Beruflich Dokumente

Kultur Dokumente

Installation Guidelines: Programming of Levels

Hochgeladen von

Sudipto MajumderOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Installation Guidelines: Programming of Levels

Hochgeladen von

Sudipto MajumderCopyright:

Verfügbare Formate

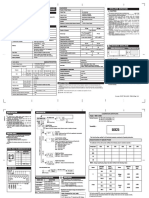

OPERATING INSTRUCTIONS Annunciator - Programmable

Reset Action - Programmable; automatic or latched

! CAUTION:

1. The equipment shall not be installed in environmental

TERMINAL CONNECTIONS

mV/TC/RTD

PIC 1000N Standby Mode - Programmable; enable or disable

8. SENSOR SUPPLY

conditions other than those mentioned in this manual.

2. Fuse Protection: The equipment does not have a built-in-

+ - FOR

PT100

ANALOG

OUTPUT

24VDC supply to power the sensors type fuse. Installation of external fuse of rating 275VAC/ A B B’ + -

9. LINEAR DC OUTPUT (optional) 1Amp for electrical circuitry is highly recommended.

3. Thermal dissipation of equipment is met through ventilation 1 2 3 4 5 6 7 8 9 10

Re-transmission: 4 to 20 mA or 0 to 5 V or 0 to 10 V holes provided on chassis of equipment. Such ventilation

Update rate: 100msec holes shall not be obstructed else it can lead to a safety 22 24

RS485

-

mA+ V+ mA / V-

10. SERIAL COMMUNICATIONS (optional) hazard. sensor supply

+

Type - RS485 4. The output terminals shall be strictly loaded to the 21

-

23

+

Protocol - MODBUS manufacturer specified values/range.

Data Format - 8 bit for Modbus Mechanical Installation: 11 12 13 14 15 16 17 18 N L

48X96 Start bit - programmable; Stop bit: programmable For installing the controller NO1 NO2 NO3 NO4 COM GND +24V

SPECIFICATIONS Parity - programmable 1. Prepare the panel cutout with proper dimensions as shown - +

1. DISPLAY Node Address - 1 to 99, max of 32 units per line DIMENSIONS (in mm)

11. ENVIRONMENTAL CONDITIONS

TERMINAL DESCRIPTION TERMINAL

4-digit (7 segment LED) 0.5" height

Operating Range: 0 to 50oC Live & Neutral L&N

Display Messages: 50 45 46 Panel Cutout

“Or” - a) Appears when measurement exceeds Storage Range: -20 to 75oC +ve mA 2

display scaling range(9999) for signal inputs Humidity: 95% max. 97.5

12. ISOLATION BREAKDOWN RATINGS 88 92 +ve V 3

b) When open sensor is detected. 10

(Applicable for TC/RTD/-5 to 56mV) AC line with respect to all inputs and 2. Remove the clamp from the controller and push the +ve mV / TC+ / RTD 1 4

“rE” - a) Appears when measurement is below outputs: 2000 Volts controller into the panel cutout. Secure the controller in its

All other inputs and outputs with respect to -ve mV / TC- / RTD 2 / -ve mA / -ve V 5

display scaling range (-1999) for signal inputs. place by pushing the clamp on the rear side.

b) Sensor reverse condition occurs. Relay contacts: 2000 VAC 3. For proper sealing, tighten the screws evenly with required +ve analog output 8

(Applicable for TC/RTD/mV) 13. CONNECTION Wire clamping screw terminals torque. -ve analog output 9

Display alternating between PV and ALrM with LED 14. WEIGHT 300 grams ! CAUTION:

of respective alarm flashing. (Programmable The equipment in its installed state must not come in close NO for relay1 12

SAFETY SUMMARY proximity to any heating sources, caustic vapors, oils, steam, or

annunciator option) All safety related codifications; symbols and NO for relay2 13

other unwanted process by-products.

LED Status Annunciators - Alarm ON (4nos) instructions that appear in this operating manual or on the

2. POWER EMC Guidelines: NO for relay3 14

equipment must be strictly followed to ensure the safety of the

AC Versions- 85 to 270 VAC, 50 or 60 Hz, 5 VA 1. Use proper input power cables with shortest connections and NO for relay4 15

operating personnel as well as the instrument.

DC Versions (Optional) - 24 VDC If the equipment is not handled in a manner specified by twisted type. COM for relay1 16

3. SETTINGS the manufacturer it might impair the protection provided by the 2. Layout of connecting cables shall be away from any internal GND / -ve sensor supply

Via three keys on front panel. EMI source.

17

equipment. +24 V / +ve sensor supply 18

4. MEMORY ! CAUTION: Read complete instructions prior to installation LOAD CONNECTIONS

Nonvolatile EEPROM retains all programmable KEYS DESCRIPTION

and operation of the unit.

parameters and values. WARNING: Risk of electric shock. 1. For load current less than 0.5A selec PIC1000

5. MAIN SENSOR INPUT (Universal) ALM

Thermocouple inputs WIRING GUIDELINES L N

1

2

3

J : -200 to 750oC WARNING: 4

1. To prevent the risk of electric shock power supply to the TC

K : -200 to 1350oC TC

equipment must be kept OFF while doing the wiring

T : -200 to 400oC arrangement. LOAD

C NO Functions Key press

R : 0 to 1750oC 2. Wiring shall be done strictly according to the terminal layout

S : 0 to 1750oC with shortest connections. Confirm that all connections are R C To enter or exit program mode + together for 3 seconds

C : 0 to 2300oC correct. MOV or till Level is displayed.

