Beruflich Dokumente

Kultur Dokumente

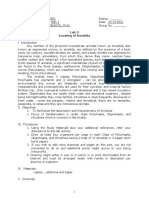

Revised Updated G.A. & Details Drg. of Air Receiver Sagar Cement

Hochgeladen von

Mani SunOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Revised Updated G.A. & Details Drg. of Air Receiver Sagar Cement

Hochgeladen von

Mani SunCopyright:

Verfügbare Formate

7 I 6 5 I 4 I 3 2 I 1

n

65".±5"

l-s:--<:- <

N0 ZZ. OD tn

w.7 TT7-1

GENERAL NOTES

c s����

� 0,.

1/4" NPT TELL � DESIGN DATA

(1YP)

tw 1) DESIGN AND CONSTRUCTION ARE ACC.TO ASME SE CT.VIII DIV.I ED.2 01 5.

� '//

TALE HOLE

- DESCRIPTION DATA

,j � 2 ) AUL DIMENS IONS ARE IN mm. UNLIES S OTHERWIS E S PECIFIED.

·.·•0/�

3 15"

@.

� 20 DES IGN CODE ASME SEC.VIII DIV. 1 -ED.2 0 17

L.J 2 3) NOZZLIE FLANGES CONFORMING TO ASME 816.5 201 3 EDITION.

11 .. ASME CODE STAMPED N/A

.,. 0-.�0

v� ���

1 .3 to 3 4) FIANGES FINIS H RF ACC.TO 8 16.5 1 25-250 AARH. NATIONAL BOARD REGISTRATION N/A

/<�""

4 5·

5) AFTER HYDROTEST THE VESSEL THOROUGHLY DRIED AND CLEANED INSIDE AND OUTSIDE. SITE LOCATION

6) BOLT HOLIES STRADDLE WITH THE PRINCIPLIE VES SEL CENTER LINES. Rl-19-20-0PV-026 & 02 7

&

DETAIL-'W1' MANUFACTURE'S S ERIAL NUMBER

7) AUL INTERNAL AND EXTERNAL PARTS WELDED TO VESSEL MADE OF THE SAME MATERIAL

SHELL TO SHELL SHELL TO EQUIPMENT TAG NUMBER / D C. NO. PCD591 & PCD 5 92

OF THE PARTS WHERE THEY ARE WELIDED.

SERVICE

DISH & EQUAL THICKNESS 2 to 4

B) ALIGNMENT TOLERANCE AS PER UW-33 AND FINISHED WELD JOINTS AS PER UW-35.

WELD WELDING DETAIL AS PER

wV, 9) S CALE/DUST/RUST REMOVED BEFORE WELIDING. OPERATING POSITION VERTICAL

1 0) NO LONGITUDINAL OR CIRCUMFERENTIAL SEAM JOINT AULOWED ON NOZZLE LOCATION. HYDROTEST POSITION VERTICAL

ASME Fig UW 9 NOZZ SIZE DESIGN (INTERNAL) Kg/cm2 (g) 10

tn Tw w L 1 1) WELDING OF AUL PRESSURE PARTS FULL PENETRATION. THIS DONE BY BACK

NO.

@ 0.D. 1.5 CHIPPING TO SOUND METAL AND RE WELDING ON THE OTHER SIDE. WHEN OTHER SIDE IS NOT � DESIGN (EXTERNAL) Kg/cm 2 (g) N/A

E E

NS, NS DN15 4.78 6.0 6.0 25

� OPERATING (INTERNAL) Kg/cm2 (g)

P.C.D. ACCESSIBLE, AT LEAST THE ROOT RUN DONE BY GTAW WELIDING AND SUBSEQUENT 7.0

N4 DN1 5 4.78 6.0 0.0 D HYDRO TEST Kg/cm2 (g) 13.5

RUNS DONE BY SMAW.

twtptstltL

R.F.DIA NOZZLE 8:

SIZE tn

... '

NI. N2AB. N7 DN2 5 6.35 6.0 6.0 25 NO. 1 2) ALL REINFORCING PADS PROVIDED WITH M6 TAPPED HOLE AND PNEUMATICALILY TESTED AT MAWP Kg/cm2 (g) 10

1.0.

N3 ON 450 8.00 8 8 8 8 8 92 1 .5 Kg./cm2 WITH S OAP SOLUTION BEFORE THE HYDROTEST IS PERFORMED.

