Beruflich Dokumente

Kultur Dokumente

PMP 3 04 Project Quality Plan

Hochgeladen von

Carl WilliamsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PMP 3 04 Project Quality Plan

Hochgeladen von

Carl WilliamsCopyright:

Verfügbare Formate

Project Quality Plan

Royal Darwin Hospital

APPENDIX 7.2

PROJECT QUALITY PLAN

Royal Darwin Hospital Expansion

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 1 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Table of Contents

1.0 REVISION & DISTRIBUTION .........................................................................................................5

1.1 Amendments .............................................................................................................................. 5

2.0 PROJECT INFORMATION .............................................................................................................5

2.1 Project Purpose ......................................................................................................................... 6

2.2 Scope of Work ........................................................................................................................... 6

3.0 INTRODUCTION .............................................................................................................................6

3.1 Referenced Documents ............................................................................................................. 7

3.2 Input Documents ........................................................................................................................ 7

3.3 Project Documents .................................................................................................................... 8

3.4 Project Deliverables ................................................................................................................... 9

4.0 QUALITY MANAGEMENT SYSTEM ..............................................................................................9

4.1 Integrated Management System Manual ................................................................................... 9

4.2 Project Quality Plan ................................................................................................................. 10

4.3 Procedures............................................................................................................................... 10

4.4 Inspection and Text Plans (ITP’s) ............................................................................................ 10

4.5 Project Safety and Environmental Management Plans ........................................................... 10

4.6 Specifications, Drawings & Programs ..................................................................................... 10

4.7 Quality Records ....................................................................................................................... 11

5.0 MANAGEMENT RESPONSIBILITY ...............................................................................................11

5.1 Policy and Commitment ........................................................................................................... 11

5.2 Quality System Planning.......................................................................................................... 11

5.3 Project Organisation ................................................................................................................ 12

5.4 Project Responsibilities ............................................................................................................ 12

5.5 Management Review ............................................................................................................... 14

6.0 RESOURCE MANAGEMENT .........................................................................................................15

6.1 Project Activities & Organizations ............................................................................................ 15

6.2 Training & Competency ........................................................................................................... 15

6.3 Facilities & Work Environment ................................................................................................. 15

7.0 PROJECT REALISATION ..............................................................................................................16

7.1 Project Planning ....................................................................................................................... 16

7.2 Client Related Processes & Communication ........................................................................... 16

7.3 Design & Development ............................................................................................................ 17

7.4 Purchasing & Subcontracting .................................................................................................. 17

7.5 Construction Control ................................................................................................................ 17

8.0 Customer Property ........................................................................................................................18

8.1 Inspection and Testing ............................................................................................................. 18

8.2 Inspection, Measuring and Testing Equipment ....................................................................... 18

8.3 Handling, Storage, Packaging and Delivery ............................................................................ 19

9.0 MEASUREMENT, ANALYSIS & IMPROVEMENT .........................................................................19

9.1 Monitoring Client Satisfaction .................................................................................................. 19

9.2 Monitoring Project Activities..................................................................................................... 19

9.3 Internal Audits .......................................................................................................................... 19

9.4 Control of Nonconforming Product .......................................................................................... 20

9.5 Analysis of Data ....................................................................................................................... 20

9.6 Improvement ............................................................................................................................ 20

10.0 DEFINITIONS ..................................................................................................................................20

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 2 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

APPENDIX 1 – HALIKOS QUALITY POLICY ................................................................................................22

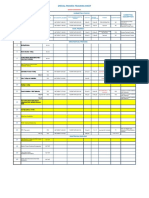

APPENDIX 2 – DOCUMENT CONTROL REGISTER ....................................................................................23

APPENDIX 3 – PROJECT ORGANISATION CHART ...................................................................................24

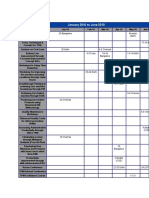

APPENDIX 4 – MASTER INSPECTION & TEST PLAN ................................................................................25

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 3 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Revision

Date Details Section Page Approved By

Chris

Jun 2013 Project inception issue for team review All All

Giannikouris

Distribution

Copy Holder Details Date Issued

Chris Giannikouris Project Manager Halikos Pty Ltd Jun 2013

Johnny McLaughlin Construction Site Manager Halikos Pty Ltd Jun 2013

Matthew Lee Procurement & Contracts Manager Halikos Pty Ltd Jun 2013

Brian Hogbin SEQ Compliance Coordinator Halikos Pty Ltd Jun 2013

Rohan Turner Services Coordination Manager Halikos Pty Ltd Jun 2013

Authorisation

Date: Version: Document Reference: Approved By:

Jun 2013 1 PMP-3-04 Chris Giannikouris

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 4 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

1.0 REVISION & DISTRIBUTION

1.1 Amendments

All amendments to this document are to be marked up in the Control Table. The issue of the

amendment is to be by the authorisation of the Project Manager. All amendments are to be

actioned by the holders of this document upon receipt of the amendment. The plan will be finalised

during the Project launch and will be progressively reviewed and updated if required.

2.0 PROJECT INFORMATION

Royal Darwin Hospital – Expansion of the Emergency Department and

Project Name

;Operating Theatre Suite

Project Number 13-1211

Project Address Royal Darwin Hospital

Project Start Date 2 August 2013

Project Completion 12 February 2015

AS4801 Certification Certification current till 8th May 2014

Federal Accreditation Accreditation till 23rd July 2014

Prepared By Brian Hogbin

Date Prepared June 2013

Postal Address GPO Box 1511 Darwin NT 0801

Contact Person Brian Hogbin brian.hogbin@halikos.com.au

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 5 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

2.1 Project Purpose

The purpose of the project is the design, documentation and construction of an extension on the

existing Emergency Department and the Operation Theatre.

