Beruflich Dokumente

Kultur Dokumente

Analytical Study and Comparison of Solid and Liquid Batteries For Electric Vehicles and Thermal Management Simulation

Hochgeladen von

UIJRT United International Journal for Research & TechnologyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Analytical Study and Comparison of Solid and Liquid Batteries For Electric Vehicles and Thermal Management Simulation

Hochgeladen von

UIJRT United International Journal for Research & TechnologyCopyright:

Verfügbare Formate

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

Analytical Study and Comparison of Solid and Liquid

Batteries for Electric Vehicles and Thermal

Management Simulation

Vaibhav Kumar Singh1 M Faisal Jamal Khan2

1,2

Masters in Mechatronics

1,2

Ravensburg-Weingarten University, Germany

Abstract— As the world is growing very fast and the I. INTRODUCTION

major role player is the technical sector, but when it The main difference between solid and liquid batteries

comes to the Automotive world one cannot forget e- is the use of solid electrolytes instead of liquid

mobility and hence we are also contributing our part in electrolytes. Lithium-ion batteries have gone so far in

it. We are doing an in-depth study on Solid-state terms of development, but experts think that lithium-

batteries and Liquid state batteries and detailed ion technology has reached the maximum level of its

comparison between them. In the end, we are also efficiency. The next step in the future will require a

doing the thermal management of the batteries using a different type of battery, and that's where the solid-state

Simulation tool called the Simulink/Simscape battery comes in.

Language Model. E-mobility is still in the developing

phase and there are a lot of opportunities available and SSBs (solid-state batteries) are low mass, compact

we targeted the Battery part. In this report we are geometry and have a higher power density than liquid

showing with different facts, proves, calculations and batteries based on liquid electrolytes. The main

experiments that how solid-state batteries (SSB) are challenge for the prevalent introduction of SSB is to

better than currently using liquid state batteries (LSB) find an appropriate and efficient electrolyte for large

because experts believe that the future is of solid-state batteries and also a cheaper mean of manufacturing.

batteries because of its versatility and many advantages

Electrochemical systems such as batteries using

over LSB. We did the comparison between the current

aqueous electrolytes were not suitable for their use in

electronic vehicles using LSB(Lithium-Ion) and the

the biomedical devices, electronic devices needing

future vehicles using SSB on various aspects according

memory backup and other consumer-oriented

to our experiment, research and the result we got is

applications [1]. As early as the turn of this century, it

outstanding and also found to be the worthy step

was recognized that certain compounds in the solid-

toward the development of SSB. We also did the

state could function as electrolytes and several studies

thermal management of the battery to increase its on-

have been done using these solid electrolytes in the

road efficiency and the result is quite satisfying as we

electrochemical cell. In recent years, considerable

took a small load to check the battery performance and

progress has been made in the development of practical

we also gave the comparison of thermal management

solid-state batteries as energy sources. A solid-state

using two different heat transfer coefficient (5 W/m^2

battery will be defined as one in which anode,

K and 25 W/m^2 K) and we are able to get better

electrolyte, and cathode are solids. Solid-State

cooling efficiency when we increase the value of heat

Batteries offer some attractive advantages over their

transfer coefficient. Results, proposed ideas, and the

liquid counterparts. They are inherently robust, spill-

research analysis clearly giving a green signal towards

proof and usually non-corrosive. They are compact and

the speedy development of Solid-state batteries and

well suited to miniaturization and the ability of the

how it overcomes the different disadvantages of Liquid

component to stay in position can do obviate the need

state batteries, whereas Thermal Management Model

for separators, membranes and/or diaphragms which

proposes with several changes give us the in-depth

add to the mass and volume of liquid systems without

view of the temperature rise and also by changing the

producing a concomitant increase in energy and power.

heat transfer coefficient one can select a better cooling

Thin-film configuration can be used and sometimes

system for batteries, to operate it in an optimized range

these can be formed into unusual shapes that fit them

of temperature.

for 191 specialized applications. They can perform

Keywords— solid battery, liquid battery, electric adequately over wide temperature ranges which are

vehicles, thermal management simulation highly desirable for military and other

All rights are reserved by UIJRT.COM. 27

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

uses. 4. Tesla

5. LG-Chem

6. A123-System

7. ecobalt-Solutions

8. BYD

9. Johnson-Control

III. COMPOSITION OF SOLID-STATE BATTERIES

3.1 Cathode

The cathode in the solid-state battery is important

because it supplies the battery with the necessary ions

Fig.1 Conventional and SSB

during charging and vice-versa during discharging.