MAEWP Kg/cm2 (g) N/A

1 3) HYDROTEST CARRIED OUT FOR MIN. 3 0 MINUTES WITH POTABLE WATER.

DESIGN (INTERNAL) ·c 35.43

DETAIL-'W2' DETAIL-'W3' 1 4) PAINTING:

BLAS TING :- SA 2.5

DESIGN (EXTERNAL) ·c 35.43

TYP. WELDING DETAIL OF NOZ. TYP. WELDING DETAIL PRIMER :- INORGANIC ZINC SILICATE 1YPE-2 , 1 COAT (65-70MICRON) OPERATING MIN./MAX. (INTERNAL) "C NIA

I

2 NOS. LIFTING MIO 1 COAT (13 0 MICRON) M ETAL TEMP. DURING HYDRO TE ST "C AMBIENT

PIPE TO SHELL D/E WITHOUT RF PAD NOZ. PIPE TO DIE WITH RF PAD FINISH PU RAL703 2 . 1 COAT (3 0 MICRON)

LUG AT 180" APART

2 25•

135"

12 MDMT ·c o

@)

Tn AS PER ASME Fig. UW-16. He) AS PER ASME Fig UW 16 1(c 1)

11 C APACl1Y OF VESSEL m3 3

VESSEL SIZE mm ID 1160 X 2500 X 8/8 IBK .

1 80 " NOZZLE NO.

SIZE Tn t1 t2 CORROSION ALLOWANCE mm 1.5

(ON) TOLERANCE TABLE

OUTSIDE 1.25 •r . JOINT EFFICIENCY

N7 OD 457 B

\

N4 , N5 ON 15 4 .78 4 .0 6.0 X IBK

min. DESCRIPTION TOLERAN CE RADIOGRAPHY TEST RT-I

- NI, N2AB, N7 DN 25 6.35 6.0 6.0

ORIENTATION PLAN VIEW INSULATION THK mm N/A

N3 DN 450 8.00 6.0 8.0 OUTSIDE CIRCUMFEREN CE ± 10 mm

PWHT EXE MPTED AS PER UCS-56

INSIDE DIAMETER ± 3 mm POST FORMING HEAT TREATMENT EXE MPTED AS PER UCS-79

DETAIL-'W4'

OUTSIDE DIAMETER ± 3 mm IMPACT TEST EXE MPTED AS PER UG-2 D(f) & UCS-66

SORF FLANGE TO NOZZLE \DLIIMETRAL CLEARANCE 'W4'

'

2.0 APPROX 0.8 mm (MAX) INSULATION CLEATS N/A

g. PIPE WELDING DETAIL ., OVERALL LIENGTH/HEIGHT ± 5 mm INTERNAL PAINT N/A

L__J.J..j..l,n ,,�-;:,

f�"" J ====t====,._,' ''�

11�"'----1----1..,u

300 AS PER ASME Fig . UW-21 DETAIL-'WS'

20 NOZZLIE PROJECTION ± 3 mm EXTERNAL PAINT AS PER SPECIFICATION.

TYP. SOCKET WELDING DETAIL +u I TOTAL EMP1Y WEIGHT Kg. -

NOZZLIE ELEVATION ± 3 mm Kg.

OPERATING WEIGHT -

2: 1 ELLIPSOIDAL HEAD 150 46 NOZZLIE ORIENTATION TOLIERANCE ± 3 MM HYDRO TEST WEIGHT / FLOODED WEIGHT Kg. -

6.8 mm(MIN.)/8mm(NOM.) 150

45 -

f

�· @, I;.,, · r ✓

t:

-� 15 ,. NOZZLIE TILT ± 1·

D ·w2· @, r@ D

"'

'W4'

--�-- ...

'W2

1

{ 'Wf NOZZLIE FLANGE FACE TILT ±

NOZZLE SCHEDULE

. - f-L_

rr - �r 0 .4 °

(FOR NOMINAL NOZZLIE SIZE 2"-4•

.,,,-- PIPE SIZE ASME 8 16.5 FLANGE

__

MARK

,,,... ...... --�-

.......

