 12

Silicon Wafer Cleaning: A Fundamental and Critical Step Binoy Bera

A Concept. IOSR Journal of Applied [13] Binoy Bera. Nanoporous Silicon

Physics (IOSR-JAP). Volume 9, Prepared by Vapour Phase Strain

Issue 3 Ver. I, PP 95-99. Etch and Sacrificial Technique. IJCA

[7] Binoy Bera, Dipankar Mandal, Proceedings on International

Madhumita Das Sarkar. Sensor Made Conference on Microelectronic

of PVDF/graphene Electrospinning Circuit and System MICRO

Fiber and Comparison between 2015(1):42-45, December 2015.

Electrospinning PVDF Fiber and [14] BinoyBera, Dipankar Mandal,

PVDF/graphene Fiber. Imperial Madhumita Das Sarkar. Porous

Journal of Interdisciplinary Research Silicon and its Nanoparticle as

(IJIR). Vol-2, Issue-5, 2016. Biomaterial: A Review. Imperial

[8] Binoy Bera, Madhumita Das Sarkar. Journal of Interdisciplinary Research

Gold Nanoparticle Doped PVDF (IJIR). Vol-2, Issue-11, 2016. (4).

Nanofiber Preparation of [15] Binoy Bera. A Review on Polymer,

Concurrently Harvesting Light and Graphene and Carbon Nanotube:

Mechanical Energy. IOSR Journal of Properties, Synthesis and

Applied Physics (IOSR-JAP). Applications. Imperial Journal of

Volume 9, Issue 3 Ver. III (May - Interdisciplinary Research (IJIR).

June 2017), PP 05-12. Vol-3, Issue-10, 2017.

[9] Binoy Bera, Madhumita Das Sarkar. [16] Hari Sarkar, Binoy Bera, Sudakshina

PVDF based Piezoelectric Kundu. Sleep Mode Transistor Sizing

Nanogenerator as a new kind of Effect of MTCMOS Inverter Circuit

device for generating power from on Performance in Deep Submicron

renewable resources. IOSR Journal of Technology. Global Journal of

Polymer and Textile Engineering Trends in Engineering (GJTE). Vol.

(IOSR-JPTE). Volume 4, Issue 2 (2)-Issue (4), 2015.

(Mar. - Apr. 2017), PP 01-05. [17] Binoy Bera, Madhumita Das Sarkar.

[10] Binoy Bera. Preparation of polymer Piezoelectric Effect, Piezotronics and

nanofiber and its application. Asian Piezophototronics: A Review.

journal of physical and chemical Imperial Journal of Interdisciplinary

sciences. volume 2, issue 4, 1-4, Research (IJIR). Vol-2, Issue-11,

2017. article no. AJOPACS. 35651. 2016.

[11] Binoy Bera. Literature Review on [18] I. Teerlinck, P. W. Mertens, H. F.

Triboelectric Nanogenerator. Schmidt, M. Meuris, and M. M.

Imperial Journal of Interdisciplinary Heyns, J. Electrochem. Soc, 143,

Research (IJIR). 2(10):1263- 3323, 1996.

1271·January2016. [19] S. Verhaverbeke, M. Meuris, M.

[12] Binoy Bera. Preparation of MoS2 Schackers, L. Haspeslagh, P. Mertens,

nanosheets and PVDF nanofiber. M. M. Heyns, R. De Blank, and A.

Asian journal of physical and Philipossian, Symp. on VLSI Tech.

chemical sciences. volume 2, issue 4, Digest of Tech. Papers, p. 22, 1992.

1-9, 2017.article no. AJOPACS. [20] https://www.americancleanrooms.co

35176. m/cleanroom-classifications.

Cite this Article: Binoy Bera. Silicon Wafer Cleaning: A Fundamental

and Critical Step in Semiconductor Fabrication Process. International

Journal of Applied Nanotechnology. 2019; 5 (1): 8–13p.

