Beruflich Dokumente

Kultur Dokumente

Standard Specification For Restriction Orifice Plates

Hochgeladen von

JITENDER KUMAROriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Standard Specification For Restriction Orifice Plates

Hochgeladen von

JITENDER KUMARCopyright:

Verfügbare Formate

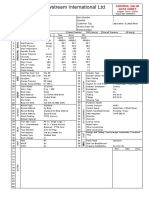

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

0el ENGINEERS FOR RESTRICTION ORIFICE 6-52-0006 Rev. 4

ty eg

51:gar fail- INDIA LIMITED PLATES

1.2 everoste OsT,AT4,11 IA Govt of India Undo,tang)

Page 1 of 6

amItrw aifftm icrR

1-4174r

STANDARD SPECIFICATION FOR

RESTRICTION ORIFICE PLATES

(Ar

4 09.11.15 Revised and Reissued as Standard Specification . SC

3 29.11.10 Revised and Reissued as Standard Specification RS RG TGM/JMS ND

2 02.05.05 Revised and Reissued as Standard Specification AR TGM PM VJ N

1 10.06.97 Revised and Reissued as Standard Specification RK BRS RB AS

0 11.03.85 Issued as Standard Specification PVS TSN AKV AK

Standards Standards

Committee Bureau

Rev. Prepared Checked

Date Purpose Convenor Chairman

No by by

Approved by

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1240 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

otil ENGINEERS

INDIA LIMITED FOR RESTRICTION ORIFICE 6-52-0006 Rev. 4

laaVar etenaldnandral) IA Gout of India Undertaking)

PLATES Page 2 of 6

Abbreviations:

NIL

Instrumentation Standards Committee

Convener: Mr. Rajiv Gupta

Members: Mr. M Nandi

Mr. Sandeep Arora

Mr. A S D Barman

Mr. S Mahesh Kumar

Ms. N P Guha (Proj.)

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1241 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

1.1 ft

ri ENGINEERS FOR RESTRICTION ORIFICE

ogej, 22-egwi INDIA LIMITED 6-52-0006 Rev. 4

to Govt of IfOa Undenak.n9) PLATES Page 3 of 6

CONTENTS

1.0 GENERAL 4

2.0 DESIGN AND CONSTRUCTION 5

3.0 NAMEPLATE 5

4.0 INSPECTION AND TESTING 6

5.0 SHIPPING 6

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1242 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

ENGINEERS

$1g-ar &Reg INDIA LIMITED FOR RESTRICTION ORIFICE 6-52-0006 Rev. 4

I OWN 0900W an acme , (A GovI 01 India Undedaking(

PLATES Page 4 of 6

1.0 GENERAL

1.1 Scope

1.1.1 This specification, together with the data sheets, describes the requirements for the design,

materials, nameplate marking, inspection, testing and shipping of restriction orifice plates and

multistage restriction orifice assemblies.

1.1.2 The related standards referred to herein and mentioned below shall be of the latest edition of

the following codes, standard practices & publications unless specified otherwise: -

ASME American Society of Mechanical Engineers

B 16.5 Pipe Flanges and Flanged Fittings

B16.34 Valves Flanged, Threaded and Welding End

B 36.10 Welded and Seamless Wrought Steel Pipe.

EN European Standards

10204 Inspection Documents for Metallic Products

ISO International Organisation For Standardisation

5167 Measurement of fluid flow by means of orifice plates, nozzles

and venturi tubes inserted in circular cross-section conduits

running full.

1.1.3 In the event of any conflict between this standard specifications, data sheets, statutory

regulations, related standards, codes etc., the following order of priority shall govern:

a) Statutory Regulations

b) Data Sheets

c) Standard specification

d) Codes and standards

1.1.4 In addition to compliance to the purchaser's specification in totality, vendor's extent of

responsibility shall include the following:

a) Purchaser's data sheets specify the material for restriction orifice plates. Unless

specifically indicated otherwise, alternate superior material of construction shall

also be acceptable provided vendor assumes complete responsibility for the

selected materials for their compatibility with the specified fluid and its operating

conditions.

b) Purchaser's data sheets indicate the thickness of the restriction orifice plate. If

found necessary, vendor may provide higher thickness of the restriction orifice

plate considering process conditions, specified in the purchaser's datasheets.

c) Sizing of the multistage restriction orifice plate assembly and the number of stages

to meet the process conditions specified in purchaser's data sheet.