3. Use lugged terminals to meet M3 screws. Snubber To change levels + / to increase or

E : -200 to 750oC 4. To eliminate electromagnetic interference use of short wire

B : +150 to 1820oC decrease the level number.

with adequate ratings and twists of the same in equal size 2. For bigger loads, use interposing relay / contactor

N : -200 to 1300oC shall be made. L N To view function on the same or key once to view the

L : -200 to 600oC 5. Cable used for connection to power source, must have a TC level and to display the

next/previous function.

U : -200 to 900oC 2

cross section of 1mm or greater. These wires shall have TC Contactor current option.

W : 0 to 2300oC insulation capacity made of at least 1.5KV. + to increase and

Platinel II: 0 to 1390oC

C NO To increase or decrease the

MAINTENANCE R C

value of a particular function.

+ to decrease the

RTD inputs (2 wire or 3 wire) 1. The equipment should be cleaned regularly to avoid value of particular function.

MOV

PT100: -100 to 850oC blockage of ventilating parts. Snubber

NOTE: The unit will autoexit program mode after 60 seconds of inactivity.

PT1000: -200 to 300oC 2. Clean the equipment with a clean soft cloth. Do not use C

LOAD

Signal inputs Isopropyl alcohol or any other cleaning agent. To enter or exit program mode:

mV (linear) : -5mV to 56mV

mV (linear) : 0mV to 100mV

INSTALLATION GUIDELINES 1) Snubber Part No.: APRC - 01. Press & together for 3 seconds

! CAUTION: 2) MOV Part No.: AP-MOV - 03.

Voltage : 0 - 10 VDC Note: For inductive loads, use of snubber and

Current : 0 - 20mA DC

1. This equipment, being built-in-type, normally becomes a part

of main control panel and in such case the terminals do not MOV, as shown above, is recommended. PROGRAMMING OF LEVELS

6. INDICATION ACCURACY remain accessible to the end user after installation and PROGRAMMING OF LEVEL 0

ELECTRICAL PRECAUTIONS DURING USE

Temperature:0.25% of Span ±1oC(20min. Warmup) internal wiring.

Signal input: 0.05 % ±1 digit 2. Conductors must not come in contact with the internal Electrical noise generated by switching of inductive loads can KEY PRESS DISPLAY DESCRIPTION

7. ALARM OUTPUTS circuitry of the equipment or else it may lead to a safety create momentary disruption, erratic display, latch up, data loss

hazard that may in turn endanger life or cause electrical or permanent damage to the instrument. To reduce noise: Press + Key

4 nos : Relay output: 5A @ 250VAC or 24VDC shock to the operator. a) Use of MOV across supply of temperature controller & snub Parameters in this level

Alarm modes - Alarm High, Alarm Low, Band, 3. Circuit breaker or mains switch must be installed between power Ber circuits across loads are recommended Press + Key

Fault output and Fault diagnosis source and supply terminals to facilitate power 'ON' or 'OFF' b) Use separate shielded wires for inputs. can be set.

Hysteresis Programmable function. However this switch or breaker must be installed in a Document name: Operating/0807/PIC1000N OP-169-V03 Page 1 of 4

convenient position normally accessible to the operator.

FUNCTIONS MENU KEY PRESS DISPLAY DESCRIPTION KEY PRESS DISPLAY DESCRIPTION

er te g g ng ms Press key to select Reverse scaling

nu

mb da ca

lin g

ca

lin g ali lim

it

lim

it ra Press key to select Resolution

e nit on e t up lin lin sc

Pr

og

Default setting:

am t yp .U luti tim tan lay e as ys ) sca y s h) t sca h) rse igh ow f t Default value: 1

og

r ut

m p s o r

te ns isp rat Bi la t ) la

sp (low npu (low isp (hig npu (hig ev e P.

H

P.

L . o se

Pr Inp Te Re Fil co D PV Di I D I R S. S. No Re NOTE: This parameter is not prompted if input is R, S type thermocouple. NOTE: This parameter is not prompted if TC/RTD input types are selected

Resolution Reverse scaling*

INPUT PARAMETERS ( to scroll through functions press / ) Display for 1sec Display for 1sec

Range: 1 / 0.1 for TC / RTD The display scaling point

er or

it it es

is iat settings can be reversed

mb lim lim ter nc

nu igh ys er de tus nu

r am h low h tim mo sta an Press + 1 / 0.1 / 0.01 / 0.001 for AIN Press + by selecting Reverse

og ar

m

ar

m

ar

m lay ar

m tch ld ar

m

ar

m

Pr Al Al Al De Al La Ho Al Al scaling as

Press key to select Filter time constant

*** Default value: 1sec Press key to select Set point high limit

ALARM MODULE ( ALARM 1) ( to scroll through functions press / ) Filter time Default value: 750oC

Display for 1sec

constant * Set point high limit

+

Display for 1sec

*** Press + / (SPHL)

Range: OFF, 1 to 99 sec

to change value

OR

ALARM MODULE ( ALARM 2) ( to scroll through functions press / )

Press + / Range :SPLL to max.

Press key to select Display update rate to change value range of sensor

Default value: 1.0 sec (for TC/RTD)SPLL to

***

+

DSCH (for AIN)

ALARM MODULE ( ALARM 3) ( to scroll through functions press / ) Display for 1sec Display update rate For AIN display as per decimal point selected.

