Beruflich Dokumente

Kultur Dokumente

Storage Tank Gas Breathing For Purge Gas Sizing

Hochgeladen von

guhadebasisOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Storage Tank Gas Breathing For Purge Gas Sizing

Hochgeladen von

guhadebasisCopyright:

Verfügbare Formate

431833112.

xls

08/02/2019 - 09:14:32

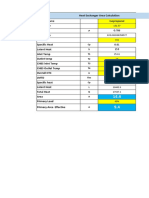

Tank Blanket Gas Venting Calculation Based on API 2000 September, 1992 Edition

Joint Operations Wafra

Pressure Maintenance Plant

Description TPM-01 TPM-02 TPM-03 New Tank

Inlet Tank Skim Tank Inlet Tank 30,000

Tank Capacity (Barrels) 10,000 2,000 10,000 30,000

Tank Diameter (Ft) 52.0 24.0 52.0 85.0

Tank Wetted Height (Ft), To A Max Of 30' 30.0 24.0 30.0 30.0

Maximum Design Inlet Flow (BPSD) 300,000 10,000 300,000 600,000

Maximum Design Outlet Flow (BPSD) 300,000 10,000 300,000 1,000,000

Flash Gas Rate (SCFD) 300,000 10,000 300,000 10,000

Latent Heat Of Vapourization (Btu/Lb) 970 120 970 970

Molecular Weight 18 142 18 18

Temperature Of Relief Vapour (F) 220 300 220 220

Number of Thief Hatches/PVSVs 1 1 1 0

Insulation Thickness 0 0 0 0

Other Cases

Failure Of Regulator (SCFD)

LCV Failure (SCFD)

431833112.xls

08/02/2019 - 09:14:32

Tank Blanket Gas Venting Calculation Based on API 2000 September, 1992 Edition

Joint Operations Wafra

Pressure Maintenance Plant

API 2000 Description TPM-01 TPM-02 TPM-03 New Tank TOTALS

Reference Inlet Tank Skim Tank Inlet Tank 30000

Section 0 0 0 0

Tank Design Information

Tank Capacity (Barrels) 10,000 2,000 10,000 30,000 52,000

Tank Diameter (Ft) 52 24 52 85 ---

Tank Wetted Height (Ft), To A Max Of 30' 30 24 30 30 ---

Maximum Design Inlet Flow (BPSD) 300,000 10,000 300,000 600,000 ---

Maximum Design Outlet Flow (BPSD) 300,000 10,000 300,000 1,000,000 ---

Calculated Wetted Surface Area (Sq. Ft.) 4,901 1,810 4,901 8,011 19,622

Inbreathing Calculations

2.4.2.1 Normal Inbreathing (SCFD) 1,680,000 56,000 1,680,000 5,600,000 9,016,000

2.4.2.1.2 Thermal Inbreathing (SCFD) 240,000 48,000 240,000 720,000 1,248,000

Total Inbreathing Rate (SCFD) 1,920,000 104,000 1,920,000 6,320,000 10,264,000

Outbreathing Calculations

2.4.2.2.1 Normal Outbreathing Rate (SCFD) 1,800,000 60,000 1,800,000 3,600,000 7,260,000

2.4.2.2.2 Thermal Outbreathing Rate (SCFD) 144,000 28,800 144,000 432,000 748,800

Flash Gas Rate (SCFD) 300,000 10,000 300,000 10,000 620,000

Total Outbreathing Rate (SCFD) 2,244,000 98,800 2,244,000 4,042,000 8,628,800

2.4.3.2.2 Non-Rigourous Fire Case (See Documentation Note 3)

Emergency Venting - Fire (MSCFH) 1,175 519 1,175 1,759 4,629

Using Insulation Derating Factor Of 0.15 (MSCFH) 176 78 176 264

2.4.3.2.1 Fire Case (Rigourous)

Latent Heat Of Vapourization (Btu/Lb) 970 120 970 970 ---

Molecular Weight 18 142 18 18 ---

Temperature Of Relief Vapour (F) 220 300 220 220 ---

Insulation Thickness 0 0 0 0 ---

Table 4 Insulation Derating Factor 1.00 1.00 1.00 1.00 ---

Heat Input (MMBtu/Hr) 14.1 12.2 14.1 14.1 54.4

Emergency Fire Flow (MSCFH) 276 725 276 276 1,552

Number Of Thief Hatches 1 1 1 0 3

Required Flow Per Hatch (MSCFH/Hatch) 276.0 724.5 276.0 #DIV/0! 517.5

Other Cases

Failure Of Regulator (SCFD) 0 0 0 0 0

LCV Failure (SCFD) 0 0 0 0 0

Tank Blanket Gas Venting Calculation Based on API 2000 Sept., 1992

Edition

Joint Operations Wafra

Pressure Maintenance Plant

1 This spreadsheet calculates the inbreathing and outbreathing requirements for above ground

storage tanks based on API 2000 September 1992 edition for tanks of under 25,000 barrel capacity

and less than 1 Psig design pressure.

