Beruflich Dokumente

Kultur Dokumente

Prashanth Vavilala MGR

Hochgeladen von

sharma301Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prashanth Vavilala MGR

Hochgeladen von

sharma301Copyright:

Verfügbare Formate

PRASHANTH VAVILALA

Engineering Manager - 10 years Diversified experience on Projects, Development & Leadership

Mobile: +918897207575 E-mail: prase301@gmail.com Current Location: Hyderabad, India

PROFILE SUMMARY

Mechanical engineer with expertise in Design & development of wellhead completion equipment,

Pressure vessels, Tools and fixtures.

Technical leader executing projects with team of engineers and designers. Managed projects in

various phases of engineering - estimation, execution,

Global work experience at USA & UK. Communicates well across regions.

Strength areas: Project scope evaluation by Interpretation of customer specifications & industry

standards, create engineering scope for Technical bids/Tenders, delegate activities for team and

provide technical support, conduct design reviews, approve Deliverables, manage repository of

lessons.

Familiarized with Industry standards API 17-D, API 6A, ASME Section VIII Division 1

Software/Tool experience:

MS office, Team Center 10, MathCAD, SAP basic modules, PV Elite, ANSYS-Fluent Basic &

CAD software (UG, AutoCAD& Solid works).

Academic Background:

Master of Technology (M. Tech) in Thermal Engineering from Indian Institute of

Technology, Delhi, India with CGPA of 8.56/10

Bachelor of Technology (B. Tech) in Mechanical Engineering from JNTU, Hyderabad with

84.5%.

PROFESSIONAL EXPERIENCE

1. TechnipFMC (Formerly FMC Technologies), India Mar 2011- Till date

1.1. Engineering Manager - Surface Technologies group July 2018-Till date

1.2. Lead Engineer , Surface Technologies group Mar 2013 –June 2018

1.3. Senior Engineer, Subsea drilling systems Mar 2011 - Mar 2013

Supervising engineering team of 23(11 engineers, 12 Designers) for Surface Technologies, Hyderabad,

India for wellheads, gate valves, Fluid control and Measurement solutions.

In Technical role, responsible to:

- Execute projects with design specific challenges for surface wellheads, connectors, valves, pumps &

pressure containing vessels.

- Define/Clarify project requirements, develop design & conduct Design reviews

- Technical approval or project deliverables

- Engage with Product and Subject matter experts to resolve on field issues.

In Leadership role, responsible to:

- Communicate the capabilities of team & generate the workflow working with global counterparts

from USA, UK, Singapore.

- Define strategy, create/update processes for work flow, define team objectives & Performance

assessment.

- Develop Project Estimates, Work prioritization & allocation, maintain operating KPIs for On time

delivery, Project Budget, team & individual efficiency

- Recruiting, Team coaching & development per long term strategy.

Major accomplishments/projects working at TechnipFMC :

2016-2018: Approved designs for surface wellhead systems, Gate valves and responsible for

any engineering questions on delivered products.

2013-2018: Delivering numerous sales order projects on time resulted in customer success &

business growth by 40% in 3 years.

2015-2018: Developed long term workflow & growth Strategy for Surface Technologies group

which resulted in continuous workflow and consistence performance of team for past 4 years.

2018 : Currently Developing test fixtures for Pressure pump mechanical run test, hydro and NPSH

tests.

2012: Product development for 30” conductor housing lift tool, 5 ksi Desander, 7 1/16-10K

North sea Speedloc connector qualification enhanced knowledge on project management with

focus on stage gate deliverables.

2016: FEED study & technical bids for full scale Unihead wellhead system for Odessa and

Alaska projects resulted in 15% increase of sales.

Qualification projects : 10 3/4 Slip hanger Load testing per API 6A, 13 5/8-20K Speedloc Clamp

PR-2 testing, M 101 PR-2 testing, CRA packoff development for UWD-15 system.

