Beruflich Dokumente

Kultur Dokumente

Automatic Speed Control Based On Iot

Hochgeladen von

Dhruva CasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Automatic Speed Control Based On Iot

Hochgeladen von

Dhruva CasCopyright:

Verfügbare Formate

© 2019 IJRAR June 2019, Volume 6, Issue 2 www.ijrar.

org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Automatic speed control based on IoT

1

Ashiq V M, 2Sayed Muhammed N A

1 2

Student, Student,

1

Department of Computer Science , 2 Department of Electronics

1

IHRD College of Applied Science, Palakkad, India

Abstract : Most of the road accidents in India occur due to over speed and rash driving of vehicles on public roads. The rate of

accidents has increased as more vehicles come on to the ground. To control and monitor the speed of the vehicle on public roads the

respective departments of government has taken the necessary step. But it is not doing enough. Presently the motor vehicle

departments have been provided with laser speed detectors. But a man has to be there on the road, which is not an ideal way o f

monitoring. Also, the laser tracker is very costly. The IoT is recognized as one of the most important areas of future technology and

is gaining vast attention from a wide range of industries Here in this paper, we tried to develop a system to track the speed of the

vehicle in a much simpler, economical way. This system has to work 24x7 automatically by using an RFID module as its main

component, automatic speed control of our vehicle can be achieved. The RFID tag is fixed on the different signboards and RFID

reader on the vehicle. When the reader comes in the speed limit area, speed is controlled automatically

IndexTerms - IoT, RFID Module, Laser tracker.

I. INTRODUCTION

Accidents are occurring frequently in highly traffic areas .Drivers drive vigorously without caring the signals. Intimation of driver

about speed necessary. It can be done by using automatic technology with the help of embedded system and sensors. Due to the

accident cases reported daily on the major roads in all parts of the developed and developing countries, more attention is needed for

research in the designing an efficient car driving aiding system. It is expected that if such a device is designed and incorporated into

our cars as a road safety device, it will reduce the incidence of accidents on our roads and various premises, with subsequent

reduction in loss of life and property. However, a major area of concern of an engineer should be safety, as it concerns the use of

his/her inventions and the accompanying dangers due to human limitations. Here in this paper, we tried to develop a system to track

the speed of the vehicle in a much simpler, economical way. This system has to work 24x7 automatically The first idea was to use

laser module, but finding it costly it was dropped. Later we found out that IR transceivers will help in achieving the goal, which is

very simple to construct and very cheap, but it works only if the line of sight is maintained which was the main reason it was dropped.

Finally, we found that RFID module can fulfill our requirements with its key features as more economical, high reliability, etc.

II. BLOCK DIAGRAM

Microcontroller is the heart of the project. Here we are using PIC16F877A microcontroller. The overall circuit is

controlled by this microcontroller.

MICROCONTROLLER

An embedded microcontroller is a chip, which has a computer processor with all its support function, memory and I\O

built into the device. These built in function minimize the need for external circuit and device. These built in function minimize

the need for external circuit and device to the designed in the application. The improvements in microcontroller technology has

meant that it is often more cost effective, faster and more efficient to develop an application using a microcontroller rather than

discreet logic. Creating application for microcontroller is completely different than any other application, number of subsystems

and interfaces are available but this is not the case for the microcontroller where the following responsibilities have to be taken.

SWITCH

In electronics a switch is an electrical component which can break an electrical circuit, interrupting the current or diverting

it from one conductor to another. The most familiar form of switch is a manually operated electromechanically device with one

or more set of electrical contacts. Each set of contacts can be one or two states: either closed meaning the contacts are touching

the electricity can flow between them, or open meaning the contact is separated and non-conducting.

RELAY

A relay is a simple electromechanical switch made up of an electromagnet and a set of contacts. Relays are found

hidden in all sorts of devices. In fact, some of the first computers ever built used relays to implement Boolean gates. Relay are

used where it is necessary to control a circuit by a low power signal or where several circuits must be controlled by one signal.