2 For process tanks with constant level the inflow and outflow should be inputed for process upsets

only. For the filling and emptying case the thief hatch can be used. If the blanketing system is

sized for these cases for tanks with high inlet and outlet flows this can lead to very conservative

sizing.

3 The non-rigourous fire case assumes a tank surface area of over 2,800 sq. ft. and hexane as the

liquid.

4 The rigourous fire case requires the latent heat of vaporization which can be obtained from HYSIM

if the composition of the liquid is known.

5 Insulation factors are taken from API 2000 as shown in the table below

Insulation Thickness "F" Factor

0 1

1 0.3

2 0.15

4 0.075

Das könnte Ihnen auch gefallen

- Estimate BOR in LNG Type C TankDokument14 SeitenEstimate BOR in LNG Type C TankNgoVietCuongNoch keine Bewertungen

- Flash CalculationsDokument10 SeitenFlash CalculationsHamza AliNoch keine Bewertungen

- PH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackDokument16 SeitenPH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackRanu JanuarNoch keine Bewertungen

- Kod SizingDokument2 SeitenKod SizingCan YıldırımNoch keine Bewertungen

- Load CalculationDokument10 SeitenLoad CalculationalbertooooooNoch keine Bewertungen

- Nomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersDokument8 SeitenNomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersshikerNoch keine Bewertungen

- Final Ventury Working For Wet Alkaline ScrubberDokument11 SeitenFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNoch keine Bewertungen

- GPSA - Methanol Inhibition Rate RevisedDokument11 SeitenGPSA - Methanol Inhibition Rate RevisedrmaganNoch keine Bewertungen

- Reformer CalculationsDokument5 SeitenReformer CalculationssahilchemNoch keine Bewertungen

- Art's Liq Vapor SeparatorRev1Dokument12 SeitenArt's Liq Vapor SeparatorRev1iuiuiooiuNoch keine Bewertungen

- Test Gas CalculationDokument4 SeitenTest Gas CalculationgrabettyNoch keine Bewertungen

- R 134a ChillerDokument48 SeitenR 134a ChillerAshfaq NoorNoch keine Bewertungen

- Vessel 2 Is To 1 Ellipsoidal VesselDokument3 SeitenVessel 2 Is To 1 Ellipsoidal VesselHoang-Vu BuiNoch keine Bewertungen

- Dowtherm Vent CondenserDokument1 SeiteDowtherm Vent Condensersushant_jhawerNoch keine Bewertungen

- DN Process Plan WKG - BKNDokument13 SeitenDN Process Plan WKG - BKNBui Khoi NguyenNoch keine Bewertungen

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDokument2 SeitenAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahNoch keine Bewertungen

- Art's Liquid-Vapor SeparatorDokument13 SeitenArt's Liquid-Vapor Separatorlutfi awnNoch keine Bewertungen

- Dowtherm BookDokument30 SeitenDowtherm BookMeghnad M GavitNoch keine Bewertungen

- BFW Cooler Datasheet Rev 2Dokument3 SeitenBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNoch keine Bewertungen

- Heat Exchanger Area & Boilup Rate CalculationDokument19 SeitenHeat Exchanger Area & Boilup Rate CalculationNitin KurupNoch keine Bewertungen

- Blending Parameters by NeniDokument8 SeitenBlending Parameters by NeniAjinkya PatilNoch keine Bewertungen

- Liquid Pipe Sizing: Group Technology SolutionsDokument1 SeiteLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNoch keine Bewertungen

- Conversion FactorDokument4 SeitenConversion Factorpks_2410Noch keine Bewertungen

- Desuperheater Boiler Feed Water RequirementDokument2 SeitenDesuperheater Boiler Feed Water Requirementmehul10941Noch keine Bewertungen

