Beruflich Dokumente

Kultur Dokumente

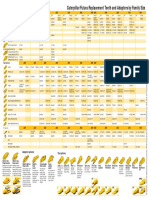

299D XHP Compact Track Loader AEHQ6565-01

Hochgeladen von

Jan HendriksCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

299D XHP Compact Track Loader AEHQ6565-01

Hochgeladen von

Jan HendriksCopyright:

Verfügbare Formate

Cat ®

299D XHP

COMPACT TRACK LOADER

FEATURES:

The Cat® 299D XHP Compact Track Loader, with its vertical lift design, delivers Cat “Intelligent Leveling” system (ILEV) provides industry leading

extended reach and lift height for quick and easy truck loading. The torsion technology, integration and features such as dual direction self level,

axle suspension system provides superior traction, flotation and the ability to work tool return to dig and work tool positioner.

work in a wide range of underfoot conditions and applications. The 299D XHP XHP hydraulic system provides high flow and high pressure that delivers

features the following: industry leading hydraulic horsepower to efficiently run even the most

Sealed and pressurized cab provides a cleaner and quieter operating power hungry work tools.

environment. Standard fully independent torsion axle suspension combined with

Seat mounted adjustable joystick controls and air ride seat make the the Speed Sensitive Ride Control system improves operation on rough

D Series the industry leader in operator comfort. terrain, enabling better load retention, increased productivity and greater

High performance power train provides maximum performance operator comfort.

and production capability through the Electronic Torque Management Easy routine maintenance helps reduce machine downtime for

system, standard two speed travel and an industry exclusive electronic greater productivity.

hand/foot throttle with decel pedal capability. Broad range of performance matched Cat Work Tools make the

Electronically controlled Cat C3.8 aftercooled engine provides Cat Compact Track Loader the most versatile machine on the job site.

high horsepower and torque while meeting U.S. EPA Tier 4 Interim

(EU Stage IIIB) requirements.

Specifications

Engine Operating Specifications

Engine Model Cat® C3.8 (turbocharged) Rated Operating Capacity:

Gross Power SAE J1995 82 kW 110 hp 35% Tipping Load 1445 kg 3,185 lb

Net Power SAE 1349 79 kW 106 hp 50% Tipping Load 2064 kg 4,550 lb

Displacement 3.8 L 232 in3 Tipping Load 4128 kg 9,100 lb

Stroke 120 mm 4.7 in Breakout Force, Tilt Cylinder 3348 kg 7,381 lb

Bore 100 mm 3.9 in Breakout Force, Lift Cylinder 2767 kg 6,100 lb

Ground Contact Area 1.41 m2 2,184 in2

Weights* Ground Pressure 36.8 kPa 5.3 psi

Operating Weight 5283 kg 11,647 lb

Cab

Power Train ROPS SAE J1040 MAY94,

ISO 3471:1994

Travel Speed (Forward or Reverse):

FOPS SAE J1043 SEPT87,

One Speed 8.1 km/h 5.0 mph ISO 3449:1992 Level I

Two Speed 13.6 km/h 8.5 mph FOPS Level II SAE J231 JAN81,

ISO 3449:1992 Level II

Hydraulic System

Hydraulic Flow – XHP: Service Refill Capacities

Max. Loader Hydraulic Pressure 28 000 kPa 4,061 psi Cooling System 14 L 3.7 gal

Max. Loader Hydraulic Flow† 150 L/min 40 gal/min Engine Crankcase 10 L 2.6 gal

Hydraulic Power (calculated) 70 kW 94 hp Fuel Tank 117 L 30.8 gal

Standard Flow Mode: Hydraulic System 61 L 16.0 gal

Loader Hydraulic Pressure 23 000 kPa 3,335 psi Hydraulic Tank 39 L 10.3 gal

Loader Hydraulic Flow 86.4 L/min 23 gal/min

*Operating Weight, Operating Specifications and Dimensions all based on

75 kg (165 lb) operator, all fluids, 2 speed, counterweights, 1981 mm (78 in)

Dirt Bucket, 400 mm (15.7 in) wide tracks, triple flange front/rear idlers, ride

control, enclosed cab with glass door, side windows, air conditioning, air

ride seat and manual quick coupler (unless otherwise noted).

†When equipped with Cat 400 Series work tools.