IJAN (2019) 8-13 © JournalsPub 2019. All Rights Reserved Page 13

View publication stats

Das könnte Ihnen auch gefallen

- A Guide On Health Hazards & Their Control in Wafer Fabrication FacilitiesDokument42 SeitenA Guide On Health Hazards & Their Control in Wafer Fabrication FacilitiesDarrenGCGNoch keine Bewertungen

- Nitrification and Denitrification in the Activated Sludge ProcessVon EverandNitrification and Denitrification in the Activated Sludge ProcessNoch keine Bewertungen

- Cleaning of Silicon WafersDokument14 SeitenCleaning of Silicon WafersManas KapurNoch keine Bewertungen

- Ic FabricationDokument7 SeitenIc FabricationphooolNoch keine Bewertungen

- A Brief Introduction To WaferDokument35 SeitenA Brief Introduction To Wafervish1213Noch keine Bewertungen

- Unit 3Dokument74 SeitenUnit 3ronnie199288% (8)

- MTS RcaDokument7 SeitenMTS RcaАлекандр ВоробьевNoch keine Bewertungen

- Chapter 4 Clean Room Wafer Cleaning and GetteringDokument31 SeitenChapter 4 Clean Room Wafer Cleaning and GetteringBablu VermaNoch keine Bewertungen

- CN4223R Lecture - Cleaning Technology 2018Dokument16 SeitenCN4223R Lecture - Cleaning Technology 2018JohnNoch keine Bewertungen

- Leading Edge Semiconductor Wafer Surface Cleaning Technologies That Support The Next Generation of Semiconductor DevicesDokument4 SeitenLeading Edge Semiconductor Wafer Surface Cleaning Technologies That Support The Next Generation of Semiconductor DevicesukalNoch keine Bewertungen

- Fabrication Lab-1 Wafer Preparation and MetallizationDokument3 SeitenFabrication Lab-1 Wafer Preparation and MetallizationShubham MishraNoch keine Bewertungen

- 104-Article Text-173-1-10-20200206Dokument4 Seiten104-Article Text-173-1-10-20200206Rishav SainiNoch keine Bewertungen

- Course Title: VLSI Technology Course No.: EEE 489Dokument18 SeitenCourse Title: VLSI Technology Course No.: EEE 489Rubel RiadNoch keine Bewertungen

- Ee2254 Lica QBDokument0 SeitenEe2254 Lica QBnjparNoch keine Bewertungen

- Industrial Silicon Wafer Solar CellDokument15 SeitenIndustrial Silicon Wafer Solar CellranggaNoch keine Bewertungen

- Ee6303 - Linear Integrated CircuitsDokument13 SeitenEe6303 - Linear Integrated CircuitsSaran ArunNoch keine Bewertungen

- M Group: Linear Integrated Circuits (Ec1313) IC FabricationDokument17 SeitenM Group: Linear Integrated Circuits (Ec1313) IC Fabricationscribdm100% (1)

- EC1313 Two Marks Linear Integrated CircuitsDokument11 SeitenEC1313 Two Marks Linear Integrated Circuitsmoney_kandan2004Noch keine Bewertungen

- Applicability and New Trends of Different Electrode Materials and Its Combinations in Electro Coagulation Process - A Brief ReviewDokument6 SeitenApplicability and New Trends of Different Electrode Materials and Its Combinations in Electro Coagulation Process - A Brief ReviewCUEVA VASQUEZ BRYAN ALBERTONoch keine Bewertungen

- Introduction To Integrated Circuit TechnologyDokument45 SeitenIntroduction To Integrated Circuit TechnologyShrikant JagtapNoch keine Bewertungen

- Journal of Crystal Growth: T.Y. Wang, Y.C. Lin, C.Y. Tai, R. Sivakumar, D.K. Rai, C.W. LanDokument4 SeitenJournal of Crystal Growth: T.Y. Wang, Y.C. Lin, C.Y. Tai, R. Sivakumar, D.K. Rai, C.W. LanMinh TrầnNoch keine Bewertungen

- Chemistry, Relationships and Trouble Shooting of Optical Media Electroforming BathsDokument18 SeitenChemistry, Relationships and Trouble Shooting of Optical Media Electroforming BathsKeily VilcarromeroNoch keine Bewertungen

- The Application of Industrial Scale Ultrasonic Cleaning To Heat ExchangersDokument3 SeitenThe Application of Industrial Scale Ultrasonic Cleaning To Heat Exchangersbai tap hoa vo coNoch keine Bewertungen

- Paper Hoda NiberDokument5 SeitenPaper Hoda NiberAzmeer AsryNoch keine Bewertungen