2. General Electric, India Mar 2010- Feb 2011

Worked as Design Engineer for short span of 1 year providing thermal cooling solutions for Power

distribution equipment like motor control centers(MCC), circuit breakers.

Gained awareness of six sigma & lean principles, enhanced knowledge on product development

process

Achieved award for developing excel logic to avoid recurring manufacturing issues on MCC

3. Transparent Energy Systems Private Limited(TESPL), India Apr 2008- Feb 2010

Started career as Static Equipment Engineer for design of pressure vessels, boilers.

Conceptual (Thermal) design of heat exchangers, Fuel (Liquid/Solid/Gas) fired boilers pressure

vessels & power boilers.

Interpretation of pressure vessel design codes such as ASME Section VIII Div1, IBR

(Indian boiler regulations) & prepare mechanical designs using hand calculation & PV-Elite

software.

Communication with sales, procurement, manufacturing & testing departments to gain overall

understanding of product life cycle.

Major accomplishments working at TESPL :

Developed designs of pressure vessels for ASME U & S Stamp approval audit projects

Visited customer sites & provided design solutions for waste heat recovery boilers for process, sugar

industries.

Das könnte Ihnen auch gefallen

- The Certified Oil and Gas Project ManagerVon EverandThe Certified Oil and Gas Project ManagerBewertung: 4 von 5 Sternen4/5 (2)

- Power Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011Dokument332 SeitenPower Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011hainguyenbkvhv100% (6)

- Lead Mechanical EngineerDokument5 SeitenLead Mechanical EngineervcharlesNoch keine Bewertungen

- Santosh ResumeDokument4 SeitenSantosh ResumeSantosh KumarNoch keine Bewertungen

- Senior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerDokument2 SeitenSenior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerSteven FischerNoch keine Bewertungen

- Lean Management: Business ExcellenceDokument68 SeitenLean Management: Business Excellencesharma301100% (3)

- Afsal - Mechanical - Technical Engineer - 28 APR 2014Dokument4 SeitenAfsal - Mechanical - Technical Engineer - 28 APR 2014afsalmohmdNoch keine Bewertungen

- Super Critical Boiler DetailDokument81 SeitenSuper Critical Boiler Detailsen_subhasis_58100% (2)

- Assistant Mechanical Engineer ResumeDokument4 SeitenAssistant Mechanical Engineer ResumeDinkar BajpaiNoch keine Bewertungen

- ResumeDokument5 SeitenResumeRamanathan KrishnamoorthyNoch keine Bewertungen

- Vigneshwaran.S: Areas of ExposureDokument2 SeitenVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNoch keine Bewertungen

- Statim 5000 5000S 5000 G4 Service ManualDokument271 SeitenStatim 5000 5000S 5000 G4 Service Manualpedropc100% (1)

- COmpanies Above 20 CR 20130927Dokument36 SeitenCOmpanies Above 20 CR 20130927venkatesh_1829Noch keine Bewertungen

- Bachelor of Mechanical Engineering With 10 Years of ExperienceDokument5 SeitenBachelor of Mechanical Engineering With 10 Years of ExperienceChandra ReddyNoch keine Bewertungen

- Curriculum Vitae: Total Years of Experience - 12 YearsDokument4 SeitenCurriculum Vitae: Total Years of Experience - 12 YearsnandakumarNoch keine Bewertungen

- Resume Piping Engineer Shadab KhanDokument3 SeitenResume Piping Engineer Shadab Khanwasim92khanNoch keine Bewertungen

- Mechanical Engineer Resume Sample PDFDokument0 SeitenMechanical Engineer Resume Sample PDFMajestic MahiNoch keine Bewertungen

- CV Nirav Patel (BE Mechanical) - 4Dokument5 SeitenCV Nirav Patel (BE Mechanical) - 4Nirav PatelNoch keine Bewertungen

- Air and Flue Gas Tightness TestDokument5 SeitenAir and Flue Gas Tightness TestDipnarayan KumarNoch keine Bewertungen