1.2 Bids

1.2.1 Vendor's quotation shall be strictly as per the bidding instruction to the vendor attached with

the Material Requisition.

1.2.2 All documentation submitted by the vendor including their quotation, drawings, installation,

operation and maintenance manuals etc. shall be in English language only.

1.3 Drawings and Data

1.3.1 Detailed drawings, data, specification sheet and manuals shall be submitted by vendor as per

vendor data requirement attached with Requisition.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1243 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

151f4TA ENGINEERS

fge..JI INDIA LIMITED FOR RESTRICTION ORIFICE 6-52-0006 Rev. 4

1>HE'n 2,20R7 WRJ.R.11 IA God of India Undertaking)

PLATES Page 5 of 6

1.3.2 Final documentation consisting of design data, installation manual, operation and

maintenance manual etc., shall be submitted by the vendor after placement of purchase order

as per vendor data requirement attached with Requisition.

2.0 DESIGN AND CONSTRUCTION

2.1 Unless otherwise specified, restriction orifice plates shall be concentric square edge type.

2.2 Whenever multi-orifice plate assembly is specified, vendor shall supply complete assembly

with orifice plates, spool piece and flanges duly welded. The orifice plate design shall be

either of the concentric or eccentric type. The number of stages of orifice plates shall be

calculated by vendor based upon the process data indicated in the purchaser's data sheet.

2.3 Each restriction orifice plate shall have an integral handle, which upon assembly shall extend

by minimum of 50mm beyond flange edge.

2.4 Where weld-in type restriction orifice plates have been specified, the welding and edge

preparation shall be as per ASME B 36.10.

2.5 Where the restriction orifice plate is to be mounted between ring-type joint flanges, vendor

shall supply the plate with a plate-carrying holder. Flange assembly including studs, nuts &

gasket shall be supplied by vendor in case specified in Purchase datasheets.

2.6 The inlet face of the orifice plate shall be as per ISO-5167 or any other standard indicated in

the purchaser's datasheet.

2.7 The fluid outlet surface of the plate should be flat and smooth and shall not have roughness

and scores that can be ascertained by touch or sight.

2.8 Restriction orifice plates in oxygen and chlorine service shall be thoroughly degreased using

reagents like trichloro-ethylene or carbon tetrachloride and all connections shall be plugged

after degreasing process in order to avoid entrance of grease or oil particles.

3.0 NAMEPLATE

3.1 Each restriction orifice plate shall have the following nameplate information punched on its

handle: -

a) Tag no. as per purchaser's data sheets.

b) Nominal pipe size in inches and rating in pounds.

c) Orifice plate and assembly material of construction

d) Bore diameter

3.2 Each multi-orifice plate assembly shall have a stainless steel nameplate attached firmly to it

at a visible place, furnishing the following information:

a) Tag number as per purchaser's datasheet

b) Manufacturer's name / trade mark

c) Nominal end connection size and rating

d) Orifice plate and assembly material of construction

e) Number of orifice plate stages

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1244 of 2303

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

tr- ENGINEERS

ft

Ogell EtOteuliV. INDIA UMITED FOR RESTRICTION ORIFICE 6-52-0006 Rev. 4

1.11271 eleMr2+331390.1) (A Govt of India Undertaking)

PLATES Page 6 of 6

4.0 INSPECTION AND TESTING

Purchaser reserves the right to inspect and witness testing at vendor's works as per

Inspection Test Plan and approved quality documents. All these tests shall be completed by

the vendor and test reports shall be submitted to Purchaser for scrutiny.

PMI on all incoming material shall be carried out as per Inspection and Test Plan as

applicable.

5.0 SHIPPING

5.1 Each restriction orifice plate shall be packed inside thick polythene bags with suitable

protective packing outside.

5.2 Each plate shall be packed separately.

5.3 All restriction orifice plates in oxygen and chlorine service shall be separately packed along

with a certificate indicating 'SUITABLE FOR OXYGEN/CHLORINE SERVICE', as

applicable.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1245 of 2303

Das könnte Ihnen auch gefallen

- EIL-STD Specifiction For Centrifugal Pumps PDFDokument21 SeitenEIL-STD Specifiction For Centrifugal Pumps PDFM Danish john paul100% (1)

- 6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsDokument20 Seiten6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsSachinShinde100% (2)

- Tech Notes For ValvesDokument20 SeitenTech Notes For ValvesmanuneedhiNoch keine Bewertungen

