Beruflich Dokumente

Kultur Dokumente

RED BOOK - Full - Download - 01c5 PDF

Hochgeladen von

Daniel CastroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RED BOOK - Full - Download - 01c5 PDF

Hochgeladen von

Daniel CastroCopyright:

Verfügbare Formate

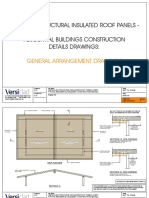

The Red Book ™

FIRE & ACOUSTIC DESIGN GUIDE

Including Green Building Systems

November 2011

You can be sure with CSR

CSR is a leading diversified manufacturing company with operations throughout

Australia as well as Asia and New Zealand. For more than 150 years, CSR has

been famous for the certainty built in to the company’s range of leading products

and services.

Gyprock™ plasterboard and Cemintel™ fibre cement sheet products are proudly

made in Australia.

Sustainability

CSR produces a range of energy efficient building products and systems which

have the potential to reduce heating and cooling costs of homes and buildings,

essentially saving tonnes of greenhouse gases each year. Many of these

products are also produced from recycled materials thus:

• Reducing the demand for raw materials

• Lowering emissions and pollution during manufacturing

• Saving land-fill space.

CSR Guarantee

CSR Building Products guarantees its Gyprock™ products to be free of defects

in materials and manufacture.

If a CSR product does not meet our standard, we will, at our option, replace or

repair it, supply an equivalent product, or pay for doing one of these.

CSR recommends that only products, components and systems recommended

by it be used. If this is not done, CSR will need to be satisfied that any defect

in its product is attributable to our failure to meet our standard (and not another

cause) before this guarantee applies.

This guarantee excludes all other guarantees and liability for damage or loss

in connection with defects in CSR's product, other than those imposed by

legislation.

A2 The Red Book™

Introduction A

Steel Stud Wall Systems B

Timber Stud Wall Systems C

Masonry Wall Systems D

Ceiling Systems E

Services Systems F

Flanking Path Systems G

Junctions & Penetrations Z

Index IN

The Red Book™ A3

How to Use The Red Book

™

Section Index – Page A3 System Index –

Inside back cover

➊ A section index is provided Index to Systems

System Page System Page System Page System Page System Page System Page

A Nº Nº Nº Nº Nº Nº Nº Nº Nº Nº Nº Nº

➊ An index of all systems

005 B10 226 B17 512 B20 697 C22 833 E9 953 E12

on page A3. The Red Introduction 010 B10 230 B18 513 B20 698 C22 834 E9 955 E12

015 B10 231 B18 515 B20 722 D16 835 E9 958 E11

025 B10 235 B18 516 B20 723 D16 836 E9 959 E11

032 B10 240 B19 520 B21 724 D16 837 E9 967 B31

035 B10 241 B19 521 B21 730 D16 838 E9 968 B31

B is provided on the inside

039 B11 243 B19 522 B21 731 D16 839 E9 969 B31

Book ™ is divided into

040 B12 244 B19 523 B21 732 D16 841 E10 970 B30

Steel Stud Wall Systems

043 B14 248 B31 526 D12 737 D6 845 E10 971 B30

044 B14 249 B31 527 D12 738 D7 846 E10 972 B30

045 B14 250 B15 528 D12 739 D7 847 E10 981 E17

046 B14 255 B16 530 D12 760 D6 848 E10 982 E17

back cover and adjacent

050 B12 275 B16 531 D12 761 D6 849 E10 983 E17

9 sections with colour

055 B12 280 B16 532 D12 762 D6 851 E14 985 E17

Timber Stud Wall Systems C 060

061

062

075

B27

B27

B27

B12

290

291

292

293

B24

B24

B24

B24

533

534

535

540

D12

D12

D12

D10

763

764

765

766

D6

D6

D6

D6

852

853

856

857

E14

E14

E14

E14

986

987

992

993

E17

E18

E18

E18

080 B12 294 B25 541 D10 767 D7 858 E14 994 E18

page. Here all systems

089 B29 295 B25 542 D10 768 D7 859 E14 995 E18

coded stripes at the side

090 B29 296 B26 543 D10 769 D7 860 E15 997 E18

D

091 B29 297 B25 544 D11 774 D8 862 E13 75PP D13

092 B29 298 B26 545 D11 775 D8 863 E13 75PP-DC D13

Masonry Wall Systems 093

110

B29

B22

305

310

C6

C6

548

549

D10

D11

776

777

D8

D8

864

865

E13

E16

75SS

75SS-DC

D14

D14

are listed in numerical

121 B33 315 C6 550 C9 778 D9 866 E16 Hebel

and bottom of each page.

122 B33 320 C6 551 D11 779 D9 867 E13 Powerwall D15

123 B33 325 C6 555 C9 780 D8 868 E13 001

Hebel

E

125 B22 330 C6 575 C9 781 D8 870 E12 B35

126 B34 335 C7 580 C9 783 D8 871 E12 Powerwall

127 B34 350 C7 582 C9 784 D8 874 E13 Hebel

Ceiling Systems

C19

128 B34 352 C7 600 B11 787 D9 875 E13 Powerwall

order with a page number

129 B34 354 C7 601 B11 788 D9 876 E13 PF-001 E11

The section letter and

131 B22 355 C7 605 B11 795 D17 877 E16 SS01 F4

135 B22 375 C8 606 B11 796 D17 878 E16 SS02 F4

150 B23 380 C8 610 B13 797 D17 890 E19 SS04 F4

F

152 B23 390 C16 611 B13 798 D17 891 E15 SS08 F5

155 B23 391 C16 613 B13 801 E6 892 E15 SS09 F5

reference.

Service Systems 165 B36 392 C16 614 B13 803 E6 893 E15 SS10 F5

section page number is

167 B36 393 C16 630 B23 804 E6 894 E15 SS11 F5

168 B36 403 C15 631 B22 805 E6 900 C17 SS12 F5

170 B37 410 C15 632 B22 806 E6 901 C17 SS13 F5

171 B37 411 C15 652 C7 807 E6 902 C17 SS17 F5

SS18 F6

G

175 B23 415 C15 653 C8 808 E6 903 C17

178 B37 419 C15 654 C8 809 E6 911 C18 SS19 F6

SS20 F6

provided at the bottom of

179 B37 425 C13 660 C8 810 E7 912 C18

Flanking Path Systems 180

185

B23

B35

430

450

C13

C13

661

662

C14

C14

811

812

E7

E7

915

916

C18

C18

SS21

SS22

F6

F6

186 B35 455 C13 663 C14 813 E7 920 C20 SS23 F6

192 B38 475 C13 664 C14 814 E7 921 C20 SS24 F6

193 B38 480 C13 665 C8 815 E7 923 C20 SS26 F6

Z

194 B38 493 C23 670 C14 816 E7 924 C20 SS30 F7

each page.

195 B38 494 C23 671 C14 817 E7 925 C20 SS31 F7

Junctions & Penetrations 196

197

B38

B38

495

496

C23

C23

672

674

C14

C10

818

819

E7

E7

927

928

C20

C20

SS32

SS33

F7

F7

198 B38 497 C23 675 C10 820 E6 940 B32 SS34 F7

206 B15 498 C23 677 C9 821 E8 940+ SS38 F7

B32 SS39 F7

207 B15 500 C11 678 C9 822 E8 ExpressWall

IN

208 B15 501 C11 680 C10 823 E8 941 B32 SS40 F8

212 B16 502 C11 681 C10 824 E8 942 B32 SS41 F8

216 B16 503 C11 682 C10 825 E8 945 B28 SS42 F8

Index 217

218

B15

B15

506

507

C12

C12

690

693

C21

C21

826

827

E8

E8

946

947

B28

B28

SS44

SS45

F4

F4

222 B17 508 C12 694 C22 829 E8 950 E12 SS46 F4

223 B17 509 C12 695 C22 831 E9 951 E12

225 B17 510 B20 696 C21 832 E9 952 E12

The Red Book™ A3 IN1 The Red Book™

System Tables – Sections B, C, d, e & F Steel Frame Internal Wall Systems – Single Stud

SYSTEM SPECIFICATION TYPICAL LAYOUT (CSR 010a shown) ACOUSTIC

➊ System number and icon illustration.

OPINION

PKA-052

• Lining material as per system table.

• Steel Studs at 600mm maximum centres.

➎ ➏ ➐

➋ Check for appropriate fire rating (FRL) if required.

• Lining material as per system table.

NOTES:

Acoustic performance valid for studs 0.50 BMT.

➌ Check for appropriate acoustic performance (Rw/Rw+Ctr) if required. FRL

Report/Opinion

SYSTEM

Nº

WALL LININGS

STUD DEPTH mm

CAVITY INFILL

(Refer to Section ‘A’)

51 64 76

Rw / Rw+Ctr

92 150

CSR 005

Acoustic performance values are provided via a matrix of options.

(a) Nil 31/23 32/24 33/26 35/28 38/31

(b) 50 GW Partition 11kg 36/26 37/27 38/29 40/31 42/33

BOTH SIDES (c) 75 GW Partition 11kg – 39/29 39/30 41/32 43/34

–/–/– • 1 x 10mm GYPROCK

(d) TSB3/ASB3 Polyester 36/28 36/28 37/30 39/32 41/34

Plasterboard CD.

(e) 60 Soundscreen™ 1.6 – 38/27 39/29 41/31 43/33

WALL THICKNESS mm 71 84 96 112 170

➍ Check System Lining details. CSR 010 (a) Nil

(b) 50 GW Partition 11kg

34/26 35/28 36/29 37/30 40/33

39/29 40/31 41/32 42/33 44/35

➌

BOTH SIDES (c) 75 GW Partition 11kg – 42/33 42/33 43/34 45/36

➋

–/–/–

➊ ➍

• 1 x 13mm GYPROCK

Plasterboard CD.

