Beruflich Dokumente

Kultur Dokumente

Flywheel 2

Hochgeladen von

Gautam TyagiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Flywheel 2

Hochgeladen von

Gautam TyagiCopyright:

Verfügbare Formate

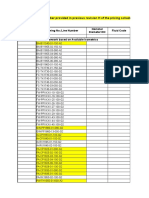

FLYWHEELS 509

TABLE 26-1

Required Coefficient of Steadiness m

Driven Machinery Type of Drive m

Hammers, crushers, punch presses Belt 5

Compressors, concrete mixers, excavators . . Belt 7-10

Pumps, shears Belt or flexible coupling 20-25

Metalworking and woodworking machinery Belt 30

Flour, paper, and textile mills Belt 40-50

Compressors, pumps, and similar machines. Gears 50

Spinning machinery, coarse to fine Belt 50-65

D-C generators, single or parallel Belt 35

D-C generators, single or parallel Direct-coupled 70

A-C generators, single or parallel Belt 60

A-C generators, single or parallel DirectTcoupled 100

where k is the polar radius of gyration of the rim, in feet, and n is the speed,

in revolutions per minute. Then

m2JJ2AgE

—

Til1 12

The product Wk2 is the polar moment of inertia. It is also known as the

flywheel effect.

Speed fluctuation. The relative speed variation is determined from the

relation

m--^—

Hi

—

m

(26-6)

where n is the mean speed of the flywheel, and «i and n% are the maximum

and minimum speeds, respectively. The number m is called the coefficient

of and its reciprocal «= \/m is called the coefficient of fluctuation of

steadiness,

rotation.The value of m, or u, depends on the nature of the service for which

the machine is built; that

is,

on the permissible variation between the high

est and lowest speeds during each operating cycle of the driven machine and

on the method of connecting to the driving motor. With a flexible con

it

nection, such as belt drive, the coefficient m may be smaller than with

a

less flexible connection. An electric generator requires a more uniform

drive, and greater m, than pump. Two or more generators operating in

a

a

parallel require still greater value of m. Table 26-1 gives minimum values

a

of m for number of typical drives. The maximum limit, as used in practice,

a

about 25 per cent higher.

is

The mean speed may be determined by the relation

+

«i n2

(26-7)

Das könnte Ihnen auch gefallen

- Power System Dynamic ModelingDokument12 SeitenPower System Dynamic ModelingSyed Muhammad Munavvar HussainNoch keine Bewertungen

- Analysis - Simulation and Practical Evaluation of Torque Vector Control Strategies For Medium Power Highly Responsive PMSM DrivesDokument8 SeitenAnalysis - Simulation and Practical Evaluation of Torque Vector Control Strategies For Medium Power Highly Responsive PMSM Drives22dr0302Noch keine Bewertungen

- Final design of dynamic systems modeled and analyzedDokument5 SeitenFinal design of dynamic systems modeled and analyzedJESUS DAVID FRANCO GOMEZNoch keine Bewertungen

- Speed Control of Induction Motor PDFDokument12 SeitenSpeed Control of Induction Motor PDFbalaer05Noch keine Bewertungen

- Accurate Steady-State Representation of A Doubly Fed Induction MachineDokument6 SeitenAccurate Steady-State Representation of A Doubly Fed Induction MachineNoa Noa ReyNoch keine Bewertungen

- Turn-Off Angle Control of Switched Reluctance Motor For Optimum Torque OutputDokument6 SeitenTurn-Off Angle Control of Switched Reluctance Motor For Optimum Torque Outputapi-26587237100% (1)

- SMC pitch control for variable speed wind turbine considering actuator dynamicsDokument5 SeitenSMC pitch control for variable speed wind turbine considering actuator dynamicsDuyên Nguyễn NgọcNoch keine Bewertungen

- Introduction To Cavitation in Hydraulic MachineryDokument14 SeitenIntroduction To Cavitation in Hydraulic Machineryclaudio.ferreirademoNoch keine Bewertungen