II. SOLID STATE BATTERY COMPANIES Commonly used cathode materials for lithium-based

Comparison between two companies on different solid-state batteries are lithium metal oxides, as they

parameters for a solid-state battery. exhibit most of the above-mentioned necessary

properties. Lithium cobalt oxide (LCO), which has the

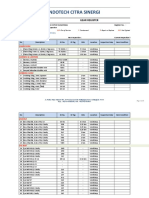

Table No. 1 stoichiometric structure LiCoO2, is a widely used

S.No Parameters Hitachi Stereax lithium metal-based oxide. LCO has a layer structure

Zosen suitable for the lithium/delithiation process and has a

1 Electrolyte Solid Solid relatively high specific energy of about 150 mAh g-1,

electrolyte electrolyte making it a preferred cathode material. Lithium

sulphide (Li2 manganese oxide (LiMn2O4) is another material used

-P2) in the cathode of solid-state batteries. In addition to

2 Cathode Ni series Lithium these lithium-based oxides, vanadium-based oxides

Cobaltate have also been tested as they have similar layer

3 Anode Graphite type Silicon structures that help in the lithium/delithiation process

4 Size 50 mm × 50 12 mm x 12 [3].

mm mm, 3.2 Anode

5 Industry In In Medical Carbon and carbon-based materials are commonly used

Automotive field for anode materials in solid-state batteries. Graphite is also

sector for small power widely used as an anode material in solid-state

more power requirement. batteries, which has several advantages, such as a

requirement layered structure capable of absorbing lithium ions

6 Status Still under In use for during the lithing/delitriding process, its ability to

research very small withstand a large number of charge and discharge

purposes. cycles, and its relatively simple fabrication. Graphite

7 Expected Expected Already in can also be easily doped with other materials to

launching the market. improve its capacity. The main problem with graphite

year would is its relatively low capacity. Soft carbon is another

be 2021-22. material that is used. Anodic systems based on metallic

8 Operating -40 ° C to -20°C to alloys have also been studied, in particular, Sn, Pb, Sb,

temperature 130 ° C * 100°C Al and Zn and their alloy systems [3].

*These are the approximate values given by different 3.3 Electrolyte

companies because nobody has a concrete idea about Since the performance of a solid-state battery depends

the actual temperature. on the diffusion of ions within the electrolyte, solid

electrolytes must have high ionic conductivity, very

There are some companies who are major manufacturer

low electronic conductivity and a high degree of

of liquid state batteries (Lithium-ion), but currently

chemical stability. Crystalline materials such as lithium

involved in research & development of Solid-State

halides, lithium nitride, oxy salts, and sulphides have

Batteries (SSB).

proven themselves as solid electrolytes. The most

1. Samsung-SDI advantageous properties of the solid electrolyte are that

2. Panasonic there are no corrosive or explosive leaks and the risk of

3. Toshiba an internal short circuit is lower and therefore safer.

All rights are reserved by UIJRT.COM. 28

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

The most commonly used thin-film solid electrolyte is solid batteries so as to achieve favourable energy and

the LiPON electrolyte (lithium phosphorus oxide power.

nitride). It is usually a glass-like electrolyte obtained by

RF magnetron sputtering [3]. 4.2 Temperature

At low temperature, below 0°C flow of ions is irregular

resulting in less energy and power. Companies are

currently researching this problem.