- Tie in Point (TP) 08 ADokument19 SeitenTie in Point (TP) 08 At_i_f_anoNoch keine Bewertungen

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDokument2 Seiten7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNoch keine Bewertungen

- Venting-CalculationsDokument3 SeitenVenting-CalculationsKartik PatelNoch keine Bewertungen

- Emergency Vent Flam LiquidsDokument3 SeitenEmergency Vent Flam LiquidsSharon LambertNoch keine Bewertungen

- Xebec Hydrogen BrochureDokument24 SeitenXebec Hydrogen BrochureJoshNoch keine Bewertungen

- Crude Tower Simulation-HYSYS v8.6 PDFDokument62 SeitenCrude Tower Simulation-HYSYS v8.6 PDFrawadNoch keine Bewertungen

- LNG UNIT-1 2018-19 PDFDokument13 SeitenLNG UNIT-1 2018-19 PDFAnil KumarNoch keine Bewertungen

- Minimum Maximum LPG Energy Content (Btu/f)Dokument5 SeitenMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanNoch keine Bewertungen

- Materials: Drying in TraysDokument10 SeitenMaterials: Drying in TraysMira FazziraNoch keine Bewertungen

- Filter Vessel Shell VelocityDokument12 SeitenFilter Vessel Shell VelocityAye KyweNoch keine Bewertungen

- CPI SeparatorDokument3 SeitenCPI SeparatorRajdeepsinhNoch keine Bewertungen

- Simulation Diagram of Simple RefineryDokument1 SeiteSimulation Diagram of Simple RefineryTouhidBinAnwarNoch keine Bewertungen

- Trim Heater PDFDokument2 SeitenTrim Heater PDFsaadashfaq100% (1)

- New Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5Dokument11 SeitenNew Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5rym romdhanNoch keine Bewertungen

- IncineratorDokument6 SeitenIncineratorKamal DeshapriyaNoch keine Bewertungen

- 205 PV LPGDokument211 Seiten205 PV LPGf166Noch keine Bewertungen

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDokument15 SeitenRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11Noch keine Bewertungen

- Macro: This Worksheets Use Visual Basic Module Regarding ToDokument56 SeitenMacro: This Worksheets Use Visual Basic Module Regarding ToOlumuyiwa FasehunNoch keine Bewertungen

- Pipes. Maxi 1Dokument1 SeitePipes. Maxi 1Nasrul AdliNoch keine Bewertungen

- C3CYCLVDokument13 SeitenC3CYCLVUok RitchieNoch keine Bewertungen

- Shell K.O.drum SeparatorDokument11 SeitenShell K.O.drum SeparatorChitu Ionut LaurentiuNoch keine Bewertungen

- AspenHYSYSOLIIF V7 3-Ref PDFDokument230 SeitenAspenHYSYSOLIIF V7 3-Ref PDFamerico007Noch keine Bewertungen

- LNG Tank Cool Down Calculation 1. InputDokument4 SeitenLNG Tank Cool Down Calculation 1. InputThinh ViproNoch keine Bewertungen

- 20 - Condensate Line SizingDokument2 Seiten20 - Condensate Line SizingJunaid MateenNoch keine Bewertungen

- Section 7 - Separation EquipmentDokument9 SeitenSection 7 - Separation Equipmentlulis171Noch keine Bewertungen

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDokument3 SeitenPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasNoch keine Bewertungen

- Vent Dispersion CalcDokument9 SeitenVent Dispersion CalcPeddy Nesa0% (1)

- Demister Calc.Dokument4 SeitenDemister Calc.shazanNoch keine Bewertungen

- GPSA Section 2Dokument6 SeitenGPSA Section 2braianvegas12Noch keine Bewertungen

- CH-RA3 Page 1Dokument1 SeiteCH-RA3 Page 1Sonya LoveraNoch keine Bewertungen

- Uniflair SDA0601: Equipment Computech Close Control A/C Units (Main Data Centre)Dokument6 SeitenUniflair SDA0601: Equipment Computech Close Control A/C Units (Main Data Centre)Arnold MokuaNoch keine Bewertungen

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDokument37 SeitenDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONoch keine Bewertungen

- Pipeline Cathodic Protection Design - Compress PDFDokument20 SeitenPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- 30SCC160 2pdeDokument30 Seiten30SCC160 2pdeمحمد مرسيNoch keine Bewertungen