2.2 Scope of Work

The Works comprise of demolition, excavation, fabrication, supply, installation and construction of

the expansion of the Emergency Department, Operating Theatre Suite and associated office space

over four levels as described in the contract documents.

Generally, RDH require:

A new Plant Room is proposed on the lower ground floor level.

The Emergency Department is increasing space to provide a new Short Stay Unit with

associated facilities. In order for this to occur additional office and ancillary space must be

developed on the ground floor.

The Operating Theatre Suite located on Level 1 is increasing capacity with the addition of 2

new operating theatres and required supporting facilities.

A new level 2 floor is to be developed for office space and plantroom.

It must be recognised by the contractor that this development requires RDH operations to be

business as usual. Significant effort must be displayed by the contractor to maintain RDH

operations and staff and patient safety.

3.0 INTRODUCTION

The Project Quality Management Plan (PSMP) prepared by Halikos sets out in detail all

procedures the Project team shall implement to manage its activities on and near the site. The

PQMP will be implemented and maintained throughout the duration of the Project.

The Project has been assessed by Halikos to provide options for consideration in relation to

Barracks noise, dust and recycling strategies.

Halikos have proposed a Project Management team led by the Construction Manager, an

experienced Project Manager who has managed projects of similar size and complexity to the

Royal Darwin Hospital Emergency Department and Operating Theatre Expansion.

The Halikos Project Management Team selected for this project will consist of experienced

personnel with a demonstrated ability to manage the construction workforce and who have

undertaken many design and construction projects.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 6 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Bringing together a proven team who have previously worked together, and who are local Darwin

residents, eliminates many of the problems associated with project start-up and reduces the risk of

mid-project staff changes.

All of the personnel nominated are proven performers with regards to delivering construction

projects to the highest quality, on budget and on time.

Our project team have been working full time on this project during the tender period and have

comprehensive knowledge of this project’s objectives and challenges. The project team is

currently available and ready to immediately mobilise on to this project.

3.1 Referenced Documents

AS/NZS ISO 9001:2008 – Quality Management System - Requirements

AS/NZS ISO 9004:2009 - Managing for the sustained success of an organization -- A

quality management approach

Halikos Pty Ltd Integrated Management System Manual

Halikos Pty Ltd Project Safety Plan

Halikos Pty Ltd Project Environmental Plan

Halikos Pty Ltd Procedures

3.2 Input Documents

RFT number T13-1211 includes drawings as set out in clause 4.7

Royal Darwin Hospital Site Rules

Australasian Health Facility Guidelines

General Conditions of Contract NPWC Edition 3

NT of Australia Radiation Protection Act

Guide to Traffic Engineering Practice – Part 5 Intersections at Grade

Urban Road Design – Guide to the Geometric Design of Major Urban Roads

AS2890.1 Off Street Parking

AS/NZS 3500.3 – Plumbing and Drainage Part 3

The Building Code of Australia

Managing Urban Stormwater, Soils and Construction – Vol 1, 4th Edition, Landcom

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 7 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

3.3 Project Documents

The following documents will be maintained for the project:

Management Review records

Records of contract and tender reviews

Subcontractor records including quotes & transmittals, subcontract agreements, purchase

orders, instructions, payments, variations and correspondence

Register of Subcontractors

Delivery dockets and Invoices

Records of inspections and tests and test results

Suppliers and subcontractors compliance certificates

Calibration register and calibration results

Noncompliance reports

Records of corrective and preventive action

Audit records

Training and competency records

Permits and approvals

Drawings and drawing registers

Revisions to project documentation & transmittals

Site Diaries

Progress payment claims and contract variations

Correspondence with all project stakeholders

Construction programs

Minutes of meetings

Monthly progress reports

Requests for Information

Record of Defects

Relevant procedures and records (including site safety and environmental management)

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 8 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

3.4 Project Deliverables

The project will be delivered in three separate parts as follows:

TIME FOR DEFECTS

SEPARABLE PART COMPLETION LIABILITY

(WEEKS) (WEEKS)

STAGE 1D Level 1 Staffroom/Tutorial/ Anaesthetists

37 weeks 52 weeks

Office Area

STAGE 2C – Level 1 Changerooms/ Anaesthetists

48 weeks 52 weeks

Office Area

STAGE 4 – Project Completion 81 weeks 52 weeks

Works will be staged in accordance with the criteria set out in Preliminary Clause 5.10 – Time

Schedule:

TARGET TARGET

CRITICAL WORK STAGE COMMENCEMENT COMPLETION

DATE DATE

STAGE 1D Level 1 Staffroom/Tutorial/ Anaesthetists Office Area 10/12/2013 09/04/2014

STAGE 2C - L1 Changerooms/ Anaesthetists Office Area 11/03/2014 21/06/2014

STAGE 2D - L2 - Surgeons Office Fitout 24/03/2014 02/07/2014

STAGE 3A - L1 Nurses Office Fitout 10/04/2014 21/08/2014

STAGE 4 - GF SSU Fitout 11/09/2014 12/02/2015

4.0 QUALITY MANAGEMENT SYSTEM

The Quality Management System for Halikos defines and identifies the Policies, Plans, Procedures

and templates used to ensure a consistent product output to the same exceptionally high standard

every time Halikos undertakes an activity, which in this case a Major Government Project. This

plan is a steering statement of intent used to identify the tools and resources required to comply

with and exceed customer expectations.

4.1 Integrated Management System Manual

The Integrated Management Systems Manual presents a summary of the elements that make up

the Halikos Management System, together with references to the relevant documentation detailing

the individual elements.

This nucleus is based on the best product at the best price to the best standard. This is

institutionalised in the Halikos culture and ethos.

The Integrated Management System identifies the elements required to achieve these outputs and

this plan is one of the major contributing pillars to the outcomes being achieved.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 9 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

4.2 Project Quality Plan

This Plan is directly in relation to the intent described in ISO 9001:2008 – Quality Management

System – Requirements. Note only is this plan used as a directional resource for the Halikos

Group, it is also an enabling methodology for resourcing the responsibilities for the Project outputs.