The first relays were used in long distance telegraph circuit, repeating the signal coming in from one circuit and re-transmitting

it to another. Relays were used extensively in telephone exchanges and early computer to computer to perform logical

operations .A type of relay that can handle the high power required to directly control an electric motor or other loads is called a

contractor. Solid-state relay control power circuits with no moving parts, instead using a semiconductor device to perform

switching. Relay with calibrated operating characteristic and sometimes multiple operating coils are used to protect electrical

circuits form overload or faults; in modern electric power systems these functions are performed by digital instruments still

called “protective relay”.

IJRAR19K3099 International Journal of Research and Analytical Reviews (IJRAR)www.ijrar.org 784

© 2019 IJRAR June 2019, Volume 6, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Fig:1 (a) Transmitter

(b) Receiver

LCD

Liquid crystal displays (lcds) have materials which combine the properties of both liquids and crystals. Rather than

having a melting point, they have a temperature range within which the molecules are almost as mobile as they would be in a

liquid, but are grouped together in an ordered form similar to a crystal.

An lcd consists of two glass panels, with the liquid crystal material sand witched in between them. The inner surface of

the glass plates are coated with transparent electrodes which define the character, symbols or patterns to be displayed polymeric

layers are present in between the electrodes and the liquid crystal, which makes the liquid crystal molecules to maintain a

defined orientation angle.

SOLINOID PUMB

Micro DC 3-6V Micro Submersible Pump Mini water pump For Fountain Garden Mini water circulation System DIY

project DC 3v to 6v submersible pump micro mini submersible water pump 3v to 6v DC water pump for DIY DC pump for

HOBBY kit Mini Submersible Pump Motor This is a low cost, small size Submersible Pump Motor which can be operated from a

2.5 ~ 6V power supply. It can take up to 120 liters per hour with very low current consumption of 220ma. Just connect tube pipe

to the motor outlet, submerge it in water and power it. Make sure that the water level is always higher than the motor. Dry run

may damage the motor due to heating and it will also produce noise. Specifications Operating Voltage : 2.5 ~ 6V Operating

Current : 130 ~ 220ma Flow Rate : 80 ~ 120 L/H Maximum Lift : 40 ~ 110 cm Continuous Working Life : 500 hours Driving

Mode : DC, Magnetic Driving Material : Engineering Plastic Outlet Outside Diameter : 7.5 mm Outlet Inside Diameter : 5 mm

SPEED SENSOR

Magnetic sensors are designed to respond to a wide range of positive and negative magnetic fields in a variety of

different applications and one type of magnet sensor whose output signal is a function of magnetic field density around it is

called the hall effect sensor. Hall effect sensors are devices which are activated by an external magnetic field. We know that a

magnetic field has two important characteristics flux density, (b) and polarity (north and south poles). The output signal from a

hall effect sensor is the function of magnetic field density around the device. When the magnetic flux density around the sensor

exceeds a certain pre-set threshold, the sensor detects it and generates an output voltage called the hall voltage, vh.

BUZZER

Fdkpiezoceramic buzzers generate sound through the bending vibrations of a thin metal plate adhered to a piezoceramic

disc. These buzzers feature a low power consumption, a safe, spark-free and non-contact structure, and a small size and light

weight for an easy mounting to printed circuit boards. As a result, an increasing number of piezoceramic buzzers are now used

to generate an artificial voice in combination with voice synthesizing ics. To produce high-quality piezoceramic buzzers, fdk has

capitalized on many years of piezoceramics production and outstanding ceramic processing technologies and thin film forming

techniques. By adding a sophisticated audio know-how to this manufacturing expertise, fdk offers a large array of electronic

tone generating products, such as piezoceramic diaphragms, sounders and buzzers, to meet loud sound outputs, wide frequency

ranges, and many other requirements.

