Beruflich Dokumente

Kultur Dokumente

VDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)

Hochgeladen von

Anonymous vqsuRyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)

Hochgeladen von

Anonymous vqsuRyCopyright:

Verfügbare Formate

STEMENSVtr)O

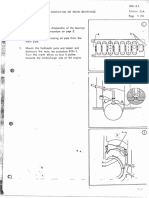

Parts List Float Arm Installation:

Item Descriotion Ag. 1. To installthe float arm assembly,loosenscrew'h', remov€

the short pieceof rod, and discardit.

1. FuelLevelSender 1 2. lnsertthe float rod until the properlength'R' ftom Table 1 is

2. FloatArm 1 met, then tightenthe screwsecurefy.

3. Gasket 1

4. FittingInstructions 1 3. Allor 25 mm to protrudeout from the "h" point(oppositeof

the float arm) see Fig 2.

Note: Mountinoflanqeo/n 23950/9Aand yveldinoffance:

oln 22502641141are accessoriesand not part of the kit. 4. Carefully cut off any excess rod with a bolt cutler or similar

Please order lhe above aoccssories, froding lo your EquiGment. tool, takingcare not lo damagethe assembly.

CAUTION:

Readtheseinstructionsthoroughlybeforemaking

installation.

Do not deviateftom assemblyor wiring instructions.

Alwaysdisconneclpositivebatterylead beforemakingany

electricalconneclions.

lf in doubt,pleasecontactyour dealeror SiemensVDO

AutomotiveServiceAgents.

Whenmakingmodificationsto fuel tanks. it is essentialthat

the tank be removedfrom the vehicle, and that it is ernpty,

dean, and dry.After drilling,make sure all chipsand other

breQn matterhave been removed from the tank

Beforedrillingany holesinto tank. placethe sender

assemblyon top of the tank to judge properhole placement

allowingflo3tarm clearanceinsidegl tank.

SiemensVDOrecornmendsthat the fuel sender and the

fuel gauge be wired together and checked for cornpatibility

priorto installingfuel senderinto tank.

FuelSendersOhms Ranges: Tank unit depths below 400 mm

220.W3Empty= 10 Ohms - Full 180Ohms 1. Removetwo screurs"d" and discard.

2- Removetwo screws'e" ftom the plastichousingand

220.@4Empty= 5 Ohms - Full 90 Ohms neservefor later use.

3. Carefullyremovebracket"f fromthe plastichousingand

220.005Empty= 240 Ohms - Full 33 Ohms discardit.

1. Replacebracket'.f'withbracket'g' in the housingand

Referto the SiemensVDO Cataloguefor matchingfuel looselyre-installthe two screws'e" into housing.

gauges. 5. UsingTable 1, checktank depthsize on "H" columnand

corresponding "L" & "R"

The unit can be adjustedto read accuratelyin tanks from 6. Slidehousingup or downuntildimension"L' is reached,

150mm lo 600 mm deep. For senderadjustment,referto then tightenscrewssecurely.

TableI and Fig.1. 7. To installthe floatarm assembly, loosenscrew'h', remove

the short piece of rod, and discardit.

GALIBRATION

and INSTALLATION 8. Insertthe float rod until the properlength"R" from Table.l

is met, then tightenthe screw securely.

Tank unit depths of 150mm to 600mm 9. Allow 25 mm to protrudeout frcm the "h" point(oppositeof

no disassemblyof the senderbracketis necessary. the floatarm) see Fig 2.

FromTable1, 10. Carefullycut off any excessrod with a boltcutteror similar

tool, takingcare not to damagethe assembly.

H=Tankunitheight,

L=bodylength"g & f',

R=armlengthfrom "h" pointto float centre.

1, UsingTable1, checktank depth size on "H" column NOTE: Makesurethe floatis installedas shownin Fig .1.lf

andcorresponding "L'& "R" installedbackwards,the fuelgaugewill indicate"full'whenthe

2. Loosenthetwo screws"d" and adjustthe plastic tankis empty,and "empty"whenthe tank is full.

housingup or downuntilthe properdimension"U' is

obtained,then re-tightenscrews securely.

F Al6sio 20 Jub 2fi)(' R6 4 lNtrucrio6 p/n 22o Fitling Inst

SIEMENSVtrDC)

Fuel render fnstallatlon Inslde tfie tank Assembly - mountingscrews

i,/ \,

To lmtell the tank unit sender lnto the fuel tank

flange

udng a flange kit:

gastek

lank

t. Cut a 59 mm hole in the top of the tank. mounting

flange

2. Refer to Fig. 3 and slide the rubber gasket up to the Hole Pattern

bottomofthe tuel senderfrange.