299D XHP Compact Track Loader

STANDARD EQUIPMENT

19 ELECTRICAL

12 volt Electrical System

100 ampere Alternator

Automatic Glow Plug Activation

20 13 Ignition Key Start/Stop Switch

9 6 15 17

Lights: Gauge Backlighting, Two Rear Tail Lights, Two Rear Halogen

7

Working Lights, Two Adjustable Front Halogen Lights, Dome Light

Backup Alarm

10

5 18 14 Heavy Duty Battery, 1,000 CCA

OPERATOR ENVIRONMENT

12

16 Gauges: Fuel Level, Hour Meter

11

8 Operator Warning System Indicators: Air Filter Restriction, Alternator Output,

1

2

Armrest Raised/Operator Out of Seat, Engine Coolant Temperature, Engine

3

Oil Pressure, Glow Plug Activation, Hydraulic Filter Restriction, Hydraulic

4 Oil Temperature, Park Brake Engaged, Regeneration – Engine Emissions

Cloth Seat, Air Suspension

Dimensions Fold in Ergonomic Contoured Armrest

1 Length of Track on Ground 1767 mm 69.6 in Control Interlock System, when operator leaves seat or armrest

raised: Hydraulic System Disables, Hydrostatic Transmission Disables,

2 Overall Length of Track 2270 mm 89.4 in

Parking Brake Engages

3 Length w/o Bucket 3138 mm 123.5 in ROPS Cab, Enclosed, Tilt Up

4 Length w/Bucket on Ground 3850 mm 151.6 in FOPS, Level I

5 Height to Top of Cab 2104 mm 82.8 in Top, Rear and Side Windows

6 Max. Overall Height 4048 mm 159.4 in Headliner, Deluxe

7 Bucket Pin Height at Max. Lift 3217 mm 126.6 in Floor Mat

Interior Rearview Mirror

8 Bucket Pin Height at Carry Position 195 mm 7.7 in

12 volt Electric Socket

9 Reach at Max. Lift and Dump 787 mm 31.0 in Horn

10 Clearance at Max. Lift and Dump 2418 mm 95.2 in Hand (Dial) and Foot Throttle, Electronic with Decel Feature

11 Ground Clearance 231 mm 9.1 in Advanced Machine Information and Control System (AMICS)

12 Departure Angle 39°

POWER TRAIN

13 Maximum Dump Angle 52° Cat® C3.8, Turbo, Tier 4 Interim (Stage IIIB) Certified Engine

14 Vehicle Width 1931 mm 76.0 in Air Cleaner, Dual Element, Radial Seal

15 Turning Radius from Center – Machine Rear 1849 mm 72.8 in S·O·SSM Sampling Valve, Hydraulic Oil

16 Turning Radius from Center – Coupler 1535 mm 60.4 in Filters, Cartridge-type, Hydraulic

17 Turning Radius from Center – Bucket 2347 mm 92.4 in Filters, Cartridge-type, Fuel and Water Separator

Radiator/Hydraulic Oil Cooler (side-by-side)

18 Max. Reach w/Arms Parallel to Ground 1288 mm 50.7 in

Spring Applied, Hydraulically Released, Wet Multi Disc Parking Brakes

19 Rack Back Angle at Max. Height 83° Hydrostatic Transmission, Two Speed Travel

20 Bucket Pin Reach at Max. Lift 410 mm 16.1 in Suspension – Independent Torsion Axles (4)

Ride Control

MANDATORY EQUIPMENT OTHER

Quick Coupler, Mechanical or Electric Engine Enclosure, Lockable

Seat Belt, 50 mm (2 in) or 75 mm (3 in) Extended Life Antifreeze, –37° C (–34° F)

Machine Tie Down Points (4)

COMFORT PACKAGE Support, Lift Arm

Enclosed ROPS with Heat (C3): Cup Holder, Radio Ready, Air Ride Seat, Hydraulic Oil Level Sight Gauge

Air Conditioner with Heater and Defroster, Side Windows, Door Radiator Coolant Level Sight Gauge

(Glass or Polycarbonate) Radiator, Expansion Bottle

Cat ToughGuard™ Hose

HYDRAULIC PERFORMANCE PACKAGE

Auxiliary, Hydraulics, Continuous Flow

(H3) XHP Hydraulics, Dual Direction Electronic Self Level (raise and lower), Heavy Duty, Flat Faced Quick Disconnects with Integrated Pressure Release

Work Tool Return to Dig, Work Tool Positioner, Electronic Snubbing (Lift) Split D-Ring to Route Work Tool Hoses Along Side of Left Lift Arm

UNDERCARRIAGE Electrical Outlet, Beacon

Belly Pan Cleanout

Steel Imbed Rubber Track – 400 mm (15.7 in) with Triple Flange Idlers

Variable Speed Demand Fan

(front and rear), Suspension – 4 Independent Torsion Axles

Counterweights

OPTIONAL ATTACHMENTS

Beacon, Rotating

Engine Block Heater – 120V

Oil, Hydraulic, Cold Operation

Paint, Custom

AM/FM/Weather Band Receiver with CD Player and Auxiliary Input Jack

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www.cat.com AEHQ6565-01 (05-12)