- Treatment of Real Printing Wastewater Using Electrocoagulation Process With Titanium and Zinc ElectrodesDokument9 SeitenTreatment of Real Printing Wastewater Using Electrocoagulation Process With Titanium and Zinc ElectrodesCUEVA VASQUEZ BRYAN ALBERTONoch keine Bewertungen

- Recycling of Electrode Materials From Spent Lithium-Ion BatteriesDokument4 SeitenRecycling of Electrode Materials From Spent Lithium-Ion Batteriesdine2315Noch keine Bewertungen

- 10 1016@j Cattod 2015 09 016Dokument6 Seiten10 1016@j Cattod 2015 09 016Grinder Hernan Rojas UrcohuarangaNoch keine Bewertungen

- Chapter 6 Water Treatment and Environmental Remediation Applications of Carbon Based Nanomaterials Xiaoli Tan Xin Wang Full ChapterDokument68 SeitenChapter 6 Water Treatment and Environmental Remediation Applications of Carbon Based Nanomaterials Xiaoli Tan Xin Wang Full Chapterdonna.crow358100% (3)

- ICEC2002 - 2 Silicon Contamination RelayDokument6 SeitenICEC2002 - 2 Silicon Contamination RelayCE DNoch keine Bewertungen

- Bioremediacion de Cianuro PDFDokument11 SeitenBioremediacion de Cianuro PDFAcosta FaustoNoch keine Bewertungen

- 080 Chlorine AlkalineDokument6 Seiten080 Chlorine AlkalineChristian CoboNoch keine Bewertungen

- Accepted Manuscript: Applied Surface ScienceDokument15 SeitenAccepted Manuscript: Applied Surface ScienceRASHI LAKHYANINoch keine Bewertungen

- Semi Conduct o 1Dokument10 SeitenSemi Conduct o 1Chaitu ChaitanyaNoch keine Bewertungen

- Rog Record - SakthiDokument37 SeitenRog Record - Sakthisakthi thiruNoch keine Bewertungen

- Materials Today: Proceedings: Archita Mohanty, Niharbala Devi, Lala Behari Sukla, Nandita SwainDokument5 SeitenMaterials Today: Proceedings: Archita Mohanty, Niharbala Devi, Lala Behari Sukla, Nandita SwainSelya AmandaNoch keine Bewertungen

- EE2254 LIC 2marks 2013Dokument16 SeitenEE2254 LIC 2marks 2013sivagamiNoch keine Bewertungen

- 10 1016@j Seppur 2020 116520Dokument10 Seiten10 1016@j Seppur 2020 116520khue tranNoch keine Bewertungen

- Sharma Rao2Dokument6 SeitenSharma Rao2ER Publications, IndiaNoch keine Bewertungen

- Guidelines For Interpreting Ionic Contamination TestingDokument10 SeitenGuidelines For Interpreting Ionic Contamination TestingjackNoch keine Bewertungen

- Nur Hamizah Shaidah Our SAMPLEDokument52 SeitenNur Hamizah Shaidah Our SAMPLEBarathan RajandranNoch keine Bewertungen

- Solar Cell Fabrication Lab: Final ReportDokument8 SeitenSolar Cell Fabrication Lab: Final ReportPrateek SinghNoch keine Bewertungen

- The Influence of Electrode Type On Electrocoagulation Process For Removal of Chromium (VI) Metal in Plating Industrial WastewaterDokument6 SeitenThe Influence of Electrode Type On Electrocoagulation Process For Removal of Chromium (VI) Metal in Plating Industrial WastewaterNórida Pájaro GómezNoch keine Bewertungen

- Application of Ultrasonic-Enhanced Active Seed Crystals in The Removal of Sodium Oxalate From Alumina Refinery Waste LiquorDokument10 SeitenApplication of Ultrasonic-Enhanced Active Seed Crystals in The Removal of Sodium Oxalate From Alumina Refinery Waste LiquornirupamadastaneNoch keine Bewertungen

- Water Treatment Technologies in Removing Heavy Metal Ions From WastewaterDokument14 SeitenWater Treatment Technologies in Removing Heavy Metal Ions From WastewaterNURSYAZANA AFIQAH MOHD NAZRINoch keine Bewertungen