- CO2 Condenser 02-03-2023-15 PMDokument37 SeitenCO2 Condenser 02-03-2023-15 PMahmad santosoNoch keine Bewertungen

- VCP MecayucanDokument3 SeitenVCP MecayucanAlberto ReyesNoch keine Bewertungen

- Form Lopa Summary SheetDokument1 SeiteForm Lopa Summary SheetguhadebasisNoch keine Bewertungen

- COLLABORATIVEDokument8 SeitenCOLLABORATIVEguhadebasisNoch keine Bewertungen

- SafetyIntegrityLevel PDFDokument17 SeitenSafetyIntegrityLevel PDFzazaNoch keine Bewertungen

- SummaryDokument1 SeiteSummaryguhadebasisNoch keine Bewertungen

- Simplified Risk Analysis (LOPA)Dokument8 SeitenSimplified Risk Analysis (LOPA)hmatora72_905124701Noch keine Bewertungen

- Haz ChemDokument5 SeitenHaz ChemguhadebasisNoch keine Bewertungen

- Catalytic PolymerisationDokument7 SeitenCatalytic PolymerisationguhadebasisNoch keine Bewertungen

- Sweetening: Fig. 26-1 Merox Treating-LPG UnitDokument3 SeitenSweetening: Fig. 26-1 Merox Treating-LPG UnitguhadebasisNoch keine Bewertungen

- Safety: Layer of Protection: Process Operability Class MaterialsDokument48 SeitenSafety: Layer of Protection: Process Operability Class MaterialsguhadebasisNoch keine Bewertungen

- Waste Treatment and DisposalDokument2 SeitenWaste Treatment and DisposalguhadebasisNoch keine Bewertungen

- Tail Gas Clean UpDokument2 SeitenTail Gas Clean UpguhadebasisNoch keine Bewertungen

- System Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigDokument5 SeitenSystem Pressure Drop: Cumulative Back Pressure 0.08 Psig 0.00 PsigguhadebasisNoch keine Bewertungen

- Two Fa: Interpreting Ure RatesDokument14 SeitenTwo Fa: Interpreting Ure RatesguhadebasisNoch keine Bewertungen

- LT HC ProcessDokument9 SeitenLT HC ProcessguhadebasisNoch keine Bewertungen

- PSM Compliance ChecklistDokument18 SeitenPSM Compliance ChecklistSachin SikkaNoch keine Bewertungen

- Light Distillate ProcessDokument11 SeitenLight Distillate ProcessguhadebasisNoch keine Bewertungen

- 7Dokument13 Seiten7Raju GummaNoch keine Bewertungen

- Crude Oils, Hydrocarbons, and Refinery Products: Petroleum Supply/Demand PictureDokument13 SeitenCrude Oils, Hydrocarbons, and Refinery Products: Petroleum Supply/Demand Pictureul84Noch keine Bewertungen

- 2 PDFDokument31 Seiten2 PDFRaju GummaNoch keine Bewertungen

- 3 PDFDokument9 Seiten3 PDFRaju GummaNoch keine Bewertungen

- Bypass Worksheet: Check The Appropriate BoxDokument1 SeiteBypass Worksheet: Check The Appropriate BoxguhadebasisNoch keine Bewertungen

- All in OneDokument28 SeitenAll in OnezakiralitalibNoch keine Bewertungen

- Refinery Economics 2Dokument9 SeitenRefinery Economics 2guhadebasisNoch keine Bewertungen

- Delayed Coking Process DescriptionDokument14 SeitenDelayed Coking Process DescriptionRaju GummaNoch keine Bewertungen

- Guidance Note-Supporting Safety Studies PDFDokument29 SeitenGuidance Note-Supporting Safety Studies PDFFrancesco MonacoNoch keine Bewertungen

- Flammables, Explosion Risks and DSEARDokument10 SeitenFlammables, Explosion Risks and DSEARTitash Mukherjee SenNoch keine Bewertungen

- Cost of Compressed Air FormulaDokument1 SeiteCost of Compressed Air FormulaguhadebasisNoch keine Bewertungen

- 1238-Security Announcement Unexploded Ordnance 10 October 2011Dokument2 Seiten1238-Security Announcement Unexploded Ordnance 10 October 2011guhadebasisNoch keine Bewertungen

- Processsafety Beacon 2011Dokument12 SeitenProcesssafety Beacon 2011kavehNoch keine Bewertungen