The proposed solution for this problem is that we

require a separate lithium-ion battery which heats the

heater around the solid-state battery to preheat solid

battery to its operating temperature range.

4.3 Cost

Cost is the measure drawback in the development of

SSB. According to research at the University of Florida

using current thin-film technology, the cost of a single

20Ah battery would be $100,000 A high range EV will

require 800-1000 20Ah cells.

Fig. 2 A schematic representation of a representative

lithium based solid state battery To reduce the cost, the following solutions are

proposed:

3.4 Advantages of Solid State Batteries

Solid state batteries are more efficient and a) Avoid semiconductor grade chemicals

Advantageous than Liquid state Batteries. Below are

Develop process around inexpensive chemicals

some advantages of Solid-State Batteries :

b) Avoid Vacuum technologies

1. High Energy (Higher voltage cathodes possible)

2. High Power (Large discharge rates possible) 1. Slows Manufacturing

3. Low Mass (Less inert material) 2. High Capital expense

4. High cycle number (10 times life cycle than

typical Liquid) c) Develop high throughput process

5. Compact Geometry (Require less space in a

vehicle) e.g. roll to roll

6. Environment Friendly

V. COMPARISON OF LIQUID BATTERY USED IN

7. Cell Separator will not break at higher temperature ELECTRIC VEHICLE ‘NISSAN LEAF’ WITH

(165) in contrast to liquid batteries. STANDARD SOLID STATE BATTERY

8. Leakage of Electrolyte is not happened (Because Currently, ‘Nissan’ is using liquid-state batteries for

of Solid Electrolyte). their vehicles but they are also planning to move on

solid-state batteries in upcoming years because the

3.5 Disadvantages researches on SSB has proved that, it is way more

1. High Cost efficient in every aspect except operating temperature.

2. Temperature Sensitive (not easy to operate at low

temperature) Here, the given table proposed by us is focusing on

3. Ceramic electrolytes involve elevated pressure to some key aspects to differentiate between LSB used in

keep the electrodes in touch. one car segment “Leaf” of Nissan & standard SSB.

IV. CHALLENGES AND SOLUTION Table No. 2

4.1 Material Composition: Parameters Solid Liquid

Interfaces are always a challenge for solid-state Capacity 24 KWh 24 KWh

systems. It is difficult to interface between cathode, Energy Density 350 Wh/kg 140

anode and solid electrolyte due to their different Wh/kg

chemical properties and physical structure. The Nominal 360V 360V

proposed solution is Thick composite positive Voltage

electrode layers (high active mass loading) and thin Number of 80 (according to 192

solid electrolyte layers need to be considered for all- Cells calculation)

All rights are reserved by UIJRT.COM. 29

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

Rated Capacity 80Ah 32.5Ah power. A passive system can offer some hundreds of

Operating 0-150* ° C -20 to 60 watts cooling or heating power and an active system

Temperature °C power is limited to 1 kW.

Range We can achieve the 150 km

existing range of Because in both cases the air is supplied by a blower,

150km in only 80 they are also called forced air systems. The following

solid battery cells, figure shows a schematic description of systems.

and this range can

be increased also by

increasing the no. of

cells.

*data obtained from Solid Power company, Canada.

The above comparison is based on our calculations and

the data given on Solid Power, Canada website.

After studying the comparison table, we concluded that

Solid battery will be more efficient than Liquid

Batteries based on Energy Density and also the

geometry is compact due to less number of cell, which Fig.3 Active & Passive System

provides the require Nominal Voltage with Higher

Our simulation results shows how important thermal

Rated Capacity.

management is in order to control the battery behaviour

5. 1 Thermal Management System

for better performance and also to enhance the

Battery thermal management system always improves

efficiency. One can also do further experiments by

the battery behaviour and also plays indispensable role

combining the our simulation model with electric

in increasing battery life cycle. Thermal management

vehicles or may be any CFD simulation models.[5]

of the batteries can be done by several means like air,

refrigerant, water etc. More appropriately it is termed 5.3 Battery Thermal Management Model

as; This model is composed of Lithium Cell 1RC

(Resistance Capacitor), one thermal management

1. Air Cooling System

block. We are using the inbuilt library of thermal

2. Liquid Cooling System

systems to do the thermal management of the battery

3. Direct Refrigerant Cooling System

and to control the battery temperature in its optimum

4. Phase Change Material (PCM) Cooling

working range.