Next,slide the second llange over fuel sender to 2 . 1 2 5 "( 5 4 m m )

diameterbolt

bottomof rubbergasket. circle.

Al[n the pre-threadedholes in mountingflangeand

rubbergasketwith those in fuel sender llange.

Use25 mm screwto looselyattachmountingflange.

Do not tightencompletely.

Flg.3

3. Referto Fig.4 and slip the fuel senderassemblyinto

the 59 mm hole in the tank, tuming until it goes into the CAUT|ON:ilakecertainfloatarmhasa clearfieldof molion

tank before

tightening

screws inflange

assembly.

L Tightenall scrals until flange is fully seated onto the

gasket.

5. Hookup gaugesensorwire to centerstud terminal. .708(18mm)

6. Hookup groundwire to smallterminal. T

Warranty: Referto the warrantyconditionson the VDO

Catalogue.

25.mm

a;)'/--A

\}qf

Fs2 Flg.4

Table | (Dlrnenrtonr In mml

160 80 94 270 135 160 380 'r90 252 490 215 3ao

185 82.5 97 275 137.5 163 385 192.5 256 495 217.5 u

170 85 roo 2AO 11() 166 390 t95 260 500 2fi 3a8

175 a7.5 t03 245 14'2.5 169 395 1S7.5 261 505 252.5 352

180 90 106 26 145 172 400 2@ 268 510 255 356

185 92.5 109 2e5 117.5 175 405 202.5 272 515 257.5 36()

't90 95 r12 30(, r50 174 4to m5 274 520 280 3Aa

195 97.5 115 305 152.5 181 115 207.5 2AA 525 262.5 364

2N l(xl 118 3to 155 184 420 210 2A4 530 265 372

205 1A2.5 121 315 157.5 147 .,25 212.5 2Aa 535 247.5 376

210 105 121 320 r60 190 /+3O 215 29.2 5ao 270 x80

215 107.5 127 325 't62.5 193 435 277.5 296 545 272.5 344

20 t10 130 330 165 t96 440 22o 300 550 275 388

25 t 12.5 t33 335 167.5 199 415 222.5 304 555 277.5 392

2fi 115 136 3{0 170 202 450 22s 308 560 2SO 396

235 117.5 139 345 172.5 205 455 227.s 312 s65 242.5 rl(X,

240 120 142 350 175 20s 460 230 316 570 285 4Orl

215 r22,5 145 355 177.5 211 465 232.5 320 575 2A7.5 l'()8

2fi 125 148 360 t80 211 170 235 324 580 290 412

255 127-5 151 365 182_5 217 475 237.5 324 585 292.5 /118

260 130 r54 370 185 220 /r80 240 332 s90 295 120

265 132.5 157 375 187.5 24A 445 242.5 336 595 297.5 421

Add 25 mm to all values of "R"

F. Alqio 20 Jdy 2m6 Rlv 4 lGtMuoB p/n 220.Filin8 lNa

Das könnte Ihnen auch gefallen

- OAK Generator Fault Codes7!30!2017 Ver3Dokument15 SeitenOAK Generator Fault Codes7!30!2017 Ver3alphonse persicoNoch keine Bewertungen

- OAK Generator Fault Codes7!30!2017 Ver3Dokument15 SeitenOAK Generator Fault Codes7!30!2017 Ver3alphonse persicoNoch keine Bewertungen

- New DP200 and DP210 Fuel Injection Pump Spring Gen202E1Dokument1 SeiteNew DP200 and DP210 Fuel Injection Pump Spring Gen202E1Md ShNoch keine Bewertungen

- Woodworking Crafts February 2018Dokument92 SeitenWoodworking Crafts February 2018edgar velasco50% (2)

- 2.041 Woodward - EasyGen O&M PDFDokument69 Seiten2.041 Woodward - EasyGen O&M PDFJoséNoch keine Bewertungen

- 15 - PCC 1302 Troubleshooting TablesDokument15 Seiten15 - PCC 1302 Troubleshooting TablesAnbuNoch keine Bewertungen

- ST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Dokument24 SeitenST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Arc HieNoch keine Bewertungen

- 1300 Edi Series 80 SplitDokument10 Seiten1300 Edi Series 80 Split何青Noch keine Bewertungen

- Ats 520 Ats Controller User ManualDokument39 SeitenAts 520 Ats Controller User ManualAnonymous vqsuRy100% (1)