- No. Option A Option B Option C Option DDokument3 SeitenNo. Option A Option B Option C Option DNevil ModiNoch keine Bewertungen

- Speed Control 2Dokument2 SeitenSpeed Control 2clinthen100% (1)

- Sec 1Dokument23 SeitenSec 1Wahyu DiNoch keine Bewertungen

- Dd6da66a 33a3 410F A2e4 4ad5ce71d30fDokument7 SeitenDd6da66a 33a3 410F A2e4 4ad5ce71d30fmarris09Noch keine Bewertungen

- STA 2013 LiliaDokument6 SeitenSTA 2013 LiliaHAFEDH ABIDNoch keine Bewertungen

- 2009 Sayed PIDDokument8 Seiten2009 Sayed PIDCumhur ÖzbaşNoch keine Bewertungen

- EncoderDokument8 SeitenEncoder126 N.EZHILARASAN EEERNoch keine Bewertungen

- Tesla-Symp06 Emil LeviDokument11 SeitenTesla-Symp06 Emil Levicoyote533Noch keine Bewertungen

- Control of A Power Circuit Interface of A Flywheel-Based Energy Stor-Age SystemDokument6 SeitenControl of A Power Circuit Interface of A Flywheel-Based Energy Stor-Age SystemSantiago Bonilla RiveraNoch keine Bewertungen

- Back Backconverter DFIMDokument11 SeitenBack Backconverter DFIMAbhimanyu YadavNoch keine Bewertungen

- Simulation Model of Hydro Power PlantDokument7 SeitenSimulation Model of Hydro Power Plantwoldemariam workuNoch keine Bewertungen

- Model Predictive Control of DFIG-based Wind Turbines PDFDokument6 SeitenModel Predictive Control of DFIG-based Wind Turbines PDFLaOrt MLNoch keine Bewertungen

- Dynamic Model and Simulation of Doubly Feed Induction: Generator Wind TurbineDokument5 SeitenDynamic Model and Simulation of Doubly Feed Induction: Generator Wind TurbineSandeepKumarNoch keine Bewertungen

- l6 Machine PDFDokument58 Seitenl6 Machine PDFmomen ShaheenNoch keine Bewertungen

- Vector Control SynRMDokument9 SeitenVector Control SynRMMusical CreationsNoch keine Bewertungen

- Wind TurbineDokument5 SeitenWind TurbineAnthony WellsNoch keine Bewertungen

- Setting Considerations: 9.1 Power System Configuration and OperationDokument32 SeitenSetting Considerations: 9.1 Power System Configuration and Operationదర్భ.రవి థెజNoch keine Bewertungen

- 45 1530697786 - 04-07-2018 PDFDokument5 Seiten45 1530697786 - 04-07-2018 PDFrahul sharmaNoch keine Bewertungen

- Comparison of power converter topologies for small wind turbinesDokument6 SeitenComparison of power converter topologies for small wind turbinesJayamohan MNoch keine Bewertungen

- Numerical Simulation of Rotor-Stator Interactions in a Propeller TurbineDokument7 SeitenNumerical Simulation of Rotor-Stator Interactions in a Propeller Turbinejohansarache1986Noch keine Bewertungen

- 4th Module 2Dokument11 Seiten4th Module 2dilja aravindanNoch keine Bewertungen

- Steady-State Analysis and Stability of Synchronous Reluctance Motors Considering Saturation EffectsDokument6 SeitenSteady-State Analysis and Stability of Synchronous Reluctance Motors Considering Saturation Effectshenflo992Noch keine Bewertungen

- 58 WetzerDokument6 Seiten58 WetzerWaleed ElzanatiNoch keine Bewertungen

- Short-Circuit Calculations: 4.1 Symmetrical ComponentsDokument21 SeitenShort-Circuit Calculations: 4.1 Symmetrical ComponentsYahya GharbiNoch keine Bewertungen