System

5. Thermo-Electric Cooling System

Due to inefficiency, battery cells will not only generate

electricity but also heat. This heat should be moved

from the battery pack when the battery temperature

reaches the optimum temperature or even in advance.

Thus, a cooling function is required in Battery thermal

Management system (BTMS).

Here we used Air cooling system in our experiment

and also showed how free convection and forced

convection can enhance the cooling efficiency. Fig. 4 Thermal Model[6]

5.2 Air Cooling System 1. Lithium Cell 1RC

Air systems use air as the thermal medium. The intake 2. Test Inputs (For Ambient temperature 20 and

air could be direct either from atmosphere or from the Current)

cabin and could also be conditioned air after a heater or 3. A Heat Convective Transfer

evaporator of an air conditioner. The former is called 4. Input Current Sensor

passive air system and the latter is active air system. 5. Voltage Sensor (V_Load)

Active systems can offer additional cooling or heating 6. Scope (It shows Terminal Voltage, Temperature

and State of Charge)

All rights are reserved by UIJRT.COM. 30

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

Lithium Cell 1 RC

In this model we are using a standard cylindrical

Lithium Cell, which consist of a thermal management

block, one capacitance block and two resistance block.

Fig. 6 Thermal Model

In the above model we consider Battery Thermal Mass,

Ideal Heat Flow, Temperature Sensor. These

component are predefined in Thermal Library of

Simscape.

a. Battery Thermal Mass

This block models internal energy storage in a thermal

network. The rate of temperature increase is

proportional to the heat flow rate into the material and

inversely proportional to the mass and specific heat of

the material. [6]

b. Ideal Heat Flow

Fig.5 Inside Electrical Model This block represents an ideal energy source in a

thermal network that can maintain a controlled heat

For Lithium Cell terminal voltage calculation, we are flow rate regardless of the temperature difference. The

using component block of Em_table. In the component heat flow rate is set by the physical signal port S. A

block there is equation on the basis of lookup table of positive heat flow rate flows from port A to port B. In

SOC(State of Charge) and Temperature. The system this block physical signal i.e. P_in (sum of power

calculates the nominal and terminal voltage of the generated in battery resistor and load) is connected to

battery according to the current drawn from it on the port S and consider A as ground reference or thermal

load. reference. [6]

According to those calculations the Cell SOC is .5 at c. Temperature Sensor

the beginning, but when the load is connected, the cell This block measures temperature is a thermal network.

voltage as well SOC of the system changes. There is no heat flow through the sensor. The physical

signal port T reports the temperature difference across

During that time the Cell Nominal Voltage is 3.75

the sensor.

Volts and Peak Voltage is 4.5 at SOC

The measurement is positive when the temperature at

All calculations are done by the equations that are used

port A is greater than the temperature at port B. [6].

in component block source code. We connect the

Em_Table (Cell) to the RC circuit to optimize the Parameter that we consider and put in the work space

working and charging. of model is in the following table:

R_table value is calculated by SOC and the Table No. 3

temperature in the MATLAB lookup table and also the

Parameter Value Units

amount of heat generated i.e power (temperature) is

Nominal Voltage 3.75 Volts

transferred to thermal management block.