© 2012 Caterpillar Replaces AEHQ6565

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice. Featured machines in photos may include additional

equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow” and the “Power Edge” trade dress, as

well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Peterbilt Heavy Duty Body Builder Manual 2017Dokument290 SeitenPeterbilt Heavy Duty Body Builder Manual 2017Jan Hendriks100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kubota z482 d722Dokument81 SeitenKubota z482 d722jaumegusNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Chapter 2 - Construction Equipments and Plants AAUDokument60 SeitenChapter 2 - Construction Equipments and Plants AAUyared100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Service Manual S630 Skid-Steer Loader: S/N A3NT11001 & Above S/N A3NT11001 & Above S/N A3NU11001 & AboveDokument890 SeitenService Manual S630 Skid-Steer Loader: S/N A3NT11001 & Above S/N A3NT11001 & Above S/N A3NU11001 & AboveMayki Aparicio CNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Despiece Motor Kubota V-2203-DI PDFDokument43 SeitenDespiece Motor Kubota V-2203-DI PDFMario Aguirre100% (2)

- 12M Motorgrader PDFDokument28 Seiten12M Motorgrader PDFJan HendriksNoch keine Bewertungen

- 12M Motorgrader PDFDokument28 Seiten12M Motorgrader PDFJan HendriksNoch keine Bewertungen

- Shop Manual - Mega 300V - Tier I y II PDFDokument650 SeitenShop Manual - Mega 300V - Tier I y II PDFJose Luis Poma M100% (4)

- 416e, 422e, and 428e Esquema HidraulicoDokument38 Seiten416e, 422e, and 428e Esquema HidraulicostalinNoch keine Bewertungen

- Volvo BL 71 1 Standard Parts, ServiceDokument127 SeitenVolvo BL 71 1 Standard Parts, ServiceVygintas Balcius100% (2)

- PEBJ0079-10 3-24-20 Composite Low ResDokument342 SeitenPEBJ0079-10 3-24-20 Composite Low ResTony Wilden Angelo PeñaNoch keine Bewertungen

- Catalog Komatsu PDFDokument202 SeitenCatalog Komatsu PDFJan Hendriks82% (11)

- 5027 (UK) TLT25-HL-30-35 Iss3Dokument4 Seiten5027 (UK) TLT25-HL-30-35 Iss3aiulica20Noch keine Bewertungen

- 5 Cruces Cat-FuturaDokument1 Seite5 Cruces Cat-Futurakarijoseph02Noch keine Bewertungen

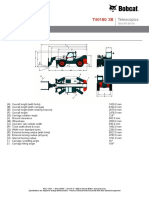

- TL35 70Dokument1 SeiteTL35 70Jan HendriksNoch keine Bewertungen

- D21a P 8Dokument6 SeitenD21a P 8Jan HendriksNoch keine Bewertungen

- Brochure ZW310 5Dokument20 SeitenBrochure ZW310 5Jan HendriksNoch keine Bewertungen

- BR350JG 1Dokument8 SeitenBR350JG 1Jan HendriksNoch keine Bewertungen

- 340 7 PDFDokument8 Seiten340 7 PDFJan HendriksNoch keine Bewertungen

- Diesel or LPG Engine Pneumatic Tires: CMP50 CMP60 CMP70 CMP50Dokument6 SeitenDiesel or LPG Engine Pneumatic Tires: CMP50 CMP60 CMP70 CMP50MA TotalforkliftNoch keine Bewertungen

- E SpecCMP15 18 20sDokument6 SeitenE SpecCMP15 18 20sJan HendriksNoch keine Bewertungen

- I60O 150930 Trilithic CT 4 KKDokument2 SeitenI60O 150930 Trilithic CT 4 KKJan HendriksNoch keine Bewertungen

- C15-20 Gen-2 PDFDokument6 SeitenC15-20 Gen-2 PDFJan HendriksNoch keine Bewertungen

- 51468Dokument6 Seiten51468Jan HendriksNoch keine Bewertungen

- Wheel Loaders: Innovative Drivetrain SolutionsDokument4 SeitenWheel Loaders: Innovative Drivetrain SolutionsAli Tavakoli NiaNoch keine Bewertungen

- Teleboom HandlersDokument8 SeitenTeleboom HandlersArturo AndNoch keine Bewertungen

- D350ahg - D400ahg - en PDFDokument69 SeitenD350ahg - D400ahg - en PDFJan HendriksNoch keine Bewertungen