(d) TSB3/ASB3 Polyester

(e) 60 Soundscreen™ 1.6

39/31 39/32 40/33 41/34 43/36

– 41/31 42/32 43/33 45/35

➎ Check System Specifications for elements common to the systems. CSR 011

SIDE ONE

• 1 x 13mm GYPROCK

WALL THICKNESS mm

(a) Nil

(b) 50 GW Partition 11kg

77 90 102 118

35/27 37/30 37/30 38/31 41/34

39/29 41/32 42/33 43/34 45/36

176

AQUACHEK Plasterboard. (c) 75 GW Partition 14kg – 44/35 44/35 45/36 47/38

–/–/–

SIDE TWO (d) TSB3/ASB3 Polyester 39/31 40/33 41/34 42/35 44/37

➏ Check the typical layout illustration for the basic system format.

• 1 x 13mm GYPROCK (e) 60 Soundscreen™ 1.6 – 42/32 43/33 44/34 46/36

Plasterboard CD.

WALL THICKNESS mm 77 90 102 118 176

CSR 015 (a) Nil 38/30 39/32 40/33 42/35 45/38

SIDE ONE

(b) 50 GW Partition 11kg 43/33 44/35 45/36 47/38 49/40

• 1 x 13mm GYPROCK

(c) 75 GW Partition 14kg – 46/37 46/37 48/39 50/41

➑

Plasterboard CD.

➐ Acoustic Opinion or Test references information.

–/–/–

SIDE TWO (d) TSB3/ASB3 Polyester 43/35 43/36 44/37 46/39 48/41

• 2 x 13mm GYPROCK (e) 60 Soundscreen™ 1.6 – 45/35 46/36 48/38 50/40

Plasterboard CD.

WALL THICKNESS mm 90 103 115 131 189

CSR 025 (a) Nil 35/28 37/30 38/31 40/33 43/37

Flanking Paths via Ceiling (b) 50 GW Partition 11kg 40/31 42/33 43/34 45/36 47/39

BOTH SIDES

➑ Check for alternative systems on the same and adjacent pages.

SYSTEM SPECIFICATION (c) 75 GW Partition

TYPICAL LAYOUT 11kg – 44/35 44/35 ACOUSTIC

46/37 48/40

–/–/– • 1 x 10mm GYPROCK

SUPERCHEK (d) TSB3/ASB3 Polyester OPINION

40/33 41/34 42/35 44/37 46/40

plasterboard. (e) 60 Soundscreen™ 1.6 – 43/33 44/34 46/36 48/39

PKA–A031

WALL THICKNESS mmRondo71 84

DUO Two-way 96 112 170

Steel angle to

Steel Grid Ceiling

CSR 032 support ceiling grid

(a) Nil 37/30 38/31 40/33 41/34 44/38

System

• Floor or roof structure. 100mm

➒ Relevant selection and design information is provided at the beginning of each

min 11kg

System insulation (b) 50 GW Partition 42/33insulation

System 43/34 45/36 46/37 48/40

• 200mm minimum cavity. BOTH SIDES

(c) 75 GW Partition 11kg – 45/36 46/37 47/38 49/41

• 50mm • 1–x 13mm GYPROCK

– / – / –Bradford Glasswool Partition batts

11kg/m3 to extent specified in table. SOUNDCHEK (d) TSB3/ASB3 Polyester 42/35 42/35 44/37 45/38 47/41

plasterboard. (e) 60 Soundscreen™ 1.6 – 44/34 46/36 47/37 49/40

• Ceiling lining as per system table.

section. Installation layouts are shown at the back of sections (where applicable).

• Wall with required sound rating. WALL THICKNESS mm 77 90 102 118 176

GYPROCK

Panel

Ceiling

B9

System

The Red Book™

EXTENT OF INSULATION

1200mm each side

SYSTEM Nº CEILING LININGS Nil Entire Ceiling

of the wall

Rw

(a) Gyprock plasterboard panel 10mm 38 44 45

(b) Ecophon 20mm Focus A, Ds or E 20mm 21 24 25

(c) Ecophon 20mm Focus Glasswool Panels + plasterboard

42 48 49

CSR FP01 panels 10mm

(d) Ecophon Master A 40mm 30 31 31

Flanking Path Systems – Section G (ef) USG Radar, Impressions, Olympia Micro 15mm

(f) USG Mars, Millenia 19mm

30-35

35

30-36

35-36

30-36

35-36

➊ System number details. SYSTEM SPECIFICATION TYPICAL LAYOUT ACOUSTIC

OPINION

PKA–A031

100mm

➋ Check the typical layout illustration for the appropriate system format.

• Floor or roof structure. System insulation min System insulation

• 200mm minimum cavity.

➎

• 50mm Bradford Glasswool Partition batts –

11kg/m3 to extent specified in table.

Ceiling Framing

➏

• Ceiling lining as per system table.

Tape and set or

• Wall with required sound rating.

➋

GYPROCK

➌ Check for appropriate acoustic performance (Rw/Rw+Ctr if required).

cornice finish

plasterboard

ceiling

EXTENT OF BUILDING BLANKET

Acoustic performance values are provided via a matrix of options. SYSTEM Nº CEILING LININGS Nil

1200mm each side

of the wall

Rw / Rw+Ctr

Entire Ceiling

(a) 1 x 10mm GYPROCK Plasterboard panel. 41/32 47/38 48/39

Head & Base Details

FIG Z027: INSTALLATION DETAIL FOR FIRE DAMPER IN SHAFT WALL SYSTEM – APPRAISAL: CSIRO FCO 2109

➍ Check System Lining details. Non-Fire Rated Applications

➊

CSR FP02

➍

(b) 1 x 13mm GYPROCK Plasterboard panel.

(c) 1 x 13mm GYPROCK FYRCHECK Plasterboard

1500mm max.

(d) 1 x 13mm + 1 x 16mm

43/34

46/38

J-Track fixed to studs

➌49/40

52/44

50/41

53/45

55/47 59/51 60/52

GYPROCK FYRCHECK Plasterboard

Note: Wall/ceiling intersection details require engineers approval where seismic loads are expected.

(e) 2 x 13mm GYPROCK FYRCHECK Plasterboard Promaseal IBS™ backing58/50

54/46 59/51

rod 20% larger diameter

FIG Z001: FRICTION FIT HEAD FIG Z004: HEAD FOR than gap (gap 15-30mm)

(f) 2 x 16mm GYPROCK FYRCHECK Plasterboard 55/47 59/51 60/52

➎ Check System Specifications for elements common to the systems.

SUSPENDED TEE-LOCK CEILING

G3

Fix track at each

main runner

The Red Book™ J-Track

Main Runner

Mechanical fire

damper tested and

approved for

AS1530.4 10mm dia. MS rod

➏ Acoustic Opinion or Test references information.

6 – 10mm

100mm max. clearance to fixed to slab and

to first fastener GYPROCK support angle

(Do not fix plasterboard 1400mm max.

through track) RONDO P50 or P60

Shadowline Stopping

Fill gap with CSR Bead (finish as Damper seal angles

Gyprock Sealant for required) 75mm x 50mm x

acoustic integrity 1.2mm MS

Stud Fix wall sheets at 10

6mm to15mm below head NOTE: This method of

NOTE: Junction may be clear Track section with track flanges Stud construction is not

finished square, with of 32mm flange fastened recommended for studs

stopping bead or with soffit to soffit at 600mm adjacent to windows or Support angle 50mm

cornice. Do not rigidly centres max. doors or studs carrying

loads greater than x 50mm x 5mm MS

fix cornice to walls

where friction joints are 0.25kPa. 1 or 2 layers GYPROCK

used FYRCHEK Plasterboard

as per FRL

GYPROCK Shaft

Liner Panel

Junctions & Penetrations – Section Z FIG Z002: DEFLECTION HEAD FIG Z005: HEAD FOR SUSPENDED CEILING

Additional Furring Channel

where wall runs parallel to Suspended Ceiling

setout Top Cross Rail

FIG Z028: TYPICAL INTUMESCENT FIRE DAMPER

➊ Refer to typical wall and ceiling junction details. 20mm gap

100mm max.

(do not fix Fix cornice to

Refer to manufacturer for assessment number and installation details.

Steel studs

at 600mm

Furring Channel in centres

through track) ceiling only with normal setout position Rondo angles

Gyprock Cornice Finish as required mechanically

Cement fixed to studs

➋ Refer to typical penetration details.