- Dse 509Dokument2 SeitenDse 509SOSNoch keine Bewertungen

- PCC2100, PCC3100Dokument5 SeitenPCC2100, PCC3100Giapy Phuc TranNoch keine Bewertungen

- C633a GCM PDFDokument6 SeitenC633a GCM PDFibrahemNoch keine Bewertungen

- Lovato Engine and Gen Controllers PDFDokument10 SeitenLovato Engine and Gen Controllers PDFMariano Macchi100% (1)

- PSG Governor With Aluminum CaseDokument98 SeitenPSG Governor With Aluminum CaseNam Anh TrầnNoch keine Bewertungen

- MX-321Dokument6 SeitenMX-321Akun BackupNoch keine Bewertungen

- Diesel Generator Set N14 Series: Specification SheetDokument4 SeitenDiesel Generator Set N14 Series: Specification Sheetsusmitamandali100% (1)

- Installation: Ems 2 Industrial Engines IDokument70 SeitenInstallation: Ems 2 Industrial Engines INasser Ayoub100% (1)

- 60 Kva, M020172a, Iveco, 8065eDokument66 Seiten60 Kva, M020172a, Iveco, 8065eGermán Andrés100% (2)

- Cummins pcc1301 Manual DDokument6 SeitenCummins pcc1301 Manual DAnonymous vqsuRy100% (1)

- Cummins pcc1301 Manual DDokument6 SeitenCummins pcc1301 Manual DAnonymous vqsuRy100% (1)

- Installation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVDokument14 SeitenInstallation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVOmer HejeirNoch keine Bewertungen

- 542931c Atys T M Nmo EN PDFDokument32 Seiten542931c Atys T M Nmo EN PDFkunkzNoch keine Bewertungen

- DC4xD MK3 Genset Controller User ManualDokument43 SeitenDC4xD MK3 Genset Controller User ManualAnonymous vqsuRyNoch keine Bewertungen

- DC4xD MK3 Genset Controller User ManualDokument43 SeitenDC4xD MK3 Genset Controller User ManualAnonymous vqsuRyNoch keine Bewertungen

- LXC9210 User Manual PDFDokument46 SeitenLXC9210 User Manual PDFAnonymous vqsuRyNoch keine Bewertungen

- FR 5277 QST30 G4 ATADokument6 SeitenFR 5277 QST30 G4 ATABernardo GarridoNoch keine Bewertungen

- Datakom d700tft Installation ManualDokument179 SeitenDatakom d700tft Installation ManualJaime Calmet0% (1)

- Wiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsDokument12 SeitenWiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsHammim HamzhahhNoch keine Bewertungen

- DSE Link 5000 Software ManualDokument61 SeitenDSE Link 5000 Software ManualAnonymous vqsuRyNoch keine Bewertungen

- 2Gr-Fe Engine: JdescriptionDokument2 Seiten2Gr-Fe Engine: JdescriptionMaiChiVuNoch keine Bewertungen

- Multis /: 96 x96 - Three Phases - All Electrical Parameters MeasurementDokument4 SeitenMultis /: 96 x96 - Three Phases - All Electrical Parameters MeasurementFrendy OeyNoch keine Bewertungen

- Canbus Wiring For DSE Controllers Issue6 20110719 PDFDokument87 SeitenCanbus Wiring For DSE Controllers Issue6 20110719 PDFmanuelbeasNoch keine Bewertungen

- DC 6 Digital Gov Data Sheet PDFDokument4 SeitenDC 6 Digital Gov Data Sheet PDFCarlos MajanoNoch keine Bewertungen

- Kea 071 AnlDokument12 SeitenKea 071 Anlamin shirkhaniNoch keine Bewertungen

- P1500PB (4012 46tag2a)Dokument4 SeitenP1500PB (4012 46tag2a)astwan81Noch keine Bewertungen

- ATyS M 3s (Reversing Switch) CatalogueDokument8 SeitenATyS M 3s (Reversing Switch) CataloguePaulMathewNoch keine Bewertungen

- LR200Dokument21 SeitenLR200atheb12345100% (1)

- Avr As440 Datasheet: 1.product DescriptionDokument7 SeitenAvr As440 Datasheet: 1.product DescriptionAnonymous vqsuRyNoch keine Bewertungen

- ESG2001C1-W Controller PDFDokument12 SeitenESG2001C1-W Controller PDFRenato MatičevićNoch keine Bewertungen