- Bomag Technical DataDokument4 SeitenBomag Technical DataJan HendriksNoch keine Bewertungen

- PN Infosheet Compressors K-Series en May18 LQDokument1 SeitePN Infosheet Compressors K-Series en May18 LQJan HendriksNoch keine Bewertungen

- 120 H GraderDokument20 Seiten120 H GraderSuyash Kumar Labh100% (1)

- 299D XHP Compact Track Loader AEHQ6565-01Dokument2 Seiten299D XHP Compact Track Loader AEHQ6565-01Jan HendriksNoch keine Bewertungen

- BR500JG 1a PDFDokument8 SeitenBR500JG 1a PDFJan HendriksNoch keine Bewertungen

- Max Lifting Height 16.35mDokument4 SeitenMax Lifting Height 16.35mJan HendriksNoch keine Bewertungen

- Telescopics: DimensionsDokument10 SeitenTelescopics: DimensionsJan HendriksNoch keine Bewertungen

- Grease 15-16 PDFDokument1 SeiteGrease 15-16 PDFJan HendriksNoch keine Bewertungen

- CD60R - 1A Brochure PDFDokument4 SeitenCD60R - 1A Brochure PDFJan HendriksNoch keine Bewertungen

- 1275 EnuDokument2 Seiten1275 EnuJan HendriksNoch keine Bewertungen

- JD PC2322 PreviewDokument41 SeitenJD PC2322 Previewpiter suarezNoch keine Bewertungen

- Operatorsmanual Backhoe 170 A33748 2012 1Dokument16 SeitenOperatorsmanual Backhoe 170 A33748 2012 1TomekNoch keine Bewertungen

- Alliance Technical Catalog Sept 2019 - LR Final - 1571832848Dokument208 SeitenAlliance Technical Catalog Sept 2019 - LR Final - 1571832848Александр ФедоровNoch keine Bewertungen

- Kmax Designed To Produce BrochureDokument12 SeitenKmax Designed To Produce Brochure2222222222222-242735Noch keine Bewertungen

- 457 Stage V BrochureDokument28 Seiten457 Stage V BrochureMárton SzőkeNoch keine Bewertungen

- TufferDokument4 SeitenTufferChristopher JeffreyNoch keine Bewertungen

- Application Center Backhoe Loaders: Head: Philippe FillonDokument12 SeitenApplication Center Backhoe Loaders: Head: Philippe FillonStar SealNoch keine Bewertungen

- MP0512Dokument32 SeitenMP0512Justin OrbienNoch keine Bewertungen

- 980 K BrakeDokument42 Seiten980 K BrakeMohamed W. KandilNoch keine Bewertungen

- Wa200 5Dokument7 SeitenWa200 5Richi Munez100% (2)

- BS en 474-4 (Latest)Dokument26 SeitenBS en 474-4 (Latest)AkhilNoch keine Bewertungen

- Major E & P Used For Different Activities: A) Backhoe LoaderDokument7 SeitenMajor E & P Used For Different Activities: A) Backhoe LoaderNajam Ul IslamNoch keine Bewertungen

- B-12-02961 - KMT - Ugm13 - en - LR - BitsDokument182 SeitenB-12-02961 - KMT - Ugm13 - en - LR - BitsEdi FiebichNoch keine Bewertungen

- Catalogue Produits Rexroth Volvo DumperDokument108 SeitenCatalogue Produits Rexroth Volvo DumperBoumediene CHIKHAOUINoch keine Bewertungen

- Case 621D Wheel LoaderDokument2 SeitenCase 621D Wheel Loaderbugsy20155Noch keine Bewertungen

- Workmaster Utility TractorsDokument16 SeitenWorkmaster Utility TractorsAliNoch keine Bewertungen

- Collins Curriculum VitaeDokument3 SeitenCollins Curriculum VitaecollinsNoch keine Bewertungen

- List of Machinery and Equipment Owned by Age: Age'nin Sahip Olduðu Makina Ve Ekipman ListesiDokument8 SeitenList of Machinery and Equipment Owned by Age: Age'nin Sahip Olduðu Makina Ve Ekipman Listesiİbrahim HarmancıNoch keine Bewertungen

- Product List1Dokument6 SeitenProduct List1afquipNoch keine Bewertungen

- 2016 17 New Holland Toy CatalogueDokument12 Seiten2016 17 New Holland Toy Cataloguelaura100% (1)

- Hydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDokument2 SeitenHydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNoch keine Bewertungen

- TG Series Compact TractorsDokument12 SeitenTG Series Compact Tractorsحسن الديب hassan eldeebNoch keine Bewertungen