Beruflich Dokumente

Kultur Dokumente

Metal Working For Electronics

Hochgeladen von

Jonathan Rea0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten1 Seitemetal working

Originaltitel

metal working for electronics

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenmetal working

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

36 Ansichten1 SeiteMetal Working For Electronics

Hochgeladen von

Jonathan Reametal working

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Electronic Hombrewer's "Hints & Kinks"

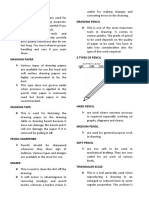

WORKSHOP PRACTICES DOING THE METAL WORK -- LINE-UP

Tapping Holes #1 1 BENDING THE METAL

BEND HERE

NOTCHES

Buying a couple of tap drills, taps

and a tap driver can greatly ALUMINUM

enhance your metal-working OR ANGLE

ME

capabilities. The most common IRON AC ICE

V o.

sizes for electronic work are 4-40 OR C

and 6-32. Drills are $1, taps $2 Drill pilot ½ X 1"

MAKE NOTCHES WITH FILE

hole using TO MARK BEND LINE -- HELPS HARD

HINT: Use drop of oil to the TAP DRILL MAKE A STRAIGHT BEND. WOOD

lubricate tap bit BEND ALUMINUM ON SMALL BENCH VICE USING

Tap Bit ANGLE -IRON OR WOOD "EXTENDERS"

#2 #3 2 PREPARING TO DRILL

FOR ALUM. OR COPPER

COVER FRONT CLAD DRILLING

PANEL WITH

MASKING MASKING

TAPE TAPE

Tap Driver LAYOUT "TAP"

(or Tap Chuck) Remove LOCATION OF HOLES WITH

Insert tap into tap by THE FRONT PANEL TAP PUNCH

hole and slowly turning CCW. Remove CONTROLS AND MARK OR FINISH NAIL

turn clockwise. any burrs on far side WITH BALL-POINT PEN

Tap will thread the hole. Use that might jam tap.

proper tap drill ... a smaller sized

A couple of applications

3 THE DRILLING 4 FINISHING TOUCHES

drill can cause tap to jam ONCE TAPPED ... USE DEBURRING

and snap-off. for tapped holes DRILL HOLES USING TOOL OR A

m A SMALL DRILL FIRST

i nu re -- THEN

LARGE DRILL

m u

#4 Alu clos

E n P.C

.B.

INCREASING TO

DESIRED SIZES.

DRILL AGAINST A

BIT TO

REMOVE

METAL

BURRS

WOOD BLOCK.

T

R ONEL

F N 2x4

Machine screw can PA CLEAN HOLES

OR SHAPE TO

now be inserted Tapped SIZE WITH A

Hole ROUND FILE

DRILL SIZES

Size Tap Drill Thru Drill

2-56 .070" #50 .086" #44 Flat head Tapped USE

machine FILE FOR

4-40 .089" #43 .116" #32

screws Hole "C"

6-32 .107" #36 .144 #27 SHARPENING CHAIN

CLAMP SAWS FOR SMALL HOLES

Das könnte Ihnen auch gefallen

- How We Went Off-Grid -: The Full Approved Planning Application, Foreword by Ben Fogle, Easy-to-follow Business Plan for Simple LivingVon EverandHow We Went Off-Grid -: The Full Approved Planning Application, Foreword by Ben Fogle, Easy-to-follow Business Plan for Simple LivingNoch keine Bewertungen

- Ways To Start A FireDokument5 SeitenWays To Start A FireDarious KaterNoch keine Bewertungen

- Eagle Scout ProjectDokument17 SeitenEagle Scout Projectmrchubs100% (1)

- WWMM Marshmallow Crossbow PDFDokument5 SeitenWWMM Marshmallow Crossbow PDFrob mitchellNoch keine Bewertungen

- Cross BowDokument6 SeitenCross BowTakeshi Goda100% (1)

- System of Wheat IntensificationDokument25 SeitenSystem of Wheat IntensificationPappu Yadav100% (1)

- 1 Tan Your Own Hide PDFDokument13 Seiten1 Tan Your Own Hide PDFTanya Michaela Kneidinger0% (3)

- Water Wheel EngineeringDokument13 SeitenWater Wheel Engineeringrobert131Noch keine Bewertungen