- 6-76-0002 Bolt Tension For FlangesDokument33 Seiten6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- 6 44 0005 A2Dokument25 Seiten6 44 0005 A2S.selvakumarNoch keine Bewertungen

- Restriction Orifice CPPDokument9 SeitenRestriction Orifice CPPparykoochakNoch keine Bewertungen

- Engineering Standard: IPS-E-PR-330Dokument30 SeitenEngineering Standard: IPS-E-PR-330Akmal ZuhriNoch keine Bewertungen

- Datasheet Level GaugeDokument9 SeitenDatasheet Level GaugeedcielNoch keine Bewertungen

- PZ D CS Pi SP 015 02Dokument60 SeitenPZ D CS Pi SP 015 02epbamdadNoch keine Bewertungen

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDokument12 SeitenSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNoch keine Bewertungen

- FCI ListofStandardsOct2017Dokument2 SeitenFCI ListofStandardsOct2017cukimayNoch keine Bewertungen

- Liquid Orifice SizingDokument8 SeitenLiquid Orifice SizingrmaganNoch keine Bewertungen

- Pressure Reducing Cum Desuperheating ValveDokument99 SeitenPressure Reducing Cum Desuperheating Valvejp220288100% (3)

- Audco Valve HandbookDokument39 SeitenAudco Valve HandbookEzhil Vendhan Palanisamy50% (2)

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Dokument206 SeitenRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanNoch keine Bewertungen

- Attachment#5 Temporary NitrogenDokument15 SeitenAttachment#5 Temporary NitrogenYusufNoch keine Bewertungen

- Iit MumbaiDokument243 SeitenIit MumbaiYogesh JagdaleNoch keine Bewertungen

- RotameterDokument9 SeitenRotameterSimbu Arasan100% (1)

- Steam DumpingDokument9 SeitenSteam DumpingsrinivasanNoch keine Bewertungen

- 28-JAN-2019 Sadhna Singh (8424) : Interlock SummaryDokument24 Seiten28-JAN-2019 Sadhna Singh (8424) : Interlock SummarySandip SurNoch keine Bewertungen

- Facts at Your Fingers - Positive-Displacement-Pumps PDFDokument1 SeiteFacts at Your Fingers - Positive-Displacement-Pumps PDFjohn VilladaNoch keine Bewertungen

- Data Sheet Sight GlassDokument5 SeitenData Sheet Sight GlassAdhya RazanNoch keine Bewertungen

- ASME ImpDokument6 SeitenASME ImpMarc AnmellaNoch keine Bewertungen

- Restriction Orifice Final CalculationDokument1 SeiteRestriction Orifice Final CalculationJasperTanNoch keine Bewertungen

- ACC - Offer 000984 Rev PDFDokument31 SeitenACC - Offer 000984 Rev PDFMohamed SaaDNoch keine Bewertungen

- Valve Data Sheet: BCXS302TDokument1 SeiteValve Data Sheet: BCXS302TRoo FaNoch keine Bewertungen

- Balanced Bellows Type Pressure Relief Valve NumbersDokument17 SeitenBalanced Bellows Type Pressure Relief Valve NumbersswatkoolNoch keine Bewertungen

- Material Requisition For Expansion Joint - Rev1Dokument4 SeitenMaterial Requisition For Expansion Joint - Rev1altipatlarNoch keine Bewertungen

- Control Valve Data SheetDokument6 SeitenControl Valve Data SheetsisesetNoch keine Bewertungen

- Strainer Screen & Mesh Selection GuideDokument4 SeitenStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Dokument17 SeitenReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNoch keine Bewertungen

- 6-79-0013 - r1 Material in Sour ServiceDokument6 Seiten6-79-0013 - r1 Material in Sour ServiceMurli ramchandran100% (1)

- 01SA0S02Dokument5 Seiten01SA0S02raobabar21Noch keine Bewertungen

- P&ID For Metering PackagesDokument11 SeitenP&ID For Metering PackagesJan Richardo GultomNoch keine Bewertungen

- Specification ChillerDokument28 SeitenSpecification Chillermishtinil100% (1)

- 6206 Guide For Selection Installation andDokument32 Seiten6206 Guide For Selection Installation andakbavra80% (5)

- S-00-1360-001 Rev.0 - FC (General Specification For Piping)Dokument11 SeitenS-00-1360-001 Rev.0 - FC (General Specification For Piping)ajmainNoch keine Bewertungen

- Training Manual-Instruments: Self Regulating ValveDokument9 SeitenTraining Manual-Instruments: Self Regulating Valvemilton1987Noch keine Bewertungen