- Module 3Dokument48 SeitenModule 3Sameer HussainNoch keine Bewertungen

- Applied Surface Science Advances: P.N. Belkin, S.A. Kusmanov, E.V. ParfenovDokument30 SeitenApplied Surface Science Advances: P.N. Belkin, S.A. Kusmanov, E.V. ParfenovKaren AnnNoch keine Bewertungen

- Applied Catalysis B: Environmental: SciencedirectDokument12 SeitenApplied Catalysis B: Environmental: Sciencedirectapriya_ninaniNoch keine Bewertungen

- A Combined Recovery Process of Metals in Spent Lithium Ion Batteries (Li Et Al 2009)Dokument5 SeitenA Combined Recovery Process of Metals in Spent Lithium Ion Batteries (Li Et Al 2009)irdantoNoch keine Bewertungen

- Contaminations On SemiconductorsDokument24 SeitenContaminations On SemiconductorsJohn Stephen Herida BernilNoch keine Bewertungen

- Electroflocculation in The Treatment of Polluted WDokument13 SeitenElectroflocculation in The Treatment of Polluted WteguheafNoch keine Bewertungen

- Pemisahan Katoda AnodaDokument11 SeitenPemisahan Katoda AnodaHamdi Zae malikNoch keine Bewertungen

- Treatment of Galvanic Effluent Through Electrocoagulation Process MN RemovalDokument15 SeitenTreatment of Galvanic Effluent Through Electrocoagulation Process MN RemovalGuillermo CarrasquillaNoch keine Bewertungen

- J Jhazmat 2009 11 026Dokument6 SeitenJ Jhazmat 2009 11 026cardenaslNoch keine Bewertungen

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDokument9 SeitenIjesrt: International Journal of Engineering Sciences & Research TechnologyAnonymous oaeClqNoch keine Bewertungen

- Effect of Solder Flux Residues On Corrosion of ElectronicsDokument7 SeitenEffect of Solder Flux Residues On Corrosion of ElectronicsPaavo HeiskanenNoch keine Bewertungen

- Tafreshi 2019Dokument11 SeitenTafreshi 2019Heshan KamaljithNoch keine Bewertungen

- CatalystDokument9 SeitenCatalystNazifa. E. AzmanNoch keine Bewertungen

- Separation and Purification Technology: Cheng-Chun He, Ching-Yao Hu, Shang-Lien LoDokument7 SeitenSeparation and Purification Technology: Cheng-Chun He, Ching-Yao Hu, Shang-Lien LoYerson Alcedo EspinozaNoch keine Bewertungen

- Handbook for Cleaning for Semiconductor Manufacturing: Fundamentals and ApplicationsVon EverandHandbook for Cleaning for Semiconductor Manufacturing: Fundamentals and ApplicationsKaren A. ReinhardtNoch keine Bewertungen

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationVon EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationNoch keine Bewertungen

- On Solar Hydrogen and NanotechnologyVon EverandOn Solar Hydrogen and NanotechnologyLionel VayssieresNoch keine Bewertungen

- Literature Review On Triboelectric NanogDokument9 SeitenLiterature Review On Triboelectric NanogBINOY BERANoch keine Bewertungen

- WBUT Annual Report 2015-2016 PDFDokument84 SeitenWBUT Annual Report 2015-2016 PDFBINOY BERANoch keine Bewertungen

- A Review On Polymer Graphene and CarbonDokument10 SeitenA Review On Polymer Graphene and CarbonBINOY BERANoch keine Bewertungen

- Synthesis, Properties and Applications of Amorphous Carbon Nanotube and Mos Nanosheets: A ReviewDokument17 SeitenSynthesis, Properties and Applications of Amorphous Carbon Nanotube and Mos Nanosheets: A ReviewBINOY BERANoch keine Bewertungen

- Synthesis and Applications of Acnt-Mos2 Nanocomposite: A ReviewDokument9 SeitenSynthesis and Applications of Acnt-Mos2 Nanocomposite: A ReviewBINOY BERANoch keine Bewertungen

- Amendment No. 2 August 2019 TO Is 2508: 2016 Polyethylene Films and Sheets - SpecificationDokument2 SeitenAmendment No. 2 August 2019 TO Is 2508: 2016 Polyethylene Films and Sheets - SpecificationSOMNATHNoch keine Bewertungen