NOTE: Stopping bead

or cornice finish as Flexible Mastic

required. Do not rigidly Fix wall sheets at 10 Fix Head Track to Furring

fix cornice to walls Deflection Head Track to15mm below head Channel at 600mm max. GYPROCK

where friction joints are fastened at 600mm track flanges centres FYRCHEK

used Stud centres max. plasterboard Steel studs at

Where wall runs 600mm centres

Stud perpendicular to furring

➋

channel fix track to furring

at each intersection

FIG Z003: HEAD USING ALUMINIUM HEAD TRACK

➊ FIG Z006: WALL BASE DETAIL

STEEL STUD WALL SYSTEM Proprietary

Fix extruded track at intumescent

Furring each furring channel damper

Spigot to terminate

Channel with break joint

Fix track at 600mm max.

centres. With 150mm width

track, use 2 fixings Stud

approximately 20mm in GYPROCK

GYPROCK plasterboard Proprietary extruded from each side of track plasterboard

ceiling fixed to furring aluminium track Perimeter gaps sealed

channel at appropriate Studs bottomed

centres Fill gap with CSR Gyprock

Sealant for acoustic in track

integrity Steel studs

at 600mm

10mm max. gap centres

at bottom of sheet

Stud

Z2 The Red Book™ Z22 The Red Book™

A4 The Red Book™

Section A

Introduction

Contents

An Introduction to The Red Book™ A6

Components A6 – A15

Product Properties A15 – A16

Material & Construction Standards A16

Fire Testing A17

Lining Design A18 – A20

Building Acoustics A21

Building Acoustics in Practice A22 – A23

Definitions A24

The Red Book™ A5

Introduction to Components

The Red Book

™ CSR manufactures and supplies a diverse range of

plasterboard and fibre cement sheets, acoustic panels

and accessories to suit a multitude of wall, ceiling and

The Red Book™ Fire & Acoustic Design Guide provides a

encasement applications.

ready reference to the performance of an extensive range of

CSR Gyprock™ and Cemintel™ fire and acoustic systems. Gyprock™ Plasterboard Cd is composed of a gypsum

core encased in a heavy duty linerboard. Available with long

Over the last 60 years, CSR has developed effective,

edges recessed (RE) to assist in producing a smooth, even

practical and cost effective fire and acoustic systems for

and continuous surface once jointed, in square edge (SE),

most applications. Fire, acoustic and structural testing

and in combination RE/SE. Gyprock™ Plasterboard CD

has been carried out for all plasterboard and fibre cement

incorporates Controlled Density (CD) technology. Gyprock™

products, as well as those of CSR Bradford Insulation,

Plasterboard CD is suitable for internal walls and ceilings.

CSR Hebel and Rondo Building Products. To complement

this extensive testing program, CSR has obtained certified Gyprock Supaceil ™ is a 10mm thick sheet designed

assessments from appropriate authorities on the likely to span up to 600mm in ceiling applications. Gyprock

performance of some systems. These assessments are Supaceil™ is composed of a gypsum core encased in a

based on test results and expert opinion. heavy duty linerboard. Long edges are recessed for flush

jointing. Gyprock Supaceil™ incorporates CD (Controlled

CSR Gyprock™ and Cemintel™ fire rated systems have been

Density) technology.

tested or assessed to AS1530.4 : 1997 or 2005 at approved

testing laboratories. Gyprock Soundchek ™ has been designed to provide

increased acoustic resistance in wall and ceiling systems.

CSR has developed systems with ‘Fire Resistance

Gyprock Soundchek ™ is composed of a high density

Levels’ (FRL) up to –/180/180 (3 hours). The systems and

gypsum core encased in a heavy duty linerboard. Long

performance specifications detailed in this manual are

edges are recessed to assist in producing a smooth, even

guaranteed only for the construction specified. Any variation

and continuous surface once jointed. Gyprock Soundchek™

or substitution of materials or assembly requirements, or

is suitable for internal walls and ceilings.

any compromise in assembly may result in failure under

critical conditions. It is recommended that only accredited Gyprock Impactchek ™ is high strength plasterboard

plasterboard fixers install fire rated systems. designed for impact areas. It is composed of a glass fibre

reinforced gypsum core plus a fibreglass mesh bonded to

CSR Gyprock™ and Cemintel™ are continuously developing

the inside of the back face. 13mm IMPACTCHEK is encased

products, which may result in changes to product

in a violet linerboard and has equivalent fire and acoustic

specifications, range and performance. The systems and

performance to 13mm Fyrchek™. The long edges of both

products in this Fire and Acoustic Design Guide are current

are recessed for flush jointing.

at the publication date.

Gyprock Aquachek ™ is designed for use in lining the

Gyprock™ plasterboard lining products are manufactured

walls of ‘wet areas’ of residential and commercial buildings.

to AS2588 - ‘Gypsum Plasterboard’, and Cemintel™ fibre

It is a gypsum plasterboard with a core treated to make it

cement products are made to AS2908.2 - ‘Cellulose Cement

resistant to moisture and humidity. It is manufactured to

Products’.

satisfy the requirements of AS2588 – Gypsum Plasterboard.

It is encased with light blue linerboard and the long edges

are recessed.

Gyprock Fyrchek ™ can be used in wall and ceiling

systems where an FRL is to be achieved, or where acoustic

performance is required. Gyprock Fyrchek™ is composed

of a specially processed glass fibre reinforced gypsum core

encased in a heavy duty pink liner board.

Gyprock FyrchekMR™ is primarily intended for walls and

ceilings in ‘wet area rooms’ and for soffits and external walls

that must achieve fire resistance. Gyprock Fyrchek MR™ is

composed of a specially processed glass fibre reinforced

gypsum core which is treated in manufacture to withstand

the effects of moisture, and encased in a heavy duty light

blue liner board.

A6 The Red Book™

Gyprock ™ Shaft Liner Panel is a 25mm thick sheet Gyprock™ Plasterboard Panels

composed of a glass fibre reinforced gypsum core encased

Gyprock™ Plasterboard Panels have a gypsum core and

in a heavy duty linerboard. Gyprock Shaft Liner Panel is

various face treatments. Gyprock™ Panels are produced

used to enclose lift shafts, stairwells and service shafts in

to fit metric grid specifications of (600 x 1200mm nominal).

multistorey construction. Gyprock Shaft Liner Panel can be

used to achieve fire resistance in wall and ceiling systems. Perforated Panel has a white vinyl face finish, and a regular

grid of 6mm full depth holes. Perforations are approximately

Superchek™

10% of the panel area, and combined with suitable insulation,

Gyprock Superchek™ is 10mm plasterboard with a very provide a medium level of acoustic absorption.

dense core and heavy duty facing. It has an impact resistance

designed to withstand the knocks typical of residential FIG A2: GYPRoCk PeRFoRATed PANeL dIMeNSIoNS.

buildings, and has excellent sound resistance. It spans

600mm on ceilings and has a white paper face to assist

paint coverage.

eC08 Range

530mm

590mm

EC08 Partition is an economical, non-fire rated board for

general areas where acoustic requirements are not high.

EC08 Fire is the original GECA certified EC08™ board with

fire and acoustic rating for party walls and meeting rooms.

EC08 Impact is fire and acoustic rated with impact resistance 1130mm

1191mm

for high traffic areas such as hallways and stairs in education

and health facilities. All products in the range have been

certified by GECA as meeting the requirements of their

environmental standard for Panel Boards. Supatone™ is a paper faced white ceiling tile suited to basic

commercial ceilings. A low maintenance bright white panel,

Gyprock ™ Flexible Plasterboard has been designed

it can be wiped clean with a damp cloth.

for curved wall and ceiling systems and has an enhanced

core to enable bending to a small radius. It is composed of Freshtone™ diamond White has a lightly textured vinyl

a gypsum core encased in a heavy duty linerboard. Long surface which resists fading and mould growth. With a white

edges are recessed to assist in producing a smooth, even finish, it is suitable for shopping centres, factories and offices.

and continuous surface once jointed. Gyprock™ Flexible Acoustic Wall and Ceiling Panels

Plasterboard is 6.5mm thick and is installed in two layers.

CSR provides a range of acoustic ceiling and wall products

CeminSeal™ Wallboard is an autoclaved, cellulose fibre through the Fricker Comprador division. The range includes

reinforced cement sheet that is immune to permanent mineral fibre and glasswool ceiling panels, metal pan ceiling

water damage and has high impact resistance. Ceminseal™ panels, and glasswool wall panels. Brands include Ecophon,

Wallboard is suitable for internal walls as well as internal USG, Daiken, Fricker and Comprador.

and external ceiling applications. It has a recess on both

The products have a variety of physical properties to assist

long edges so that sheets may be flush jointed, using CSR

in their specification, including Noise Reduction Coefficient

jointing materials.

(NRC), Ceiling Attenuation Class (CAC), Light Reflectance

Gyprock™ Perforated Plasterboard has been designed for (LR), colour and edge profile. These and other properties

use on walls and ceilings where additional sound absorption are listed in Section E.

is required. It is composed of a gypsum core encased in a

CSR Fricker Comprador supplies fully integrated ceiling

heavy duty linerboard and incorporates CD technology. Long

solutions including suspension systems, ceiling tiles, lights,

edges are recessed for flush jointing. Perforations total 8.2%

diffusers and perimeter trims.

of the sheet area. For detailed pattern information, refer to

Section ‘E’. For more information call 1300 374 253.

FIG A1: PeRFoRATIoN PATTeRN

1200mm

3600mm

The Red Book™ A7

Gyprock™ Cornice

CSR Gyprock manufactures six popular machine made

eclipse ClimaPlus™ cornice profiles to cater for many styles and applications.

• 19mm thick mineral Please refer to Table A1 in this section for general product

fibre panels with three information.

edge options.

GYPRoCk™ GYPRoCk™

CoVe CoRNICe JAZZ CoRNICe

Impressions

ClimaPlus™

• 15mm thick mineral

fibre panels with three

edge options.

GYPRoCk™ GYPRoCk™

SYMPhoNY CoRNICe CoNCeRTo CoRNICe

Mars ClimaPlus™

• 19mm thick mineral

fibre/glasswool

panels with three

edge options.

GYPRoCk™ GYPRoCk™

TeMPo CoRNICe CLASSIC CoRNICe

olympia Micro

ClimaPlus™

• 15mm thick mineral

fibre panels with three

edge options.

GYPRoCk™ ShAdoWSeT

A8 The Red Book™

Gyprock™ Plasterboard Range CeminSeal™ Wallboard Range

TABLe A1: GYPRoCk™ PRoduCT WeIGhTS TABLe A2: CeMINSeAL™ WALLBoARd PRoduCTIoN

SIZeS ANd ToLeRANCeS

Colour shading behind each product approximates the

colour of the product face liner sheets. For detailed sheet CeminSeal™ Wallboard is manufactured in the following sizes

sizes and availability, contact the CSR Gyprock Sales Centre and available in all states.

in your region. CeminSeal™ Wallboard has two long edges recessed to

Thickness Mass allow seamless jointing.