- Simulation of DFIG Wind Turbines Ride Through CapabilityDokument9 SeitenSimulation of DFIG Wind Turbines Ride Through CapabilityDanny LiNoch keine Bewertungen

- Adaptive Variable Structure Rotor Flux Observer For An Induction MotorDokument6 SeitenAdaptive Variable Structure Rotor Flux Observer For An Induction Motorapi-3826450Noch keine Bewertungen

- Jurnal Internasional PDFDokument10 SeitenJurnal Internasional PDFsyahrial chaniagoNoch keine Bewertungen

- Nonlinear Wind Turbine Control Under Wind Speed Variation and Voltage DipsDokument1 SeiteNonlinear Wind Turbine Control Under Wind Speed Variation and Voltage DipsabdelhakNoch keine Bewertungen

- Critical Clearing Time of DFIGDokument7 SeitenCritical Clearing Time of DFIGmv1970Noch keine Bewertungen

- Steady-State Characteristics of DFIM The PotentialDokument28 SeitenSteady-State Characteristics of DFIM The PotentialMahdi HERMASSINoch keine Bewertungen

- Robust DTC Control of Doubly-Fed Induction Machines Using Recurrent Neural NetworksDokument7 SeitenRobust DTC Control of Doubly-Fed Induction Machines Using Recurrent Neural NetworksnaserhashemniaNoch keine Bewertungen

- Bodson - Chiasson - Induction Motor Via Input-Output LinearDokument9 SeitenBodson - Chiasson - Induction Motor Via Input-Output LinearmorilloatilioNoch keine Bewertungen

- A Hybrid PWM Approach For The Traction Motor Control of Alternative Energy VehiclesDokument5 SeitenA Hybrid PWM Approach For The Traction Motor Control of Alternative Energy VehiclesEga PramNoch keine Bewertungen

- VLM 3dpanelDokument7 SeitenVLM 3dpanelSîImoHäāķīīmNoch keine Bewertungen

- IC 20 SPSingh ICPCES2012 RajneeshDokument6 SeitenIC 20 SPSingh ICPCES2012 RajneeshEmmanuel ZangueNoch keine Bewertungen

- Dynamic Model Analysis of Three Phase Induction Motor Using Matlab SimulinkDokument6 SeitenDynamic Model Analysis of Three Phase Induction Motor Using Matlab SimulinkSuhail Ahmad SuhailNoch keine Bewertungen

- Common-Mode Voltage Reduction For Regenerative AC DrivesDokument8 SeitenCommon-Mode Voltage Reduction For Regenerative AC DrivesDao DaoNoch keine Bewertungen

- An Optimal Speed Controller For Permanent-Magnet Synchronous Motor DrivesDokument8 SeitenAn Optimal Speed Controller For Permanent-Magnet Synchronous Motor Drives22dr0302Noch keine Bewertungen

- Malah Et Al. - 2020 - Backstepping Controllers Design For A Grid Connected Wind-Photovoltaic Hybrid Power System-AnnotatedDokument6 SeitenMalah Et Al. - 2020 - Backstepping Controllers Design For A Grid Connected Wind-Photovoltaic Hybrid Power System-AnnotatedMohamed Riyad BoudallaaNoch keine Bewertungen

- Apec 1996 500498Dokument9 SeitenApec 1996 500498hamidrezaNoch keine Bewertungen

- Maquinas de Corriente ContinuaDokument111 SeitenMaquinas de Corriente ContinuaValentina Alzugaray BatallaNoch keine Bewertungen

- Fuzzy Speed Controller Design of Three Phase Induction MotorDokument6 SeitenFuzzy Speed Controller Design of Three Phase Induction MotorELECTRICAL DEPARTMENTNoch keine Bewertungen

- Fuzzy logic excitation control for synchronous generatorsDokument6 SeitenFuzzy logic excitation control for synchronous generatorswilliamNoch keine Bewertungen

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkVon EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNoch keine Bewertungen

