Beruflich Dokumente

Kultur Dokumente

002 - Repair - Trough Thickness-PQR - Rev.1

Hochgeladen von

Ricardo Napitupulu0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

192 Ansichten2 Seiten,mlk

Originaltitel

4. 002 -Repair - Trough Thickness-PQR_Rev.1

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden,mlk

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

192 Ansichten2 Seiten002 - Repair - Trough Thickness-PQR - Rev.1

Hochgeladen von

Ricardo Napitupulu,mlk

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

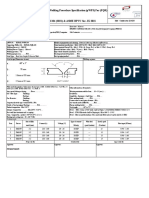

PROCEDURE QUALIFICATION RECORD (PQR)

PIPELINE BUTT-WELD THROUGH THICKNESS REPAIR

SUPPORT FOR WELDING PROCEDURE SPECIFICATION OF

PIPELINE BUTT-WELD THROUGH THICKNESS REPAIR PROCEDURE NO. 002/WPS/API1104-SWE-2016

SHEET 01 OF 02

VISUAL INSPECTION : PQR NO. : 002/PQR/API1104-SWE-2016

: RADIOGRAPHIC : DATE :

NDE RESULT

: DYE PENETRANT TEST : N/A APPLICABLE CODE : API 1104

NO./NAME WELDER : WELDING PROCESS : SMAW MANUAL

WELDING MACHINE TYPE : WELDING POSITION : 6G FIXED

TEMPERATURE : AMBIENT TEMPERATURE PROGRESSION : ROOT PASS: UP HILL

JOINT DESIGN : SINGLE V-GROOVE FILLER & CAPPING: DOWN HILL

: API 5L X 65 POLARITY : DC RP

MATERIAL SPECIFICATION

SMYS = 65.000 Psi TIME LAPS BETWEN PASS : 5 (FIVE) MINUTES

: ROOT :AWS A5.5 E7010 P : AT LEAST 50% OF ROOT,

FILLER METAL LINE UP CLAMP

: HOT, FILL, CAP: AWS A.5.5 E8010 P EVENLY SPACE AROUND PIPE CIRCUMFERENCE

CLEANING METHOD : GRINDING AND/OR BRUSHING NO. OF BEAD : SEE BELOW

DIAMETER : 16 Inchi (OD) PRE-HEAT/STRESS RELIEVE : N/A

METHOD OF DEFECT REMOVAL : GRINDING AND/OR AIR GOUGING THICKNESS : 12.7mm

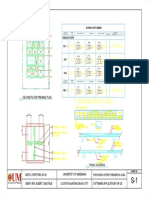

JOINT DESIGN JOINT DETAIL

CLEANING BEFORE WELDING MIN. 25 MM FROM SQUENCE OF BEADS

THE EDGE (IN AND OUT-SIDE)

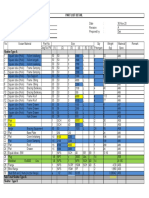

WELDING PARAMETER

Consumables Current Technique

Time

PASSES Trevel

Process Current AMPERE VOLTAGE Heat Input Lapsed

NO. Brand Dia. (mm) AWS Class Speed Bead Type Progression

Polarity (A) (V) (KJ/ mm) Between

(mm/min)

Pass

1 SMAW LINCOLN 2.6/ 3.2 A.5.5 DC RP STRING UPHILL

2 SMAW LINCOLN 3.2/ 4 A.5.5 DC RP WEAVED DOWNHILL

3 SMAW LINCOLN 3.2/ 4 A.5.5 DC RP WEAVED DOWNHILL

4 SMAW LINCOLN 3.2/ 4 A.5.5 DC RP WEAVED DOWNHILL

5 SMAW LINCOLN 3.2/ 4 A.5.5 DC RP WEAVED DOWNHILL

6 SMAW LINCOLN 3.2/ 4 A.5.5 DC RP WEAVED DOWNHILL

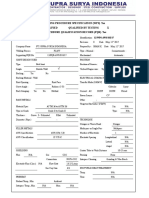

MECHANICAL TEST

1. TENSILE TEST LAB.TEST REPORT NO. :

SIZE (MM) AREA TENSILE STRENGTH

SPECIMEN NO MAX. LOAD (kgf) CHARACTER & LOCATION OF FAILURE REMARKS

WIDTH THICK (MM2) (kgf/mm2)