Gyprock™ Lining Products

mm kg/m2 Thickness

10 6.5 (6mm RE = ✓) (9mm RE = ■) (12mm RE = ✤)

CD RECESSED EDGE

13 8.5 Length Width (mm)

10 6.5

CD SQUARE EDGE (mm) 900 1200 1350

13 8.5

CD RECESSED EDGE/SQUARE EDGE 10 6.5 1800 ✓

SUPACEIL™ 10 7.2 2400 ✓ ✓■ ✓

SOUNDCHEK™ 13 13.0 2700 ✓■

10 8.0 3000

AQUACHEK™ ✓ ✓■✤ ✓

13 10.4

3600 ✓ ✓

IMPACTCHEK™ 13 10.3

SUPERCHEK™ 10 10.4 4200 ✓

EC08™ PARTITION 13 9.3 Mass 6mm thickness (nominal) 9.7kg/m2

EC08™ FIRE 13 10.5

Mass 9mm thickness (nominal) 14.3kg/m2

EC08™ IMPACT 13 12.1

FLEXIBLE 6.5 4.25 Mass 12mm thickness (nominal) 18.8kg/m2

13 10.5 Length +0 to -4mm

FYRCHEK™

16 12.5 Width +0 to -3mm

13 10.7 Thickness +0.25 to -0.25mm

FYRCHEK™ MR

16 13.5

Diagonals Difference (max) 3mm

PERFORATED SHEET 13 10.0

SHAFT LINER PANEL 25 19.8

Mass

Gyprock™ Cornice Products Size

kg/m2

55 0.7kg/m

COVE CORNICE 70 0.9kg/m

90 1.3kg/m

CLASSIC™ CORNICE 90 1.2kg/m

TEMPO™ CORNICE 90 1.8kg/m

SYMPHONY™ CORNICE 75 0.9kg/m

CONCERTO™ CORNICE 90 1.6kg/m

JAZZ™ CORNICE 75 1.8kg/m

SHADOWSET™ 105 1.0kg/m

The Red Book™ A9

Steel Components Stud Adhesive

CSR recommends steel building elements manufactured by Gyprock™ Acrylic Stud Adhesive is coloured blue for easy

Rondo Building Services Pty Ltd, for our systems. identification. It can be used on both timber and steel in

General information on Rondo steel building components is temperatures not less than 5ºC.

provided throughout this manual. Additional information can Contact surfaces must be free of oil, grease or other foreign

be obtained from the Rondo Building Services Pty Ltd office materials before application. The adhesive is applied with a

in your state, or telephone 1300 367 663. broad knife to form 25mm diameter by 15mm high walnuts.

T h i s p ro d u c t

CSR Gyprock™ Resilient Mount is suitable for

use with pre-

The CSR Gyprock ™ Resilient Mount is a proprietary

painted metal

component used in conjunction with Rondo steel sections for

battens and

fastening Gyprock™

some treated

plasterboard

t i m b e r s .

to a supporting

Always follow

structure while

directions on

simultaneously

packaging

i s o l a t i n g i t f ro m

when using

structure bor ne

CSR stud

vibration.

adhesive.

This significantly reduces the amount of impact noise, speech

and low frequency sound filtering through to rooms above,

Masonry Adhesive

below or alongside the noise generating room. The resilient

mount has been design for use on ceilings and can be Gyprock™ Masonry Adhesive is used to adhere Gyprock™

used on walls provided plasterboard with minimum mass of plasterboards to concrete and all masonry substrates.

12.5kg/m2 is fixed on the resilient mount side of the wall. The

mount can be used in fire rated and non-fire rated systems.

A10 The Red Book™

Jointing Accessories & Compounds Mastics & Sealants

CSR has a wide range of compounds, cements and Gyprock™ Fire Mastic must be used in fire rated systems

accessories for finishing plasterboard installations. where caulking is indicated and is recommended for caulking

Refer to the Gyprock ™ Residential Installation Guide, acoustic systems.

NºGYP547 for detailed jointing and finishing information. Gyprock™ Wet Area Acrylic Sealant is recommended for

sealing non-fire rated wet area systems.

Fasteners

CSR Gyprock distributes a comprehensive range of ring

shank nails, hot-dip galvanised clouts, and screws for

use with timber and steel framing to accommodate most

installation applications. For exterior applications, refer to the

appropriate installation guide.

The Red Book™ A11

TABLe A3: FIxING PLASTeRBoARd To SoFTWood

Plasterboard 1st Layer 2nd Layer 3rd Layer

Thickness

6.5mm 2.8x40mm Gal Clout or 2.8x40mm Gal Clout or

Plasterboard 2.8x25mm Ring Shank Nail or 2.8x30mm Ring Shank Nail or

Type S #6-18 x 25mm NP Screw Type S #6-18 x 32mm NP

Screw

10mm 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or

Plasterboard 2.8x30mm Ring Shank Nail or Type S #6-18 x 40mm NP

Type S #6-18 x 25mm NP Screw (on wall) Screw

Type S #6-18 x 30mm NP Screw (on ceiling)

13mm 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or 3.75x75mm Gal Clout or

Plasterboard 2.8x30mm Ring Shank Nail or Type S #6-18 x 45mm NP Type S #8-15 x 65mm NP Screw or

Type S #6-18 x 32mm NP Screw Screw #10x40mm Laminating Screw

16mm 2.8x50mm Gal Clout or 3.15x65mm Gal Clout or 3.75x75mm Gal Clout or

Plasterboard Type S #6-18 x 32mm NP Screw Type S #6-18 x 50mm NP Type S #8-15 x 65mm NP Screw or

Screw #10x40mm Laminating Screw

13mm + 16mm 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or

Plasterboard 2.8x30mm Ring Shank Nail or Type S #6-18 x 45mm NP

Type S #6-18 x 32mm NP Screw Screw

TABLe A4: FIxING PLASTeRBoARd To hARdWood

Plasterboard 1st Layer 2nd Layer 3rd Layer

Thickness

6.5mm 2.8x30mm Gal Clout or 2.8x30mm Gal Clout or

Plasterboard 2.8x25mm Ring Shank Nail or 2.8x25mm Ring Shank Nail or

Type S #6-18 x 25mm NP Screw Type S #6-18 x 32mm NP

Screw

10mm 2.8x30mm Gal Clout or 2.8x40mm Gal Clout or

Plasterboard 2.8x25mm Ring Shank Nail or Type S #6-18 x 32mm NP

Type S #6-18 x 25mm NP Screw (on wall) Screw

Type S #6-18 x 30mm NP Screw (on ceiling)

13mm 2.8x30mm Gal Clout or 2.8x40mm Gal Clout or 3.15x65mm Gal Clout or

Plasterboard 2.8x25mm Ring Shank Nail or Type S #6-18 x 45mm NP Type S #8-15 x 65mm NP Screw or

Type S #6-18 x 32mm NP Screw Screw #10x40mm Laminating Screw

16mm 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or 3.15x65mm Gal Clout or

Plasterboard Type S #6-18 x 32mm NP Screw Type S #6-18 x 45mm NP Type S #8-15 x 65mm NP Screw or

Screw #10x40mm Laminating Screw

13mm + 16mm 2.8x30mm Gal Clout or 2.8x50mm Gal Clout or

Plasterboard 2.8x25mm Ring Shank Nail or Type S #6-18 x 45mm NP

Type S #6-18 x 32mm NP Screw Screw

TABLe A5: FIxING FIBRe CeMeNT ANd PLASTeRBoARd To TIMBeR

Lining Thickness 1st Layer 2nd Layer

6mm Wallboard 2.8x40mm Gal Clout or

Type S #8-15 x 20mm NP Screw

9mm Wallboard 2.8x40mm Gal Clout or

Type S #8-15 x 30mm NP Screw

13mm Plasterboard + 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or

6/9mm Wallboard over 2.8x30mm Ring Shank Nail or Type S #8-15 x 40mm NP Screw

Type S #6-18 x 32mm NP Screw

16mm Plasterboard + 2.8x50mm Gal Clout or 2.8x50mm Gal Clout or

6/9mm Wallboard over Type S #6-18 x 32mm NP Screw Type S #8-15 x 40mm NP Screw

6mm Wallboard + 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or

13/16mm Plasterboard over Type S #8-15 x 20mm NP Screw Type S #6-18 x 45mm NP Screw

9mm Wallboard + 2.8x40mm Gal Clout or 2.8x50mm Gal Clout or

13/16mm Plasterboard over Type S #8-15 x 30mm NP Screw Type S #6-18 x 45mm NP Screw

NOTES:

Type 'W' screws of equivalent length may be used as an alternative to Type S ‘NP’ when fixing to timber only.

Predrill 9mm and 12mm Wallboard for easier fixing.

Fixings are suitable for internal applications only.

NP = Needle Point Screws.

DP = Drill Point Screws.

GAL = Galvanised.