TO CHANGE LEVELS PRESS

Press + / Press key to select Set point low limit

Range : 0.5 to 6.0 sec

*** to change value Default value: -200oC

ALARM MODULE ( ALARM 4) ( to scroll through functions press / ) Press key to select PV bias Set point low limit

te s s Default value: 0.0 Display

ra es

rity bit for 1sec

Ba

ud

Ad

dr

Pa St

op

PV bias * (SPLL)

Appearance of all shaded menus Display for 1sec Range :min. range of

dependent on selection of other parameters. Press + /

Press + /

Range : -200 to 200 to change value sensor to SPHL

*COMMUNICATION MODULE (To change function / ) Refer programming for futher details

r *- Applicable only for communication models. to change value (fixed 0.1oC for TC/RTD) (for TC/RTD)

t t ro

mi mi er For AIN display as per decimal point selected. DSCL to SPHL (for AIN)

al r li r li or g t% **-Applicable only for analog output models.

nu we pe ns evel alo tpu

Ma Lo Up Se l An ou ***-Looping depends on selection of other Press key to select Display value scaling point1 For AIN display as per decimal point selected.

parameters. Default value: 0 Press key to select No. of Programs

**ANALOG O/P MODULE (To change function / ) NOTE: This parameter is not prompted if TC/RTD input types are selected Default setting: 25

n

ca

tio rd Display value scaling Number of

tifi el

0

el

1

el

2

el

3

el

4

el

5

el

6

rd wo Display for 1sec point Display for 1sec

en ss low (DSCL) *

id

er de ck

lev

ck

lev

c kl

ev

ck

lev

ck

lev

ck

lev

c kl

ev ge wo

an ss w

pa Programs

Us co Lo Lo Lo Lo Lo Lo Lo Ch pa Ne Press + / Range : -1999 to DSCH Press + / Range :01 to 25

to change value For AIN display as per decimal point

to change value

selected.

LOCKOUT MODULE ( to scroll through functions press / )

Press key to select input value scaling point 1 Press key to select Reset

Default value: 0.00 Default setting:

NOTE: This parameter is not prompted if TC/RTD input types are selected Reset

KEY PRESS DISPLAY DESCRIPTION KEY PRESS DISPLAY DESCRIPTION Display for 1sec

Press key to select input sensor type o Input value scaling

Press + W (0 to 2300 C) Display for 1sec point low (ISCL) *

Default setting: J All parameters set to

o

Press + Platinel II: 0 to 1390 C Press + / Range : 0.0mA / -5mV / Press + factory setting

to change value

0.0 V to ISCH NOTE: After altering the value of the input parameters

Input sensor Press + PT100: -100 to 850oC (default value changes as per analog

Display for 1sec input selected)

press or for the change to actually take effect.

selection Press + PT1000: -200 to 300oC NOTE: Programming steps for Level 1 (Alarm 1 module)

J ( -200 to 750oC ) Press key to select Display value scaling point 2 Level 2 (Alarm 2 module), Level 3 (Alarm 3 module),

mV(linear): Default value: 9999 Level 4 (Alarm 4 module) is same.

Press +

Press + K (-200 to 1350oC) -5mV to 56mV NOTE: This parameter is not prompted if TC/RTD input types are selected Programming of level 1 is shown.

o mV(linear): Display value scaling

Press + T (-200 to 400 C) Press + Display for 1sec point

PROGRAMMING OF LEVEL 1

0.0mV to 100mV high (DSCH) *

Press + R (0 to 1750 C) o Press + till Level 1 is displayed

Press + / Range : DSCL to 9999

o

Press + 10VDC to change value For AIN display as per decimal point selected. KEY PRESS DISPLAY DESCRIPTION

Press + S (0 to 1750 C)

Press + 20mA DC Press key to select Input value scaling point 2 Parameters in this level

Press + C (0 to 2300oC) Default value: 20.0mA can be set.

Press key to select Temperature unit NOTE: This parameter is not prompted if TC/RTD input types are selected Press key to select Program number

Press + E (-200 to 750oC) Default setting: OC

Input value scaling Default setting: 1

NOTE: This parameter is not prompted if analog input is selected.

Press + B (+150 to 1820oC) Display for 1sec

point high (ISCH) * NOTE: This parameter is not prompted if alarm mode is /

/

N (-200 to 1300 C ) o Temperature Press + / Range: ISCL to 20.00mA

Press + Display for 1sec

Unit to change value Program number

o

/ 56mV / 10.00V Display for 1sec

Press + L (-200 to 600 C) Value displayed in OC (default value changes as per analog input selected)

Note: * mark explained in the user guide. Press + / Range: 01 to number

Press + U (-200 to 900oC) Press + Value displayed in OF to change value of Programs

AIN - Analog Input

Document name: Operating/0807/PIC1000N OP-169-V03 Page 2 of 4

PROGRAMMING OF LEVEL 1 KEY PRESS DISPLAY DESCRIPTION KEY PRESS DISPLAY DESCRIPTION PROGRAMMING OF LEVEL 7

KEY PRESS DISPLAY DESCRIPTION Press key to select Alarm hold status. Press key to select Stop bits. Press + till Level 7 is displayed

Press key to select Alarm high limit Default setting: Default value: 1

Default value: 750oC NOTE: This parameter is not prompted if alarm mode is Stop bits KEY PRESS DISPLAY DESCRIPTION

Display for 1sec

NOTE: This parameter is not prompted if alarm mode is / Hold Alarm* Parameters in this level

Display for 1sec Selectable between

/ / can be set.

Alarm high limit Used to avoid alarm at 1&2 Press key to select user Identification Code

Display for 1sec Press + (Stop bit 2 is not valid only if Parity

power ON. Alarm is is other than NONE)

Default setting: 0

Range: LA to SPHL Press + enabled only after the

Press + / (BAND mode) NOTE: Applicable only if Analog output is available. Display

User Identification

for 1sec

to change value process value has Code

SPLL to SPHL(HA mode) PROGRAMMING OF LEVEL 6

( display as per resolution selected.) reached the set point. Press + / Range: 0000 to 9999

KEY PRESS DISPLAY DESCRIPTION to change value

Press key to select Alarm low limit Press key to select Relay status for alarm1.