This plan describes the unique requirements of this project and its application throughout the

project lifecycle. This plan will also be the prescribed mechanism for the quality compliance

benchmark throughout the project.

4.3 Procedures

Project procedures provide specific details for the management of the identified quality issues at

the project level, including any relevant forms or checklists. Project procedures will always be

subject to evolutionary change throughout the project lifecycle as the expected standard of service

provision may change.

Project procedures are also used as the provision of compliance confidence within the Project

itself. This compliance confidence enables both the customer and Halikos to ensure all system

targets are maintained as enablers to the identified output of the Project.

4.4 Inspection and Text Plans (ITP’s)

Subject to project requirements Inspections and Test Plans are prepared to identify, plan and

provide a record of project specific inspections and tests from project commencement to

completion. Although ITP’s are a control mechanism for the activity being undertaken to ensure

quality of product is met, this quality control function will form part of the standard of evidence

required to fulfil the customers confidence in service provision.

4.5 Project Safety and Environmental Management Plans

The Halikos Pty Ltd Safety and Environmental Management Systems (EMS) are comprised of

various elements. The project Safety and Environmental Management Plans are an integral part of

the quality management system and will ensure that Halikos operates within a safe working

environment and in an environmentally responsible manner in accordance with Company policies

and as required by the relevant Northern Territory Acts and Regulations and customer

requirements.

4.6 Specifications, Drawings & Programs

Versions of specifications, drawings, and project programs are all controlled electronically on the

company computer system. This project specific data is classified as technical data and will be

managed in a catalogued manner throughout the project.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 10 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

4.7 Quality Records

The Halikos “Document & Data Control” procedure provides guidelines to effectively manage key

documents. Documents to be used in this project are listed in appendix 2.

Halikos maintain project records to provide evidence of compliance to requirements in accordance

with written procedures. Electronic records are protected by a backup system. The computer

system is run from an Uninterrupted Power Supply.

5.0 MANAGEMENT RESPONSIBILITY

5.1 Policy and Commitment

Halikos senior managers understand the vital importance of quality to the company’s continuing

success. Management therefore accepts total responsibility for setting clear company policy for

quality and for providing resources to put the Policy into practice. Company Quality Objectives are

communicated to all workers through regular induction, reporting and project meetings.

The Halikos Quality Policy is included in appendix 1 of this plan. The Policy has been formulated

with regard to Halikos organisational aims and the needs and expectations of its clients.

Copies of the Quality Policy will be displayed at all Halikos offices. All workers are instructed in the

Quality Policy and their roles and responsibilities in the Quality System at initial induction and

through regular communication.

5.2 Quality System Planning

Quality planning for this project is performed during the tender stage by the Quality Management

Representative and the Project Quality Representative. On award of the contract, a project launch

is conducted and detailed quality planning is performed in accordance with the “Project Launch”

and “Project Documentation & Control” procedures.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 11 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

5.3 Project Organisation

Halikos Pty Ltd is structured into operating in two distinct areas of operation, these being;

Operations and Projects. Functional reporting within Halikos Pty Ltd with respect to quality is

summarised as follows:

At Operation level, the Project Manager (or delegated staff member) is the Quality Manager

Representative (QMR) and has overall responsibility for Quality; Safety and Environmental

functions of the Halikos Group, these functions are managed at the Halikos Company

Headquarters.

At Project level, the Construction Site Manager (or delegated staff member) is The Project

Quality Manager Representative (PQMR) and has overall responsibility for Quality, Safety

and Environmental functions of Halikos Pty Ltd on the Project. The PQMR reports directly

to the QMR.

Fundamental checking by site supervisory staff and site based subcontractors will also be a

feature of the PQP. Placing responsibility for the achievement of quality objectives at the

workface will lead to greater accountability at this level.

The proposed organisation structure for the Project is detailed in Appendix 3.

The duties and responsibilities of Halikos staff are defined in position descriptions maintained by

the Human Resource Manager at the Halikos Company Headquarters.

5.4 Project Responsibilities

The duties and responsibilities of key personnel with respect to quality management on this project

are described below:

Project Director/Manager:

The Project Manager has overall authority in the determination of all matters affecting the

implementation and operation of the project. The Project manager reports directly to the

Managing Director.

The Project manager is responsible for:

Reviewing and authorising the Project Quality Plan (PQP), and other project plans;

Assigning quality responsibilities to all project personnel;

Ensuring all project personnel are suitably trained, and possess the necessary skills to

undertake their designated quality responsibilities;

Continually monitoring of quality performance to ensure compatibility and continued

effectiveness with the Company’s policy and objectives;

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 12 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Communicating quality performance to the Managing Director;

Providing sufficient funds, materials and equipment to ensure the PQP objectives are

achievable;

Participating in the review of the quality system and other relevant quality meetings and

programs;

Providing appropriate training in quality to all project personnel.

Project Quality Management Representative (PQMR)

The PQMR is responsible for the implementation of the Project Quality Plan (PQP). The

PQMR reports directly to the Project Manager and has a reporting function to the Quality

Manager Representative.

The PQMR has the authority to resolve all quality assurance matters in conjunction with the Project

Manager. The PQMR has the authority to reject non-conforming products/processes and the

responsibility to ensure that remedial measures are implemented to curtail further non-

conformance.

The PQMR is responsible for:

Ensuring the Project Quality Plan is correctly implemented to meet the requirements of the

project;

Allocating project staff to perform inspections duties;

Ensuring non-conformance is reported;

Ensuring a non-conformance is dispositioned within the required time-frame and that

disposition/remedial solutions are effectively implemented;

Reviewing inspection reports are ensuring any actions required are initiated;

Ensuring subcontractors fulfil their quality system obligations;

Attending meetings called to discuss quality issues;

Identifying and documenting quality system problems;

Assisting with the updating of the Project Quality Plan;

Reviewing and approving Inspection and Test Plans, Project Forms/Checklists;

Liaising with the quality assurance representative from the client;

Assisting in the auditing/assessment of suppliers/subcontractors

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 13 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Verification and Validation Personnel (Generally Site Supervisors)

Verification Personnel are responsible for inspecting and testing works in accordance with the

Inspection and Test Plans. Such work shall include off-site manufacture and fabrication and onsite

works.