- Flame ArresterDokument16 SeitenFlame Arresteriran1362Noch keine Bewertungen

- 6 44 0006 Rev6Dokument415 Seiten6 44 0006 Rev6karunaNoch keine Bewertungen

- Instrument Air SizingDokument2 SeitenInstrument Air Sizingmilton1987100% (1)

- Selection Guide FlowMeterDokument16 SeitenSelection Guide FlowMeterRedaNoch keine Bewertungen

- Globe Valve1 DatasheetDokument1 SeiteGlobe Valve1 DatasheetobumuyaemesiNoch keine Bewertungen

- Re 622761 - A 1 Datasheet Anti Scale Anti CorrosionDokument8 SeitenRe 622761 - A 1 Datasheet Anti Scale Anti Corrosion张强Noch keine Bewertungen

- 7856-Me-Spc-198-025 Rev - ADokument17 Seiten7856-Me-Spc-198-025 Rev - Ashameer_febi100% (1)

- BB3 Vs BB5Dokument10 SeitenBB3 Vs BB5kambleyogNoch keine Bewertungen

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDokument7 SeitenOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Control Valve Technical Specification For Severe Service - CCIDokument5 SeitenControl Valve Technical Specification For Severe Service - CCIVikas SinghNoch keine Bewertungen

- 9 - Horizontal Flare Knock Out Drum Sizing1Dokument2 Seiten9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- Pump Suction Design RulesDokument1 SeitePump Suction Design Rulesuetian729Noch keine Bewertungen

- Separator Design Guide PDFDokument36 SeitenSeparator Design Guide PDFAdam RizkyNoch keine Bewertungen

- Valve Material SelectionDokument8 SeitenValve Material SelectionerovhoNoch keine Bewertungen

- Control Valve SpecificationDokument4 SeitenControl Valve Specificationmanoj nirgudeNoch keine Bewertungen

- Gary Pratt - Air Cooled Condensers - Key Elements For A Successful SpecificationDokument38 SeitenGary Pratt - Air Cooled Condensers - Key Elements For A Successful SpecificationNirmalNoch keine Bewertungen

- TBE Inlet Separator V 2100 FLNG2Dokument6 SeitenTBE Inlet Separator V 2100 FLNG2halipzramlyzNoch keine Bewertungen

- Flare System - P&IDDokument3 SeitenFlare System - P&IDANANDAN N100% (1)

- Mucg06m1tw - List of DocumentsDokument62 SeitenMucg06m1tw - List of DocumentsKalai SelvanNoch keine Bewertungen

- 6-12-0015 - Standard Specification For Clad Plates.Dokument5 Seiten6-12-0015 - Standard Specification For Clad Plates.pl_arunachalam79100% (1)

- General Specification For Wire Mesh Demisters: Fgeir FmfgitgDokument6 SeitenGeneral Specification For Wire Mesh Demisters: Fgeir Fmfgitgpriti kumariNoch keine Bewertungen

- 6-24-0004 Catridge FilterDokument9 Seiten6-24-0004 Catridge FilterMurli ramchandran100% (1)

- Standard Specification For Concrete Lining in CanalsDokument6 SeitenStandard Specification For Concrete Lining in CanalsJITENDER KUMARNoch keine Bewertungen

- Standard Specification For Mechanical AgitatorsDokument11 SeitenStandard Specification For Mechanical AgitatorsJITENDER KUMARNoch keine Bewertungen

- Standard Specification For Inspection, Flushing and Testing of Piping SystemsDokument9 SeitenStandard Specification For Inspection, Flushing and Testing of Piping SystemsJITENDER KUMARNoch keine Bewertungen

- Standard Specification For Storage TanksDokument22 SeitenStandard Specification For Storage TanksJITENDER KUMAR75% (4)

- Technical 03of05 35Dokument6 SeitenTechnical 03of05 35JITENDER KUMARNoch keine Bewertungen

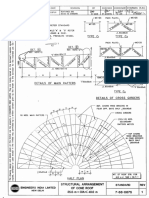

- Structural Arrangment of Cone Roof Tanks - 12Dokument1 SeiteStructural Arrangment of Cone Roof Tanks - 12JITENDER KUMARNoch keine Bewertungen

- ComfortClass S407 USADokument20 SeitenComfortClass S407 USAPhilippine Bus Enthusiasts SocietyNoch keine Bewertungen