-

-

2. NICK BREAK TEST LAB.TEST REPORT NO. :

SPECIMEN NO NECK WIDTH OF NICK (mm) WELD THICKNESS (mm) AREA SECTION (mm2) TEST RESULT

3. BEND TEST LAB.TEST REPORT NO. :

SIZE (mm) PIN DIA. OF

SPECIMEN NO BEND TEST BEND ANGLE TEST RESULT

WIDTH THICK BENDING

4. HARDNESS TEST LAB.TEST REPORT NO. :

HEAT-AFFECTED

LOAD TIME WELD METAL

ZONE

SPECIMEN NO HARDNESS TEST TEST RESULT

Root/ Root/

(kg) (second) Midthicness

Cap Midthickness

Cap

PROCEDURE QUALIFICATION RECORD (PQR)

PIPELINE BUTT-WELD THROUGH THICKNESS REPAIR

5. CHARPY V - NOTCH TEST LAB.TEST REPORT NO. : SHEET 02 OF 02

TEMPERATURE SIZE (mm) RESULT

SPECIMEN NO

°C WIDTH THICK LENGTH Joule

6. MACRO TEST LAB.TEST REPORT NO. :

SPECIMEN NO MACRO TEST RESULT

Das könnte Ihnen auch gefallen

- WPS Pipe 08'' SHD 40 SMAW REV02Dokument2 SeitenWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNoch keine Bewertungen

- 4260Dokument10 Seiten4260Lipika GayenNoch keine Bewertungen

- Nm-Dairy Planning Data SheetDokument16 SeitenNm-Dairy Planning Data SheetRicardo NapitupuluNoch keine Bewertungen

- Ultrasonic Test Report: Before AfterDokument7 SeitenUltrasonic Test Report: Before AfterMenad SalahNoch keine Bewertungen

- Tempering ChocolateDokument2 SeitenTempering ChocolatesidiahidraNoch keine Bewertungen

- Manual Joints (QW - 402) : Page 1 of 12Dokument12 SeitenManual Joints (QW - 402) : Page 1 of 12miteshpatel191Noch keine Bewertungen

- SP 1285Dokument215 SeitenSP 1285qaiserNoch keine Bewertungen

- Hardness Test Report: Test Details Machine DetailsDokument1 SeiteHardness Test Report: Test Details Machine DetailsESHWAR CHARYNoch keine Bewertungen

- WPQ Template (Asme Ix) No LogoDokument4 SeitenWPQ Template (Asme Ix) No LogorcpretoriusNoch keine Bewertungen

- QW-403.2 InterpretationDokument1 SeiteQW-403.2 Interpretationlaz_kNoch keine Bewertungen

- Welding Insection ReportDokument4 SeitenWelding Insection ReportRanjeet MouryaNoch keine Bewertungen

- Welder Qualification Test RecordDokument75 SeitenWelder Qualification Test RecordVenkatesh Sundarrajan100% (1)

- SD DURABILITY FACTOR ACI 350-06Dokument2 SeitenSD DURABILITY FACTOR ACI 350-06wafa100% (1)

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDokument4 SeitenVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNoch keine Bewertungen

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDokument1 SeiteWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNoch keine Bewertungen

- Welding Parameters Control PipelineDokument1 SeiteWelding Parameters Control PipelinemusheerNoch keine Bewertungen

- J 1 PQR GMAW FCAW D1.1 2020 FormDokument2 SeitenJ 1 PQR GMAW FCAW D1.1 2020 FormCristian Narro100% (1)

- PQR Is7307Dokument1 SeitePQR Is7307Tridib Dey100% (1)

- Wps Non PWHTDokument193 SeitenWps Non PWHTMaxwell G SihotangNoch keine Bewertungen

- TopCoreBelco 101 FCDokument9 SeitenTopCoreBelco 101 FCCesar ArellanoNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDokument9 SeitenVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNoch keine Bewertungen

- SMAW DuniDokument4 SeitenSMAW DuniMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Dokument64 Seiten1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianNoch keine Bewertungen

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Dokument3 SeitenNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNoch keine Bewertungen

- Welding Coordinator WeldMap Weld Data Sheet PDFDokument1 SeiteWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNoch keine Bewertungen

- Joints (Qw-402) DetailsDokument3 SeitenJoints (Qw-402) DetailsNaqqash SajidNoch keine Bewertungen

- 7413 001 Standard Support UopDokument76 Seiten7413 001 Standard Support UopPierre RamirezNoch keine Bewertungen

- Wps Model 2 PDFDokument17 SeitenWps Model 2 PDFbeyNoch keine Bewertungen

- Proposed WPS For API 5LDokument1 SeiteProposed WPS For API 5LMecon HyderabadNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - FCAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNoch keine Bewertungen

- Folded Plate StructureDokument13 SeitenFolded Plate StructurekomalNoch keine Bewertungen

- Welding Procedure Qualification Record (WPQR)Dokument8 SeitenWelding Procedure Qualification Record (WPQR)Belin InversoNoch keine Bewertungen

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Dokument2 SeitenLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNoch keine Bewertungen