__v ....._ -�

NOZZLIE FLANGE FACE TILT ± 0.5 ° N 0 ZZ. SERVICE

DN. SCH. MATERIAL CLASS TYPE FACE MATERLAL PAD SIZE

QTY. REMARK

_ JJ..._ ________________________ ,,,'W1' (FOR NOMINAL NOZZLE SIZE 6"- 1 2"

• �f- N1 AIR INLET 25 160 SA1 06Gr.B 1 50 SO RF SA 1 05

W.L.

I Ir---..

CS -j1

� FILLIET SIZE + 1 .0 0 MM N2A/B AIR OUTLIET 25 160 SA1 06Gr.B 1 50 SO RF SA 1 05 2

_>-w-"'-@

46 - 0.25 MM

I t>....:t

-- 1 3) 23

'-' N3 MANHOLIE 4 50 BTHK. SA516GR.70 1 50 SO RF SA 1 05 OD 700 I WITH BLIND FL

I N4 DRAIN 15 16 0 SA1 06Gr.B 1 50 SO RF SA 1 05

I I &

-+--tll-+-·-

VENT

I I

DETAILS OF NOZZLE 'N1' DETAILS OF NOZZLE 'N2A' 'N28' DETAILS OF NOZZLE 'N3' N5 15 160 SA1 06Gr.B 1 50 SO RF SA 1 05

1

--

I I

N6 PRES SURE GAUGE 15 160 SA1 06Gr.B 30 0 0 S.W. - SA 1 05 I HALF COUPLING

I I

1 75 10 76 SHELL

39 N7 PRESSURE RELIEF VALVE 25 160 SA1 06Gr.B 1 50 SO RF SA 1 05

OOxB IBK

I I

300

- I "' .

W6 FROM CL

1500

41 MATERIAL DATA

I

I :1 --

Sr. No. Ili&.idPl.iUN IIAlllRW..SPACE.

'

:il'W5 'W2' 43 1.

I - '\

SHEUL SA 5 16 Gr.70

W4..J 2. DISHED END SA 516 Gr.70

f------����16=0��=� . -----t-•' -ii�

I' __J 3. LEG IS 2 062 Gr.B

l

10 1 X BTHK L,J

I ' ' 48 }---;-----,- 4. NOZZLE PIPES SA 1 06 Gr.B

i I

U1 47

I

--

' ' 31 5. SA 1 05

I I

L,,. NOZZLE FLANGES

0 37J.36 1

W4' 6.

I

I

BOLT SA 1 9 3 Gr.87

__J ,, 38 }-----!II

CJ 'W4' 7. NUT SA1 9 4 Gr.2 H

"] II

NP 35 8. GA S K ET SS316 SPIRAL WOUND

47 ' '.,....

DETAILS OF NOZZ. 'N7' '

I l::--® 43

W4

9_ FITTINGS SA 2 3 4 WPB

C -- 31

--,

C

I

(,,s\_ 25'1

'C/HINGE BAR 3 IBK. WASHER 33X32

I /WE';!;ED TO HINGE

BAR 28 'W2' 43

I

5 70

/A-::4 --ff)-"'$_ I

'

s� - 'Iii :,-1.-'!W, + I N .. �

',

I 3 lliK. DETAILS OF NOZZ. 'N6'

i\ !I

(( � .._, t:J

DETAILS OF NOZZ. 'N4'

t,............ @) �

I WASHER

I r,

I

-------<f----++i-,. -- I

52 BIRO MESH •22 CS 01

DETAILS OF NOZZ. 'NS'

k_!81.. I

PRES SURE GAUGE

!J � '8

51 1 /2" NPT(M) 0 TD 16 Kg/cm2, 6" DIAL - 01

-- I

50 AN CHOR BOLT, NIii & WASHER M16 X 300 LG. CS 0 8

�if./

PRESSURE RE LIF VALVE

I I,..,,,...l

Yft. �D 385 49 DN 25 X #150 X SORF - 01

-l-�

77 18

BALL VALVE

I jj

'$... 48 ON 15 X SW X #400 CS 01

"'

..,._ 20

lf---+ 15

!

47 BALL VALVE ON 15 X #150 X SORF CS 02

3

--

II

1,1 '27 46 BALL VALVE ON 25 X #150 X SORF CS 03

v�

- HINGE:

I

q NRV

W.L. CS-1- 2 Ill B 45 ON 25 X #BOD X S0RF CS 01

_ L.