- PIPE CourseheroDokument28 SeitenPIPE CourseheroDiether Rigor67% (3)

- Sterile Processing Assessment Recommendation CollectionDokument31 SeitenSterile Processing Assessment Recommendation CollectionTianti Puadi100% (2)

- Venkadachalapathy Thangavel: LinkedinDokument4 SeitenVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNoch keine Bewertungen

- Resume-Rahul Sah2Dokument5 SeitenResume-Rahul Sah2Rahul SahNoch keine Bewertungen

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDokument12 SeitenAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNoch keine Bewertungen

- Mohanraj KaruppusamyDokument6 SeitenMohanraj KaruppusamytechgovindNoch keine Bewertungen

- M.Sai Sri Harsha: Areas of ExposureDokument2 SeitenM.Sai Sri Harsha: Areas of Exposuremamillapalli sri harshaNoch keine Bewertungen

- Mechanical Engineer Sample ResumeDokument3 SeitenMechanical Engineer Sample ResumePawan Kumar YadavNoch keine Bewertungen

- Monster Resume FormatDokument3 SeitenMonster Resume FormatMSKumarNoch keine Bewertungen

- Ramcharan Resume LatestDokument4 SeitenRamcharan Resume LatestSri Surya LankapalliNoch keine Bewertungen

- Resume Karthik AllimuthuDokument2 SeitenResume Karthik AllimuthuNithish KuttanNoch keine Bewertungen

- Venkatachalapathy ThangavelDokument4 SeitenVenkatachalapathy ThangavelVivekanand MuthuvananNoch keine Bewertungen

- Sumantra Skills May 2020Dokument6 SeitenSumantra Skills May 2020Sumantrra ChattopadhyayNoch keine Bewertungen

- Parmeshwar Sudhakar Kadam - CVDokument4 SeitenParmeshwar Sudhakar Kadam - CVENoch keine Bewertungen

- Monster CV Template Graduate - Mechanical - EngineeringDokument2 SeitenMonster CV Template Graduate - Mechanical - EngineeringZaid Bin AkberNoch keine Bewertungen

- Patel - ResumeDokument2 SeitenPatel - ResumeAnkit PatelNoch keine Bewertungen

- NafeesShaikh (7 0)Dokument4 SeitenNafeesShaikh (7 0)ajuuNoch keine Bewertungen

- Winson Lim Hui Wah - Mechanical Engineer (Static Equipment)Dokument4 SeitenWinson Lim Hui Wah - Mechanical Engineer (Static Equipment)WinsonLimHuiWahNoch keine Bewertungen

- 1527854274515resume MANOJKUMAR PDFDokument2 Seiten1527854274515resume MANOJKUMAR PDFManoj KumarNoch keine Bewertungen

- Resume-Chetan-Dhuri-Mechanical Design FEADokument4 SeitenResume-Chetan-Dhuri-Mechanical Design FEAChetan DhuriNoch keine Bewertungen

- CV-Jose George Alex-EngineeringDokument2 SeitenCV-Jose George Alex-EngineeringAnilkumar GNoch keine Bewertungen

- Monster CV Template Graduate - Mechanical - EngineeringDokument2 SeitenMonster CV Template Graduate - Mechanical - Engineeringvinh nguyenNoch keine Bewertungen

- Sasank Sekhar Panda: Present AddressDokument3 SeitenSasank Sekhar Panda: Present AddressDanistergladwinNoch keine Bewertungen

- Mechanical Design Professional: Ashok KumarDokument3 SeitenMechanical Design Professional: Ashok KumarPrabhat SharmaNoch keine Bewertungen

- SAHIB RESUME LatestDokument5 SeitenSAHIB RESUME Latestvdpathak.pathakNoch keine Bewertungen