- FRA5310 TechDokument2 SeitenFRA5310 TechBash MatNoch keine Bewertungen

- Work Financial Plan: Progra M/Output/ Acti Vi Ti Es Paymentofbasic ServicesDokument4 SeitenWork Financial Plan: Progra M/Output/ Acti Vi Ti Es Paymentofbasic ServicesloretaNoch keine Bewertungen

- Deep Excavation KLCCDokument20 SeitenDeep Excavation KLCCamirriyyah100% (1)

- CD54HC14, CD74HC14, CD54HCT14, CD74HCT14: Features DescriptionDokument16 SeitenCD54HC14, CD74HC14, CD54HCT14, CD74HCT14: Features DescriptionCésar Díaz LiberonaNoch keine Bewertungen

- Panel Simplex 2008Dokument86 SeitenPanel Simplex 2008JhonyLazoNoch keine Bewertungen

- (No Subject) - Inbox - Yahoo! MailDokument2 Seiten(No Subject) - Inbox - Yahoo! Mailpradhap87Noch keine Bewertungen

- Feed Water System ComponentsDokument11 SeitenFeed Water System ComponentsBlitz XyrusNoch keine Bewertungen

- 4.1 Introduction To Studying Two Factors: ESGC 6112: Lecture 4 Two-Factor Cross-Classification DesignsDokument14 Seiten4.1 Introduction To Studying Two Factors: ESGC 6112: Lecture 4 Two-Factor Cross-Classification DesignsragunatharaoNoch keine Bewertungen

- HMC 045Dokument12 SeitenHMC 045Mohamed ElmakkyNoch keine Bewertungen

- Experiment:-1 (Role of Software) : ObjectiveDokument6 SeitenExperiment:-1 (Role of Software) : ObjectiveRahul goume100% (1)

- BIFFI RHPS CatalogueDokument11 SeitenBIFFI RHPS CatalogueblloewyNoch keine Bewertungen

- Arduino DisassemblyDokument2 SeitenArduino DisassemblyJose100% (1)

- Lean Case Study Part IDokument6 SeitenLean Case Study Part IAnonymous QI9xEjrbplNoch keine Bewertungen

- Stadium ACL Test PlanDokument10 SeitenStadium ACL Test Planonlycisco.tkNoch keine Bewertungen

- Dropping Anomalous Cyber Case AnalysisDokument5 SeitenDropping Anomalous Cyber Case AnalysisSam Gitonga100% (1)

- Week 5Dokument20 SeitenWeek 5UMAIR JAVEDNoch keine Bewertungen

- CattronControl Excalibur by Cattron - Industrial Wireless Remote Control PDFDokument2 SeitenCattronControl Excalibur by Cattron - Industrial Wireless Remote Control PDFJose Gabriel Aguirre AndradeNoch keine Bewertungen

- Steel ProcessDokument2 SeitenSteel ProcessferengoNoch keine Bewertungen

- Cold ChainDokument15 SeitenCold ChainLok KannNoch keine Bewertungen

- ESE 568: Mixed Signal Design and Modeling Lecture Outline: Simplified For Hand AnalysisDokument13 SeitenESE 568: Mixed Signal Design and Modeling Lecture Outline: Simplified For Hand AnalysisVarun SinghalNoch keine Bewertungen

- (Free Scores - Com) - Di Capua Eduardo o Sole Mio 22271 PDFDokument3 Seiten(Free Scores - Com) - Di Capua Eduardo o Sole Mio 22271 PDFSeulki HongNoch keine Bewertungen

- Opening Ving Card LocksDokument1 SeiteOpening Ving Card LocksFilipe FernandesNoch keine Bewertungen

- 1 Historical AntecedentsDokument12 Seiten1 Historical AntecedentshithereNoch keine Bewertungen

- LH T6540Dokument54 SeitenLH T6540raja1701Noch keine Bewertungen

- Linked PDFDokument73 SeitenLinked PDFroparts clujNoch keine Bewertungen

- MikrotikDokument4 SeitenMikrotikShinichi Ana100% (1)

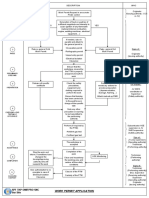

- PTW Logic DiagramDokument1 SeitePTW Logic DiagramAdrianNoch keine Bewertungen

- TSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaDokument2 SeitenTSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaIronko Pepe100% (1)

- OpenShift Container Platform 3.7 Architecture en USDokument156 SeitenOpenShift Container Platform 3.7 Architecture en USVel_stNoch keine Bewertungen