- Build A Car: Karol Castañeda Deivy EspitiaDokument4 SeitenBuild A Car: Karol Castañeda Deivy Espitiakarol castañeda0% (1)

- Water Storage Water Storage: For Off-Grid LivingDokument5 SeitenWater Storage Water Storage: For Off-Grid LivingjessyjaviNoch keine Bewertungen

- Solar Cooking: Quinton Stowell Product Development Manager Nordson UV LTDDokument30 SeitenSolar Cooking: Quinton Stowell Product Development Manager Nordson UV LTDPatel SharvinNoch keine Bewertungen

- List of Root VegetablesDokument6 SeitenList of Root VegetablesAlarm GuardiansNoch keine Bewertungen

- Tabbed Sections For Patrol NotebooksDokument28 SeitenTabbed Sections For Patrol NotebooksShawn M CookNoch keine Bewertungen

- Cyberpunk 2020 - Net - Rules - Oceanpunk Neo-Cetaceans by MorninmanDokument4 SeitenCyberpunk 2020 - Net - Rules - Oceanpunk Neo-Cetaceans by MorninmanArixsonNoch keine Bewertungen

- Camping Packing ListDokument11 SeitenCamping Packing ListUjjwalNoch keine Bewertungen

- Arcadia Glasshouse Planning Guide PDFDokument12 SeitenArcadia Glasshouse Planning Guide PDFArya ParamelNoch keine Bewertungen

- Black Hawk Protective GearDokument17 SeitenBlack Hawk Protective GearSigurdrvargrNoch keine Bewertungen

- Commando Toggle RopeDokument4 SeitenCommando Toggle RopeTokatuuNoch keine Bewertungen

- General/Basic Principles OF Fire PreventionDokument33 SeitenGeneral/Basic Principles OF Fire PreventionYounisQamarNoch keine Bewertungen

- Emergency Cooking OverviewDokument41 SeitenEmergency Cooking OverviewDixieGuns AmmoNoch keine Bewertungen

- Makeshift Tear-Gas Mask: Disobedient ObjectsDokument1 SeiteMakeshift Tear-Gas Mask: Disobedient ObjectsVermin CloneNoch keine Bewertungen

- What's Happening in The World of AquaponicsDokument6 SeitenWhat's Happening in The World of AquaponicsLindaM857Noch keine Bewertungen

- Composting Toilet Construction ManualDokument23 SeitenComposting Toilet Construction ManualalinupNoch keine Bewertungen

- Bottle Oil LampDokument6 SeitenBottle Oil LampcagedraptorNoch keine Bewertungen

- Camping Food: Backcountry Camping Food Includes Ingredients Used To PrepareDokument5 SeitenCamping Food: Backcountry Camping Food Includes Ingredients Used To PreparestevenspillkumarNoch keine Bewertungen

- Improved Wood Waste and Charcol Burning StovesDokument234 SeitenImproved Wood Waste and Charcol Burning StovespcbstepNoch keine Bewertungen

- 11 Vegetables Anyone Can Grow On Their OwnDokument5 Seiten11 Vegetables Anyone Can Grow On Their OwnDivyajyoti DevaNoch keine Bewertungen

- Basic Plumbing: 2 - PreparationDokument8 SeitenBasic Plumbing: 2 - PreparationJen CooperNoch keine Bewertungen

- How To Grow LentilsDokument13 SeitenHow To Grow LentilsJosephLaderaFugataNoch keine Bewertungen

- Guide To Wild-Harvested Mushrooms and Spring Greens: The Morel Is One The Most Popular andDokument7 SeitenGuide To Wild-Harvested Mushrooms and Spring Greens: The Morel Is One The Most Popular andO.L.D.E.Noch keine Bewertungen

- Germination Instructions For Seeds (Prairie Moon Nursery)Dokument21 SeitenGermination Instructions For Seeds (Prairie Moon Nursery)jonowelserNoch keine Bewertungen

- Hunting With The Bow and Arrow by Pope, Saxton, 1875-1926Dokument127 SeitenHunting With The Bow and Arrow by Pope, Saxton, 1875-1926Gutenberg.orgNoch keine Bewertungen

- Are There Different Types of Hiking?: Cultural AdventureDokument10 SeitenAre There Different Types of Hiking?: Cultural AdventureMae Guanzon Saludes CorderoNoch keine Bewertungen