- ACS Analogue Control Systems eDokument12 SeitenACS Analogue Control Systems eKhaled KamelNoch keine Bewertungen

- D7a Ta - Ucm274f - 3Dokument4 SeitenD7a Ta - Ucm274f - 3ozakyus100% (1)

- CDokument620 SeitenCHung Cuong PhamNoch keine Bewertungen

- Governoor Heinzma NDokument4 SeitenGovernoor Heinzma NRudi HendarNoch keine Bewertungen

- Protection Expansion/ Annunciator: DescriptionDokument2 SeitenProtection Expansion/ Annunciator: Descriptionabduallah muhammad100% (1)

- Standard Motors AustriaDokument24 SeitenStandard Motors AustriaFlorinD2014Noch keine Bewertungen

- TAD1640GE: Volvo Penta Genset EngineDokument2 SeitenTAD1640GE: Volvo Penta Genset EngineRenzo zuñiga ahon100% (1)

- Sync Step Speed Adj Motor For UG Govs 03027 - BDokument8 SeitenSync Step Speed Adj Motor For UG Govs 03027 - Bcrazycanuck100% (1)

- TAD1642GE: Volvo Penta Genset EngineDokument2 SeitenTAD1642GE: Volvo Penta Genset EngineMahdi DehghankarNoch keine Bewertungen

- COMAP-Electronic Engines Support January-08Dokument163 SeitenCOMAP-Electronic Engines Support January-08mahmod alrousanNoch keine Bewertungen

- PMG PDFDokument6 SeitenPMG PDFrajan_2002eeeNoch keine Bewertungen

- Delphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsDokument2 SeitenDelphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsAsif ShahNoch keine Bewertungen

- R250 RegulatorDokument12 SeitenR250 Regulatoremerson212121100% (2)

- Unigen Plus Technical DocumentationDokument35 SeitenUnigen Plus Technical Documentationincore1976100% (1)

- DSE8003 MKII Operator ManualDokument74 SeitenDSE8003 MKII Operator ManualEdgar GonzalezNoch keine Bewertungen

- 1012 1013 PDFDokument120 Seiten1012 1013 PDFAndrejs Liepkauls100% (1)

- S 1250AJP JLG Service EnglishDokument788 SeitenS 1250AJP JLG Service EnglishmilandilovNoch keine Bewertungen

- MK PPR KD Do en 72Dokument32 SeitenMK PPR KD Do en 72Bandit PolskaNoch keine Bewertungen

- Cb2410ac D PDFDokument1 SeiteCb2410ac D PDFdinhvu100% (1)

- LXC701 V1.1 enDokument8 SeitenLXC701 V1.1 enAnonymous vqsuRy100% (1)

- Deep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualDokument92 SeitenDeep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualMostafa ShannaNoch keine Bewertungen

- Diesel Pump Clamping Device MANUALDokument61 SeitenDiesel Pump Clamping Device MANUALBii NguyễnNoch keine Bewertungen

- Hds HDSX UL Burner Manual, 9-14Dokument56 SeitenHds HDSX UL Burner Manual, 9-14kosmc123Noch keine Bewertungen

- Governor 3062322 Data SheetDokument2 SeitenGovernor 3062322 Data Sheetkhanh khanhNoch keine Bewertungen

- Telys 2: Procedure To Upgrade The TELYS2 With Firmwares (From Versions 1.1.8 and 1.0.18)Dokument3 SeitenTelys 2: Procedure To Upgrade The TELYS2 With Firmwares (From Versions 1.1.8 and 1.0.18)TomaBogdanovNoch keine Bewertungen

- 5245f en PDFDokument28 Seiten5245f en PDFdinhvuNoch keine Bewertungen

- Institutional EN PDFDokument40 SeitenInstitutional EN PDFKadirOzturkNoch keine Bewertungen

- CSA 5,5 - 7,5 - 10 - 15 - 20 HP: Rotary Screw CompressorDokument8 SeitenCSA 5,5 - 7,5 - 10 - 15 - 20 HP: Rotary Screw CompressorJohnny Diaz VargasNoch keine Bewertungen

- Kawasaki Staffa Radial Hydraulic Motors 41 62Dokument22 SeitenKawasaki Staffa Radial Hydraulic Motors 41 62Samuel Lopez BenitesNoch keine Bewertungen

- Main Bearing 'B & W'Dokument5 SeitenMain Bearing 'B & W'aliakbar tavafiNoch keine Bewertungen