- Senior Project Manager Mechanical in Portland OR Resume Rich McGinnisDokument2 SeitenSenior Project Manager Mechanical in Portland OR Resume Rich McGinnisRichMcGinnisNoch keine Bewertungen

- Raghavendra Hegde: ND STDokument5 SeitenRaghavendra Hegde: ND STvijaygalaxyNoch keine Bewertungen

- Senior Mechanical Engineer in Illinois Resume Sandesh AravindaDokument2 SeitenSenior Mechanical Engineer in Illinois Resume Sandesh AravindaSandeshAravindaNoch keine Bewertungen

- Muhammad Inam AhmedDokument5 SeitenMuhammad Inam AhmedHassaanAhmedNoch keine Bewertungen

- #Rachit Shah ResumeDokument2 Seiten#Rachit Shah ResumeRachit ShahNoch keine Bewertungen

- UV ResumDokument4 SeitenUV ResumAkash ThummarNoch keine Bewertungen

- Sumit Sah Resume - Sep23 PDFDokument4 SeitenSumit Sah Resume - Sep23 PDFchaugule807Noch keine Bewertungen

- Project Engineer CV - Ghulam Ahmad - Copy 2Dokument3 SeitenProject Engineer CV - Ghulam Ahmad - Copy 2Ghulam AhmadNoch keine Bewertungen

- Kumaravel Resume 14+ Lead Mechanical Designer - TLDokument3 SeitenKumaravel Resume 14+ Lead Mechanical Designer - TLKumarNoch keine Bewertungen

- Jitesh Satish PatiDokument3 SeitenJitesh Satish Paticecertificateqvc1Noch keine Bewertungen

- KM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyDokument5 SeitenKM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyvikranthjNoch keine Bewertungen

- V G Barani: E-MailDokument4 SeitenV G Barani: E-MailMagesh ChanderNoch keine Bewertungen

- C V of Engineer Habibur Rahman For ChevDokument5 SeitenC V of Engineer Habibur Rahman For Chevshafiq_05Noch keine Bewertungen

- Skills: Industrial/Mechanical EngineerDokument4 SeitenSkills: Industrial/Mechanical EngineerBivek SapkotaNoch keine Bewertungen

- Job Description For Design and Developement EngineerDokument1 SeiteJob Description For Design and Developement Engineersachin sabaleNoch keine Bewertungen

- Piping Engineer - 24Dokument5 SeitenPiping Engineer - 24sttc2007Noch keine Bewertungen

- Ahmed Buksh Lilla CVDokument3 SeitenAhmed Buksh Lilla CVAhmed Bux LillaNoch keine Bewertungen

- Document 2Dokument2 SeitenDocument 2Zeke YurixoNoch keine Bewertungen

- Junaid Mateen: Mechanical EngineerDokument2 SeitenJunaid Mateen: Mechanical EngineerJunaid MateenNoch keine Bewertungen

- Vishnu Priya RamakrishnanDokument2 SeitenVishnu Priya RamakrishnanarunashireenNoch keine Bewertungen

- Arvind Pati TripathiDokument4 SeitenArvind Pati TripathiAnish SinghNoch keine Bewertungen

- Resume of Anandakumar - T - May2023Dokument3 SeitenResume of Anandakumar - T - May2023AKT InvestmentNoch keine Bewertungen

- Vavilala: Letter of Invitation (Loi) RequestDokument2 SeitenVavilala: Letter of Invitation (Loi) Requestsharma301Noch keine Bewertungen

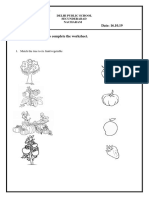

- Nur EVS WorksheetDokument3 SeitenNur EVS Worksheetsharma301Noch keine Bewertungen

- Prashanth Vavilala 2019Dokument2 SeitenPrashanth Vavilala 2019sharma301Noch keine Bewertungen

- Prashanth Vavilala 2019Dokument2 SeitenPrashanth Vavilala 2019sharma301Noch keine Bewertungen