- Introduction To Field TargetDokument55 SeitenIntroduction To Field Targetradio-chaserNoch keine Bewertungen

- Solar Power: The Getting-Started GuideDokument27 SeitenSolar Power: The Getting-Started Guidem_asifNoch keine Bewertungen

- Mel Tappen's Personal Survival LettersDokument540 SeitenMel Tappen's Personal Survival Lettersstjohn45Noch keine Bewertungen

- LP4 Timber and LumberDokument12 SeitenLP4 Timber and Lumberglenn salandananNoch keine Bewertungen

- Bug Out BagDokument3 SeitenBug Out Baglors.avakim6799100% (1)

- Wilderness Survival: Merit Badge WorkbookDokument4 SeitenWilderness Survival: Merit Badge WorkbookagungpremonoNoch keine Bewertungen

- Wilderness Survival - Poisonous Plants To AvoidDokument8 SeitenWilderness Survival - Poisonous Plants To AvoidBarry L Brumfield100% (1)

- Camp Latrine:: A Long-Term Survival Guide - Improvised Camp EquipmentDokument20 SeitenCamp Latrine:: A Long-Term Survival Guide - Improvised Camp Equipmentjames 13Noch keine Bewertungen

- Power in The Apocalypse How To Build A Wood GasifiDokument9 SeitenPower in The Apocalypse How To Build A Wood GasifiAristides AgotadoNoch keine Bewertungen

- Wood Species: Acacia MangiumDokument8 SeitenWood Species: Acacia MangiumAlarm GuardiansNoch keine Bewertungen

- What (Trivial) Knowledge Might Save Your Life One Day - QuoraDokument62 SeitenWhat (Trivial) Knowledge Might Save Your Life One Day - QuoraShrey RawatNoch keine Bewertungen

- Handbook For Reducing Basement FloodingDokument35 SeitenHandbook For Reducing Basement FloodingJohn SmithNoch keine Bewertungen

- DIY Armor ZineDokument8 SeitenDIY Armor Zinesnidely_whiplash0% (1)

- FM 24-12 - Communications in A Come-As-you-Are WarDokument69 SeitenFM 24-12 - Communications in A Come-As-you-Are WarSurvivIt100% (1)

- Knife Sharpening Angle Guide - Best Sharpening Angles - Blade HQDokument4 SeitenKnife Sharpening Angle Guide - Best Sharpening Angles - Blade HQjanNoch keine Bewertungen

- Tennis Ball Launching Crossbow PDFDokument30 SeitenTennis Ball Launching Crossbow PDFMarcelo Rovea SerresNoch keine Bewertungen

- Beginners Recipe PDFDokument5 SeitenBeginners Recipe PDFLiviuNoch keine Bewertungen

- Boerseep Warm MetodeDokument5 SeitenBoerseep Warm Metodefleur_as100% (1)

- 301 Prome Series Laser Pointer ManualDokument2 Seiten301 Prome Series Laser Pointer Manualisabella matosNoch keine Bewertungen

- Knots DecorativeDokument13 SeitenKnots DecorativeOdrareg OdisedocNoch keine Bewertungen

- Campsite SelectionDokument7 SeitenCampsite SelectionFriti FritiNoch keine Bewertungen

- Survival - Wilderness Shelter Types PDFDokument9 SeitenSurvival - Wilderness Shelter Types PDFSorin CraciunNoch keine Bewertungen

- Wilderness SurvivalDokument9 SeitenWilderness Survivalapi-247199458Noch keine Bewertungen

- Passive Wilderness Survival Food AcquisitionDokument3 SeitenPassive Wilderness Survival Food AcquisitionMoreMoseySpeedNoch keine Bewertungen

- How To Make Your Own BiodieselDokument10 SeitenHow To Make Your Own BiodieselKhasvinNoch keine Bewertungen

- PVCPipe Bow PlansDokument1 SeitePVCPipe Bow Planscharles blairNoch keine Bewertungen

- Gibson Tropical BootsDokument3 SeitenGibson Tropical BootsJonathan ReaNoch keine Bewertungen

- PEC Design RulesDokument4 SeitenPEC Design RulesJonathan ReaNoch keine Bewertungen

- Health Department Checklist FinalDokument6 SeitenHealth Department Checklist FinalChris-Goldie LorezoNoch keine Bewertungen