Default value: -200oC Default setting: Press + till Level 6 is displayed Press key to select Lock level 0

NOTE: This parameter is not prompted if alarm mode is

Default setting:

NOTE: This parameter is not prompted if alarm mode is /

/ / Parameters in this level

Relay status for Display for 1sec Lock level 0

Display for 1sec can be set.

Display for 1sec Alarm low limit Alarm1 full access to level 0 parameters

Relay Energized. Press key to select Manual Mode.

Range: SPHL to HA Default setting: Press + level 0 parameters can be read

Press + / (BAND mode) Relay De - energized

Press +

to change value

SPLL to SPHL (LA mode) Manual Mode Press + No access to level 0 parameters

Display for 1sec

For AIN display as per decimal point selected. Press key to select Alarm annunciator.

Press key to select Lock level 1

Default setting: Used to set manual Default setting:

Press key to select Alarm hysteresis.

NOTE: This parameter is not prompted if alarm mode is

Default value: 1.0 Press + output On / Off.

Display for 1sec Lock level 1

NOTE: This parameter is not prompted if alarm mode is / Display for 1sec Alarm annunciator*

/ Press key to select Analog low scaling point full access to level 1 parameters

No annunciator Default value: -1999

Display for 1sec Alarm hysteresis LED of alarm1 blinks at Press + level 1 parameters can be read

NOTE:This parameter is prompted only if manual =

Press + the rate of 0.2sec

Range: 0.1 to 99.9 oC Press + No access to level 1 parameters

Press + / LED blinking; display

(for TC/RTD) Press + Low scaling point

to change value flashing b/w PV and Display for 1sec Press key to select Lock level 2

1 to 999 (for analog input) message (ALRM) at 1sec Default setting:

For AIN display as per decimal point selected. Press + / Programmable from

Press key to select Delay timer PROGRAMMING OF LEVEL 5 to change value -1999 to 9999. Display for 1sec Lock level 2

Default value: 0.00 Press + till Level 5 is displayed Fixed 1oC resolution for TC / RTD. full access to level 2 parameters

For AIN display as per decimal point selected

NOTE: This parameter is not prompted if alarm mode is / KEY PRESS DISPLAY DESCRIPTION level 2 parameters can be read

/

Press +

Parameters in this level Press key to select Analog high scaling point

Press + No access to level 2 parameters

Display for 1sec Delay timer can be set. Default value: 9999

Press key to select Baudrate. NOTE:This parameter is prompted only if manual = Press key to select Lock level 3

Press + / Range: 0.0 to 99.59 Default value:9600 Default setting:

to change value min.sec Baud rate Display High scaling point

for 1sec Display Lock level 3

Display for 1sec for 1sec

Press key to select Alarm mode.

Press + /

Programmable for 300, Press + / Programmable from full access to level 3 parameters

Default setting: for level 1 & 3 600, 1200, 2400, 4800, to change value

Default setting: for level 2 & 4. to change value -1999 to 9999 level 3 parameters can be read

9600 bps. o

Fixed 1 C resolution for TC / RTD.

Press +

Display for 1sec Alarm mode * Press key to select Address. For AIN display as per decimal point selected

Press + No access to level 3 parameters

Default value:01

Alarm off Press key to select Sensor error level Press key to select Lock level 4

Address

Display for 1sec Default setting: Default setting:

Press + High Alarm

Press + / Range: 01 to 99 Display for 1sec Lock level 4

Press + Low Alarm to change value Display for 1sec Sensor error level

full access to level 4 parameters

Press + Band Alarm Press key to select Parity. Incase of sensor failure

Default setting: the output can be set to Press + level 4 parameters can be read

Press + Fault Diagnosis Alarm

Display

Parity Press + high or low value of Press + No access to level 4 parameters

Fail Output Alarm for 1sec

Press + range.

None Press key to select Lock level 5

Press key to select Alarm latch status. Default setting:

Default setting: Press key to select Analog output %.

Press + Even NOTE: This parameter is not prompted if Level 5 is not present.

NOTE: This parameter is not prompted if alarm mode is

Default setting:

Press + Odd NOTE: This parameter is prompted only if manual =. Display for 1sec Lock level 5

Display

Latch alarm*

for 1sec Press + Mark full access to level 5 parameters

Display for 1sec Analog output %

When latch is ON Alarm Press + Space level 5 parameters can be read

Programmable from Press +

status will be preserved Press + /

Press + at any process condition. Note: * mark explained in the user guide. to change value 0.0 to 100.0 Press + No access to level 5 parameters

Document name: Operating/0807/PIC1000N OP-169-V03 Page 3 of 4

KEY PRESS DISPLAY DESCRIPTION Alarm display options: KEY PRESS DISPLAY DESCRIPTION CALIBRATION CERTIFICATE

Press key to select Lock level 6 (1) Press the key to view the status of alarms (Selection for Date:

and then display

Default setting: (2) Press + to view the status of next alarm retransmission mode)

NOTE: This parameter is not prompted if Level 6 is not present. (after alarm 4 it rolls over to alarm 1). Press Model No:

Lock level 6 Only the alarms that are active can be viewed. Sr. No.:

Display for 1sec Alarm status ( e.g : of alarm 1) will be displayed as follows: Press + / Adjust the display to 0

full access to level 6 parameters LA-1 for low alarm for alarm1, Press

Claimed Accuracy: ± 0.25 % of full scale ± 1

HA-1 for high alarm for alarm 1, Press + / digit (After 20min warmup time)

Press + level 6 parameters can be read FO-1 for Fail output alarm for alarm 1, Adjust the display to 400

Press key

No access to level 6 parameters FD-1 for fault diagonosis for alarm1.