A12 The Red Book™

TABLe A6: FIxING PLASTeRBoARd To STeeL 0.5 – 0.8mm BMT

Plasterboard Thickness 1st Layer 2nd Layer 3rd Layer

6.5mm Plasterboard Type S #6-18 x 25mm NP Screw Type S #6-18 x 25mm NP Screw

10mm Plasterboard Type S #6-18 x 25mm NP Screw Type S #6-18 x 40mm NP Screw

13mm Plasterboard Type S #6-18 x 25mm NP Screw Type S #6-18 x 40mm NP Screw Type S #8-15 x 65mm NP Screw or

#10x40mm Laminating Screw

16mm Plasterboard Type S #6-18 x 30mm NP Screw Type S #6-18 x 45mm NP Screw Type S #8-15 x 65mm NP Screw or

#10x40mm Laminating Screw

13mm + 16mm Type S #6-18 x 25mm NP Screw Type S #6-18 x 45mm NP Screw

Plasterboard

TABLe A7: FIxING PLASTeRBoARd To STeeL 0.8 – 2.4mm BMT

Plasterboard Thickness 1st Layer 2nd Layer 3rd Layer

6.5mm Plasterboard Type S #6-18 x 25mm DP Screw Type S #6-18 x 25mm DP Screw

10mm Plasterboard Type S #6-18 x 25mm DP Screw Type S #6-18 x 40mm DP Screw

13mm Plasterboard Type S #6-18 x 25mm DP Screw Type S #6-18 x 40mm DP Screw #10x40mm Laminating Screw

16mm Plasterboard Type S #6-18 x 30mm DP Screw Type S #6-18 x 45mm DP Screw #10x40mm Laminating Screw

13mm + 16mm Type S #6-18 x 25mm DP Screw Type S #6-18 x 45mm DP Screw

Plasterboard

TABLe A8: FIxING FIBRe CeMeNT ANd PLASTeRBoARd To STeeL 0.5 – 0.8mm BMT

Lining Thickness 1st Layer 2nd Layer

6mm Wallboard Type S #8-15 x 20mm NP Screw or

FibreZIPS® M5-18 x 20mm

9mm Wallboard Type S #8-15 x 30mm NP Screw or

FibreZIPS® M5-18 x 30mm

6mm Wallboard + Type S #8-15 x 20mm NP Screw or Type S #6-18 x 40mm NP Screw

13/16mm Plasterboard over FibreZIPS® M5-18 x 20mm

9mm Wallboard + Type S #8-15 x 30mm NP Screw or Type S #6-18 x 40mm NP Screw

13/16mm Plasterboard over FibreZIPS® M5-18 x 30mm

13mm Plasterboard + Type S #6-18 x 25mm NP Screw Type S #8-15 x 40mm NP Screw

6/9mm Wallboard over

16mm Plasterboard + Type S #6-18 x 30mm NP Screw Type S #8-15 x 40mm NP Screw

6/9mm Wallboard over

TABLe A9: FIxING FIBRe CeMeNT ANd PLASTeRBoARd To STeeL 0.8 – 2.4mm BMT

Lining Thickness 1st Layer 2nd Layer

6mm Wallboard Type S #8-15 x 20mm DP Screw

9mm Wallboard Type S #8-15 x 30mm DP Screw

6mm Wallboard + Type S #8-15 x 20mm DP Screw Type S #6-18 x 40mm DP Screw

13/16mm Plasterboard over

9mm Wallboard + Type S #8-15 x 30mm DP Screw Type S #6-18 x 40mm DP Screw

13/16mm Plasterboard over

13mm Plasterboard + Type S #6-18 x 25mm DP Screw Type S #8-15 x 40mm DP Screw

6/9mm Wallboard over

16mm Plasterboard + Type S #6-18 x 30mm DP Screw Type S #8-15 x 40mm DP Screw

6/9mm Wallboard over

NOTES:

Predrill 9mm and 12mm Wallboard for easier fixing.

Fixings are suitable for internal applications only.

NP = Needle Point Screws.

DP = Drill Point Screws.

GAL = Hot-Dip Galvanised.

The Red Book™ A13

Insulation Materials Wall System Thermal Performance

CSR Fire and Acoustic Systems incorporate CSR Bradford Timber and steel stud external walls in this manual include

glasswool and rockwool insulation. These products thermal ratings expressed as Rt(win) and Rt(sum), to represent

have undergone significant acoustic testing and have Total R-values for the Winter and Summer design conditions

a proven track record of performance and durability in as required by the BCA.

service. Additional information on CSR Bradford Insulation The Total R-values presented are based on assessments

materials is available by telephoning CSR Bradford on c a r r i e d o u t i n a c c o rd a n c e w i t h t h e m e t h o d s o f

1300 850 305. AS/NZS4859.1 amdt 1:2006 (“Materials for thermal

Although insulation materials are often specified for insulation of buildings - Part 1: General criteria and technical

thermal resistance, they can contribute significantly to the provisions”). Any included bulk insulation is a CSR Bradford

acoustic performance of wall and ceiling systems. CSR product that has a material R-Value compliant with the

only recommends materials that have been tested for fire standard, and building elements have thermal values sourced

and acoustic applications, have proven durability, and are from the AIRAH handbook. No allowance has been made

supported by their manufacturer for these applications. for thermal bridging from the structural members. Thermal

Should other insulation materials be used, the manufacturer performances quoted are based on an assessment through

of those materials must verify the performance of the the insulation path.

complete system, CSR will not support the performance of The contribution to Total R-values depends on installation,

substitute materials. workmanship and environmental conditions and it is

Acoustic Polyester insulation manufactured by Tontine and assumed that cavities that are ventilated.

Autex have been tested in acoustic applications by the

manufacturer and are specifically made for that purpose. CSR

accepts the use of Tontine and Autex Polyester insulation.

TABLe A10: SPeCIFIed INSuLATIoN ANd ABBReVIATIoNS

(Abbreviated names have been used in system tables).

Product Abbreviation

25mm Bradford Fibertex 450 – 80kg/m3 25 Fibertex 450

45mm Bradford Rockwool Partition batts – 38kg/m3 45 Rockwool Partition batts

60mm Bradford Soundscreen™ R1.6 wall batts (Rockwool) – 35kg/m3 60 Soundscreen™ 1.6

75mm Bradford Soundscreen™ R2.0 wall batts (Rockwool) – 32.5kg/m3 75 Soundscreen™ 2.0

88mm Bradford Soundscreen™ R2.5 wall batts (Rockwool) – 40kg/m3 88 Soundscreen™ 2.5

120mm Bradford Soundscreen™ R3.0 floor / ceiling batts (Rockwool) – 30kg/m3 120 Soundscreen™ 3.0

50mm Bradford Glasswool Partition batts – 11kg/m3 50 GW Partition – 11kg

75mm Bradford Glasswool Partition batts – 11kg/m3 75 GW Partition – 11kg

110mm Bradford Glasswool Partition batts – 11kg/m3 110 GW Partition – 11kg

165mm Bradford Glasswool Partition batts – 11kg/m3 165 GW Partition – 11kg

50mm Bradford Glasswool Partition batts – 14kg/m3 50 GW Partition – 14kg

75mm Bradford Glasswool Partition batts – 14kg/m3 75 GW Partition – 14kg

100mm Bradford Glasswool Partition batts – 14kg/m3 100 GW Partition – 14kg

75mm Bradford Gold Batt™ R1.5 wall batts (Glasswool) – 8.8kg/m3 75 Gold Batts™ 1.5

75mm Bradford Gold Batt™ R2.0 wall batts (Glasswool) – 18.0kg/m3 75 Gold Batts™ 2.0

90mm Bradford Gold Batt™ R2.0 wall batts (Glasswool – 10.5kg/m3 90 Gold Batts™ 2.0

90mm Bradford Gold Batt™ R2.7 wall batts (Glasswool) – 34.0kg/m3 90 Gold Batts™ 2.7

140mm Bradford ceiling Gold Batt™ R2.5 (Glasswool) – 6.4kg/m3 140 Gold Batts™ 2.5

165mm Bradford ceiling Gold Batt™ R3.0 (Glasswool) – 6.7kg/m3 165 Gold Batts™ 3.0

215mm Bradford ceiling Gold Batt™ R4.0 (Glasswool) – 6.9kg/m3 215 Gold Batts™ 4.0

Tontine TSB 2 (50mm) / Autex ASB 2 (50mm) Polyester Insulation TSB2/ASB2 Polyester

Tontine TSB 3 (65mm) / Autex ASB 3 (60mm) Polyester Insulation TSB3/ASB3 Polyester

Tontine TSB 4 (75mm) / Autex ASB 4 (70mm) Polyester Insulation TSB4/ASB4 Polyester

Tontine TSB 5 (85mm) Polyester Insulation TSB5 Polyester

Tontine Blanket (25mm) 10kg/m3 Polyester Insulation TBL/1025 Polyester

38mm Bradford Masonry Wall Blanket (HP Glasswool) Masonry Wall Blanket R1.2

A14 The Red Book™

TYPICAL BRAdFoRd INSuLATIoN PRoduCTS For wet area walls and external ceilings subject to intermittent

high humidity where plasterboard is specified, Gyprock

Aquachek ™ or Gyprock FyrchekMR ™ or CeminSeal ™

Wallboard are recommended. In all cases follow product

installation brochures.

Thermal Performance

Gyprock™ and Cemintel™ products have been tested to

ASTM C518 for thermal performance.

The ‘R’ values for Gyprock™ plasterboards are:

• 10mm plasterboard = 0.04 – 0.05 m2K/W.

• 13mm plasterboard = 0.05 – 0.07 m2K/W.

• 16mm plasterboard = 0.07 – 0.09 m2K/W.

The ‘R’ values for Cemintel™ products are:

• 6mm fibre cement = 0.02 m2K/W.

• 7.5mm fibre cement = 0.03 m2K/W.

• 9mm fibre cement = 0.03 m2K/W.

Product

Properties

Thermal & Moisture Stability

Gyprock ™ plasterboard and Cemintel ™ fibre cement

products are stable building materials when subjected to the

normal range of interior temperature and humidity conditions.

Thermal coefficient of Linear Expansion (α).

• Plasterboard: α =16.2 x 10 -6 mm (mm/ºC) in the

temperature range 4°C to 38°C.

• Fibre cement: α = 7.5 x 10-6/°C.

• Final length is calculated as follows:

Lf = Li (1 + αT).