- 4.0 User Manual For TBS Sensors v6Dokument18 Seiten4.0 User Manual For TBS Sensors v6Alexandre MandettaNoch keine Bewertungen

- SB Ibl P CBL Submersible Power CableDokument23 SeitenSB Ibl P CBL Submersible Power CableMuhammad ShahrukhNoch keine Bewertungen

- NGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core IdeasDokument5 SeitenNGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core Ideasapi-300263583Noch keine Bewertungen

- Engine: HMK 102 Energy Workshop ManualDokument20 SeitenEngine: HMK 102 Energy Workshop ManualJonathan WENDTNoch keine Bewertungen

- Biogas Technology in Bangladesh: A Comprehensive Study On History, Present Situation, Technologies and Electricity Generation PotentialDokument45 SeitenBiogas Technology in Bangladesh: A Comprehensive Study On History, Present Situation, Technologies and Electricity Generation PotentialEagleNoch keine Bewertungen

- Pract 05Dokument2 SeitenPract 05Timothy CNoch keine Bewertungen

- IB Physics Topic 2Dokument18 SeitenIB Physics Topic 2wee100% (1)

- Crude Oil As Say ManualDokument42 SeitenCrude Oil As Say Manualsakthi service EngrNoch keine Bewertungen

- DCC ChecklistDokument1 SeiteDCC Checklistluci_camNoch keine Bewertungen

- 8 The Application of Deep Sea Water PDFDokument7 Seiten8 The Application of Deep Sea Water PDFGraci AngelNoch keine Bewertungen

- Data Sheet Belt Feeder 50 20 02Dokument6 SeitenData Sheet Belt Feeder 50 20 02GIANMARCONoch keine Bewertungen

- LC1044 LRP14 3PH QRG 0823Dokument2 SeitenLC1044 LRP14 3PH QRG 0823FlakooNoch keine Bewertungen

- 01 Three-Phase Diode Rectifiers AsmarDokument65 Seiten01 Three-Phase Diode Rectifiers AsmarVenkedesh RNoch keine Bewertungen

- VP01-VP10 d900Dokument6 SeitenVP01-VP10 d900Constantin294Noch keine Bewertungen

- EXPT. 1 Common Laboratory OperationsDokument8 SeitenEXPT. 1 Common Laboratory Operationsjazzmin dulceNoch keine Bewertungen

- 4.16 Clear Water High Lift Pump HouseDokument4 Seiten4.16 Clear Water High Lift Pump HousePrasenjit DeyNoch keine Bewertungen

- Physics-Pt With SolutionDokument19 SeitenPhysics-Pt With SolutionChris Paul D VarelaNoch keine Bewertungen

- Chapter 4 Psychomentry, Humidification and DehumidificationDokument14 SeitenChapter 4 Psychomentry, Humidification and DehumidificationNurshaqina SufianNoch keine Bewertungen

- Fcaw Cost ControlDokument13 SeitenFcaw Cost ControlAsad Bin Ala QatariNoch keine Bewertungen

- Doseuro Ficha TécnicaDokument8 SeitenDoseuro Ficha TécnicaAdiel EnriquezNoch keine Bewertungen

- MIL-H-5440G Hydraulic Systems, AircraftDokument49 SeitenMIL-H-5440G Hydraulic Systems, AircraftRonny Valero Montoya0% (1)

- VW Oil SpecDokument18 SeitenVW Oil Specjpsum161100% (2)

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsDokument2 SeitenSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXANoch keine Bewertungen

- FSD101eng FSG Seals Catalog A4Dokument64 SeitenFSD101eng FSG Seals Catalog A4ASHOKNoch keine Bewertungen

- Boiler Water ConditioningDokument3 SeitenBoiler Water ConditioningShahin AfrozNoch keine Bewertungen

- Task 1Dokument6 SeitenTask 1ashkar aliNoch keine Bewertungen

- SP-60-27 (LV Bus Ducts)Dokument6 SeitenSP-60-27 (LV Bus Ducts)Hadi MoosaviNoch keine Bewertungen

- Catalogue2014 PDFDokument158 SeitenCatalogue2014 PDFاشرينكيل مسونكيل100% (1)

- ISC Physics Sample Paper 1Dokument9 SeitenISC Physics Sample Paper 1amit77999Noch keine Bewertungen

- Register of Licences and Permits For Electric Power Undertakings PDFDokument20 SeitenRegister of Licences and Permits For Electric Power Undertakings PDFNyasclemNoch keine Bewertungen