Press +

(3) Press + to acknowledge the particular alarm Eg. : 2) For analog Input :- Sources calibrated against:

Press key to select change password Hinditron Multimeter, Model 86, Sr.No.:1094

(Alarm will be acknowledged only if latch ON). Retransmission output : 4 - 20 mA

Default setting: Desired output : 4mA at 0V, 20mA at 10V Multimeter calibration report no:

SCALING FOR ANALOG INPUT: Input scaling : 0V - 0; 10V - 400 ERTL (W), Mumbai, INDIA

Display for 1sec Change password To scale the controller, two scaling points are necessary. Settings:

Each scaling point has a coordinate pair of Display Values The calibration of this unit has been verified at the

and Input Values. It is recommended that the two scaling Press + following values:

Press + points be at the low and high ends of the input signal being Press + CALIBRATION DISPLAY

Press key to select new password measured. Process value scaling will be linear between and SENSOR TEMP.(OC) VALUE

Press

Default value: 0 continue past the entered points to the limits of the input ( 0.1 Resolution) (OC)

This parameter is prompted only if - range. (Factory settings example will display 0.0 at 0 mA Select the Input type as

Using + / voltage

input and display 9999 at 20.00 mA input.)

35.0 35.0

Display for 1secNew password

Reverse acting indication can be accomplished by setting Press until Is displayed K 700.0 700.0

Press + / Range : 0000 to 9999

to change value reverse scaling parameter as DISPLAY

Using + / Adjust the display to 0 1350 1350

YES. In this case referring the 0.0 0.0

Press

USER GUIDE : above eg. for 0.00 mA input 9999

PT100 500.0 500.0

the display will show 9999 and Press + / Adjust the display to 0 800.0 800.0

ALARM MODES

High Alarm: 20.00 mA input the display will 0.0

0.0 0.0

Press

The alarm is turned ON when PV rises above a preset value. show 0.0. 0.00mA 20.00mA

INPUT

NOTE : This change will not be Press + / Adjust the display to 400 PT1000 100.0 100.0

Low Alarm: ISC.L = 0.00 ISC.H = 20.00

visible in the programming menu. DSC.L = 0.0 DSC.H = 9999 250.0 250.0

The alarm is turned ON when PV falls below a preset value. RSCL = no Press

Band Alarm:

Press + / Adjust the display to 10 CALIBRATION DISPLAY

The alarm is turned ON when PV rises above or falls below a KEY PRESS DISPLAY DESCRIPTION INPUT VALUE VALUE

preset value. Note : By default the display will be 10.00 for 0-10V Input ( 0.1 Resolution)

Fault Diagnosis Alarm: Setting for Manual output mode :- Press Key

Eg. For 4-20 mA if constant 12mA output current is desired then Voltage 0.0 0.0

The alarm is turned ON in case a hardware failure occurs. Setting for Retransmission :

Fail Output Alarm: Setting for manual output : (VDC)

Press + till 10.0 10.0

The alarm is turned ON in case of : Press +

a) measurement value exceeds range Press key displays momentarily

Press key display momentarily Current 0.0 0.0

B) Sensor reverse condition(applicable for TC/RTD/0- 56mV). and then display (mA)

Latch Alarm: Press + / (Selection for 20.0 20.0

manual output mode) Press

This function is used to latch the alarm. When activated, the

Press 0.0 0.0

alarm is latched until it is acknowledged manually, even Press + / Adjust the display to 0

though the alarm condition may have disappeared. Press + / Adjust display to 50.0% to 0-100mV

get 12mA at output Press 100.0 100.0

FILTER TIME CONSTANT: Press key

Press + / Adjust the display to 400

The filter is an adaptive digital filter that discriminates Setting for Retransmission mode The actual results versus the input given falls

Press key within specified accuracy of 0.25% & hence the

between measurement noise and actual process changes. Eg. :1) For Temperature Input :-

If the signal is varying too greatly due to measurement noise, unit is certified & passed.

Input : RTD Input Connection with 2-wire Transmitter

increase the filter value. If the fastest controller response is Connection with Internal 24VDC supply :

needed, decrease the filter value.

Retransmission output : 4 - 20 mA

Desired output : 4mA at 00C Eg: To give 0-20mA DC analog input CHECKED BY:

20mA at 4000C -

Two-wire

BIAS: Settings : Transmitter

This value offsets the controller's PV display value by the +

Press +

entered amount. This is useful in applications in which the + -

sensor cannot provide the actual temperature signal due to Press + (Specifications subject to change as development

1 2 3 4 5 6 7 8 9 10

mounting constraints, inaccuracy etc. Press key is a continuous process).

22 24

RS485

-

Using + / Select the Input type as RTD

mA+ V+ mA / V-

Selec Controls Pvt. Ltd., India,

ALARM ANNUNCIATOR: GND +24V

+

21 23

When alarm annunciator is ON, during alarm condition, visual - +

annunciation is given by the upper display altering between AL-NO Press till is displayed Tel:91-22-28476443/1882, Fax:91-22-28471733,

11 12 13 14 15 16 17 18 N L

and process temperature where NO is the alarm number. The Press + till is display Toll free: 1800 227 353, Website: www.selec.com

annunciator may be disabled by selecting function ANN as OFF. NO1 NO2 NO3 NO4 COM

- + E- mail: sales@selec.com.