- Coating IntroDokument2 SeitenCoating IntroShohan ParvezNoch keine Bewertungen

- QuestionsDokument8 SeitenQuestionsAntonioNoch keine Bewertungen

- MAE 333 SyllabusDokument4 SeitenMAE 333 SyllabusastrobarbyNoch keine Bewertungen

- Die CastDokument7 SeitenDie CastLokesh BaviskarNoch keine Bewertungen

- Engineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)Dokument4 SeitenEngineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)psatyasankarNoch keine Bewertungen

- The Diffusion Coefficients of Different Types of Liquid Environments Into Binary Polymer BlendDokument11 SeitenThe Diffusion Coefficients of Different Types of Liquid Environments Into Binary Polymer BlendabdussalamNoch keine Bewertungen

- CB CatalogueDokument79 SeitenCB CatalogueXung Lệnh HồNoch keine Bewertungen

- CH 5Dokument36 SeitenCH 5Istiaque AhmedNoch keine Bewertungen

- Hygiene Gradeslate For Plastic N Resin enDokument4 SeitenHygiene Gradeslate For Plastic N Resin envelan lanNoch keine Bewertungen

- Sae j419 1983 Methods of Measuring Decarburization PDFDokument8 SeitenSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNoch keine Bewertungen

- IPC2010-31273 IPC2010-: The Effect of Sample Flattening On Yield Strength Measurement in Line PipeDokument6 SeitenIPC2010-31273 IPC2010-: The Effect of Sample Flattening On Yield Strength Measurement in Line PipeDhrumil ChauhanNoch keine Bewertungen

- CHE617M Schoenfiles, Hermann-Mauguin, Miller Planes, SupercellsDokument46 SeitenCHE617M Schoenfiles, Hermann-Mauguin, Miller Planes, SupercellsIthan Jessemar Dollente100% (2)

- ME2151 Tutorial Solution 1Dokument21 SeitenME2151 Tutorial Solution 1benjaminyc96Noch keine Bewertungen

- UNit 2 MEC 305Dokument32 SeitenUNit 2 MEC 305Fuzzy is EasyNoch keine Bewertungen

- Minilite IIDokument2 SeitenMinilite IIariosuxNoch keine Bewertungen

- Response of Ferrocement Confinement On Behavior of Square RC Short ColumnDokument10 SeitenResponse of Ferrocement Confinement On Behavior of Square RC Short ColumnPANKAJ TAMBAKHENoch keine Bewertungen

- Skin Tribology: Science Friction?: Eview ArticleDokument13 SeitenSkin Tribology: Science Friction?: Eview ArticleCrissa TayamNoch keine Bewertungen

- AB Wool GlasswoolDokument2 SeitenAB Wool GlasswoolCatur Oka Nurfansyah0% (1)

- VLSI Technology Dr. Nandita Dasgupta Department of Electrical Engineering Indian Institute of Technology, MadrasDokument30 SeitenVLSI Technology Dr. Nandita Dasgupta Department of Electrical Engineering Indian Institute of Technology, MadrasfilmfilmfNoch keine Bewertungen

- A Critical Review of Carbon Fiber and Related Products From An Industrial PerspectiveDokument17 SeitenA Critical Review of Carbon Fiber and Related Products From An Industrial Perspectivechatgpt51023Noch keine Bewertungen

- Materials 10 01148Dokument20 SeitenMaterials 10 01148Lin TianNoch keine Bewertungen

- MM222 Lec 10-12Dokument23 SeitenMM222 Lec 10-12ObeydullahKhanNoch keine Bewertungen

- Topological Insulators My LectureDokument56 SeitenTopological Insulators My LectureRavikumar KottalankaNoch keine Bewertungen

- 3Cr2W8V PDFDokument2 Seiten3Cr2W8V PDFFARID MIFTAHUL ANWARNoch keine Bewertungen

- ESHF RSHF GSHF For Different SystemsDokument2 SeitenESHF RSHF GSHF For Different Systemsgowtham gNoch keine Bewertungen

- FM and SM Lab ManualDokument87 SeitenFM and SM Lab ManualGeorge OliverNoch keine Bewertungen

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDokument2 SeitenWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNoch keine Bewertungen

- Outline SpectraDokument6 SeitenOutline SpectraLoren Victoria AgbayNoch keine Bewertungen