- Wps Mma PipeDokument2 SeitenWps Mma PipeDimitris NikouNoch keine Bewertungen

- WPS and PQR of GMAWDokument8 SeitenWPS and PQR of GMAW魏利强Noch keine Bewertungen

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDokument11 SeitenCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNoch keine Bewertungen

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Dokument4 SeitenSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNoch keine Bewertungen

- 10.LPI. Report FormatDokument1 Seite10.LPI. Report FormatEr Sumant Kumar SinghNoch keine Bewertungen

- UDokument1 SeiteUmohd as shahiddin jafriNoch keine Bewertungen

- BS 7533 1 2001 PDFDokument20 SeitenBS 7533 1 2001 PDFMirela100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDokument3 SeitenN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNoch keine Bewertungen

- Leak Test Procedure of Atmospheric VesselDokument9 SeitenLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- Saipem Wps ListDokument2 SeitenSaipem Wps ListookaNoch keine Bewertungen

- 1662 15Dokument117 Seiten1662 15RajamanikkamNoch keine Bewertungen

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDokument2 SeitenWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- Sample Wps Carbon Steel GTAW SMAW PDFDokument2 SeitenSample Wps Carbon Steel GTAW SMAW PDFirwanNoch keine Bewertungen

- Eng052 20erw 000 Qa WQS 0004 000 - 01Dokument7 SeitenEng052 20erw 000 Qa WQS 0004 000 - 01Mohammed ShehinNoch keine Bewertungen

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDokument9 Seiten2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDokument2 SeitenSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNoch keine Bewertungen

- PQR - PipeDokument3 SeitenPQR - PipeAdvanced Quality Centre AQC100% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDokument5 SeitenBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNoch keine Bewertungen

- Eng052 20erw 000 Qa WQS 0015 000 - 01Dokument6 SeitenEng052 20erw 000 Qa WQS 0015 000 - 01Mohammed ShehinNoch keine Bewertungen

- Welding & NDE Summary Sheet (BE)Dokument12 SeitenWelding & NDE Summary Sheet (BE)MulPXNoch keine Bewertungen

- B H e L Limited RTDokument13 SeitenB H e L Limited RTbhavin17850% (2)

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Dokument1.913 SeitenPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Supercito (E 42 5 B 32 h5)Dokument1 SeiteSupercito (E 42 5 B 32 h5)brunizzaNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium WeldingMohammed MusaNoch keine Bewertungen

- Alishar SP 2Dokument84 SeitenAlishar SP 2Alam MD SazidNoch keine Bewertungen

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Dokument6 SeitenInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument6 SeitenNew Microsoft Excel Worksheetravi00098Noch keine Bewertungen

- WPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticDokument2 SeitenWPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticAlex MendozaNoch keine Bewertungen

- Sample Forms WPS PQRDokument22 SeitenSample Forms WPS PQRGMNoch keine Bewertungen

- Baking and Drying Temperature of ElectrodesDokument1 SeiteBaking and Drying Temperature of ElectrodesshisNoch keine Bewertungen

- Tips Wps FormatDokument5 SeitenTips Wps FormatWaqas WaqasNoch keine Bewertungen

- Procedure Qualification Record (PQR) FormDokument1 SeiteProcedure Qualification Record (PQR) FormEarl HarbertNoch keine Bewertungen

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDokument3 SeitenWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNoch keine Bewertungen

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDokument2 SeitenName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNoch keine Bewertungen

- MTC Er70s 2Dokument1 SeiteMTC Er70s 2Mirza BaigNoch keine Bewertungen

- Weld Consumables SelectionDokument3 SeitenWeld Consumables SelectionArputharaj Maria LouisNoch keine Bewertungen

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokument2 SeitenASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNoch keine Bewertungen

- Draf WPSDokument2 SeitenDraf WPSMj EdinNoch keine Bewertungen

- It - PT - Asme - 01 - Rev 00Dokument16 SeitenIt - PT - Asme - 01 - Rev 00Ricardo NapitupuluNoch keine Bewertungen

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDokument1 SeiteDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDokument3 SeitenVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorDokument3 SeitenVp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam TurbinDokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam TurbinRicardo NapitupuluNoch keine Bewertungen

- 0 Cover Page & Work ScopeDokument1 Seite0 Cover Page & Work ScopeRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-065 Heat Exchanger Drawing For Mechanical SealDokument2 SeitenVp-15-109-001-A01-P-237-004abc-Sk-065 Heat Exchanger Drawing For Mechanical SealRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Motor)Dokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Motor)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-004 P&id For Pump (Steam Turbine)Dokument3 SeitenVp-15-109-001-A01-P-237-004ab-Sk-004 P&id For Pump (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Dokument2 SeitenVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvDokument3 SeitenVp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-004 P&id For Pump (Motor)Dokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-004 P&id For Pump (Motor)Ricardo NapitupuluNoch keine Bewertungen

