Beruflich Dokumente

Kultur Dokumente

Agric Mach Design-9

Hochgeladen von

Myrla Mae Sintos0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten12 SeitenAgricultural Machinery

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAgricultural Machinery

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten12 SeitenAgric Mach Design-9

Hochgeladen von

Myrla Mae SintosAgricultural Machinery

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

Embodiment Design

Activities of Embodiment Design

• Product architecture— determining the

arrangement of the physical elements of the

design into groupings, called modules

• Configuration design—the design of special-

purpose parts and the selection of standard

components, like pumps or motors

• Parametric design— determining the exact

values, dimensions, or tolerances of the

components or component features that are

deemed critical-to-quality

Configuration Design

In configuration design we establish the

shape and general dimensions of

components.

A component is used in the generic sense to include

special-purpose parts, standard parts, and standard

assemblies.

A Part is a designed object that has no assembly

operations in its manufacture. A part is characterized

by its geometric features such as holes, slots, walls,

ribs, projections, fillets, and chamfers. The

arrangement of features includes both the location and

orientation of the geometric features.

Ex. Four possible configurations of features

of a right-angle bracket

(a) Bent from a flat plate.

(b) Machined from a solid block.

(c) Bracket welded from three pieces.

(d) Cast bracket.

A standard part is one that has a generic function

and is manufactured routinely without regard to

a particular product. Examples are bolts,

washers, rivets, and I-beams.

A special-purpose part is designed and

manufactured for a specific purpose in a specific

product line

A subassembly is an assembly that is included

within another assembly or subassembly.

A standard assembly is an assembly or

subassembly that has a generic function and is

manufactured routinely. Examples are electric

motors, pumps, and gearboxes

Steps in making Configuration Design

1. Review the product design specification and any

specifications developed for the particular subassembly to

which the component belongs.

2. Establish the spatial constraints that pertain to the product

or the subassembly being designed.

3. Create and refine the interfaces or connections between

components.

4. Answer the following questions: Can the part be eliminated

or combined with another part?

5. Can a standard part or subassembly be used? While a

standard part is generally less costly than a special-

purpose part, two standard parts may not be less costly

than one special-purpose part that replaces them.

Schematic illustrating the close interrelationship

between function and form and, in turn, their

dependence on the material and the method of

production

Figure shows the progression of a design configuration

from a rough sketch (a) to a 3-D computer model (b) to a

detailed three-view engineering drawing. Note the

increase in detail from (a) to (b) to (c).

Generating Alternative Configurations

Images that come to a designer’s mind when

making a design of a bolted connection.

Patching and Refining Activities

• Substituting looks for other concepts, components, or

features that will work in place of of the current idea.

• Combining aims to make one component replace

multiple components or serve multiple functions.

• Decomposing is the opposite approach from

combining.

• Magnifying involves making some feature of a

component larger relative to adjacent components.

• Minifying involves making some feature of a

component smaller.

• Rearranging involves reconfiguring the components

or their features.

Best Practices for Configuration Design

1. Clarity of function pertains to an unambiguous

relationship between the various functions and the

appropriate inputs and outputs of energy, material,

and information flow

2. Simplicity refers to a design that is not complex and

is easily understood and readily produced. One way

to minimize information content is to reduce the

number and complexity of the components.

3. Safety should be guaranteed by direct design, not

by secondary methods such as guards or warning

labels.

4. Minimal impact on the environment is of growing

importance, and should be listed as a fourth basic

guideline.

Das könnte Ihnen auch gefallen

- Life Cycles and AgeDokument2 SeitenLife Cycles and AgeMyrla Mae SintosNoch keine Bewertungen

- Commodity AnalysisDokument57 SeitenCommodity AnalysisMyrla Mae SintosNoch keine Bewertungen

- Case StudyDokument39 SeitenCase StudyJeanivy ManejaNoch keine Bewertungen

- Biology and Life Cycles of Prawns PDFDokument8 SeitenBiology and Life Cycles of Prawns PDFMyrla Mae SintosNoch keine Bewertungen

- PRODUCTION1Dokument1 SeitePRODUCTION1Myrla Mae SintosNoch keine Bewertungen

- Agex1321 PDFDokument5 SeitenAgex1321 PDFMyrla Mae SintosNoch keine Bewertungen

- Chapter 4Dokument7 SeitenChapter 4Myrla Mae SintosNoch keine Bewertungen

- Aquaculture Lab Exercise 1 TilapiaDokument17 SeitenAquaculture Lab Exercise 1 TilapiaMyrla Mae SintosNoch keine Bewertungen

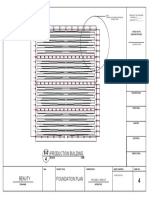

- Foundation PlanDokument1 SeiteFoundation PlanMyrla Mae SintosNoch keine Bewertungen

- Note To Ramel (Insert The System or Procedure of Plant Management/ How It Will Works)Dokument2 SeitenNote To Ramel (Insert The System or Procedure of Plant Management/ How It Will Works)Myrla Mae SintosNoch keine Bewertungen