Halikos has a qualitative measure for Verification and Validation and they are defined as:

Customer Validation - The assurance that a product, service, or system meets the needs of

the customer and other identified stakeholders. It often involves acceptance and suitability

with external customers.

Internal Verification - The evaluation of whether or not a product, service, or system

complies with a regulation, requirement, specification, or imposed condition. It is often an

internal process.

Verification Personnel have the authority to reject any nonconforming product/process and are

answerable to the PQMR in this regard. Various project personnel with relevant

experience/qualifications will be used to perform the necessary inspections to ensure the quality of

product is being upheld.

Verification Personnel are responsible for:

Performing the inspection and testing, or witnessing the inspection and testing by others, as

laid down in the Inspection and Test Plans including release of Halikos nominated Hold

Point;

Preparing records of inspection/tests and making these available to the PQMR;

Verifying that the procedures being used are adequate for effective control of quality;

Rejecting defective workmanship and materials;

Ensuring and verifying corrective action is taken when nonconforming work is identified.

5.5 Management Review

Regular reviews are undertaken by Halikos management to ensure that the project management

system continues to be suitable, adequate and effective. A standard procedure and agenda are

followed to ensure that opportunities for improvement to the management system are assessed

and that changes are implemented in a controlled manner.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 14 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

6.0 RESOURCE MANAGEMENT

The adequacy of existing equipment and personnel resources and the need for new resources is

identified and reviewed regularly by the Project Manager.

Equipment and trained personnel are provided at all organisational levels to carry out the project

processes, verification as well as internal audits to ensure conformance to the project specification.

6.1 Project Activities & Organizations

ACTIVITY ORGANISATION

Architectural Design, review & analysis

Architectural Documentation

Building Supervision Halikos Pty Ltd

Progress Payment Certification Halikos Pty Ltd

Project Administration Halikos Pty Ltd

Structural Engineering

Civil Engineering

Hydraulic Engineering

Surveying

Quantity Surveying

6.2 Training & Competency

To ensure that staff, are competent to perform their assigned tasks, the following systems have

been put in place:

- Position Descriptions including competency/education requirements

- Training is provided as determined by the position descriptions and performance reviews

-Job/quality requirements are communicated through Procedures

-A project “Training & Competency Matrix” will be maintained

The Halikos “Training” procedure provides guidelines and information to effectively manage

identification and implementation of Quality programs.

6.3 Facilities & Work Environment

Halikos will ensure that adequate facilities and a suitable work environment are provided to ensure

that workers are able to perform work in a safe and productive manner.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 15 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

7.0 PROJECT REALISATION

7.1 Project Planning

Quality planning for this project is performed during the tender stage by the Quality Manager

Representative and the Project Quality Representative. On award of contract, a project launch is

conducted and detailed quality planning is performed in accordance with the “Project Launch” and

“Project Documentation & Control” procedures.

7.2 Client Related Processes & Communication

Once the Client has issued a full set of contract documents for signature/sealing, these documents

shall be reviewed by the Project Manager against the “Tender” documents to ensure that any

deficiencies are identified and are resolved with the Client. The Project Manager shall ensure that

any matters affecting design are transmitted to the Services and Coordination Manager for action

as appropriate.

Any variation to the contract shall be reviewed by the Project Manager in conjunction with other

project staff with appropriate technical knowledge as required. The review is to ensure that

technical and quality requirements are clearly defined ant that the project has the necessary

resources, organisation and facilities to perform its obligations under the terms of the variation.

All head contract variations shall be controlled via a register.

Upon completion of the review, the Project Manager shall sign and date the variation, and ensure

distribution of the amendment to all concerned parties.

Methods of communication include RFI (Request for Information) to Design Consultants

and Site Instructions to subcontractors. Client complaints shall be handled in accordance

with the Halikos “Noncompliance” procedure.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 16 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

7.3 Design & Development

Design will be performed by external Consultants as per the Halikos “Design Management”

procedure.

Project Plans and procedures are updated as necessary as the design proceeds.

Design review meetings will be conducted at the stages defined below and in accordance with RFT

T13-1211:

Initial start up meeting

20% of design / documentation

40% of design / documentation

60% of design / documentation

95% of design / documentation

7.4 Purchasing & Subcontracting

In accordance with RFT T13-1211 all subcontractors who are contracted to provide trade services

valued at over $50,000.00 must have industry accreditation.

Additionally Halikos will endeavour to use local subcontractors and suppliers wherever possible,

refer to the project “Industry Participation Plan (IPP)”.

All purchased products (including subcontracted works) shall be subject to verification to ensure

conformance to contractual requirements.

The Project Manager shall review all purchase documents prior to approval and release. Halikos

Position Descriptions detail purchasing authority levels and responsibilities.

Halikos may arrange for offsite Inspectors to conduct inspection and verification activities at

subcontractor’s premises as required. The verification arrangements and the method of release

shall be specified in the purchasing documents.

7.5 Construction Control

Identification and planning of manufacture/construction activities is detailed in “Process Control”

procedure.

Qualification of personnel, equipment and procedures for these processes shall be in accordance

with the applicable Standards, Specification and Codes. Records of qualified processes,

procedures, personnel and equipment will be maintained in accordance with Halikos documented

procedures.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 17 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

8.0 Customer Property

The Principal will be responsible for the supply, delivery and installation of items described in of

RFT T13-1211.