Press key display momentarily Document name: Operating/0807/PIC1000N OP-169-V03 Page 4 of 4

Das könnte Ihnen auch gefallen

- Volvo: Electrical Wiring DiagramDokument7 SeitenVolvo: Electrical Wiring Diagramrusadi100% (5)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Furuno Felcom 18 Installation ManualDokument60 SeitenFuruno Felcom 18 Installation ManualtariktunadNoch keine Bewertungen

- Omron - FY18 - Price List - MRP PDFDokument235 SeitenOmron - FY18 - Price List - MRP PDFSudipto MajumderNoch keine Bewertungen

- Instrumentation and Test Gear Circuits ManualVon EverandInstrumentation and Test Gear Circuits ManualBewertung: 5 von 5 Sternen5/5 (1)

- EPT12 EZ Error CodesDokument5 SeitenEPT12 EZ Error CodesKiều Văn TrungNoch keine Bewertungen

- 07 Protection of HV TransformersDokument36 Seiten07 Protection of HV TransformersSuresh KumarNoch keine Bewertungen

- Manual 924HDokument811 SeitenManual 924HJuliana Magalhães100% (1)

- Special Electrical MachinesDokument5 SeitenSpecial Electrical MachinesEswaran0% (1)

- TWIX 1 230V - Instruction ManualDokument2 SeitenTWIX 1 230V - Instruction ManualKeval MistryNoch keine Bewertungen

- Controller: Important: Retain These InstructionsDokument12 SeitenController: Important: Retain These InstructionsAnonymous XYAPaxjbYNoch keine Bewertungen

- Installation Detectores CAP320-CAH330-CAPT340Dokument2 SeitenInstallation Detectores CAP320-CAH330-CAPT340Yuri OliveiraNoch keine Bewertungen

- Ds 2mlf Ad4s Ai 200 v10 PDFDokument2 SeitenDs 2mlf Ad4s Ai 200 v10 PDFsamim_khNoch keine Bewertungen

- Pic101 User ManualDokument2 SeitenPic101 User Manualசசி குமார்Noch keine Bewertungen

- Pic 101Dokument2 SeitenPic 101சசி குமார்Noch keine Bewertungen

- IS0259A00MMDokument2 SeitenIS0259A00MMSupuran RichardoNoch keine Bewertungen

- PIC101A Instruction ManualDokument2 SeitenPIC101A Instruction ManualSalome BitutuNoch keine Bewertungen

- KV-5500/5000/3000 KV-DR1: Programmable ControllerDokument2 SeitenKV-5500/5000/3000 KV-DR1: Programmable ControllerCatngoNoch keine Bewertungen

- Sem203P User Guide: Push Button Pt100 Two Wire (4 To 20) Ma OutputDokument2 SeitenSem203P User Guide: Push Button Pt100 Two Wire (4 To 20) Ma OutputCesar Alejandro Lopez PortelesNoch keine Bewertungen

- Operating Instructions PIC152N: Keys DescriptionDokument4 SeitenOperating Instructions PIC152N: Keys DescriptionSudipto MajumderNoch keine Bewertungen

- 905-0001 Sita Multipoint ASD Detector Base: Installation and Maintenance InstructionsDokument2 Seiten905-0001 Sita Multipoint ASD Detector Base: Installation and Maintenance Instructionsamartins1974Noch keine Bewertungen

- PNOZ s6.1: Safety RelaysDokument18 SeitenPNOZ s6.1: Safety RelaysRafael CarmoNoch keine Bewertungen

- Op XC410 Op033-V06Dokument1 SeiteOp XC410 Op033-V06yaserNoch keine Bewertungen

- Installation Instructions: GB D142H 32 Ed.06 2Dokument2 SeitenInstallation Instructions: GB D142H 32 Ed.06 2madhus reddyNoch keine Bewertungen

- TWIX-1 MNLDokument2 SeitenTWIX-1 MNLsrboghe651665Noch keine Bewertungen

- Live Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetDokument4 SeitenLive Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetRig 25 Sr. ElectricianNoch keine Bewertungen

- m800 ManualDokument2 Seitenm800 ManualÁgost VitaNoch keine Bewertungen

- User Manual Selec tc344Dokument3 SeitenUser Manual Selec tc344Puneet Chaurasia100% (4)

- User Guide: IT6000-IOT Series HMIDokument2 SeitenUser Guide: IT6000-IOT Series HMINgọc NhấtNoch keine Bewertungen

- Installation Manualfelcom18 Ime-J1Dokument62 SeitenInstallation Manualfelcom18 Ime-J1TEMILOLUWA ABOLARINNoch keine Bewertungen

- Gas Transmitter With Nbiot Communication: Without AlarmsDokument2 SeitenGas Transmitter With Nbiot Communication: Without AlarmsAmic BanatNoch keine Bewertungen

- Can D500Dokument12 SeitenCan D500Khaleel KhanNoch keine Bewertungen

- Mackie SWA1501Dokument12 SeitenMackie SWA1501pepeNoch keine Bewertungen

- E+ E-0V 110 Volt Pot 1K: Installation and MaintenanceDokument12 SeitenE+ E-0V 110 Volt Pot 1K: Installation and MaintenanceRonald Gomez tapiaNoch keine Bewertungen

- Vsx305 Om-Pioneer TextDokument28 SeitenVsx305 Om-Pioneer TextMarcos MartinsNoch keine Bewertungen

- 4211l - en ALT050KP003 PMGDokument20 Seiten4211l - en ALT050KP003 PMGTTIBCCANoch keine Bewertungen

- Sc-T1ja eDokument2 SeitenSc-T1ja eAjay MayalNoch keine Bewertungen

- Instruction Manual: Kenwood CorporationDokument52 SeitenInstruction Manual: Kenwood CorporationEliel SouzaNoch keine Bewertungen