- NS22-1cncrtdesign 3Dokument43 SeitenNS22-1cncrtdesign 3userhieNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- MMW Ni Nicooooooooole5Dokument5 SeitenMMW Ni Nicooooooooole5Alex Gabilan Jr.Noch keine Bewertungen

- Algebra 2 Lesson 5.6 Day Two FinalDokument6 SeitenAlgebra 2 Lesson 5.6 Day Two Finalhoudini4Noch keine Bewertungen

- American University of Sharjah: College of Arts and Sciences Department of Mathematics and StatisticsDokument6 SeitenAmerican University of Sharjah: College of Arts and Sciences Department of Mathematics and StatisticsUmair MehboobNoch keine Bewertungen

- Sequences of Real NumbersDokument55 SeitenSequences of Real NumbersVijay ChhipaNoch keine Bewertungen

- Section7 4notesDokument15 SeitenSection7 4notesWansi Chita WailanNoch keine Bewertungen

- Module Two: Mathematical Language and SymbolsDokument44 SeitenModule Two: Mathematical Language and SymbolsLyka Rabino ArellanoNoch keine Bewertungen

- IB Mathematics+AutographDokument8 SeitenIB Mathematics+AutographRona Chisholm-ClearyNoch keine Bewertungen

- Apple ManualDokument54 SeitenApple ManualTommaso ScigliuzzoNoch keine Bewertungen

- Module IiiDokument5 SeitenModule IiiSamba Shiva Reddy.g ShivaNoch keine Bewertungen

- Devil's StaircaseDokument3 SeitenDevil's StaircasekamallakkannanNoch keine Bewertungen

- Python For Finance: Regressions, Interpolation & OptimisationDokument38 SeitenPython For Finance: Regressions, Interpolation & OptimisationSergey BorisovNoch keine Bewertungen

- JEE (Main) 2021: PAPER-1 (B.E./B. TECH.)Dokument14 SeitenJEE (Main) 2021: PAPER-1 (B.E./B. TECH.)Abhibhav DubeyNoch keine Bewertungen

- The Elements of Real Analysis. Bartle, Robert G. 1964Dokument462 SeitenThe Elements of Real Analysis. Bartle, Robert G. 1964José Daniel Rivera MedinaNoch keine Bewertungen

- Learning Module No. 2 Mathematical Languages and Symbols TemplateDokument9 SeitenLearning Module No. 2 Mathematical Languages and Symbols TemplateAira Mae Quinones OrendainNoch keine Bewertungen

- Manual de GMWINDokument217 SeitenManual de GMWINBboyJeanko MarichalesNoch keine Bewertungen

- Lecture Notes On Distributions: Hasse CarlssonDokument83 SeitenLecture Notes On Distributions: Hasse CarlssonRajesh MondalNoch keine Bewertungen

- Linear Programming QuestionsDokument5 SeitenLinear Programming QuestionsAbu Hamza Farooqui100% (1)

- 02 Inoculations The Masques of John HejdukDokument15 Seiten02 Inoculations The Masques of John HejdukFrancisco José LlinaresNoch keine Bewertungen

- NapkinDokument617 SeitenNapkinMingCho100% (1)

- Murray R. Spiegel - Applied Differential Equations - Prentice-Hall, Inc. (1967)Dokument440 SeitenMurray R. Spiegel - Applied Differential Equations - Prentice-Hall, Inc. (1967)WDaron3005100% (2)

- College Algebra Tutorial 35: Graphs of Polynomial FunctionsDokument26 SeitenCollege Algebra Tutorial 35: Graphs of Polynomial Functionssalman saeedNoch keine Bewertungen

- H2 Math NotesDokument2 SeitenH2 Math NotesKahSeng TengNoch keine Bewertungen

- A Friendly Mathematics Competition - 35 Years of Teamwork in IndianaDokument197 SeitenA Friendly Mathematics Competition - 35 Years of Teamwork in IndianaSoruth Kuntikul88% (8)

- Maximum and Minimum Values: Click Here For Answers. Click Here For SolutionsDokument5 SeitenMaximum and Minimum Values: Click Here For Answers. Click Here For SolutionsHarshyyNoch keine Bewertungen

- CAPL 1 CANNewsletter 201406 PressArticle enDokument2 SeitenCAPL 1 CANNewsletter 201406 PressArticle enSashankNoch keine Bewertungen

- Skills Practice: Name - DateDokument20 SeitenSkills Practice: Name - DateJosephine RowanNoch keine Bewertungen

- Dirac Delta FunctionDokument5 SeitenDirac Delta FunctionkrishnaNoch keine Bewertungen

- Lec 38Dokument22 SeitenLec 38AdwaithGopanNoch keine Bewertungen

- Probability Module2Dokument22 SeitenProbability Module2Nicole Maligaya MalabananNoch keine Bewertungen

- Lecture FunctionsDokument1 SeiteLecture Functions69 taguro YujinNoch keine Bewertungen