Peak Voltage 4.5 Volts

Thermal Model Cell Mass 1 Kg

The thermal model is used to control the temperature Cell Specific 850±5 J/kgK

range of battery when load is applied. Heat(cell_Cp_heat)

Ambient 20 °C

Temperature

All rights are reserved by UIJRT.COM. 31

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

Battery Initial 20 °C At heat transfer coefficient = 5 W/m2K

Temperature

Convective Heat 5,25,500 W/m2K So, at heat transfer coefficient of 5 W/m^2K. we

Transfer (h_conv) observed following things;

Area of Cell .06 m2

1. We observed that at very first, temperature of the

battery is rising (When it is connected to the load,

These are the parameters that are used in this model.

firstly it reaches to the peak voltage and then

Someone can edit in the work space of MATLAB of

comes back to certain optimum level, resulting in

this model and change the parameters according to

sudden rise in temperature) from 20 C to 38.4 C.

their requirement without changing the lookup tables.

2. We employed free convection system here which

We also did some calculations on thermodynamic

is responsible for cooling down the battery, and it

behaviour of the system, here are as follows:

brings the temperature down from 38.4 C to 29 C

First, we calculated the heat generated by battery in the and then finally around 23 C.

temperature range of (20-45 ° C) Mass of lithium ion 3. System takes 1.804 Ksec. (i.e. 30 min.) to reach to

battery = 1kg, Specific heat of lithium ion battery (Cp) its maximum temperature i.e.

= 850 J/kgK ±5, Thermal mass = m*Cp 4. 38.4 C from 20 C.

5. Cooling System (Free convection) takes 1.494

= 1*850= 850 J/K Ksec (25 min.) to cool down the battery from 38.4

C to 29.5 C.

Heat = m*Cp*(delta T) Heat = 1*850*(25)

For Heat Flow Rate by Forced Convection

Heat = 21.25 KJ

Now, for cooling we are using ambient air by

convection method. We are using Convective Heat

Transfer Block (From Simscape Thermal Library)

Convective Heat Transfer

This block models heat transfers in a thermal network

by convection due to fluid motion. The rate of heat

transfer is proportional to the temperature difference,

heat transfer coefficient, and surface area in contact

with the fluid. [6]

Heat Transfer Coefficient(h) for Ambient air (20 ° C) =

25 W/m2K Area(A) = 0.06 m2

Heat Transfer Rate = h*A*delta (T)

For Heat Flow rate by Free convection Heat Transfer Rate = (25 W/m2K)* (0.06 m2)*(18.4 K)

Heat Transfer Rate = 5.52 W

So, at heat transfer coefficient of 25 W/m2K we

observed following things;

a) We observed that at very first, temperature of the

battery is rising (When it is connected to the load,

firstly it reaches to peak voltage and then come

back to certain optimum level, resulting in

moderate rise in temperature) from 20° C to 24° C.

b) We employed forced convection system here

Heat Transfer Coefficient(h) for Ambient air (20 ° C) =

which is responsible for cooling down the battery,

5 W/m2K Area(A) = 0.06 m2

and it brings the temperature down from 24° C to

Heat Transfer Rate = h*A*delta (T) 20° C.

c) System takes 1.785 Ksec. (i.e. 29.75 or 30 min.) to

Heat Transfer Rate = (5 W/m2K) * (0.06 m2) * (18.4 K) reach to its maximum temperature i.e. 24° C from

Heat Transfer Rate = 5.52 W 20 °C.

All rights are reserved by UIJRT.COM. 32

UIJRT | United International Journal for Research & Technology | Volume 01, Issue 01, 2019

d) Cooling System (Free convection) takes 1.499 We would like to thank my family for standing by me

Ksec (25 min.) to cool down the battery from 24 through all the joys and sorrows that life had to offer.

°C to 20 °C.

VII. CONCLUSION

For Heat Flow Rate by Force Convection

After many experiments, calculations, and research we

came to an end where we can put a prominent

statement that solid-state batteries are way more batter

than currently used liquid state batteries. Above all life

risk in liquid state batteries (LSB catches fire) can be

eliminated by replacing it with solid-state batteries. We

found solid-state batteries better in terms of energy

density, life cycle, safety, etc. One problem with the

solid-state battery is, it cannot perform efficiently at

Heat Transfer Coefficient(h) for Ambient air (20 ° C) = very low temperature (e.g. negative temperature).