T. ---------- ------------ AR -- - -- - -Ott- 44 ERATHING LUG 75 X 50 X 8 THK SA 516 Gr.7 0 02

�-1> I

01 0 43 STIFFENER FLAT 30 X 5 TH K. X 20 00 LG. IS 2062 01

18

HOLIE O N 25 X S.W. X #3000

I

���-� 3 18 42

f--' '-+

ELBO

��

FLANGE

W �---�, N7

O N 25 X #150 X S0 RF

SA 234 WPB 01

3 lliK. 41 SA 105 01

- WASHER DETAIL OF PIN 40 PIPE J O N 25 X SCH 160 X 320 Lg. SA 106 Gr.a

I � 01

\ v�

DETAIL OF SR.NO.26

HINGE ARRANGEMENT DETAILS t---+=------,

39 HALF COUPLING 7

NS

O N 15 X SW #3000 X NPT SA 105 01

;!;';

�/� 38 PIPE J O N 15 X SCH 160 X 300 Lg. SA 106 Gr.B 01

I

BLIND FLANGE 37 B0 LT+Nl/l+WASHER M 12 X 60 LG. SA193 Gr.87, SAl9 4 Gr.2H 08

� 3 1 a, SS�ODTTER PIN 29

I 36 GAS KET

DT

DN 15 X #1 50

I

SS316 SPIRAL WOUND

"'"'

02

'e.J WASHER N5

35 FLANGE O N 15 X #1 50 X S0 RF SA 105

II

02

HINGE ARRGT. DETAILS F OR MANHOLE

B B

34 PIPE O N 15 X SCH 160 X 445 Lg. SA 106 Gr.B

II

01

75

\. Y 33 B0LT+Nlll+WASH ER - M 12 X 60 LG. SA193 Gr.B7, SAl94 Gr.2 H 08

25 50

m ', -1""-in-- \ 0 32 GAS KET ON 15 X #150 SS316 SPIRAL WOUND 02

�,.,_,,

31 FLANGE N4 O N 15 X #150 X SDRF SA 105 02

30 PIPE ON 15 X SCH 160 X 160 Lg. SA 106 Gr.B

-

01

ELEVATION SECT.-P-P 29 COTTER PIN .S X 40 LG. CS 01

"' "'

200 00 28 WASHER J50 X 3 TH K IS 2062

0 04

2 :1 EULIPSOIDAL HEAD \� 240 OB 27 PLATE 57 X 93 X 20 THK IS 2062 02

BTHK. OS

--

N

6.8 mm(MIN.)/8mm(NOM.) 26 PLATE 1 17 X 75 X 20 THK IS 2062 02

/@I ~'""

TELL TALIE 25 ROUND BAR J 25 X 385 LG.

04 - - HOLE ¢6

IS 2062 01

1 No.

•14 HOLE 2 4 ROUND BAR N3 J 20 X 325 LG. IS 2062 01

----+-,_::== == == =�=== == == ==

23 BOLT+Nlll+WASH ER M30 X 140 LG. SA193 Gr.B7, SA19 4 Gr.2 H 16

DETAIL FOR LIFTING LUG

Ill I

�� DETAIL OF EARTHING LUG

DETAIL OF SR.N0:-27 22 GAS KET 450 NB X 150# SS316 SPIRAL WOUND 01

PC0551 - SAGAR CEMENTS LTD

21 FLANGE 450 NB X #150 X BLRF SA 105 01

I

90 20 FLANG E 450 NB X #150 X SORF SA 105 01

.

50-50-60 - - 50-50-60

-

'JYP. I QI 'JYP.

I -=1 -

19 RF AP D OD 700 X ID 463 X 8 TH K. SA 516 Gr.7 0 01

W.L.

-

I

- al� �1-----� p

18 MANHOLE SHELL 1410 X 300 X 8 TH K. SA 516 Gr.7 0 01

_J.:�- -1 10�1�

1�60'-"-

X� 8� �K�.-----�1

IB

1 7 B0 LT+Nlll+WASH ER - M 12 X 60 LG. SA193 Gr.87, SAl9 4 G r.2 H 16

al

' 16 GASKET

N2AB

O N 25 X #150 SS316 SPIRAL WOUND 04

QTY:- 2 NOS.