- Emerson Liebert gxt3 2000va gxt3 2000rt120 Manual Do UtilizadorDokument4 SeitenEmerson Liebert gxt3 2000va gxt3 2000rt120 Manual Do UtilizadorArilson CamargoNoch keine Bewertungen

- Control Panel Catalogue: Smartgen (Zhengzhou) Technology Co., LTDDokument10 SeitenControl Panel Catalogue: Smartgen (Zhengzhou) Technology Co., LTDAnonymous vqsuRyNoch keine Bewertungen

- Manual of Fire Water Pump Control Box FPEC100: Chongqing Mebay Technology Co., LTDDokument8 SeitenManual of Fire Water Pump Control Box FPEC100: Chongqing Mebay Technology Co., LTDAnonymous vqsuRyNoch keine Bewertungen

- User Manual: CMM366-WIFI Cloud Monitoring Communication ModuleDokument16 SeitenUser Manual: CMM366-WIFI Cloud Monitoring Communication ModuleAnonymous vqsuRyNoch keine Bewertungen

- Avr As440 Datasheet: 1.product DescriptionDokument7 SeitenAvr As440 Datasheet: 1.product DescriptionAnonymous vqsuRyNoch keine Bewertungen

- 26086Dokument152 Seiten26086Khaleel KhanNoch keine Bewertungen

- Data Download HAT530N En-V1.2Dokument18 SeitenData Download HAT530N En-V1.2Anonymous vqsuRyNoch keine Bewertungen

- Guide To Synchronising and Load Sharing PART 1 - Usage of DSE Load Share Controllers in Synchronisation / Load Sharing SystemsDokument34 SeitenGuide To Synchronising and Load Sharing PART 1 - Usage of DSE Load Share Controllers in Synchronisation / Load Sharing SystemsjengandxbNoch keine Bewertungen

- Manuale DER1 en Rev06Dokument36 SeitenManuale DER1 en Rev06Mouh ElobeyNoch keine Bewertungen

- DC 70D ManualDokument17 SeitenDC 70D ManualAnonymous vqsuRyNoch keine Bewertungen

- ATS106 V1.0 en User ManualDokument7 SeitenATS106 V1.0 en User ManualAnonymous vqsuRyNoch keine Bewertungen

- IB Lite 1 8 Reference Guide r1Dokument25 SeitenIB Lite 1 8 Reference Guide r1maurosergiorovettaNoch keine Bewertungen

- Lxc7xx0 en v1.3 User ManualDokument56 SeitenLxc7xx0 en v1.3 User ManualAnonymous vqsuRyNoch keine Bewertungen

- UseMaintanceManual NEF MechInjection L31900018E Apr06 PDFDokument41 SeitenUseMaintanceManual NEF MechInjection L31900018E Apr06 PDFmanuel segoviaNoch keine Bewertungen

- DSE Link 5000 Software ManualDokument61 SeitenDSE Link 5000 Software ManualAnonymous vqsuRyNoch keine Bewertungen

- DSE91xx DSE92xx Data SheetDokument2 SeitenDSE91xx DSE92xx Data SheetGeneral Projects and Electric, C.A GEPECANoch keine Bewertungen

- A043y696 SX460 enDokument24 SeitenA043y696 SX460 enAhmed KotbNoch keine Bewertungen

- Lxi680g ManualDokument22 SeitenLxi680g ManualAnonymous vqsuRyNoch keine Bewertungen

- Guide To Synchronising and Load Sharing PART 1 - Usage of DSE Load Share Controllers in Synchronisation / Load Sharing SystemsDokument34 SeitenGuide To Synchronising and Load Sharing PART 1 - Usage of DSE Load Share Controllers in Synchronisation / Load Sharing SystemsjengandxbNoch keine Bewertungen

- DTSC-50 Manual PDFDokument106 SeitenDTSC-50 Manual PDFAcosta JohnnyNoch keine Bewertungen

- LXI980G: Industrial-Grade External GPRS / CDMA /ET Wireless Data Transmission Unit DTUDokument18 SeitenLXI980G: Industrial-Grade External GPRS / CDMA /ET Wireless Data Transmission Unit DTUHafiz AzharNoch keine Bewertungen

- Lab Report 3Dokument7 SeitenLab Report 3mamoona noreenNoch keine Bewertungen

- ECE WorkShopDokument268 SeitenECE WorkShopRaghava RaghuNoch keine Bewertungen

- LC1D80F7 DATASHEET SG en-SGDokument4 SeitenLC1D80F7 DATASHEET SG en-SGمحمد اظهرNoch keine Bewertungen