- Handbook of Power Systems Engineering with Power Electronics ApplicationsVon EverandHandbook of Power Systems Engineering with Power Electronics ApplicationsNoch keine Bewertungen

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlBewertung: 5 von 5 Sternen5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Energetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationVon EverandEnergetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationNoch keine Bewertungen

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesVon EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNoch keine Bewertungen

- Torsion SpringsDokument22 SeitenTorsion SpringsGautam TyagiNoch keine Bewertungen

- ISO - FDIS - 15552 - E Pneumatic CylinderDokument26 SeitenISO - FDIS - 15552 - E Pneumatic CylinderGautam TyagiNoch keine Bewertungen

- Form and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMDokument1 SeiteForm and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMTrọng NgôNoch keine Bewertungen

- Machine Design Flywheel Split Hub Bolt ConnectionDokument1 SeiteMachine Design Flywheel Split Hub Bolt ConnectionGautam TyagiNoch keine Bewertungen

- Thread (Computing) : A Process With Two Threads of Execution, Running On One ProcessorDokument9 SeitenThread (Computing) : A Process With Two Threads of Execution, Running On One ProcessorGautam TyagiNoch keine Bewertungen

- Flywheel 5Dokument1 SeiteFlywheel 5Gautam TyagiNoch keine Bewertungen

- FlywheelDokument1 SeiteFlywheelGautam TyagiNoch keine Bewertungen

- Spline DIN 5480Dokument27 SeitenSpline DIN 5480ewillia13100% (3)

- Design of Machine Members - Vallance & Doughtie PDFDokument580 SeitenDesign of Machine Members - Vallance & Doughtie PDFjbarr5883% (6)

- With Eliminates If Off While Rim Joint in TableDokument1 SeiteWith Eliminates If Off While Rim Joint in TableGautam TyagiNoch keine Bewertungen

- Abrasive Methods Engineering PDFDokument392 SeitenAbrasive Methods Engineering PDFGautam Tyagi100% (2)

- NBS18 Heat TreatmentDokument46 SeitenNBS18 Heat Treatmentshailesh_tiwari_mechNoch keine Bewertungen

- Tool Life in Cold Forging An Example of PDFDokument7 SeitenTool Life in Cold Forging An Example of PDFGautam TyagiNoch keine Bewertungen

- Heat TreatingDokument13 SeitenHeat TreatingGautam TyagiNoch keine Bewertungen

- DinDokument1 SeiteDinMelissa SmithNoch keine Bewertungen

- Analytical Relations Between Hardness and Strain For Cold Formed PartsDokument11 SeitenAnalytical Relations Between Hardness and Strain For Cold Formed PartsGautam TyagiNoch keine Bewertungen

- Materials BehaviourDokument1.231 SeitenMaterials BehaviourVishwarath Taduru100% (6)

- Applied Statics and Strength of Materials PDFDokument792 SeitenApplied Statics and Strength of Materials PDFGautam Tyagi92% (12)

- Mechanism Analysis Simplified Graphical and Analytical Techniqu PDFDokument472 SeitenMechanism Analysis Simplified Graphical and Analytical Techniqu PDFGautam Tyagi100% (3)

- Din 5480-1Dokument24 SeitenDin 5480-1asd50% (2)

- ASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeDokument3 SeitenASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeGautam Tyagi100% (1)

- Handbook LT en 2006-07 PDFDokument352 SeitenHandbook LT en 2006-07 PDFGautam TyagiNoch keine Bewertungen

- Study of SCADA Based Existing Water Treatment Plant-GAWSS Phase-I in Mizoram, IndiaDokument7 SeitenStudy of SCADA Based Existing Water Treatment Plant-GAWSS Phase-I in Mizoram, Indiarodden chikonzoNoch keine Bewertungen

- Mechanical IntegrityDokument9 SeitenMechanical Integritysenor pinkNoch keine Bewertungen

- 09 Icruise Best Practice v2Dokument45 Seiten09 Icruise Best Practice v2Nelson RamirezNoch keine Bewertungen