The hygrometric coefficient of expansion (δ).

• P l a s t e r b o a rd : δ = 7 . 2 x 1 0 -6 m m / m m / % R . H .

(5% – 90% R.H.). Final length is calculated as follows:

Lf = Li (1 + δRH).

• Fibre cement: δ = 0.18% (expansion from equilibrium to

saturated). Final length is calculated Lf = Li x δ x (% of

saturation).

Internal Moisture

Gyprock™ plasterboard must not be used where it will be

in contact with liquid water or an atmosphere of constant

relative humidity above 90%.

Gyprock ™ Plasterboard CD, Gyprock Supaceil ™ and

Gyprock Soundchek™ are designed for use in dry areas only.

The Red Book™ A15

Fire hazard Properties Combustibility

The BCA limits the materials used in Class 2 to 9 buildings In accordance with BCA Clause C1.12, plasterboard and

by controlling the Fire Hazard properties of linings. These fibre cement sheet may be used wherever a non-combustible

properties are assessed using AS/NZS3837 cone calorimeter material is required by the Code.

test.

Please refer to Table A11 for Gyprock™ plasterboard and

Cemintel™ product performance details. Contact Fricker

Comprador for properties of other acoustic wall and ceiling

Material &

products.

Construction

TABLe A11: FIRe hAZARd PRoPeRTIeS

ASEA Group

Standards

CSR Product Report

m2/kg Number All materials and procedures shall comply with the following

10 – 13mm Plasterboard CD <250 1 ➊ standards where applicable, and all additional details

10mm SUPACEIL™ <250 1 ➊ contained in Gyprock™ and Cemintel™ Technical Literature.

10 –13mm SOUNDCHEK™ <250 1 Plasterboard Manufacture:

➊

10 – 13mm AQUACHEK™ <250 1 ➊ AS/NZS2588 : Gypsum plasterboard.

6.5mm FLEXIBLE <250 1

Plasterboard Installation:

➊

13mm Perforated Sheet <250 1

AS/NZS2589 : Gypsum linings in residential and light

➊

commercial construction – Application and Finishing.

13 – 16mm FYRCHEK™ <250 1 ➊

Plasterboard and Fibre Cement in Wet Areas:

13 – 16mm FYRCHEK MR™ <250 1 ➊

AS3740 : Waterproofing of Wet Areas Within Residential

25mm SHAFT LINER PANEL <250 1 ➊

Buildings.

10mm SUPERCHEK™ <250 1 ➊

13mm IMPACTCHEK™ <250 1 ➊

13mm ECO8™ Partition <250 1 ➊

13mm ECO8™ Fire <250 1 ➊

13mm ECO8™ Impact <250 1 ➊

CeminSeal™ Wallboard <250 1 ➊

13mm Perforated Panels <250 1 ➊

10mm FRESHTONE™

<250 1 ➊

Diamond White

10mm SUPATONE™ <250 1 ➊

10 – 13mm Unpainted Panel <250 1 ➊

Ecophon ADVANTAGE <250 1 ➊

Ecophon FOCUS <250 1 ➊

Mars <250 1 ➋

Eclipse <250 1 ➌

Impressions <250 1 ➍

Olympia Micro <250 1 ➎

NOTES:

ASEA = Average Specific Extinction Area

➊ WFRA 45759

➋ FAR 2781

➌ FH 3619

➍ FH 3621

➎ FH 3623

A16 The Red Book™

Fire Testing

The common regulatory ‘FRL’ requirements are:

Non-Loadbearing Loadbearing

– /30/30 30/30/30

Fire resistance testing is conducted to the Australian

Standard AS1530 – part 4 ‘Fire Resistance Tests of Elements – /60/60 60/60/60

of Building Construction’. – /90/90 90/90/90

– /120/120 120/120/120

This standard gives the test method and criteria of failure for

– /180/180 180/180/180

the various elements of construction such as partition walls,

floor/ceilings and roof/ceilings. For Example: – /120/120.

The specimen assemblies are built into the test furnace • The dash indicates no requirement for ‘Structural

and subjected to furnace temperatures in accordance with Adequacy’, which applies to all non-loadbearing systems.

AS1530.4 ‘Standard Time vs Temperature Curve’.

• The first 120 indicates ‘Integrity’ for 120 minutes.

FIG A3: STANdARd TIMe vs TeMPeRATuRe CuRVe • The second 120 indicates ‘Insulation’ for 120 minutes.

1200 For any specified FRL, a system having equal or higher

respective criteria may be used. Some systems have

1100

multiple FRLs stated. FRLs expressed as –/y/z relate to

1000 non-loadbearing walls; FRLs expressed as x/y/z relate to

TEMPERATURE (°C)

900

loadbearing walls; or FRLs expressed as x/y/z* relate to walls

with additional design limits.

800

700 What is Resistance to the Incipient

600 Spread of Fire?

500

Ceiling systems may be required to achieve a ‘Resistance to

the Incipient Spread of Fire’.

0 30 60 90 120 150 180 210 240 270 300 330 360

TIME (minutes)

This requires the ceiling to provide adequate thermal

insulation to prevent combustibles in a roof/ceiling or floor/

ceiling cavity from igniting for the specified time.

how the Specimen is Assessed

The Building Code of Australia requirement for some ceiling

The test specimen is heated in the prescribed manner until

systems is to provide ‘Resistance to the Incipient Spread of

the failure criteria has been reached, or is terminated by

Fire (RISF), into the space above itself, for not less than 60

agreement between parties.

minutes’. Systems that meet this requirement are indicated

Assessment criteria are represented by three performance in the system tables.

measurements known as ‘Fire Resistance Levels’ (FRL).

Structural Adequacy Fire hazard Properties

Failure occurs when the specimen collapses under load. Fire hazard properties of wall and ceiling linings in some

Integrity classes of building are specified by the BCA. Refer to Table

Failure occurs when the specimen develops cracks or A11 for fire hazard properties of CSR products.

openings through which flames or hot gases can pass.

Insulation Smoke Proof Walls

Failure occurs when the average temperature of the Smoke proof walls are required in some Class 9a

unexposed surface of the specimen increases by more than buildings, and they must be built from non-combustible

140°C above the initial temperature, or the temperature at materials where they do not require an FRL. Steel framed

any point of the unexposed surface increases by more than wall systems clad with Gyprock ™ Plasterboard CD

180°C above the initial temperature. (eg. CSR 010) may be used.

The test performance of the specimen is expressed as a ‘Fire Fire rated smoke proof walls should be selected from the

Resistance Level’, which indicates the number of minutes for steel framed systems (refer to Section ‘B’) with an appropriate

which the specimen fulfils the requirements of the three fire FRL.

test criteria. These numbers are then rounded down to the Smoke proof walls required for Class 9c buildings may use

nearest regulatory requirement. steel or timber framing with linings of 13mm Gyprock™

All systems in this guide with a stated FRL have been Plasterboard CD or CeminSeal™ Wallboard. Refer to systems

assessed by Registered Testing Authorities, including CSIRO, CSR 010, 654 and 310.

BRANZ and Exova Warrington Fire.

The Red Book™ A17

Lining Design

In general, walls and ceilings should be specified to Level

4 Finish unless a higher or lower level of finish is required.

Complete details for a Level 4 Finish are set out in Gyprock™

There are a number of methods for ensuring that plasterboard Residential Installation Guide No. GYP 547.

linings meet end user expectations. For best results, these

A Level 5 Finish should be used wherever gloss or semi-gloss

should be considered in the planning stages of a project and

paints are to be used, where paint is mid or dark coloured, or

be clearly set out in specifications and contract documents.

where critical light conditions occur such as from windows,

It is noted in the plasterboard standard AS/NZS2589.1 skylights, or silhouette and spot lighting.

‘Gypsum linings – Application and Finishing’ that it is good

Installation is similar to Level 4 Finish with the addition of

practice to construct a reference area of decorated work

a skim coat which is used to remove differential surface

to aid in judging quality of walls and ceilings throughout a

textures and porosity. Skim coating refers to a thin finish

project.

coat, rolled, trowelled or airless sprayed and then possibly

sanded, to achieve a smooth and even finish. It is normally

Levels of Finish less than 1mm in thickness and is applied over the entire

A Level of Finish sets out the minimum specifications for surface to fill imperfections in the joint work, smooth the

installation processes from framing preparation to lining paper texture and provide a uniform surface for decorating.

decoration. The levels are defined in AS/NZS 2589.1, and are

intended to provide builders, installers and their customers Critical Light

with defined methods and practices necessary to meet the

The impression of flatness of plasterboard is influenced by

customer’s expectations in terms of the ‘Level of Finish’.

factors such as the accuracy of the substrate, the fixing

It is essential to determine the level of finish required before methods, joint formation and finishing textures. A surface

the frame construction begins, as specific tolerances are that appears perfectly flat in one lighting condition can

required for frame alignment as well as for plasterboard fixing seem uneven in another. Any imperfection or undulation in

and finishing for each of the levels of finish. Unless these a completed lining installation can become obvious under

requirements are met throughout construction, it may not be critical or glancing light, where the incident light from an

possible to attain the desired finish level without extensive artificial or natural source is nearly parallel to the surface.

corrective measures.