PARALLEL TO SERIAL & SERIAL TO PARALLEL DATA CONVERTERS

Parallel to Serial data converters converts’ parallel inputs of data into serial data.HT12E Encoder IC is an example for

parallel to serial data converters. They are capable of Encoding 12 bit of information which consists of N address bits and 12-N

data bits. Each address/data input is externally trinary programmable if bonded out. On the other hand Serial to parallel data

converters converts serial inputs of data into parallel data. Here HT12D Decoder IC is used to convert the received input which

is in serial form to corresponding parallel form. . These ICs are paired with each other. For proper operation a pair of

encoder/decoder with the same number of address and data format should be selected. The Decoder receive the serial address

and data from its corresponding encoder, transmitted by a carrier using an RF transmission medium and gives output to the

output pins after processing the data.

RF TRANSMITTER AND RECEIVER

The RF module, as the name suggests, operates at Radio Frequency. The corresponding frequency range varies between

30 kHz & 300 GHz. In this RF system, the digital data is represented as variations in the amplitude of carrier wave. This kind of

modulation is known as Amplitude Shift Keying (ASK).

IJRAR19K3099 International Journal of Research and Analytical Reviews (IJRAR)www.ijrar.org 785

© 2019 IJRAR June 2019, Volume 6, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Transmission through RF is better than IR (infrared) because of many reasons. Firstly, signals through RF can travel

through larger distances making it suitable for long range applications. Also, while IR mostly operates in line-of-sight mode, RF

signals can travel even when there is an obstruction between transmitter & receiver. Next, RF transmission is more strong and

reliable than IR transmission. RF communication uses a specific frequency unlike IR signals which are affected by other IR

emitting sources. This RF module comprises of an RF Transmitter and an RF Receiver. The transmitter/receiver (Tx/Rx) pair

operates at a frequency of 434 MHz . An RF transmitter receives serial data and transmits it wirelessly through RF through its

antenna connected at pin4. The transmission occurs at the rate of 1Kbps - 10Kbps.The transmitted data is received by an RF

receiver operating at the same frequency as that of the transmitter.

The RF module is often used along with a pair of encoder/decoder. The encoder is used for encoding parallel data for

transmission feed while reception is decoded by a decoder. HT12E-HT12D, HT640-HT648, etc. are some commonly used

encoder/decoder pair ICs.

III. WORKING

This project is developed using PIC Microcontroller (16F877A), RF module, HT Encoder, Decoder, 16x2lcd and few

components. The PIC Microcontroller having five ports like as PORT A, PORT B, PORT C,PORT D & PORT E respectively.

Here LCD interface have 7 pins which is connect to PORT D, decoded output of wireless data from RF Module generate noise

so it can’t communicate more than 5 meters. These problems are solved by using HT decoder. HT decoder have 4 data output,

which is collect data from RF module, and then convert to serial data into 4 bit binary data and it is connect to PORT C,

In zone section parallel data is applied to HR12E Encoder IC. It converts parallel data into serial data and fed the output

to RF transmitter. Each zone has unique combination of data. RF transmitter transmits data continuously at a range of 100

meters.

When the vehicle enters in the normal area it speed does not decrease and it goes normally no action is performed .when the

vehicle enters into the restricted areas that means it enters into the speed limiting zone .whenever it enters the transmitter module

just send an information that contains how much speed a vehicle can go inside the speed limited zone . Then the signal or

information is received by the receiver and the signal acquired from the speed meter is also given to the controller the signal is

basically analog in nature that will be converted into digital so only the micro controllable to process the signal.

The signal from the transmitter and the speed meter is compared by the controller . In this there are two case :

First ,the current speed is less than the transmitted speed the vehicle goes normally no action is required .