@) ,20 15 FLANGE DN 25 X #1 50 X S0 RF SA 105 04

DETAIL OF DISHED END

150 14 PIPE O N 25 X S CH 160 X 185 Lg. SA 106 Gr.B 02

13 B0 LT+Nlll+WASH ER M l2 X 60 LG. SA193 Gr.B7, SAl9 4 G r.2 H 12 - Q FIRST ISSUE FOR APPROVAL. S.S.P. P.H.B. 12.07.19

DETAIL OF SR.No.24 12 GAS KET ON 25 X #150 _ _ SS316 SPIRAL WOUND 03 -

Nl □N..c25"-- ---F"'-"'-' C..C.C.=-c.=..cc..cc..._-+ "--+--+-----,MOD.NO.

-+--J+III---+----- !

1 1 FLANGE l"- -'- -'- - -

X #l5D X SD RF

-'!,

-'

MODIFICATION AREA MOD.BY CHK.BY CHK, DATE

ISMC 100x50x5JHK.� 200 SA 105 D2

\ .l--+;-¥1\n O N 25 x SCH 160 x 185 Lg.

/ (BACK TO BACK) � 10 PIPE SA 106 Gr.B - NAME DATE SIGN. MATL. SPEC. f-O_ C ...,.. N 0...,. . : -

- - CLIENT :

-1

=�0" _

27 , 90" 01

-+-

5

09 R IB PLATE � BO x 54 x 10 rnK. 1s 206 2 - DRAWN S.S.P. 12.07.19 WT.(knl THERMAX LTD.

-_t-__

04

I AD AS GIVEN

DB P t;: 0 r.240 X 1 25�X 8 TH K . --- -::

A A

r.7�

I

> ;;;;-;;-7 ;;;: :;-;;;-;:-:;-;

SA 5 6 G=

1 ___

0 -t-_o 2 __ ED+..:P

--t.:.DE:::S::.:IG::.:N:::: H.B� :.......i..:1:.:2::.:

..:..::: ::: -

7 1 9

. 0:.:. . .:. -J----1-----...t..::.:.

::.: J OB�.:..:.NO�...L-- _-l PROJECT:-

'A'

I: \

--t '-::: ::::-' :: --t

'A'

.I

07 LIFTING HOO K PLATE - :J :i: 200 X 19 5 X 1 8 THK. IS 2062 -

8@

02 12.07.19

&

I I CHECKED P.H.B. DOC NO. GACL-NALCO ALKALIES

1' 8 06 BASE PLATE Ii: l-200_ _ _

X 25_0 _ X_1 6 _ T_H K___

_. ---4=1s=2=os=2� ----+-0�4----l -- - -+---

1

05

AD

P PLATE c, o 250 X 2 00 X 8 THK.

----lA. P PROVED P.H.B.

>---�--- ��--+---+-----�------+--------------1 12.07.19 SHEET - OF - 1 CHEMICALS PRNATE IJMITED

I I SA 516 Gr.70 -

&

04

W.L 04 COVER PLATE ":l � 1 00 x 50 x 5 TH K. IS 2062 04 - DIMN.: mm SCALE: NTS. TITLE:-

GENERAL ARRANGEMENT DETAILS

03 CHANNEL v, 1 X 50 X 1130 Lg.

00 IS 2062 OB -

T.L : MANUFACTURER SERIAL NO.

.,. HOLEI 02 DISHED END OD 1435 X 8 THK. SA 516 Gr.70 02 - Rl-19-20-0PV-026 & 0 2 7 O F AI R RECEIVER TANK

BOLT M16

- rn - REV·NO ·

06 SHE LL 3670 X 2500 X B TH K. SA 516 Gr.70 01 -

� : � RAVI INDUSTRIES DRG · NO ·

01

1B0" ,_�R._ N_ O� _ R_

OESC I_ PTIO N_ _____�_SI_ ZE_ ________�__M AT _ E_ RLAL

_ ____�Q�1Y_ .�WT=. �IN�KG=.�R=E=MA�R=K----<

® GAT NO. _ 1 71, RUPEE NAGAR,TALWADE ROAD,

DETAIL OF LEG SUPPORT VIEW FROM 'C'