500 W/m2K Area (A) = 0.06 m2

Heat Transfer Rate = h*A*delta (T) We found a very satisfactory result in the thermal

Heat Transfer Rate = (500 W/m2K)* (0.06 m2)*(.4 K) management of the batteries using simulation also.

Heat Transfer Rate = 12 W Hence, we can conclude that forced convection is

So, at heat transfer coefficient of 500 W/m2K we better and should be deployed to achieve better

observed following things; temperature control. We tested our Simulink model on

a) We observed that at very first, temperature of the three different values of heat transfer coefficient, where

battery is rising very slowly and very less from 20° at very first we used free convection but the results are

C to 20.2° C. not implementable in every battery pack of electric

b) We employed forced convection system here vehicles. Hence we switched to another one, which is

which is responsible for cooling down the battery, forced convection and the results are under control and

and it brings the temperature down from 20.2° C to implementable in any battery pack of any vehicle for

20° C. its thermal management.

c) System takes 1.696 Ksec. (i.e. 29 min.) to reach to

its maximum temperature i.e. only 20.2° C from REFERENCES

20 °C. [1] Skaarup S, in: Solid State Ionic Devices, eds.

d) Cooling System (Forced convection) takes Chowdari B.V.R et al World Scientific. Singapore

108.418 seconds to cool down the battery from (1998) 35.

20.2 °C to 20 ° [2] Fig(1) Conventional and SSB”,

https://battery9999.com/hyundai-reportedly-

VI. ACKNOWLEDGEMENTS started-pilot-production-of-next-gen-solid-state-

We take this opportunity to thank all the magnanimous batteries-for-electric-vehicles/

person who rendered their full support to our work [3] A review of lithium and non-lithium based solid

directly or indirectly. We would like to express my state batteries, Joo Gon Kim, Byungrak Son ,

deep sense of gratitude to Dr.-Ing., Professor Florian Santanu Mukherjee , Nicholas Schuppert ,Alex

Kauf for his valuable guidance. Without their Bates , Osung Kwon , Moon Jong Choi, Hyun

inspiration and generous guidance, the work would not Yeol Chung , Sam Park.

be successfully accomplished. [4] Fig. (2) A schematic representation of a

representative lithium based solid state battery”, A

We are also thankful to our Dean Dr.-Ing., Professor review of lithium and non-lithium based solid state

Raphael Ruf (Dean Master Mechatronics, RWU) for batteries Joo Gon Kim a, 1, Byungrak Son a, **, 1,

his valuable suggestions and co-operations throughout Santanu Mukherjee b, 1, Nicholas Schuppert

the scientific project apart from providing useful b,Alex Bates b, Osung Kwon c, Moon Jong Choi

material. a, Hyun Yeol Chung d, Sam Park b,

[5] “Battery Thermal Management System of Electric

We would like to express my deep appreciation to my

Vehicles”, Jiling Li, Zhen Zhu.

departmental colleagues who have been a constant

[6] Model Help and Library from MathWorks

source of inspiration. We are eternally grateful to them

(MATLAB/Simulin

for always encouraging and being with me wherever

and whenever we needed them.