- Transmision 2BS315A XCMG ZL50G - Guia de Analisis de FallasDokument12 SeitenTransmision 2BS315A XCMG ZL50G - Guia de Analisis de FallasEmmanuel Garcia Ozan100% (4)

- OGS HVAC Design Guide SummaryDokument25 SeitenOGS HVAC Design Guide Summarysolarstuff100% (1)

- High Speed Shaft Rotor-Side InspectionDokument6 SeitenHigh Speed Shaft Rotor-Side InspectionAdriano Cesário100% (1)

- Carburetor Marvel Schebler PartsDokument22 SeitenCarburetor Marvel Schebler PartsAnderson RamalhoNoch keine Bewertungen

- Serck Audco Valves: Sealants and Injection EquipmentDokument21 SeitenSerck Audco Valves: Sealants and Injection EquipmentsterlingNoch keine Bewertungen

- Specifications of 1250Tcd Sulphitation Sugar Plant Expandable To 2000 TCDDokument73 SeitenSpecifications of 1250Tcd Sulphitation Sugar Plant Expandable To 2000 TCDAHmad NaqashNoch keine Bewertungen

- Advanced Piping SolutionsDokument12 SeitenAdvanced Piping SolutionsshehanNoch keine Bewertungen

- AYK 550 ManualDokument45 SeitenAYK 550 ManualMauro S Cabral0% (1)

- PIPING IdentificationDokument49 SeitenPIPING IdentificationSiji OktoberNoch keine Bewertungen

- (NEW) TAEHA COMPANY PROFILE (해외영업)Dokument33 Seiten(NEW) TAEHA COMPANY PROFILE (해외영업)Tuyên VũNoch keine Bewertungen

- Management of Change: Did You Know?Dokument1 SeiteManagement of Change: Did You Know?baaziz2015Noch keine Bewertungen

- Liquid Piston CompressorsDokument18 SeitenLiquid Piston CompressorsBabylyn AustriaNoch keine Bewertungen

- Maquina de Circulacion ExtracorporeaDokument12 SeitenMaquina de Circulacion Extracorporeajimena lopez cardenasNoch keine Bewertungen

- ZL50GN Wheel Loader SpecsDokument2 SeitenZL50GN Wheel Loader SpecsSolomon Nebiyu100% (1)

- O-M of Water Supply and Sewerage ProjectDokument2 SeitenO-M of Water Supply and Sewerage ProjectDilawarJuttNoch keine Bewertungen

- Big Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenDokument28 SeitenBig Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenAromaBox AromakozmetikaNoch keine Bewertungen

- E-Series BrochureDokument12 SeitenE-Series BrochureDanielNoch keine Bewertungen

- Presentation On Fertilezer SprayerDokument12 SeitenPresentation On Fertilezer Sprayeragrawalyash1298Noch keine Bewertungen

- Techni-Tips: Filtration Plays Vital Role in Oil CleanlinessDokument2 SeitenTechni-Tips: Filtration Plays Vital Role in Oil CleanlinessClaudio Antonio Figueroa PulgarNoch keine Bewertungen

- NACHI Full Catalog Small RevDokument468 SeitenNACHI Full Catalog Small RevSombat MahamadNoch keine Bewertungen

- Standard P&i Condition SurveyDokument31 SeitenStandard P&i Condition Surveyluchiappi100% (9)

- Zhang 2017Dokument12 SeitenZhang 2017Maki SrbijaNoch keine Bewertungen

- Eurostream OM ManualDokument19 SeitenEurostream OM ManualGede SantosaNoch keine Bewertungen

- FT Aeroterme GEADokument15 SeitenFT Aeroterme GEACrisTimNoch keine Bewertungen

- 4 2.4L GasolineDokument262 Seiten4 2.4L GasolinejuanNoch keine Bewertungen

- EagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFDokument2 SeitenEagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFkztro066Noch keine Bewertungen

- Liste DTCDokument55 SeitenListe DTCmpereiraNoch keine Bewertungen