8.1 Inspection and Testing

Inspection and testing of items and works shall be performed by authorised personnel as detailed

in the respective Inspection and Test Plan/checklist.

Product conformance will be determined by acceptance criteria laid down in the specifications and

Inspection and Test Plans.

During inspection and testing, any nonconforming product/process detected shall be identified,

document and segregated (where possible) in accordance with the Halikos “Noncompliance”

procedure.

All manufactured/constructed items shall undergo final inspection and testing in accordance with

specified contractual requirements prior to release to the client. No manufactured/constructed

items shall be offered to the client until all the activities specified in the Project Quality Plan or

documentation procedures and instructions have been satisfactorily completed.

8.2 Inspection, Measuring and Testing Equipment

All inspection, measuring and testing equipment (including newly acquired test equipment) used for

inspection and acceptance purposes, whether owned by Halikos, provided by the client or on load,

shall be controlled calibrated and maintained in accordance with the “Monitoring and Testing

Equipment” procedure.

For this project the following inspection, measuring and test equipment shall be subject to

calibration:

Equipment Calibration Frequency Calibration Authority

Dumpy/Laser 1 month External

Theodolite 3 months External

The PQMR shall verify all test results and maintain calibration records on the project file.

Any equipment identified as having doubtful accuracy or precision shall be removed from use and

calibrated. Where any inspection, measuring and test equipment is found to be out of calibration,

the validity of the previous inspection results will be assessed and documented.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 18 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

8.3 Handling, Storage, Packaging and Delivery

All items are handled and stored in accordance with documented procedures to prevent damage

and deterioration. Designated storage and holding areas are nominated in the site layout plan.

The condition of all stock is periodically assessed during store audits.

9.0 MEASUREMENT, ANALYSIS & IMPROVEMENT

9.1 Monitoring Client Satisfaction

The Project Manager shall in conjunction with the team establish a mechanism to measure and

monitor the level of satisfaction/dissatisfaction within the Client’s team. Examples of issues to be

monitored are Industrial Relations, Progress, Quality, Safety, Environmental, local industry

participation, indigenous involvement etc. A staff member shall be nominated by the Project

Manager to establish the monitoring mechanism, which shall include the recording, analysis, and

reporting of data

9.2 Monitoring Project Activities

Project activities (including subcontractor works) are monitored regularly in accordance with the

relevant Inspection & Test Plan/Checklists.

9.3 Internal Audits

The Halikos “Internal Audit Procedure” provides guidelines to effectively assess project compliance

against internal and external legislative requirements, and identify causes of project/system failures

and to promote proactive management of quality to promote continuous improvement

opportunities.

The PQMR will implement the auditing programme, schedule audit dates, and confirm names of

the audit team participants.

Project Quality Audits will be carried out at intervals defined in the Halikos audit schedule and will

review specific sections of the PQP to provide verification of the implementation, effectiveness and

possible recommendations for further improvement.

The results of audits shall be documented and Noncompliance Reports will be raised for

deficiencies identified and brought to the attention of the Project Manager for follow up action.

Following satisfactory rectification of the noncompliance, the responsible person shall provide a

completed copy of the report to the auditor.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 19 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

9.4 Control of Nonconforming Product

Any items that do not conform to specified requirements shall be prevented from inadvertent use or

installation. The “Noncompliance” procedure describes the process for identification, segregation

(when practical), classification, documentation, disposition and reinspection of the nonconforming

product.

Where contractually required, concessions or waivers shall be sought from the client for the

proposed use of the product, which does not conform to specified requirements. All nonconformity

shall be documented and a register is maintained by the PQMR to monitor the status of the non-

conformances.

Defects identified during the defects liability period will be documented and resolved in accordance

with Halikos procedures.

9.5 Analysis of Data

Project Quality statistics shall be gathered on a regular basis using the standard report format.

Statistical information will be analysed and reported to all Halikos workers, project subcontractors

and other interested parties. The Project Manager will review project statistics regularly.

9.6 Improvement

Halikos management ensures that the effectiveness of the quality system continually improves

through the use of quality system elements such as the Quality Policy, Quality Objectives, audit

results, management reviews and the use of corrective action reports.

Corrective and/or preventative actions taken to eliminate the causes of actual or potential

nonconformity shall be in accordance with the documented procedure. The action taken shall be

to a degree appropriate to the magnitude of problems and the risks encountered.

10.0 DEFINITIONS

Client - Department of Infrastructure, Construction Division.

Contractor - Halikos Pty Ltd.

Subcontractor - Any company or person who is contracted to Halikos Pty Ltd for the purpose of

supplying goods or services.

Consultant - The architectural and engineering consultants who have been engaged by Halikos

Pty Ltd to perform the design, preparation of detailed ‘For Construction’ documentation and

necessary certification to meet contractual requirements.

Project Quality Plan (PQP) - A document that describes how the work under the contract will be

performed and controlled, i.e. this document.

Procedure - A document which describes the method for undertaking a certain activity.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 20 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

Inspection and Test Plan (ITP) - A document which describes what checks for compliance for a

particular process or activity are to be made.

Hold Point - A point in the construction or verification process beyond which work must not

proceed without the written approval of a designated person or authority.

Witness Point - A point in the construction or verification process at which an activity is to be

observed.