Second ,the information from the speed meter is greater than the transmitted speed by the transmitter module the controller

waits for few second whether the driver reduce the speed to the below value if the driver does not reduce the speed means it

automatically takes the control and reduce the speed according to it

When vehicle enters into this range, RF receiver of vehicle receives the data and sends it to the14th pin of HT12D

Decoder IC which is the input pin, and this IC converts serial input of data into parallel data and output is available at pins

10,11,12,13 respectively. The output of decoder is now fed into the PIC (PORT C pins RC0,RC1,RC2,RC3).Now

microcontroller receives the data send by the zone and it identify the zone using received data. After detection of zone it will

indicate the beep and display the zone & speed limit .The microcontroller checks the speed of vehicle with the help of hall

effect speed sensor connected to the RA4 pin of controller. Here every zone has different speed limit and already speed limit of

each zone is stored in memory. So the microcontroller compares the speed limit and vehicle’s current speed and if the speed is

above the limit buzzer will be ON for warning the driver and the controller will reduce the speed of vehicle,pin RC5 is used to

connect PUMB to microcontroller.

Fig:2 Transmitter circuit diagram

IJRAR19K3099 International Journal of Research and Analytical Reviews (IJRAR)www.ijrar.org 786

© 2019 IJRAR June 2019, Volume 6, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Fig:3 Receiver circuit diagram

IV. HARDWARE

PIC16F877A

The core of the project is a PIC MICROCONTROLLER. In our system we are using a PIC 16F877A Microcontroller. We have

all come across computers in our daily life and we all know the value and the use it has in our life. Such a computer system

hidden inside a product other than a computer is called an embedded system. Our system is an embedded system as we use a

microcontroller which is a small form of minicomputer itself. We have used a microcontroller instead of a microprocessor

because the later requires external hardware like external RAM, ROM; external peripherals etc. a microprocessor with all the

external hardware can be called a microcontroller.

We choose this PIC microcontroller 16F877A, because we have to use many peripherals such as LCD and sensors. This all

can be accomplished by our PIC since it has 5 I/O ports to connect the peripherals and also it has the computation efficiency

required for this project

RF MODULE

An RF module (radio frequency module) is a (usually) small electronic device used to transmit and/or receive

radio signals between two devices. In an embedded system it is often desirable to communicate with another device wirelessly.

This wireless communication may be accomplished through optical communication or through radio frequency (RF)

communication. For many applications the medium of choice is RF since it does not require line of sight. RF communications

incorporate a transmitter and/or receiver.

RF modules are widely used in electronic design owing to the difficulty of designing radio circuitry. Good electronic

radio design is notoriously complex because of the sensitivity of radio circuits and the accuracy of components and layouts

required to achieve operation on a specific frequency. In addition, reliable RF communication circuit requires careful

monitoring of the manufacturing process to ensure that the RF performance is not adversely affected. Finally, radio circuits are

usually subject to limits on radiated emissions, and require Conformance testing and certification by a standardization

organization such as ETSI or the U.S. Federal Communications Commission (FCC). For these reasons, design engineers will

often design a circuit for an application which requires radio communication and then "drop in" a pre-made radiomodule rather

than attempt a discrete design, saving time and money on development.

IJRAR19K3099 International Journal of Research and Analytical Reviews (IJRAR)www.ijrar.org 787

© 2019 IJRAR June 2019, Volume 6, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

V. LAYOUT

Fig 4:PCB and Components layout

VI. FUTURE ADVANCEMENTS

In this project, only the test vehicle was present on the road. In normal driving situations, we can expect other vehicles

circulating nearby and possibly blocking or attenuating some of the RFID transmitting signals, especially with large vehicles

like trucks.

In this aspect, more experiment is needed to know how this circumstance will affect the vehicle’s control performance.

A possible solution is the use of redundant RF (since their cost is relatively low), placed at different location near the restricted

zones, to guarantee RF signal reception in unfavourable conditions

VII. RESULTS AND DISCUSSION

The performance and the outcome of the project are very satisfactory.