- Prashanth Vavilala MGRDokument2 SeitenPrashanth Vavilala MGRsharma301Noch keine Bewertungen

- IOI 21st OctDokument2 SeitenIOI 21st Octsharma301Noch keine Bewertungen

- IOI 21st OctDokument2 SeitenIOI 21st Octsharma301Noch keine Bewertungen

- Vapour and Combined Power CyclesDokument37 SeitenVapour and Combined Power CyclesTarvesh KumarNoch keine Bewertungen

- FBC Boiler and Auxiliary EquipmentDokument17 SeitenFBC Boiler and Auxiliary EquipmentyogacruiseNoch keine Bewertungen

- Maximum Allowable Stress - An Overview - ScienceDirect TopicsDokument15 SeitenMaximum Allowable Stress - An Overview - ScienceDirect Topicskloe123Noch keine Bewertungen

- EJHA-AV3, EHY2KOMB-A 4PEN531180-1 2018 06 Installer Reference Guide EnglishDokument112 SeitenEJHA-AV3, EHY2KOMB-A 4PEN531180-1 2018 06 Installer Reference Guide EnglishChris BrauchliNoch keine Bewertungen

- Simple Vertical BoilerDokument11 SeitenSimple Vertical BoilerPardeep8056Noch keine Bewertungen

- Presentasi Assessment - ScorpaDokument20 SeitenPresentasi Assessment - Scorpawidada_marjiNoch keine Bewertungen

- KYPROU - in Service InspectionDokument15 SeitenKYPROU - in Service InspectionRazibul Saj EngineeringNoch keine Bewertungen

- Cis Asset f001 Form v05.0Dokument188 SeitenCis Asset f001 Form v05.0Garix LanuzixNoch keine Bewertungen

- Akhilesh Report FinalDokument30 SeitenAkhilesh Report FinalS.K. CHAYA DEVINoch keine Bewertungen

- Aux Boiler Remaining Erec & CommDokument6 SeitenAux Boiler Remaining Erec & CommWisnu Setiawan100% (1)

- Steam CondenserDokument16 SeitenSteam CondenserAtharv MarneNoch keine Bewertungen

- Power Plant ValveDokument63 SeitenPower Plant Valvenjc6151100% (2)

- Dicionario Ingles - Portugues (Em Andamento)Dokument1.446 SeitenDicionario Ingles - Portugues (Em Andamento)Laysa Correa de OliveiraNoch keine Bewertungen

- Design Criteria Eria: Guide For The Preparation of Process Flow Diagrams On of Process Flow DiagramsDokument16 SeitenDesign Criteria Eria: Guide For The Preparation of Process Flow Diagrams On of Process Flow DiagramsGabriele GabrieleNoch keine Bewertungen

- Instrumentation Junction Box To Dcs Panel Cable Schedule For Ue707 45 TPH BoilerDokument16 SeitenInstrumentation Junction Box To Dcs Panel Cable Schedule For Ue707 45 TPH BoilerKPPL Cogen Power PlantNoch keine Bewertungen

- Vitosolic 200 Sd4installationDokument172 SeitenVitosolic 200 Sd4installationGregorio JarrinNoch keine Bewertungen

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDokument20 SeitenValve Selection & Specification Guide For Building Services: Ahead of The FlowGreg FarzettaNoch keine Bewertungen

- THA BLCP Power ProjectDokument35 SeitenTHA BLCP Power Projectapi-3733731Noch keine Bewertungen

- Part PWT: GeneralDokument5 SeitenPart PWT: GeneralPopescu AlinNoch keine Bewertungen

- Coaching Set 4 PinkDokument7 SeitenCoaching Set 4 Pinkjoe1256Noch keine Bewertungen

- Steam Feed and Effect of Steam-Thermal Tire PyrolysisDokument6 SeitenSteam Feed and Effect of Steam-Thermal Tire PyrolysisWonde BogNoch keine Bewertungen