- Franck Hertz Experiment Manual SE 9639 PDFDokument25 SeitenFranck Hertz Experiment Manual SE 9639 PDFOziel MercadoNoch keine Bewertungen

- Installation Manual Marine Radar Fr-2125V: Safety Instructions System Configuration Equipment Lists MountingDokument90 SeitenInstallation Manual Marine Radar Fr-2125V: Safety Instructions System Configuration Equipment Lists MountingAnhVuNguyenNoch keine Bewertungen

- Nera Mini-C - Inst - Manual PDFDokument38 SeitenNera Mini-C - Inst - Manual PDFmrservice7782Noch keine Bewertungen

- Audio Technica 1200ser - OmDokument8 SeitenAudio Technica 1200ser - OmAbraham .YendesNoch keine Bewertungen

- Mac-Mah 18-66Dokument10 SeitenMac-Mah 18-66Сергей ДейнекоNoch keine Bewertungen

- Ako 14123Dokument2 SeitenAko 14123Ka KowkNoch keine Bewertungen

- Web p05633 Manual Triflex Connect Unificado Rev2Dokument2 SeitenWeb p05633 Manual Triflex Connect Unificado Rev2Emerson O. GomesNoch keine Bewertungen

- Honeywell Eco1000brel12l 1Dokument4 SeitenHoneywell Eco1000brel12l 1Patricio PilaguanoNoch keine Bewertungen

- 4971c en PDFDokument44 Seiten4971c en PDFdinhvuNoch keine Bewertungen

- SMC5500 Inst SheetDokument10 SeitenSMC5500 Inst SheetYasir ArfatNoch keine Bewertungen

- MVS-8000X-C MVS-7000X-CDokument26 SeitenMVS-8000X-C MVS-7000X-CAbdul MuizzNoch keine Bewertungen

- Alptec 52 PDFDokument18 SeitenAlptec 52 PDFFrancisco Borja Lorenzo GuerraNoch keine Bewertungen

- Microflat Series Types C... F S... F M... F T... FDokument13 SeitenMicroflat Series Types C... F S... F M... F T... Fwallklock47Noch keine Bewertungen

- TCL LCD32M95 Manual PDFDokument65 SeitenTCL LCD32M95 Manual PDFMario Rodriguez JuradoNoch keine Bewertungen

- Ime35550c Model1704c GD1720CDokument58 SeitenIme35550c Model1704c GD1720CWD AUTOMATICS S.A.SNoch keine Bewertungen

- DD 40NTV Installation InstructionsDokument36 SeitenDD 40NTV Installation InstructionsHosam MohamedNoch keine Bewertungen

- MA3600VZ Manual 125113 PDFDokument28 SeitenMA3600VZ Manual 125113 PDFAlvaro GonzalezNoch keine Bewertungen

- N300p ManualDokument155 SeitenN300p Manualشركة مصاعد الزيدي Alzaedy elevators co.Noch keine Bewertungen

- Features: P-9903 Loop Relay ModuleDokument2 SeitenFeatures: P-9903 Loop Relay ModuleHiteshgangeleNoch keine Bewertungen

- TCL 32d1240a PLD32HSC9 40-5nt63a-Mae2hgDokument32 SeitenTCL 32d1240a PLD32HSC9 40-5nt63a-Mae2hgLeandro RoldanNoch keine Bewertungen

- UTP Video Transmitter +12VDC Converter: Model NV-226J-PV Installation ManualDokument2 SeitenUTP Video Transmitter +12VDC Converter: Model NV-226J-PV Installation ManualTas DtNoch keine Bewertungen

- Guia Técnica Alptec 3.2 5.2 en Separe Eng PDFDokument16 SeitenGuia Técnica Alptec 3.2 5.2 en Separe Eng PDFFabian MellaNoch keine Bewertungen

- VK-P Series Tsi Transducer Model Vk-143P Transducer Instruction ManualDokument53 SeitenVK-P Series Tsi Transducer Model Vk-143P Transducer Instruction Manualravi_fdNoch keine Bewertungen

- TCL Led28t3520 Ms306d-LaDokument35 SeitenTCL Led28t3520 Ms306d-LaEdu Kees MorelloNoch keine Bewertungen

- SM Ami-208mc (E)Dokument18 SeitenSM Ami-208mc (E)DanielaCostaNoch keine Bewertungen

- Ds pm24 enDokument6 SeitenDs pm24 enKADIKINoch keine Bewertungen

- TCL Led32t3520 Chassis Ms306d-La SM PDFDokument31 SeitenTCL Led32t3520 Chassis Ms306d-La SM PDFOMARY MWAKAJENoch keine Bewertungen

- Sheet L 1 of 11: CH 24: LT Control CablesDokument11 SeitenSheet L 1 of 11: CH 24: LT Control CablesSudipto MajumderNoch keine Bewertungen

- Appendix: Agency Approvals and CertificationsDokument2 SeitenAppendix: Agency Approvals and CertificationsSudipto MajumderNoch keine Bewertungen

- Real View Mimic Brochure4 PGDokument4 SeitenReal View Mimic Brochure4 PGSudipto MajumderNoch keine Bewertungen

- CRANE DUTY - Bharat - Bijlee - Electric - Motors - PricelistDokument1 SeiteCRANE DUTY - Bharat - Bijlee - Electric - Motors - PricelistSudipto MajumderNoch keine Bewertungen

- Automation&ControlSystems - Section 8 - Integrated - Control - System - Services - v1Dokument8 SeitenAutomation&ControlSystems - Section 8 - Integrated - Control - System - Services - v1Sudipto MajumderNoch keine Bewertungen