The ever growing field of electronics found the new milestones of discoveries through embedded systems. This can be a better

platform for the fast developing technologies. During the designing, assembling and integrating the phase of the project, we faced

a lot of problem. We overcome the difficulties faced during the work. We have learned more about operation, application,

assembling of parts and successfully testing of the equipments by doing this project. We utilize the facilities that are available to

us. There are lots of features that can be used for practical applications

ADVANTAGES

Accidents are avoided at least in the speed restricted areas such as school and hospital zones.

Moreover it also ensures efficient transportation of vehicles.

Restricted areas are controlled automatically rather than manually.

Ease of checking process at high ways and check points.

The proposed on-board architecture is portable and easily adaptable to any commercial vehicle with minimal

modification.

FEATURES

Very simple design and construction

Latest Technology-Very Economically priced

Light weight, Easy to handle, simple operation

Works on Power and battery both.

ZIGBEE technology provides speedy data transfer

REFERENCES

[1] "The 8051 Microcontroller & Embedded Systems" by Mohammed Ali Mazidi and Janice Gillispie Mazidi

[2] International journal of scientific &engineering research, volume 4 oct 13

[3] ATMEL AVR studio &ATmega 16 data sheet.

[4] The 8051 micro controller Architecture, Programming & Applications by Ramesh S.Gaonkar

[5] Electronic components by D.V.Prasad

[6]Design with PIC microcontroller-John B Peatman

[7]Telecommunication Switching and networks - P Gnanasivam

IJRAR19K3099 International Journal of Research and Analytical Reviews (IJRAR)www.ijrar.org 788

Das könnte Ihnen auch gefallen

- Report On Security System Switcher (Oct 2011)Dokument19 SeitenReport On Security System Switcher (Oct 2011)scribdsunshineNoch keine Bewertungen

- Rotary Valve Functions BookletDokument17 SeitenRotary Valve Functions Bookletamahmoud3Noch keine Bewertungen

- Tribology Module 01 NotesDokument19 SeitenTribology Module 01 NotesVinayaka G P89% (9)

- 97-Article Text-143-4-10-20180303Dokument7 Seiten97-Article Text-143-4-10-20180303Qarrizalw's xdNoch keine Bewertungen

- Coin-Operated Coffee Vending Machine: A Project Proposal By: Pinili, Ellen Gold B. Ponce, Mary Rosechelle SDokument14 SeitenCoin-Operated Coffee Vending Machine: A Project Proposal By: Pinili, Ellen Gold B. Ponce, Mary Rosechelle SPauline Ermeje GozoNoch keine Bewertungen

- Final Report Format2Dokument58 SeitenFinal Report Format2aswathy_menon_4Noch keine Bewertungen

- An Area Efficient Universal Cryptography Processor For Smart CardsDokument87 SeitenAn Area Efficient Universal Cryptography Processor For Smart Cardsnagaharika25930% (1)

- Automatic Water Level Controller Using Arduino & LabviewDokument12 SeitenAutomatic Water Level Controller Using Arduino & Labviewrrajmohan28Noch keine Bewertungen

- Alcohol Detection Vehicle ControlDokument28 SeitenAlcohol Detection Vehicle ControlrahulNoch keine Bewertungen

- Smart Notice BoardDokument42 SeitenSmart Notice BoardDhiraj BhattNoch keine Bewertungen

- Unit III 8086 Microprocessor InterfacingDokument26 SeitenUnit III 8086 Microprocessor InterfacingRammanohar Lokiya100% (1)

- Project Report SandyDokument33 SeitenProject Report Sandymohit meshramNoch keine Bewertungen

- RC Phase Shift Oscillator Full DerivationDokument12 SeitenRC Phase Shift Oscillator Full DerivationPranav Itraj0% (1)

- Linux Based Speaking Medication Reminder ProjectDokument4 SeitenLinux Based Speaking Medication Reminder ProjectEditor IJTSRDNoch keine Bewertungen