FIG A4: PRoCeSS FoR deTeRMINING APPRoPRIATe LeVeL oF FINISh

DECORATION

Finish Not Important Wall covering,

Paint

or Undecorated Wallpaper or Texture

Flat/Matt/Satin/

Semi-gloss/Gloss

Low Sheen

Pastel/

Dark tones

Mid-tones

Critical & Non-critical Non-critical Critical Critical & Non-critical

Lighting Lighting Lighting Lighting

Level 3 Finish Level 4 Finish Level 5 Finish

A18 The Red Book™

To minimise the effect of critical lighting from artificial lighting Applied Finish Specification

sources:

Finishes applied to plasterboard surfaces can have a

• Locate fluorescent lights about 450mm below the ceiling significant effect on the perceived quality of the installation,

to give a more even distribution of light. particularly where critical lighting conditions exist. The

• Use more lights at regular spacings to give an even, difference in texture and absorption characteristics between

diffused light. the body of the sheet and joints may show through thin and

low quality paint coatings. Recommended paint systems

• Recess light fittings into a ceiling.

consist of one coat of a plasterboard sealer followed by two

• Allow a generous angle of incidence to the surface for coats of finishing paint.

feature lighting, such as spotlights, to minimise the

Always follow the manufacturer’s instructions for application

highlighting of imperfections.

and recoating. For best results, specify that coatings are

• Do not use up-lights or unshaded light sources close to a applied with a roller to achieve a full even coat and a light,

wall or ceiling. uniform texture over the entire surface.

To minimise natural lighting problems, particularly from direct General rules when specifying an applied finish are:

sunlight:

• Textured or heavy patterned finishes tend to hide

• Avoid placing windows immediately adjacent to the end imperfections.

of a wall.

• Matt finishes minimise imperfection visibility.

• Do not take window glazing up to ceiling level.

• Semi-gloss and gloss finishes highlight imperfections.

• Provide sun shades over windows.

• Light colours are less likely to show imperfections and

impact damage. They are also more effective at diffusing

light and reducing shadow effects, particularly in smaller

FIG A5: TYPICAL GLANCING LIGhT SITuATIoNS rooms.

• Gloss paints tend to highlight paint application variations

(e.g. where a good wet edge has not been maintained

when painting).

• Paint applied with a longer pile roller tends to mask

imperfections better than those applied with a short pile

roller.

Glancing light

Jointing Shadow zone

Shadow zone

Jointing

Glancing light

Wall mounted light

The Red Book™ A19

Resistance to Impact Curved Walls and Ceilings

Wall lining materials may be selected for properties relating Gyprock ™ plasterboard can be curved for installation

to resistance to damage. These properties include bending on walls and ceilings that have appropriately designed

strength (resistance to static load), soft body impact framing. Maximum frame spacing for curved walls is reduced

resistance (resistance to damage from ‘people’ impact, compared to straight walls, and can be found in the relevant

measured with a swung sand bag), and surface damage installation manuals.

resistance (resistance to indent from small, solid objects). The minimum curvatures for a range of products are listed

Refer to Table A12 for a selection of linings and relative in Table A13. Note that Gyprock™ Flexible plasterboard is

performance for the various properties. 6.5mm thick and is always used in two layers.

TABLe A12: STReNGTh ANd IMPACT PRoPeRTIeS TABLe A13: MINIMuM RAdIuS FoR CuRVed WALLS

Lining Bending Soft Body Surface

Plasterboard Lining Minimum Radius Minimum Radius

Strength Impact Damage

(Concave) (Convex)

Resistance Resistance

6.5mm Flexible

10mm Gyprock 450 mm 250 mm

✰ ✰ ✰ Plasterboard

plasterboard CD

10mm plasterboard

10mm Superchek ✰✰ ✰✰ ✰✰✰ 900 mm 900 mm

CD

13mm Impactchek ✰✰✰✰ ✰✰✰ ✰ 13mm plasterboard

13mm EC08 CD and 10mm 1000 mm 1000 mm

✰✰✰ ✰✰✰ ✰✰✰

Impact Supaceil

6mm CeminSeal 13 & 16mm Fyrchek 3m 3m

✰ ✰ ✰✰✰✰

Wallboard 13mm Perforated

20m 20m

Note: More ✰’s indicates higher performance. Plasterboard sheet

Gyprock ™ plasterboard of 10mm and 13mm thickness

provide adequate resistance to soft body impacts likely in

domestic or light commercial use respectively. FIG A6: FRAMING PRePARATIoN FoR CuRVed WALL

uSING RoNdo FLexI-TRACk

Walls lined with Gyprock Fyrchek ™ , Impactchek ™ and

CeminSeal™ Wallboard can meet various requirements of Refer to GYP544, Gyprock Steel Frame Wall Systems Installation Guide for

maximum stud spacings.

Specification C1.8 of the Building Code of Australia 2004.

This clause specifies resistance to Uniform Distributed Loads

(UDLs), surface indentation and impact from a weighted

sand bag that is dropped from a specified height.

Minimum curving radius for

Rondo Flexi-Track™.

Track Minimum

Depth Radius

51mm 180mm

64mm 200mm

76mm 230mm

Rondo Flexi-Track®

92mm 285mm

150mm 475mm

FIG A7: CuRVed CeILING FRAMING

Curved Furring Channel

Ceiling Framing

Curved Gyprock plasterboard

A20 The Red Book™

Building Sound Impact Ratings

The BCA has performance requirements relating to sound

Acoustics impact for floors and some walls.

For floors, this is specified as a maximum value such as:

Building acoustics can be separated into sound absorption Lnw+CI = 62. Note that lower values of Lnw+CI indicates

and sound transmission. better acoustic impact performance. Queensland and

Northern Territory have no requirements for impact rating

Sound absorption relates to control of sound that is generated of floors.

within a room and how it affects people in that room.

Walls may be required to meet the definition of ‘Discontinuous

Sound transmission relates to sound that passes through a Construction’. This means that wall leaves must be separated

dividing element (direct sound, controlled by the element’s by at least 20mm and no mechanical connection is permitted,

sound insulation), and through the surrounding structure except that masonry may have resilient ties.

(indirect or flanking transmission).

Systems that meet this specification are noted in the

Methods of controlling noise in buildings can be based on appropriate system specifications.

systems, structure and lining materials and their absorption

and transmission properties. FIG A8: CoMMoN FLANkING TRANSMISSIoN PAThS

1. Ceiling plenums, floors, walls. 4. Heating and ventilation ducting.

CSR recommends that an acoustic engineer be consulted 2. Poor seals between structural 5. Rigid plumbing connections and

for all projects where acoustics are important. elements and around service penetrations.

penetrations. 6. Back-to-back cabinets and

3. External air-borne paths. switches/power outlets.

Flanking Transmission

Flanking sounds reach adjoining areas by indirect paths,

1

rather than through the dividing element. The perimeter

junction of walls, floors and ceilings that surround the 4 1

3

2 2

dividing element are the main paths for flanking transmission.

Other paths include open windows, ducts, doorways and 2

suspended ceilings.

3 2

6

Noise sources that have a high degree of low frequency

4 2

noise such as traffic, aircraft and DVD sound systems have 3

6

potential for transmission through the building structure. 5

Transmission of this type of noise follows structural load

1

paths and can be controlled by breaking these load paths

or providing complete separation of the structure.

Noise sources that generate a high amount of mid and

high frequency noise, such as services and speech, tend to

transmit via air paths and direct transmission in lightweight

construction.

Typical problem areas for this type of transmission include

doors and door frames, glazing, suspended ceiling cavities

and ductwork. Practical methods for addressing common

situations within buildings can be seen in Section ‘Z’.

The Red Book™ A21

Building Acoustic Integrity

The acoustic integrity of a system can be influenced by the

Acoustics in combination of elements that make up the system. Single

leaf and uninsulated systems are more dependant on high

quality installation, as relatively minor defects can cause

Practice major degradation of the system performance.

Building systems that allow defects to be hidden from view

have a higher chance of gaps being left unsealed, making

System Performance them more vulnerable to performance degradation.

The Rw, Rw + Ctr and Ln,w + CI values in this manual refer to

The likelihood and effect of defects occurring with typical

expected results of a laboratory test on an element.

systems is shown in Table A14.

Extensive testing over many years has been carried out

by CSR at laboratories including the Commonwealth

TABLe A14: ACouSTIC INTeGRITY

Experimental Building Station (later CSIRO) at North Ryde

NSW, National Acoustic Laboratory at Lindfield NSW, CSIRO Chance of Effect of

Laboratories at Highett, Victoria and even, up to 1978, at Wall System Gaps Being Left Defects on

Unsealed Performance

our own NATA registered laboratory. Extensive development

testing has been carried out at Rintoul Laboratories, Seven

Hills NSW since 1995, and some of the systems subsequently

validated at other laboratories. High High Degradation

Performance values provided by PKA Acoustic Consulting

use a prediction system based on these tests, and the Single skin masonry wall

system has been updated to include the most current CSR

sponsored testing. The prediction system has been calibrated

against the ‘round robin’ European test of a standard

plasterboard wall in 24 European acoustic laboratories, and High High Degradation

has successfully predicted the performance of a calibration

wall for an acoustic laboratory in Brisbane. Masonry with stud,

uninsulated

As testing from different laboratories can vary (the European

24 laboratory test of the standard plasterboard wall was

Rw47 to Rw52), it is possible that laboratory tests may be 1

to 2 Rw points above a prediction. Low High Degradation

All care has been taken with preparation of these predictions

and it is assumed that construction is strictly in accordance Single stud, uninsulated

with this manual and relevant Gyprock ™ and Cemintel™

installation guides.

Moderate

Site Performance vs. Laboratory Low

Degradation

Performance

Single stud, insulated

As houses are not built like laboratories, it is unlikely that

performance measured in ideal test conditions will be

achieved in a building. Designers should take care to select

systems compatible with the support structure to provide the Low Low Degradation

desired level of insulation.

The BCA specifies deemed to satisfy acoustic values that Double stud, insulated

are laboratory results, and in some cases allows lower values

when site tested. For example, in a Class 2 building the

separating wall can have Rw + Ctr = 50 (a laboratory result),

or DnT,w + Ctr = 45 (tested on site). The difference of 5 is that

expected between site and laboratory, although it might not

always be the case. CSR recommends that where designers

are selecting systems based on expected site performance,

an acoustic engineer be consulted.