- TRIPPER ENTICE ORIS Price List 01nov2019Dokument40 SeitenTRIPPER ENTICE ORIS Price List 01nov2019Sudipto MajumderNoch keine Bewertungen

- Operating Instructions Econ-A: PR PR PR PR C C C C M M M MDokument21 SeitenOperating Instructions Econ-A: PR PR PR PR C C C C M M M MSudipto MajumderNoch keine Bewertungen

- Cable Tray SpecificationDokument1 SeiteCable Tray SpecificationSudipto MajumderNoch keine Bewertungen

- Test Certificate Proto ControlDokument2 SeitenTest Certificate Proto ControlSudipto MajumderNoch keine Bewertungen

- Data Sheet RTDDokument1 SeiteData Sheet RTDSudipto MajumderNoch keine Bewertungen

- Temperature TransmitterDokument3 SeitenTemperature TransmitterSudipto MajumderNoch keine Bewertungen

- Data Sheet - Temp TXDokument1 SeiteData Sheet - Temp TXSudipto MajumderNoch keine Bewertungen

- Data Sheet RTDDokument1 SeiteData Sheet RTDSudipto Majumder0% (1)

- RS485 Data Transmission Module 433MHz RF Data Transceiver 2km PLC Wireless ControllerDokument4 SeitenRS485 Data Transmission Module 433MHz RF Data Transceiver 2km PLC Wireless ControllerSudipto MajumderNoch keine Bewertungen

- Flow Transmitter GSECLDokument1 SeiteFlow Transmitter GSECLSudipto MajumderNoch keine Bewertungen

- Siemens-Sitrans-ProbeLU HartQSG 7ML19985QR81 5Dokument8 SeitenSiemens-Sitrans-ProbeLU HartQSG 7ML19985QR81 5Sudipto MajumderNoch keine Bewertungen

- Control: Specification Connection DiagramDokument1 SeiteControl: Specification Connection DiagramSudipto MajumderNoch keine Bewertungen

- Operating Instructions PIC152N: Keys DescriptionDokument4 SeitenOperating Instructions PIC152N: Keys DescriptionSudipto MajumderNoch keine Bewertungen

- Processes Affecting Changes in PropertiesDokument13 SeitenProcesses Affecting Changes in PropertiesMark julius garciaNoch keine Bewertungen

- Led LightDokument32 SeitenLed LightHugo Hernandez GustherNoch keine Bewertungen

- CombineDokument56 SeitenCombineRajagopal GanapathyNoch keine Bewertungen

- Socket and Spigot JointDokument5 SeitenSocket and Spigot Jointsarath.kumarnmk930Noch keine Bewertungen

- PH102Dokument2 SeitenPH102Shobhit ParkiNoch keine Bewertungen

- Drive Fundamentals and DC Motor CharacteristicsDokument3 SeitenDrive Fundamentals and DC Motor CharacteristicsJoeNoch keine Bewertungen

- VLT2800 Quick Guide PDFDokument2 SeitenVLT2800 Quick Guide PDFlieldNoch keine Bewertungen

- FC45X-X Cummins Leroy GRDokument7 SeitenFC45X-X Cummins Leroy GRIsrael GomezNoch keine Bewertungen

- Derbi Rambla 125 (En)Dokument258 SeitenDerbi Rambla 125 (En)Manualles100% (1)

- ItysDokument32 SeitenItysciohaniNoch keine Bewertungen

- Physics NotesDokument13 SeitenPhysics Noteswaheedlakho100% (2)

- AV65WP74Dokument19 SeitenAV65WP74ElectroCenterNoch keine Bewertungen

- France en Dec. 2022 v3Dokument37 SeitenFrance en Dec. 2022 v3Tarek OsmanNoch keine Bewertungen

- Chapter 1 Exercises PDFDokument8 SeitenChapter 1 Exercises PDFGeorges SalloumNoch keine Bewertungen

- 1. المضخهDokument20 Seiten1. المضخهالمهندسوليدالطويلNoch keine Bewertungen

- Smart Energy Coordination of Autonomous ResidentiaDokument13 SeitenSmart Energy Coordination of Autonomous ResidentiaAhmed SabriNoch keine Bewertungen

- EE2002 Lab Manual Fall 2013Dokument15 SeitenEE2002 Lab Manual Fall 2013Alex KeddyNoch keine Bewertungen

- Solar Gas Turbine Generator SystemDokument12 SeitenSolar Gas Turbine Generator Systemjulienjoyet6524Noch keine Bewertungen

- Towards 100%: ISC Osaka, 2018 JAN 23Dokument62 SeitenTowards 100%: ISC Osaka, 2018 JAN 23taufanptrNoch keine Bewertungen

- Dewatering Pump: Instruction, Installation, Operation and Maintenance ManualDokument5 SeitenDewatering Pump: Instruction, Installation, Operation and Maintenance ManualDeepNoch keine Bewertungen

- 2014 To Study High Temperature Erosion-Corrosion of Detonation 1111111111111111111111111Dokument5 Seiten2014 To Study High Temperature Erosion-Corrosion of Detonation 1111111111111111111111111Harkulvinder SinghNoch keine Bewertungen

- 11443FR TKSA ShaftAlignmentTools UnlockedDokument8 Seiten11443FR TKSA ShaftAlignmentTools UnlockedRobertoVianaCardosoNoch keine Bewertungen

- Eaton Busure (En)Dokument16 SeitenEaton Busure (En)Danish NasimNoch keine Bewertungen

- 33-50-14 (Epu301)Dokument30 Seiten33-50-14 (Epu301)BehroozNoch keine Bewertungen

- CIAT Podplafonski MJLINEDokument30 SeitenCIAT Podplafonski MJLINEIgor SpasovicNoch keine Bewertungen