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 21 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

APPENDIX 1 – HALIKOS QUALITY POLICY

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 22 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

APPENDIX 2 – DOCUMENT CONTROL REGISTER

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 23 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

APPENDIX 3 – PROJECT ORGANISATION CHART

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 24 of 25

Document Owner: Construction Division Uncontrolled When Printed

Project Quality Plan

Royal Darwin Hospital

APPENDIX 4 – MASTER INSPECTION & TEST PLAN

Document: PMP-3-04 Revision: 1 Date: June 2013 Page 25 of 25

Document Owner: Construction Division Uncontrolled When Printed

Das könnte Ihnen auch gefallen

- S4HANA Sales Certification QuestionsDokument3 SeitenS4HANA Sales Certification QuestionsSiddharth Sinha100% (2)

- CMAA Quality Mangement GuidelinesDokument86 SeitenCMAA Quality Mangement GuidelinesAnonymous 5jVybvF7C100% (1)

- CP-122 HSE Code of Practice - PDO PDFDokument96 SeitenCP-122 HSE Code of Practice - PDO PDFEmre Cengiz100% (3)

- Social Media Marketing Secrets 2020 3 Books in 1 B088QN6CFRDokument324 SeitenSocial Media Marketing Secrets 2020 3 Books in 1 B088QN6CFRmusfiq100% (1)

- 3.0 Design Schedule ProjectDokument2 Seiten3.0 Design Schedule ProjectjparsbNoch keine Bewertungen

- 04 - Human Resource PlanDokument10 Seiten04 - Human Resource PlanMohammed AffrozeNoch keine Bewertungen

- Project Management PlanDokument114 SeitenProject Management PlanसागरऊमळकरNoch keine Bewertungen

- Global Health & Safety Documents 2015Dokument199 SeitenGlobal Health & Safety Documents 2015Carl WilliamsNoch keine Bewertungen

- Project Quality PlanDokument43 SeitenProject Quality Planmkmkhairi100% (4)

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDokument34 Seiten5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Risk Management in Construction Projects As Per Indian ScenarioDokument11 SeitenRisk Management in Construction Projects As Per Indian ScenarioLithin rajuNoch keine Bewertungen

- QA Programme Rev 3 TERFDokument47 SeitenQA Programme Rev 3 TERFChav ChoubNoch keine Bewertungen

- QAP Plan For Biratnagar AirportDokument20 SeitenQAP Plan For Biratnagar AirportNirmal bhandariNoch keine Bewertungen

- Quality PlanDokument21 SeitenQuality PlanQianlei ZhuNoch keine Bewertungen

- Typical QA&QC Execution Plan and Management SystemDokument31 SeitenTypical QA&QC Execution Plan and Management Systemchao gaoNoch keine Bewertungen

- Procurment Management Plan TemplateDokument15 SeitenProcurment Management Plan TemplateMonil PatelNoch keine Bewertungen

- Quality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakDokument47 SeitenQuality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakConnielya AdamNoch keine Bewertungen

- QA Programme Rev.3, TERFDokument46 SeitenQA Programme Rev.3, TERFUmesh Mishra100% (1)

- DE-QC-IT-S01 (Inspection & Test Plan)Dokument8 SeitenDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliNoch keine Bewertungen

- MARAFIQ Project Quality Plan OverviewDokument6 SeitenMARAFIQ Project Quality Plan OverviewNABEEL ABDUL GAFFARNoch keine Bewertungen

- Project Quality PlanDokument110 SeitenProject Quality PlanJoseph Allan TolentinoNoch keine Bewertungen

- Project Execution Strategy With Key DatesDokument1 SeiteProject Execution Strategy With Key DatesPrathibha LNoch keine Bewertungen

- Lesson 10 Project Quality PlanningDokument51 SeitenLesson 10 Project Quality PlanningDevjit MandalNoch keine Bewertungen

- Builders Company ProfileDokument18 SeitenBuilders Company ProfileseetharamchNoch keine Bewertungen

- Quality Assurance Plan for ASARCO DemolitionDokument20 SeitenQuality Assurance Plan for ASARCO DemolitionRen SalazarNoch keine Bewertungen

- Project Quality PlanDokument21 SeitenProject Quality PlanbillingNoch keine Bewertungen

- Qualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesDokument7 SeitenQualtiy Plan 1. Quality Objectives & Policies 1.1 Quality ObjectivesRHOWELLE TIBAYNoch keine Bewertungen

- Quality Assessment ProcedureDokument3 SeitenQuality Assessment ProcedureAlina OnţaNoch keine Bewertungen

- Rehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01Dokument53 SeitenRehabilitation and Upgrading of Pakpattan Canal, Khadir Branch and Pakpattan Islam Link Contract: PCSBIP/ICB-01yashas sNoch keine Bewertungen

- ENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Dokument29 SeitenENCOCORP QUALITY MANUAL ISO 9001-2015 - Updated On 5-Mar-2016 Webiste With ITP REV1Sofia RegaladoNoch keine Bewertungen

- 15need of SOP in Building Construction Managemenmanagementt PDFDokument4 Seiten15need of SOP in Building Construction Managemenmanagementt PDFJannatul FirdousNoch keine Bewertungen

- Cable Ladder & Tray Installation ITPDokument5 SeitenCable Ladder & Tray Installation ITPGultom Juliana LiliesNoch keine Bewertungen

- Project Quality Plan: Mps Integrated Service LimitedDokument18 SeitenProject Quality Plan: Mps Integrated Service LimitedOGBONNAYA MARTINSNoch keine Bewertungen

- IT Project Quality Management PlanDokument4 SeitenIT Project Quality Management PlanKrishna437Noch keine Bewertungen

- PQP Vs ISO 9001 Clauses List PDFDokument1 SeitePQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- Project Deliverables TrackingDokument5 SeitenProject Deliverables Trackingmoytabura96Noch keine Bewertungen

- Deployment PlanDokument8 SeitenDeployment PlanBirhanu AtnafuNoch keine Bewertungen

- Duties of SITE STAFFDokument9 SeitenDuties of SITE STAFFAbdali SaladNoch keine Bewertungen

- Lps 01 Hti MST El 005 Point WiringDokument22 SeitenLps 01 Hti MST El 005 Point WiringJomy JohnyNoch keine Bewertungen

- Quality: To Meet Product or Service Specifications and ExpectationsDokument13 SeitenQuality: To Meet Product or Service Specifications and ExpectationsmaelikahNoch keine Bewertungen

- Draft Quality Audit GuidelineDokument50 SeitenDraft Quality Audit GuidelineHamdiNoch keine Bewertungen