SECTION 'A' -'A' f-----------BIIJ,_O_F_IU_TERI!L ________TO_�_AL_WT_. _:-__ KG_. ______

__, TALWADE PUNE, MAHARASHTRA, INDIA-412114 RAVI-0 PV-1920-026 0

DETAIL OF LEG ORIEN TATION -- PHONE : +91-20-66306632

7 I 6 5 I 4 I 3 2 I 1

Das könnte Ihnen auch gefallen

- Gmail - Redbus Ticket - TNCB29053025Dokument2 SeitenGmail - Redbus Ticket - TNCB29053025Mani SunNoch keine Bewertungen

- FORM-V CERTIFICATE BY PRINCIPAL EMPLOYER FOR SUBCONTRACTORDokument1 SeiteFORM-V CERTIFICATE BY PRINCIPAL EMPLOYER FOR SUBCONTRACTORMani SunNoch keine Bewertungen

- A12 1WH 503022Dokument1 SeiteA12 1WH 503022Mani SunNoch keine Bewertungen

- Tneb OrderDokument4 SeitenTneb Orderrgopinath5Noch keine Bewertungen

- Welcome, GOVINDARAJ Transaction HistoryDokument2 SeitenWelcome, GOVINDARAJ Transaction HistoryMani SunNoch keine Bewertungen

- Approved Busduct DrawingDokument16 SeitenApproved Busduct DrawingMani SunNoch keine Bewertungen

- SST600 en InteractiveDokument6 SeitenSST600 en InteractiveMani SunNoch keine Bewertungen

- Sagar Cement Limited 18 MW CPP Boiler Log Book: Design Value 100% BMCRDokument8 SeitenSagar Cement Limited 18 MW CPP Boiler Log Book: Design Value 100% BMCRMani SunNoch keine Bewertungen

- Siemens Industrial Steam Turbine SST 700 enDokument4 SeitenSiemens Industrial Steam Turbine SST 700 enMani SunNoch keine Bewertungen

- Boiler Safety During Construction WorkDokument1 SeiteBoiler Safety During Construction WorkMani SunNoch keine Bewertungen

- BHEL Seeks Technology for Large CFBC BoilersDokument11 SeitenBHEL Seeks Technology for Large CFBC BoilersMani SunNoch keine Bewertungen

- Viji TicketDokument2 SeitenViji TicketMani SunNoch keine Bewertungen

- Energies 07 02740 PDFDokument21 SeitenEnergies 07 02740 PDFMohsin RazaNoch keine Bewertungen

- CFBC SG Tce PaperDokument31 SeitenCFBC SG Tce PaperPiyush AgarwalNoch keine Bewertungen

- The Task To Be Maintained at H.O. PuneDokument1 SeiteThe Task To Be Maintained at H.O. PuneMani SunNoch keine Bewertungen

- Atmospheric Fluidised Bed Combustion BoilerDokument10 SeitenAtmospheric Fluidised Bed Combustion BoilersushantNoch keine Bewertungen

- Joe Woolley Process DesignDokument53 SeitenJoe Woolley Process DesignpgcedzovNoch keine Bewertungen

- Feed Pump-B Soft Foot DetailDokument10 SeitenFeed Pump-B Soft Foot DetailMani Sun0% (1)

- Joe Woolley Process DesignDokument53 SeitenJoe Woolley Process DesignpgcedzovNoch keine Bewertungen

- Boiler Foster WheelerDokument48 SeitenBoiler Foster WheelersprotkarNoch keine Bewertungen

- Form-V: Form of Certificate by Principal EmployerDokument2 SeitenForm-V: Form of Certificate by Principal EmployerMani SunNoch keine Bewertungen

- Documents Required for CEIG Drawing ApprovalDokument1 SeiteDocuments Required for CEIG Drawing ApprovalMani SunNoch keine Bewertungen

- IRCTC LTD, Booked Ticket PrintingDokument2 SeitenIRCTC LTD, Booked Ticket PrintingMani SunNoch keine Bewertungen

- Folder Covering Letter For VWHA059Dokument2 SeitenFolder Covering Letter For VWHA059Mani SunNoch keine Bewertungen

- GS Paper IiDokument48 SeitenGS Paper IikambanNoch keine Bewertungen

- Free ChargeDokument1 SeiteFree ChargeMani SunNoch keine Bewertungen

- IRCTC LTD, Booked Ticket PrintingDokument2 SeitenIRCTC LTD, Booked Ticket PrintingMani SunNoch keine Bewertungen

- Erection Procedure For Boiler StructuresDokument83 SeitenErection Procedure For Boiler Structureskutty_lakhs100% (12)