All rights are reserved by UIJRT.COM. 33

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Comparison of Rutting Resistance of Stone Mastic Asphalt With Convention MixDokument7 SeitenComparison of Rutting Resistance of Stone Mastic Asphalt With Convention MixUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Analysis of Passengers Ride Comfort Based On Smartphone Vibration Measurement For Chengdu MetroDokument12 SeitenAnalysis of Passengers Ride Comfort Based On Smartphone Vibration Measurement For Chengdu MetroUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Alagbe, J.O., Agubosi, O.C.P, Ajagbe, A.D, Shittu, M.D and Akintayo Balogun, O.MDokument10 SeitenAlagbe, J.O., Agubosi, O.C.P, Ajagbe, A.D, Shittu, M.D and Akintayo Balogun, O.MUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Growth Performance, Caeca Microbial Population and Immune Response of Starter Broiler Chicks Fed Aqueous Extract of Balanites Aegyptiaca and Alchornea Cordifolia Stem Bark MixtureDokument9 SeitenGrowth Performance, Caeca Microbial Population and Immune Response of Starter Broiler Chicks Fed Aqueous Extract of Balanites Aegyptiaca and Alchornea Cordifolia Stem Bark MixtureUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Probiotics and Medicinal Plants in Poultry Nutrition: A ReviewDokument7 SeitenProbiotics and Medicinal Plants in Poultry Nutrition: A ReviewUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Influence of Social Media As A Tool of Political Marketing in General ElectionsDokument6 SeitenInfluence of Social Media As A Tool of Political Marketing in General ElectionsUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- The Used of Probationary Period in A Contract of Employment in Cameroon: A Legal AppraisalDokument7 SeitenThe Used of Probationary Period in A Contract of Employment in Cameroon: A Legal AppraisalUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- The Construct of Comfort: A Case Study of Environmental Comfort of University ClassroomsDokument5 SeitenThe Construct of Comfort: A Case Study of Environmental Comfort of University ClassroomsUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Literature Review On On-Page & Off-Page SEO For Ranking PurposeDokument5 SeitenLiterature Review On On-Page & Off-Page SEO For Ranking PurposeUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Emerging Trends in Private Security Companies (PSCS) and Security Services in Southwest NigeriaDokument15 SeitenEmerging Trends in Private Security Companies (PSCS) and Security Services in Southwest NigeriaUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- The Problem and Prospect of Shrimp Cultivators in The Coastal Area of Bangladesh: An AnalysisDokument10 SeitenThe Problem and Prospect of Shrimp Cultivators in The Coastal Area of Bangladesh: An AnalysisUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Assessment of Proximate Composition and Phytochemical Properties of Bitter Leaf (Vernonia Amygdalina) and Water Leaf (Talinum Triangular)Dokument9 SeitenAssessment of Proximate Composition and Phytochemical Properties of Bitter Leaf (Vernonia Amygdalina) and Water Leaf (Talinum Triangular)UIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Effects of Water Quality On Strength Properties of ConcreteDokument7 SeitenEffects of Water Quality On Strength Properties of ConcreteUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Security Issues of Network Mobility (NEMO) With Tor ArchitectureDokument5 SeitenSecurity Issues of Network Mobility (NEMO) With Tor ArchitectureUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Structuring Alternative Investment in Public Private Partnership Projects Using Islamic Financial InstrumentsDokument10 SeitenStructuring Alternative Investment in Public Private Partnership Projects Using Islamic Financial InstrumentsUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- The Comparative Study On Vernacular Dwellings in BhutanDokument6 SeitenThe Comparative Study On Vernacular Dwellings in BhutanUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- ICT in Assessment: A Backbone For Teaching and Learning ProcessDokument3 SeitenICT in Assessment: A Backbone For Teaching and Learning ProcessUIJRT United International Journal for Research & Technology100% (1)

- Customer Relation Management (CRM) and Its Impact On Organizational Performance: A Case of Etisalat Telecommunication in AfghanistanDokument9 SeitenCustomer Relation Management (CRM) and Its Impact On Organizational Performance: A Case of Etisalat Telecommunication in AfghanistanUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Slum Children: Barrier Faced by Children in Accessing Primary EducationDokument7 SeitenSlum Children: Barrier Faced by Children in Accessing Primary EducationUIJRT United International Journal for Research & TechnologyNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Maximus MHX DatasheetDokument5 SeitenMaximus MHX Datasheetjulya julyaNoch keine Bewertungen

- Restrictions AOP30 enDokument1 SeiteRestrictions AOP30 enRicardo RamirezNoch keine Bewertungen

- Project Initiation and Planning (Schwalbe, 2019) : Student - Feedback@sti - EduDokument3 SeitenProject Initiation and Planning (Schwalbe, 2019) : Student - Feedback@sti - EduRhea Anne N. OcceñaNoch keine Bewertungen