- SAR - Quickrete - RMC - SteightDokument130 SeitenSAR - Quickrete - RMC - SteightMariam ZaitaaNoch keine Bewertungen

- 02779-Rizhao Project Quality PlanDokument19 Seiten02779-Rizhao Project Quality PlanmrjimmyjamNoch keine Bewertungen

- Schedule Management Plan TemplateDokument10 SeitenSchedule Management Plan TemplateVick'y A'AdemiNoch keine Bewertungen

- Derlin Construction Limited Quality Policy Manual: Document HistoryDokument30 SeitenDerlin Construction Limited Quality Policy Manual: Document HistoryAdams Bruno100% (1)

- Quality Management Plan Jan12 RevisionDokument11 SeitenQuality Management Plan Jan12 RevisionLau Meng YongNoch keine Bewertungen

- Road Construction Essentials QA/QC PlanDokument10 SeitenRoad Construction Essentials QA/QC Planrafiullah amireeNoch keine Bewertungen

- Construction EngineeringDokument24 SeitenConstruction EngineeringCátiaNoch keine Bewertungen

- Quality PlanningDokument10 SeitenQuality Planningkaushalsahu2332Noch keine Bewertungen

- Attachment 07 - Subcontractor's Quality Management RequirementsDokument6 SeitenAttachment 07 - Subcontractor's Quality Management Requirementsum erNoch keine Bewertungen

- BMJV-QUA-F18.01 Excavation Checklist R00Dokument1 SeiteBMJV-QUA-F18.01 Excavation Checklist R00Taiwo OshinNoch keine Bewertungen

- Project Quality PlanDokument9 SeitenProject Quality PlanHasan Mahmud KhanNoch keine Bewertungen

- MS 06 Reinforcement Bars Method Statement-Rev 01Dokument7 SeitenMS 06 Reinforcement Bars Method Statement-Rev 01Abdullah Al MarufNoch keine Bewertungen

- Contoh4. Project Quality PlanDokument22 SeitenContoh4. Project Quality PlanlobamlautNoch keine Bewertungen

- Method Statement: Consolidated Contractors Company & Teyseer Contracting Company J.VDokument10 SeitenMethod Statement: Consolidated Contractors Company & Teyseer Contracting Company J.Vrvsreddy1972Noch keine Bewertungen

- PM Project Quality Plan 8-7-2012Dokument27 SeitenPM Project Quality Plan 8-7-2012XozanNoch keine Bewertungen

- 02.method Statement Ver 2Dokument6 Seiten02.method Statement Ver 2Peter ade TeacherNoch keine Bewertungen

- PMBOK Quality ControlDokument2 SeitenPMBOK Quality Control000chris000Noch keine Bewertungen

- Quality Requirements For Subcontractor: Project ProcedureDokument15 SeitenQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNoch keine Bewertungen

- QC PlanDokument51 SeitenQC PlanAllan KhatasioNoch keine Bewertungen

- Procedure of L&E PDFDokument10 SeitenProcedure of L&E PDFamNoch keine Bewertungen

- Itp - EifsDokument22 SeitenItp - Eifssathiyaprasath100% (1)

- Execution Template - Quality Management ProcessDokument8 SeitenExecution Template - Quality Management ProcessAzza ShoukrNoch keine Bewertungen

- China National Machinery Imp. & Exp. Corp. DCM Pile Inspection PlanDokument6 SeitenChina National Machinery Imp. & Exp. Corp. DCM Pile Inspection Plandimuthu lasinthaNoch keine Bewertungen

- Rent Payment Schedule - FDokument3 SeitenRent Payment Schedule - FTom CatNoch keine Bewertungen

- BST WFC Qa PLN 00001.0.ifiDokument34 SeitenBST WFC Qa PLN 00001.0.ifiVenkatesan NarayanaswamyNoch keine Bewertungen

- Code of Practice Construction Work 56 PDFDokument56 SeitenCode of Practice Construction Work 56 PDFCarl WilliamsNoch keine Bewertungen

- Construction Quality Management 47 PDFDokument47 SeitenConstruction Quality Management 47 PDFCarl WilliamsNoch keine Bewertungen

- Building Quality Standards HandbookDokument248 SeitenBuilding Quality Standards HandbookKaterina Karadik100% (1)

- Construction Quality Management For ContractorsDokument272 SeitenConstruction Quality Management For Contractorsabuwanamir100% (9)

- Chapter-18-Hazard-and-Risk-Management 36 PDFDokument36 SeitenChapter-18-Hazard-and-Risk-Management 36 PDFCarl WilliamsNoch keine Bewertungen

- Site Management For Engineers 218 PDFDokument280 SeitenSite Management For Engineers 218 PDFCarl Williams100% (1)

- Code of PractiseDokument31 SeitenCode of PractiseFáber Carrijo OliveiraNoch keine Bewertungen

- Code of Practice For The Construction Industry 49 PDFDokument49 SeitenCode of Practice For The Construction Industry 49 PDFCarl WilliamsNoch keine Bewertungen

- Final Bridge Design Report (Berhampur AniDokument98 SeitenFinal Bridge Design Report (Berhampur AniYogesh Indolia100% (6)

- Chapter 12 Fire and Life SafetyDokument34 SeitenChapter 12 Fire and Life SafetyCarl WilliamsNoch keine Bewertungen

- Thf14c Hislop Key Elebments 90416Dokument36 SeitenThf14c Hislop Key Elebments 90416Lorena HernandezNoch keine Bewertungen

- EeDokument20 SeitenEeCarl WilliamsNoch keine Bewertungen

- SSWP - Commercial - Building - Pictograms 68 PDFDokument68 SeitenSSWP - Commercial - Building - Pictograms 68 PDFCarl WilliamsNoch keine Bewertungen