- Gourav Sharma - GSM Based Fuel Theft Detection, Overspeed Indicator Nad Temprature Alert System in Petroleum Transportation VehicleDokument19 SeitenGourav Sharma - GSM Based Fuel Theft Detection, Overspeed Indicator Nad Temprature Alert System in Petroleum Transportation VehicleRaj MandloiNoch keine Bewertungen

- On "GSM BASED E-NOTICE BOARD"Dokument28 SeitenOn "GSM BASED E-NOTICE BOARD"Rahul Garg75% (4)

- What Is DbiDokument4 SeitenWhat Is Dbim-rasheedNoch keine Bewertungen

- 7.performance Analysis of Wallace Tree Multiplier With Kogge Stone Adder Using 15-4 CompressorDokument38 Seiten7.performance Analysis of Wallace Tree Multiplier With Kogge Stone Adder Using 15-4 Compressoranil kumarNoch keine Bewertungen

- Trade-Off in Using DSP, FPGA and ASIC As Digital Hardware For SDRDokument13 SeitenTrade-Off in Using DSP, FPGA and ASIC As Digital Hardware For SDRKAMRAN12345786Noch keine Bewertungen

- Smart Liquid Level Controller Using Arduino With SMS AlertDokument4 SeitenSmart Liquid Level Controller Using Arduino With SMS AlertInternational Journal of Innovations in Engineering and Science0% (1)

- Presentation On Basic VlsiDokument16 SeitenPresentation On Basic VlsidivyaniNoch keine Bewertungen

- Pce Mini Project Report: "RF Transmitter and Receiver"Dokument9 SeitenPce Mini Project Report: "RF Transmitter and Receiver"sumit sanchetiNoch keine Bewertungen

- Power Quality Improvement in Distribution Network Using DSTATCOM With Battery Energy Storage SystemDokument22 SeitenPower Quality Improvement in Distribution Network Using DSTATCOM With Battery Energy Storage Systemvipin chandNoch keine Bewertungen

- IOT Lab Exp-4Dokument9 SeitenIOT Lab Exp-4Desta Yakob Doda 18BML0121Noch keine Bewertungen

- Smart Shopping Cart IEEE PDFDokument4 SeitenSmart Shopping Cart IEEE PDFradz248100% (3)

- Industrial Visit Report On Mahindra and MahindraDokument6 SeitenIndustrial Visit Report On Mahindra and MahindraSheri Green100% (1)

- Face Mask DetectionDokument44 SeitenFace Mask DetectionRasool ReddyNoch keine Bewertungen

- Smart Blind Stick Using Proteus: Electrical EngineeringDokument44 SeitenSmart Blind Stick Using Proteus: Electrical EngineeringRudra PrasadNoch keine Bewertungen

- Design of Traffic Light Controller Using Timer CircuitDokument3 SeitenDesign of Traffic Light Controller Using Timer CircuitVinooja cNoch keine Bewertungen

- Case StudyDokument33 SeitenCase StudyNathan BakerNoch keine Bewertungen

- Iot Solar Power Monitoring SystemDokument6 SeitenIot Solar Power Monitoring SystemSSReddy100% (1)

- Open Loop and Close Loop Control SystemDokument10 SeitenOpen Loop and Close Loop Control SystemAmrit SinghaNoch keine Bewertungen

- Smart Home Energy Management SystemDokument4 SeitenSmart Home Energy Management SystemDikimbie GatpuNoch keine Bewertungen

- Mini Project Report MONIKADokument24 SeitenMini Project Report MONIKAu creatorNoch keine Bewertungen

- Chapter One: Smart City SolutionsDokument27 SeitenChapter One: Smart City Solutionssnehal sabnisNoch keine Bewertungen

- Chapter One: Introduction 1.1 Background of The StudyDokument30 SeitenChapter One: Introduction 1.1 Background of The StudyUzoma FrancisNoch keine Bewertungen