- Salary Loan MEDAL Brochure2020 LowDokument2 SeitenSalary Loan MEDAL Brochure2020 LowJonathan ReaNoch keine Bewertungen

- Cop Checklist 2003 EnglishDokument17 SeitenCop Checklist 2003 EnglishbruceantoNoch keine Bewertungen

- Review Simple MachinesDokument11 SeitenReview Simple MachinesRavi AdityaNoch keine Bewertungen

- Questionnaire For Non-Professional Driver'sDokument29 SeitenQuestionnaire For Non-Professional Driver'sAnonymous WfVmRoNoch keine Bewertungen

- 0200 - Voltage Monitor PDFDokument6 Seiten0200 - Voltage Monitor PDFJonathan ReaNoch keine Bewertungen

- Dealing With Powerline EmiDokument4 SeitenDealing With Powerline EmiJonathan ReaNoch keine Bewertungen

- Fluke-Basic Electrical Installation TestingDokument6 SeitenFluke-Basic Electrical Installation TestingJonathan ReaNoch keine Bewertungen

- PEC Design RulesDokument31 SeitenPEC Design RulesReymart Manablug100% (1)

- Testing of Electrical Installations GuideDokument28 SeitenTesting of Electrical Installations Guidetsraj10Noch keine Bewertungen

- Dealing With Powerline EmiDokument4 SeitenDealing With Powerline EmiJonathan ReaNoch keine Bewertungen

- A Little Imp Coil WinderDokument1 SeiteA Little Imp Coil WinderJonathan ReaNoch keine Bewertungen

- Small Wonder QRP Bitx40Dokument5 SeitenSmall Wonder QRP Bitx40Jonathan ReaNoch keine Bewertungen

- Two Essential Add Ons For The Bitx40Dokument4 SeitenTwo Essential Add Ons For The Bitx40Jonathan ReaNoch keine Bewertungen

- Low Pass FilterDokument5 SeitenLow Pass FilterJonathan ReaNoch keine Bewertungen

- Finding Field Strength The Simple Way PDFDokument2 SeitenFinding Field Strength The Simple Way PDFJonathan ReaNoch keine Bewertungen

- A Little Imp Coil Winder PDFDokument4 SeitenA Little Imp Coil Winder PDFJonathan ReaNoch keine Bewertungen

- LSB UsbDokument1 SeiteLSB UsbJonathan ReaNoch keine Bewertungen

- Simple Audio Muting CircuitDokument2 SeitenSimple Audio Muting CircuitJonathan ReaNoch keine Bewertungen

- Cpop FixDokument1 SeiteCpop FixJonathan ReaNoch keine Bewertungen

- Kenny Martinez Agc ModDokument2 SeitenKenny Martinez Agc ModJonathan ReaNoch keine Bewertungen

- Containing RF Noise From A Sine Wave UPSDokument10 SeitenContaining RF Noise From A Sine Wave UPSJonathan ReaNoch keine Bewertungen

- Disaster KitsDokument2 SeitenDisaster Kitsturmoil8Noch keine Bewertungen

- Toroids For The Terrified PDFDokument7 SeitenToroids For The Terrified PDFJonathan ReaNoch keine Bewertungen

- Hurricane Survival GuideDokument6 SeitenHurricane Survival GuideJonathan ReaNoch keine Bewertungen

- Hurricane Survival Guide For New Jersey: Ready - Nj.govDokument20 SeitenHurricane Survival Guide For New Jersey: Ready - Nj.govJonathan ReaNoch keine Bewertungen

- Bug Out Bag Essentials PDFDokument26 SeitenBug Out Bag Essentials PDFJonathan Rea100% (2)

- Hl2mp ItalianDokument2 SeitenHl2mp ItalianMINOflushNoch keine Bewertungen

- Flow Control Valves: 1 DescriptionDokument6 SeitenFlow Control Valves: 1 Descriptionnotitle91Noch keine Bewertungen

- T-55 Chassis Fitted With S-60 57 MM Gun in Iraq - Armament Research Services (ARES)Dokument2 SeitenT-55 Chassis Fitted With S-60 57 MM Gun in Iraq - Armament Research Services (ARES)tyrant88Noch keine Bewertungen