- Project Risk Management - Methodology Development For Engineering, Procurement and Construction (EPC) Projects PDFDokument58 SeitenProject Risk Management - Methodology Development For Engineering, Procurement and Construction (EPC) Projects PDFCarl WilliamsNoch keine Bewertungen

- Sustainability Plan PDFDokument51 SeitenSustainability Plan PDFCarl WilliamsNoch keine Bewertungen

- C M Manual Bridges Structures2Dokument315 SeitenC M Manual Bridges Structures2tipsypig100% (2)

- Construction Management Plan Plymouth Airport 63Dokument63 SeitenConstruction Management Plan Plymouth Airport 63Carl WilliamsNoch keine Bewertungen

- Edinburgh Airport Quality Management Plan 43 PDFDokument43 SeitenEdinburgh Airport Quality Management Plan 43 PDFCarl WilliamsNoch keine Bewertungen

- Project Quality PlanDokument81 SeitenProject Quality PlanCarl WilliamsNoch keine Bewertungen

- CREATE Final Phase I Manual July 2016Dokument68 SeitenCREATE Final Phase I Manual July 2016Carl WilliamsNoch keine Bewertungen

- Procedures For The Examination of Plans and Inspection of ConstructionDokument25 SeitenProcedures For The Examination of Plans and Inspection of ConstructionCarl WilliamsNoch keine Bewertungen

- Construction Manual PDFDokument467 SeitenConstruction Manual PDFCarl Williams100% (2)

- Project & Construction Management Manual for the California High-Speed Rail AuthorityDokument295 SeitenProject & Construction Management Manual for the California High-Speed Rail AuthorityCarl WilliamsNoch keine Bewertungen

- FILIPINAS COMPAÑIA DE SEGUROS vs. CHRISTERN, HUENEFELD and CO., INC.Dokument2 SeitenFILIPINAS COMPAÑIA DE SEGUROS vs. CHRISTERN, HUENEFELD and CO., INC.zacNoch keine Bewertungen

- Chapter 1 problem 3 exercisesDokument18 SeitenChapter 1 problem 3 exercisesAlarich CatayocNoch keine Bewertungen

- Cba 2008-2009 PDFDokument10 SeitenCba 2008-2009 PDFjeffdelacruzNoch keine Bewertungen

- Cooperative Societies ExplainedDokument34 SeitenCooperative Societies ExplainedAnkit sharmaNoch keine Bewertungen

- Form - 03 17 July 2019Dokument2 SeitenForm - 03 17 July 2019muhammad ihtishamNoch keine Bewertungen

- BHEL AR 12-13 Eng For Web PDFDokument300 SeitenBHEL AR 12-13 Eng For Web PDFKumar KoteNoch keine Bewertungen

- TPM Event CalenderDokument3 SeitenTPM Event Calenderamarpal07Noch keine Bewertungen

- An Assignment On Niche Marketing: Submitted ToDokument3 SeitenAn Assignment On Niche Marketing: Submitted ToGazi HasibNoch keine Bewertungen

- Advanced Entrepreneurship Notes Fems 2023Dokument35 SeitenAdvanced Entrepreneurship Notes Fems 2023ghislainchindoNoch keine Bewertungen

- SAP TM Course Content.......Dokument4 SeitenSAP TM Course Content.......Prasad ChowdaryNoch keine Bewertungen

- The Importance of Reverse Logistics (#274692) - 255912Dokument11 SeitenThe Importance of Reverse Logistics (#274692) - 255912I'malookIubeNoch keine Bewertungen

- Customs Unions and Free Trade AreasDokument6 SeitenCustoms Unions and Free Trade AreasÖzer AksoyNoch keine Bewertungen

- Factors Influencing Market and Entry Mode Selection PDFDokument11 SeitenFactors Influencing Market and Entry Mode Selection PDFPaula ManiosNoch keine Bewertungen

- SCM Project - Final ReportDokument10 SeitenSCM Project - Final Reportmuwadit AhmedNoch keine Bewertungen

- Vinci NewslettersDokument1 SeiteVinci Newsletterscommunity helps itselfNoch keine Bewertungen

- Chapter 4-Art of WarDokument3 SeitenChapter 4-Art of WarMaria Gracia MolinaNoch keine Bewertungen

- Tutorial 3 QuestionsDokument2 SeitenTutorial 3 QuestionsHà VânNoch keine Bewertungen

- Colgate DCF ModelDokument19 SeitenColgate DCF Modelshubham9308Noch keine Bewertungen

- MIT's Mission: Supporting World-Class Education and Cutting-Edge ResearchDokument11 SeitenMIT's Mission: Supporting World-Class Education and Cutting-Edge ResearchDingo BingoNoch keine Bewertungen

- Diff Coke and PepsiDokument1 SeiteDiff Coke and PepsiAnge DizonNoch keine Bewertungen

- Kotler Chapter 14Dokument33 SeitenKotler Chapter 14ratih95100% (1)

- MSA-1 Syllabus Winter 2022 Financial Reporting AuditDokument14 SeitenMSA-1 Syllabus Winter 2022 Financial Reporting AuditHammad Hussain QureshiNoch keine Bewertungen

- RBI Bank Branch Audit Planning GuideDokument62 SeitenRBI Bank Branch Audit Planning Guidebudi.hw748Noch keine Bewertungen

- Sustaining Competitive AdvantageDokument4 SeitenSustaining Competitive AdvantagensucopyNoch keine Bewertungen

- OutsourcingDokument24 SeitenOutsourcingihabkarinaNoch keine Bewertungen

- Training and Development of Apple CoDokument75 SeitenTraining and Development of Apple CoYOGESH KALANNoch keine Bewertungen

- Production Management Midterm ReviewDokument21 SeitenProduction Management Midterm Reviewielsiu21184Noch keine Bewertungen

- Consumer Behavior of Parle - 'Dokument19 SeitenConsumer Behavior of Parle - 'anmolNoch keine Bewertungen