- WIRELESS e-NOTICE BOARD USING PIC18F4550 WITH ALERT SYSTEMDokument3 SeitenWIRELESS e-NOTICE BOARD USING PIC18F4550 WITH ALERT SYSTEMAkshay BhawarNoch keine Bewertungen

- Solar Wheel ChairDokument4 SeitenSolar Wheel ChairJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- Chip MorphingDokument3 SeitenChip MorphingSriram Ramachandran100% (1)

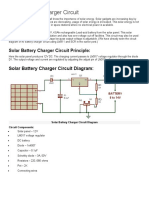

- Solar Battery Charger CircuitDokument3 SeitenSolar Battery Charger CircuitL CHNoch keine Bewertungen

- Durgapur Project Ltd. Training ReportDokument49 SeitenDurgapur Project Ltd. Training ReportSanjiv Shome0% (1)

- 1.speed Synchronization of Multiple MotorsDokument89 Seiten1.speed Synchronization of Multiple MotorsBhanu TummalapalliNoch keine Bewertungen

- Presented By: B.Divya SD - Jasmeen MD - Hafeez External Guide: Dr.Y.Ragavender RaoDokument22 SeitenPresented By: B.Divya SD - Jasmeen MD - Hafeez External Guide: Dr.Y.Ragavender RaoRaghavender MNoch keine Bewertungen

- Mini Project Presentation On: Bidirectional Visitor Counter With GSM ModuleDokument26 SeitenMini Project Presentation On: Bidirectional Visitor Counter With GSM ModuleSYED SHABAZ 1DS19EC438Noch keine Bewertungen

- DC Motor CTRL Using Single SwitchDokument44 SeitenDC Motor CTRL Using Single SwitchAbhijeet NayakNoch keine Bewertungen

- Final Year Project ProposalDokument31 SeitenFinal Year Project ProposalteklethelatterNoch keine Bewertungen

- WG 1 Sep7 Problem SetDokument2 SeitenWG 1 Sep7 Problem SetJotham HensenNoch keine Bewertungen

- Technical QuestionsDokument59 SeitenTechnical QuestionsVinen TomarNoch keine Bewertungen

- Project ListDokument20 SeitenProject ListAniket ChavanNoch keine Bewertungen

- Auto Intensity Control of Street LightDokument53 SeitenAuto Intensity Control of Street LightNikhith ReddyNoch keine Bewertungen

- Project Report 2Dokument28 SeitenProject Report 2akhileshNoch keine Bewertungen

- Local Loop and 2W/4W CircuitsDokument30 SeitenLocal Loop and 2W/4W CircuitsAli AhmadNoch keine Bewertungen

- Street Light Automation Using IoTDokument43 SeitenStreet Light Automation Using IoTAshwin100% (1)

- Intelligent Management of Electrical Systems in IndustriesDokument29 SeitenIntelligent Management of Electrical Systems in Industriesh_akbarshariff50% (2)

- Unit - 4 - Power Electronics and Energy Storage in Smart GridDokument50 SeitenUnit - 4 - Power Electronics and Energy Storage in Smart GridsujithNoch keine Bewertungen

- Asynchronous ChipsDokument25 SeitenAsynchronous ChipsAbin Varkey Varghese100% (1)

- Gas Leakage Detection and Auto DialingDokument2 SeitenGas Leakage Detection and Auto DialingsiddharthNoch keine Bewertungen

- Thesis PDFDokument50 SeitenThesis PDFabdulsemedNoch keine Bewertungen

- Bicmos TechnologyDokument37 SeitenBicmos TechnologyPriya SinghNoch keine Bewertungen

- Innovations in Telecommunications Part AVon EverandInnovations in Telecommunications Part AJamal ManassahNoch keine Bewertungen

- Modern Intelligent Instruments - Theory and ApplicationVon EverandModern Intelligent Instruments - Theory and ApplicationNoch keine Bewertungen