- Imb.E - Itb.E Start-Up, Shut-Down & Manual BypassDokument7 SeitenImb.E - Itb.E Start-Up, Shut-Down & Manual BypassJoni SruputNoch keine Bewertungen

- 03 Rig InstrumentationDokument34 Seiten03 Rig InstrumentationArkhatTompakovNoch keine Bewertungen

- Technical and Installation Principles of Koneductor Click Type and Bolted ConnectionsDokument47 SeitenTechnical and Installation Principles of Koneductor Click Type and Bolted ConnectionsRehan Afzal100% (1)

- PW2 Electronic Equipment 16DEP19F1025Dokument8 SeitenPW2 Electronic Equipment 16DEP19F1025Izzati KamaruzamanNoch keine Bewertungen

- Amiga 500/600/1200 Floppy Recap / Capacitor List: Track Zero Sensor Warning !Dokument3 SeitenAmiga 500/600/1200 Floppy Recap / Capacitor List: Track Zero Sensor Warning !Octavio PereiraNoch keine Bewertungen

- All Controls: Section 6 Section 6 Section 6 Section 6 Section 6Dokument95 SeitenAll Controls: Section 6 Section 6 Section 6 Section 6 Section 6Jose Manuel Pereira LópezNoch keine Bewertungen

- SR102AMDokument4 SeitenSR102AMMarcello ScalioniNoch keine Bewertungen

- Fire Product Systems CatalogueDokument16 SeitenFire Product Systems CatalogueDamarys A. Ulloa S.Noch keine Bewertungen

- DENELI CAN Smart Manual InstructionsDokument11 SeitenDENELI CAN Smart Manual InstructionsatvbgdNoch keine Bewertungen

- Vol02 Tab01Dokument128 SeitenVol02 Tab01jonathanNoch keine Bewertungen

- Training Material DANA TCON - Full Flow - 6196.528Dokument21 SeitenTraining Material DANA TCON - Full Flow - 6196.528aybchb20Noch keine Bewertungen

- Outside Temperature Sensor For Use With Cm900 Chronotherm: ApplicationDokument2 SeitenOutside Temperature Sensor For Use With Cm900 Chronotherm: ApplicationitsoltimbaNoch keine Bewertungen

- Part No.: 88290006-541 Date: March, 2003Dokument66 SeitenPart No.: 88290006-541 Date: March, 2003Rheza Putra AprilianNoch keine Bewertungen

- VQ400 HoneywellDokument10 SeitenVQ400 HoneywelladamsvillanuevaNoch keine Bewertungen

- Vc-Hca 1Dokument19 SeitenVc-Hca 1panasenkovasilyNoch keine Bewertungen

- Km35 Series: Installation, Care & Use ManualDokument7 SeitenKm35 Series: Installation, Care & Use Manualheri setyawanNoch keine Bewertungen

- Product Catlogus For LugsDokument18 SeitenProduct Catlogus For LugsBoobalan GnanamNoch keine Bewertungen

- SL 37 Test Internal Leakage SG - REVISION 1 - 090713Dokument8 SeitenSL 37 Test Internal Leakage SG - REVISION 1 - 090713bob228340Noch keine Bewertungen

- Lathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFDokument22 SeitenLathe Machine: Definition, Introduction, Parts, Types, Operations, and Specifications (With PDFMrTurner HoodNoch keine Bewertungen

- Lighting and Wiring Fundamentals: © 2012 Delmar, Cengage LearningDokument30 SeitenLighting and Wiring Fundamentals: © 2012 Delmar, Cengage LearningAjinkya JagtapNoch keine Bewertungen

- Working Principle of Earth Leakage Circuit Breaker ELCB and Residual Current Device RCDDokument6 SeitenWorking Principle of Earth Leakage Circuit Breaker ELCB and Residual Current Device RCDMouna NjNoch keine Bewertungen

- Park BrakeDokument11 SeitenPark Brakeandrea0bustam-795210Noch keine Bewertungen

- Sanitary Ware 1Dokument6 SeitenSanitary Ware 1HACCP Food CodeNoch keine Bewertungen

- Citizen Instruction Manual 8200Dokument2 SeitenCitizen Instruction Manual 8200davidgloomNoch keine Bewertungen

- Catalogo de TrabajoDokument91 SeitenCatalogo de TrabajoMaria teresa Ormaza gilerNoch keine Bewertungen

- SP 3500-3510 PartesFusorDokument5 SeitenSP 3500-3510 PartesFusorJohn Fsco PonceNoch keine Bewertungen