A22 The Red Book™

Background Noise • Va r i a t i o n i n o c c u p a n t p e r c e p t i o n s o f n o i s e ,

e.g. high, medium or low cost housing.

Low levels of noise transmitted from other areas can be

partially obscured by background noise. • Background noise levels may be very low.

Where the background noise level is low, such as in remote • The lack of simplicity in construction could reduce actual

areas, consideration should be given to providing a higher performance.

than standard level of sound insulation.

Minimum Performance Levels

Variation in occupant Perception of for external Walls

Noise The BCA does not set minimum performance levels of

Tolerance for noise varies greatly between people, and transmission for external walls. Guidance should be sought

variations of up to 15dB can be considered acceptable. from an acoustic consultant or local authority for setting

This means consideration should be given to the occupant’s the design requirements of these elements, as they may be

expectation of the internal acoustic environment. Users of affected by road or aircraft noise.

concert halls and practice rooms may have higher acoustic Issues that may affect the design levels for external walls are:

expectations than guests of inner city hotels.

• Va r i a t i o n i n o c c u p a n t p e r c e p t i o n s o f n o i s e ,

e.g. high, medium or low cost housing.

Minimum Performance Levels for

• Background noise levels are low.

Internal Walls and Ceilings

• Flanking transmission of the surrounding structure,

The BCA sets out minimum performance levels for internal

particularly at windows and doors.

walls and ceilings based on acceptable standards for

affordable housing. The performance requirements are in • The lack of simplicity in construction could reduce actual

terms of Rw, Rw+Ctr and Ln,w+CI. performance.

These levels may need to be increased for:

Gaps, Crack and holes

• Va r i a t i o n i n o c c u p a n t p e r c e p t i o n s o f n o i s e ,

Small openings allow airborne sound to pass through

e.g. high, medium or low cost housing.

an element and can significantly reduce sound insulation

• Local authorities have higher or additional requirements. performance. For optimum sound insulation, the element

• Background noise levels are low. must be airtight.

• Flanking transmission of the surrounding structure. Perimeters and penetrations for services must be sealed with

Lightweight structures can be more prone to low frequency an acoustic sealant that is capable of accommodating the

flanking. expected building movement.

• The presence of services will vary which BCA provisions For systems that are multi-layered, such as masonry

are applicable, and could mean separate construction is composite systems, each layer must be air tight, as services

required. such as power points and switches can act as airborne

flanking paths. To remedy this, consider using acoustic rated

• The lack of simplicity in construction could reduce actual

power boxes, the Gyprock™ Silencer, and insulation in the

performance.

cavity. Refer to flanking details, Section ‘Z’.

Minimum Performance Levels

for Services

The BCA sets out minimum performance levels for isolation

of noise from services based on acceptable standards for

affordable housing. The performance levels are in terms of

Rw and Rw+Ctr.

These levels may need to be increased for:

• The nature of the noise source and adjacent occupant

activity. Some noises are particularly annoying to

occupants.

• Systems that meet the new BCA minimum Rw+Ctr

requirements may have lower performance than systems

that meet the corresponding Rw requirements.

The Red Book™ A23

Definitions

L’nT,w – Weighted Standardised Field Impact Sound

Pressure Level. A measure of the noise impact performance

of a floor/ceiling. It is similar to Ln,w except it is measured in

Rw – Weighted Sound Reduction Index. A measure of the field and is therefore subject to the inherent inaccuracies

the sound insulation performance of a building element. Rw involved in such a measurement.

is a laboratory measurement similar to STC.

The lower the number the better the performance.

Rw is measured and calculated using the procedures from

C I – A spectrum adaptation term used to modify the

AS1276 and AS1191. The related field measurement is

measured impact sound pressure level, Ln,w or L’nT,w.

abbreviated as DnT,w.

Impact sound is generated by a laboratory grade tapping

The higher the number the better the insulation

machine placed on the floor to be tested. This tapping machine

performance.

does not accurately simulate the noise of a person’s foot steps

dnT,w – Weighted Standardised Field Level difference. on the floor above, so the CI term was developed to more

A measurement of the sound insulation performance of a closely simulate foot step noise.

building element. It describes the difference in noise level on The term is defined in ISO717-2. The Ln,w or L’nT,w alone

each side of a wall or floor, and indicates the level of speech is sufficient to characterise concrete floors covered with

privacy between spaces. It is measured in the field and is carpet. Other types of floors such as timber joist floors, bare

therefore subject to the inherent inaccuracies involved in concrete floors or polished timber or tiles laid on concrete

such a measurement. floors require the CI term to properly characterise footstep

The higher the number the better the insulation noise.

performance. Timber joist floors can have a CI value slightly positive.

Concrete floors with an effective covering such as carpet

Ctr – A spectrum adaptation value used to modify the sound have CI terms approximately equal to 0dB. Concrete floors

insulation performance of a wall or floor. Sound insulation with a hard, or less effective covering, can have CI terms

performance can be described by Rw or the DnT,w but these varying between –15dB and 0dB.

are not accurate for all noises, especially for low frequency

bass noise from modern stereo systems. Ctr values are NRC – Noise Reduction Coefficient. A measure of the

negative value which is added to either the Rw or DnT,w. ability of a material to absorb sound.

AS/NZS1276 - sets out testing methodologies for the sound

NRC is generally a number between 0 and 1. A material with

insulation properties of building elements and incorporates

an NRC rating of 1 absorbs 100 % of incoming sound, that

these factors and explains their use.

is, no sound is reflected back from the material.

Smaller negative Ctr values are more favourable than large

negative values. STC – Sound Transmission Class. A measure of the

sound insulation performance of a building element used

dB(A) – The ‘A’-scale and dB(A) noise level are used to in the BCA prior to 2000. It is measured in very controlled

degrade the performance of a sound level meter to simulate conditions in a laboratory.

what humans hear. The human ear is not a perfect listening

device, it is poor at hearing low frequency noise. dB(A) is CAC – Ceiling Attenuation Class – A single number rating

used to compare measured sound with perceived sound. from a laboratory test to measure sound reduction between

rooms via the ceiling.

A number of noise criteria refer to, and are measured in

dB(A). The larger the dB(A) level the louder the noise. dnc,w – Weighted Suspended Ceiling Normalised Level

difference. Similar to CAC.

Ln,w – Weighted Normalised Impact Sound Pressure

Level. A measure of the noise impact performance of a Source: Building Code of Australia, Sound Insulation

floor/ceiling. It is measured in very controlled conditions Guideline.

in a laboratory and is characterised by how much impact

sound reaches the receiving room via the ceiling/floor from

a standard tapping machine test.

The lower the number the better the performance.

A24 The Red Book™

Section B

Steel Stud Wall Systems

Contents

Stud Selection Tables B2 – B4

Introduction B4

Design Considerations B4 – B6

Installation B6 – B7

Components B7 – B8

Internal Wall System Specifications

Single Stud B9 – B12

Rondo Quiet Stud B13

Staggered Stud B14 – B16

Double Stud B17 – B19

StrataWall™ B20 – B22

Party Wall B23 – B24

SecurityWall™ B25 – B27

Resilient Mount B28

Cinema Wall B29

Studs Lined One Side B30 – B31

Shaft Wall B32

Laminated Services B33 – B36

External Wall System Specifications

Steel Cladding B37

ExpressWall™ B38 – B39

RendaLine™ B39 – B41

Cladding On Battens B42

Texture Base Sheet For Houses B43

Concrete B44

Hebel Powerpanel™ B44

Masonry B45

Columns & Beams B46

ECO8 Internal Wall System Specifications B47 – B52

System Installation Details B53 – B65

The Red Book™ B1

Stud Selection Tables

Tables B1 to B8 provide stud selection information suitable for all CSR Gyprock™ & Cemintel™ non-fire rated and fire rated

non-loadbearing internal wall systems that are to be designed for a Uniform Distributed Load (UDL) of 0.25kPa, 0.35kPa or

0.50kPa as detailed in each table.

Refer to Rondo for other design pressures and for loadbearing walls.

TABLE B1: MAXIMUM WALL HEIGHT WITH RONDO LIPPED STEEL STUDS – NON-LOADBEARING WALLS

– WALLS GENERALLY (LOAD = 0.25kPa)

Stud Size 51 64 76 92 150

Wall Frame and

BMT 0.5 0.75 0.5 0.75 1.15 0.55 0.75 1.15 0.55 0.75 1.15 0.75 1.15

Lining Configuration

Linings (mm) Maximum Wall Height (m)

10 2.77 2.91 3.33 3.93 4.17 3.70 4.43 4.65 4.54 4.83 5.11 6.55 7.22

600mm max. cts

13 3.20 3.32 3.72 4.22 4.43 4.13 5.02 5.22 4.94 5.50 5.75 6.99 7.54

16 3.38 3.52 3.91 4.35 4.52 4.30 5.25 5.42 5.18 5.71 5.92 7.19 7.65

CSR 080(-/180/180) 2.60 2.60 3.30 3.60 4.30 3.80 4.10 5.00 4.40 4.80 5.00 7.00 7.65

600mm max. cts 10 2.32 2.60 2.72 3.13 3.53 3.20 3.58 4.05 3.61 4.13 4.69 5.33 6.81

13 2.32 2.60 2.72 3.25 3.58 3.24 3.82 4.05 3.61 4.18 4.69 5.37 6.81

16 2.32 2.60 2.75 3.28 3.59 3.25 3.87 4.05 3.61 4.20 4.69 5.37 6.81

10 2.37 2.83 3.51

300mm 300mm