- Table of Trigonometric IdentitiesDokument2 SeitenTable of Trigonometric IdentitiesVaios PeritogiannisNoch keine Bewertungen

- Notes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFDokument9 SeitenNotes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFRahul ChauhanNoch keine Bewertungen

- EI 6702-Logic and Distributed Control SystemDokument2 SeitenEI 6702-Logic and Distributed Control SystemMnskSaro50% (2)

- T0000598REFTRGiDX 33RevG01052017 PDFDokument286 SeitenT0000598REFTRGiDX 33RevG01052017 PDFThanhNoch keine Bewertungen

- Learning MenuDokument8 SeitenLearning Menuapi-464525668Noch keine Bewertungen

- Fire Dynamic Damper Installation InstructionsDokument18 SeitenFire Dynamic Damper Installation InstructionsJohnMerrNoch keine Bewertungen

- Crack Width Design - IS456-2000Dokument1 SeiteCrack Width Design - IS456-2000Nitesh SinghNoch keine Bewertungen

- Projector Spec 8040Dokument1 SeiteProjector Spec 8040Radient MushfikNoch keine Bewertungen

- North Sails Brochure 2007 enDokument24 SeitenNorth Sails Brochure 2007 ennorthsailsNoch keine Bewertungen

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Dokument2 Seiten7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasNoch keine Bewertungen

- 1SFC132367M0201 PSE Internal Modbus RTUDokument22 Seiten1SFC132367M0201 PSE Internal Modbus RTUAhmed OsmanNoch keine Bewertungen

- Varargout Tugas - GUI (Varargin) : FunctionDokument7 SeitenVarargout Tugas - GUI (Varargin) : FunctionDwi Lestari dwi375ft.2019Noch keine Bewertungen

- PPF CalculatorDokument2 SeitenPPF CalculatorshashanamouliNoch keine Bewertungen

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDokument7 SeitenHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaNoch keine Bewertungen

- Fiber SyllabusDokument1 SeiteFiber SyllabusPaurav NayakNoch keine Bewertungen

- AlgebraDokument66 SeitenAlgebraOliseyenum Precious ChukuemekeNoch keine Bewertungen

- Bloom QuestionsDokument270 SeitenBloom QuestionsrameshsmeNoch keine Bewertungen

- Fractal Cities - A Geometry of Form and Function PDFDokument432 SeitenFractal Cities - A Geometry of Form and Function PDFDavid Diaz100% (1)

- CSIE Fisa Disciplina - Baze de DateDokument4 SeitenCSIE Fisa Disciplina - Baze de DateCostin CheluNoch keine Bewertungen

- 1.summative-Test Math7Dokument1 Seite1.summative-Test Math7Jaylor GaridoNoch keine Bewertungen

- STD XTH Geometry Maharashtra BoardDokument35 SeitenSTD XTH Geometry Maharashtra Boardphanikumar50% (2)

- Product Specifications: Handheld Termination AidDokument1 SeiteProduct Specifications: Handheld Termination AidnormNoch keine Bewertungen

- Therapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Dokument11 SeitenTherapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Jeroan MonteiroNoch keine Bewertungen

- 3 1 5b Ohms Law WorksheetDokument5 Seiten3 1 5b Ohms Law Worksheetapi-291536660100% (1)

- Cep MPDokument1 SeiteCep MPAzmat HabeebNoch keine Bewertungen

- Gen-Math11 - Q1 - Mod10 - Solving-Real-Life-Problems-Involving-Rational (EJBOY)Dokument13 SeitenGen-Math11 - Q1 - Mod10 - Solving-Real-Life-Problems-Involving-Rational (EJBOY)Angeline TumananNoch keine Bewertungen

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Dokument4 SeitenSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNoch keine Bewertungen

- Siemens Micromaster 440 Manual PDFDokument312 SeitenSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)