- M/S.NR ispat & Power PVT.LTD. Boiler Pump AlignmentDokument1 SeiteM/S.NR ispat & Power PVT.LTD. Boiler Pump AlignmentMani SunNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Progressing Cavity Pump Overhaul GuideDokument5 SeitenProgressing Cavity Pump Overhaul Guidesdsds-54Noch keine Bewertungen

- Masturbation It Might Feel Good But ItsDokument7 SeitenMasturbation It Might Feel Good But ItsKshivam KhandelwalNoch keine Bewertungen

- UPSC IFS Botany Syllabus: Paper - IDokument3 SeitenUPSC IFS Botany Syllabus: Paper - IVikram Singh ChauhanNoch keine Bewertungen

- Digestion Unit 1 QDokument15 SeitenDigestion Unit 1 QKajana Sivarasa ShenthanNoch keine Bewertungen

- Fairs in Punjab 2021-22Dokument9 SeitenFairs in Punjab 2021-22Suchintan SinghNoch keine Bewertungen

- L C R Circuit Series and Parallel1Dokument6 SeitenL C R Circuit Series and Parallel1krishcvrNoch keine Bewertungen

- Astm C27Dokument2 SeitenAstm C27nee2790Noch keine Bewertungen

- 37th APSDC Scientific PresentationsDokument7 Seiten37th APSDC Scientific PresentationsSatyendra KumarNoch keine Bewertungen

- Revised fire drill performance standardsDokument47 SeitenRevised fire drill performance standardsKartikeya GuptaNoch keine Bewertungen

- AMYLOIDOSISDokument22 SeitenAMYLOIDOSISMohan ChoudharyNoch keine Bewertungen

- Knowing Annelida: Earthworms, Leeches and Marine WormsDokument4 SeitenKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNoch keine Bewertungen

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDokument428 Seiten4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86Noch keine Bewertungen

- Cosmic Freedom: David MolineauxDokument2 SeitenCosmic Freedom: David Molineauxsalomon46Noch keine Bewertungen

- 841 Specific GravityDokument1 Seite841 Specific GravityJam SkyNoch keine Bewertungen

- DCI-2 Brief Spec-Rev01Dokument1 SeiteDCI-2 Brief Spec-Rev01jack allenNoch keine Bewertungen

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Dokument10 SeitenMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitNoch keine Bewertungen

- 4608 Eed 01Dokument29 Seiten4608 Eed 01NickNoch keine Bewertungen

- Grade 11 Holiday Homework Part 1Dokument7 SeitenGrade 11 Holiday Homework Part 1Jashfa SaboorNoch keine Bewertungen

- Company Profile 2Dokument7 SeitenCompany Profile 2R Saravana KumarNoch keine Bewertungen

- GERD – Definition, pathophysiology, epidemiology and diagnostic investigationsDokument132 SeitenGERD – Definition, pathophysiology, epidemiology and diagnostic investigationsSorana VasilescuNoch keine Bewertungen

- Semen RetentionDokument3 SeitenSemen RetentionMattNoch keine Bewertungen

- Exercise Stress TestingDokument54 SeitenExercise Stress TestingSaranya R S100% (2)

- Year 5:: NUMBERS TO 1 000 000Dokument47 SeitenYear 5:: NUMBERS TO 1 000 000Rusehaiza Bin Md DarusNoch keine Bewertungen

- Specifications Sheet ReddyDokument4 SeitenSpecifications Sheet ReddyHenry CruzNoch keine Bewertungen

- SC Earthquake GuideDokument8 SeitenSC Earthquake GuideNevin SmithNoch keine Bewertungen

- Gerovital anti-aging skin care product guideDokument10 SeitenGerovital anti-aging skin care product guideכרמן גאורגיהNoch keine Bewertungen

- Chemistry 12: Provincial ExaminationDokument25 SeitenChemistry 12: Provincial ExaminationCát TriệuNoch keine Bewertungen

- REMEDIATION-Focus BDokument13 SeitenREMEDIATION-Focus BCharmaine PerioNoch keine Bewertungen

- Symbols For Signalling Circuit DiagramsDokument27 SeitenSymbols For Signalling Circuit DiagramsrobievNoch keine Bewertungen

- PC Poles: DescriptionDokument2 SeitenPC Poles: DescriptionSantoso SantNoch keine Bewertungen