- Aljotronic Control 2Dokument30 SeitenAljotronic Control 2Fuzzbuddy100% (1)

- Guidelines and Standards For External Evaluation Organisations 5th Edition v1.1Dokument74 SeitenGuidelines and Standards For External Evaluation Organisations 5th Edition v1.1Entrepre NurseNoch keine Bewertungen

- SThe Electric Double LayerDokument1 SeiteSThe Electric Double LayerDrishty YadavNoch keine Bewertungen

- ACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrDokument14 SeitenACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrJohn Steven LlorcaNoch keine Bewertungen

- En 10143-1993Dokument7 SeitenEn 10143-1993Eduardo TeixeiraNoch keine Bewertungen

- Smartor manualENDokument148 SeitenSmartor manualENPP043100% (1)

- Mbeya University of Science and TecnologyDokument8 SeitenMbeya University of Science and TecnologyVuluwa GeorgeNoch keine Bewertungen

- Metascope An/Pas-6 (5855-790-6197) : Technical ManualDokument38 SeitenMetascope An/Pas-6 (5855-790-6197) : Technical ManualDens VillaNoch keine Bewertungen

- Product-Oriented Learning Competencies: (Beginner)Dokument4 SeitenProduct-Oriented Learning Competencies: (Beginner)Kri S ELNoch keine Bewertungen

- ESQLDokument2 SeitenESQLajay110125_kumarNoch keine Bewertungen

- Inspection List For Electrical PortableDokument25 SeitenInspection List For Electrical PortableArif FuadiantoNoch keine Bewertungen

- CAT 438 3kk Esquema ElectricoDokument2 SeitenCAT 438 3kk Esquema ElectricocasigreNoch keine Bewertungen

- Heat Power Lab ManualDokument68 SeitenHeat Power Lab ManualRaghu KrishnanNoch keine Bewertungen

- Evaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellDokument6 SeitenEvaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellTrần Hoàng ChươngNoch keine Bewertungen

- KarcherDokument21 SeitenKarcherSIVARAMANJAGANATHANNoch keine Bewertungen

- MoveInSync Native Android Mobile AppDokument12 SeitenMoveInSync Native Android Mobile AppRismaNoch keine Bewertungen

- Chemistry Project Paper ChromatographyDokument20 SeitenChemistry Project Paper ChromatographyAmrita SNoch keine Bewertungen

- Sex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerDokument444 SeitenSex, Law, and Society in Late Imperial China (Law, Society, and Culture in China) by Matthew SommerFer D. MONoch keine Bewertungen

- Literature 101 Assignment: Step 1: Graphic OrganizerDokument2 SeitenLiterature 101 Assignment: Step 1: Graphic OrganizercatarinaNoch keine Bewertungen

- Comsigua HBIDokument0 SeitenComsigua HBIproxywarNoch keine Bewertungen

- Green ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarDokument13 SeitenGreen ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarAHMAD ARESYADNoch keine Bewertungen

- Almugea or Proper FaceDokument5 SeitenAlmugea or Proper FaceValentin BadeaNoch keine Bewertungen

- Self Awareness and Self Management: NSTP 1Dokument7 SeitenSelf Awareness and Self Management: NSTP 1Fritzgerald LanguidoNoch keine Bewertungen

- Translated Copy of Jurnal B.inggris 41117110162 Aditya NurfajriDokument16 SeitenTranslated Copy of Jurnal B.inggris 41117110162 Aditya Nurfajriaditya estimatorNoch keine Bewertungen

- 17 Safety InventoryDokument47 Seiten17 Safety Inventorymishrakanchan 2396Noch keine Bewertungen

- Kelley DavisDokument3 SeitenKelley Davisapi-626701108Noch keine Bewertungen

- Job No. 25800: Quebrada Blanca Fase 2Dokument1 SeiteJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNoch keine Bewertungen