- OkkkDokument14 SeitenOkkkUmmu Hamnah DewiNoch keine Bewertungen

- gf2 gf3 ps10097 enDokument8 Seitengf2 gf3 ps10097 enOmar JarwanNoch keine Bewertungen

- Shear Blades LeafletDokument4 SeitenShear Blades LeafletphucgenjiNoch keine Bewertungen

- GF - Soul-Snatcher Cults v2.50Dokument3 SeitenGF - Soul-Snatcher Cults v2.50Frédéric KempfNoch keine Bewertungen

- Gas Ranges: Cooker With 4 Burners, 1 Gas OvenDokument2 SeitenGas Ranges: Cooker With 4 Burners, 1 Gas OvenAm MNoch keine Bewertungen

- Wusthof Household Professional ToolsDokument14 SeitenWusthof Household Professional ToolsJimmy-NeonNoch keine Bewertungen

- SWAROVSKI OPTIK Ballistic Program - Help PDFDokument4 SeitenSWAROVSKI OPTIK Ballistic Program - Help PDFpsmanasseNoch keine Bewertungen

- Catalog Strafcotools MediumDokument102 SeitenCatalog Strafcotools MediumAri BinukoNoch keine Bewertungen

- 1 - Torno - Colchester Student 1800 Lathe PDFDokument4 Seiten1 - Torno - Colchester Student 1800 Lathe PDFprofcm100% (1)

- 340FTE17311-60 4265570 Caja KalmarDokument46 Seiten340FTE17311-60 4265570 Caja KalmarBARRENECHEA DELGADO ISAACNoch keine Bewertungen

- Kertas Kerja Inventarisasi Gudang Pagardewa Tahun 2019. (Update 25 April 2020) .CEKDokument34 SeitenKertas Kerja Inventarisasi Gudang Pagardewa Tahun 2019. (Update 25 April 2020) .CEKkompresorNoch keine Bewertungen

- CatalogDokument47 SeitenCatalogsk7177Noch keine Bewertungen

- Pre Lesson Plan: MotivationDokument7 SeitenPre Lesson Plan: MotivationManoj ShuklaNoch keine Bewertungen

- Gambar 13 Clutch: Nomor Nomor Part Nama Part KeteranganDokument2 SeitenGambar 13 Clutch: Nomor Nomor Part Nama Part KeteranganHendriM89Noch keine Bewertungen

- Group 2 Removal and Installation of Unit: 1. MastDokument11 SeitenGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNoch keine Bewertungen

- 33 KV CRP DanishDokument26 Seiten33 KV CRP DanishBishnu RegmiNoch keine Bewertungen

- Gledhill Spare Parts BoilerDokument40 SeitenGledhill Spare Parts BoilerRendy Adam FarhanNoch keine Bewertungen

- Week 2 - DraftingDokument3 SeitenWeek 2 - DraftingmerylNoch keine Bewertungen

- Lancer - Character Sheets - Form Fillable - CópiaDokument2 SeitenLancer - Character Sheets - Form Fillable - CópiaJoey Vitor Freitas BritoNoch keine Bewertungen

- KC-20VS Service ManualDokument8 SeitenKC-20VS Service Manualbill_gator20059105Noch keine Bewertungen

- Tr1 Ingles Joel Flores GuerrerosDokument7 SeitenTr1 Ingles Joel Flores GuerrerosKevin Qs TipulaNoch keine Bewertungen

- Crane HoistDokument31 SeitenCrane HoistJamatindo PutraNoch keine Bewertungen

- My Flowmax Regulator Iom Gea19584a English PDFDokument32 SeitenMy Flowmax Regulator Iom Gea19584a English PDFElias ElHossariNoch keine Bewertungen

- Atlas Copco: Stationary Air CompressorsDokument220 SeitenAtlas Copco: Stationary Air CompressorsRebeca SantosNoch keine Bewertungen

- Bell 429 Helicopter - High Resolution PanelDokument1 SeiteBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- Sk-Photo, Sk-Photo-T and Sk-Photor: Intelligent Photoelectric Smoke SensorsDokument2 SeitenSk-Photo, Sk-Photo-T and Sk-Photor: Intelligent Photoelectric Smoke Sensorsjosev_3000Noch keine Bewertungen

- Afilador Cuchillos Edgeselect Diamond Hone 120Dokument48 SeitenAfilador Cuchillos Edgeselect Diamond Hone 120GonzaloNoch keine Bewertungen