- Shell and Tube Heat Exchanger Tube Counts PDFDokument2 SeitenShell and Tube Heat Exchanger Tube Counts PDFSK TomarNoch keine Bewertungen

- Heat ExchangerDokument16 SeitenHeat ExchangerAudrey Patrick KallaNoch keine Bewertungen

- Ga R 101 Rev-0Dokument1 SeiteGa R 101 Rev-0Ricardo NapitupuluNoch keine Bewertungen

- Heat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)Dokument1 SeiteHeat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)amr kouranyNoch keine Bewertungen

- Recovery Schedule Plan 3 PDFDokument1 SeiteRecovery Schedule Plan 3 PDFRicardo NapitupuluNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Outstandin Schedule Schedule Plan 4Dokument1 SeiteOutstandin Schedule Schedule Plan 4Ricardo NapitupuluNoch keine Bewertungen

- Eng - M - Lifting Lug Cal - 2Dokument6 SeitenEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNoch keine Bewertungen

- Support and Non Pressure Part Calculation of Foul ProductionDokument34 SeitenSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNoch keine Bewertungen

- PLD - Shelter - 30 11 2020Dokument3 SeitenPLD - Shelter - 30 11 2020Ricardo NapitupuluNoch keine Bewertungen

- S Curve Instrument CepuDokument1 SeiteS Curve Instrument CepuRicardo NapitupuluNoch keine Bewertungen

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDokument2 SeitenTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNoch keine Bewertungen

- 6 BLP Spesifikasi Teknis 49 SMA 14920Dokument6 Seiten6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNoch keine Bewertungen

- Serc - Group 2Dokument8 SeitenSerc - Group 2Arwa IbrahimNoch keine Bewertungen

- Thermal Lab PPT - Water Tube BoilerDokument10 SeitenThermal Lab PPT - Water Tube BoilerAyush Singhal100% (1)

- AgriculturalDokument16 SeitenAgriculturalkafi1234Noch keine Bewertungen

- CR Brochure 2019 V1 D PDFDokument29 SeitenCR Brochure 2019 V1 D PDFAshaari Cha-eNoch keine Bewertungen

- Design of Earth Tube Heat Exchanger: Devika Padwal, Tejaskumar Kharva, Jaiminkumar BhattDokument6 SeitenDesign of Earth Tube Heat Exchanger: Devika Padwal, Tejaskumar Kharva, Jaiminkumar BhattAnuj MalewarNoch keine Bewertungen

- What Are Cermets PDFDokument5 SeitenWhat Are Cermets PDFKamranNoch keine Bewertungen

- Sem 4 QBDokument31 SeitenSem 4 QBArvind ThankappanNoch keine Bewertungen

- BROMEN™Pleated Cartridge FilterDokument1 SeiteBROMEN™Pleated Cartridge FilterCarlos BarriosNoch keine Bewertungen

- Iom 11 2017 30RB 30RQ A 017-040 30rby 017-033Dokument26 SeitenIom 11 2017 30RB 30RQ A 017-040 30rby 017-033sergio saldivia ramirezNoch keine Bewertungen

- Building Material Science - GlassDokument53 SeitenBuilding Material Science - GlassMuskaan Chowdhary100% (2)

- Katalog HIDRIA Climmy 4 PDFDokument32 SeitenKatalog HIDRIA Climmy 4 PDFgoranm-mnflexNoch keine Bewertungen

- Breather Valves For Tank # 6907-08-09-010 Chakpirana Dia 3.8m Length 18mDokument2 SeitenBreather Valves For Tank # 6907-08-09-010 Chakpirana Dia 3.8m Length 18mSohail AzharNoch keine Bewertungen

- Precedent Report Final ExamDokument18 SeitenPrecedent Report Final ExamExaudi SitumorangNoch keine Bewertungen

- A Study On The Heat Dissipation of High Power Multi-Chip COB LEDsDokument8 SeitenA Study On The Heat Dissipation of High Power Multi-Chip COB LEDsdangerous livingNoch keine Bewertungen

- A Guideline For The Design and Construction of Asphalt Parking Lots in ColoradoDokument18 SeitenA Guideline For The Design and Construction of Asphalt Parking Lots in ColoradothescubataterNoch keine Bewertungen

- Problem 18.2 PDFDokument2 SeitenProblem 18.2 PDFAlexis YepezNoch keine Bewertungen

- Microstructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsDokument6 SeitenMicrostructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsastronotusNoch keine Bewertungen

- BCP 2007Dokument279 SeitenBCP 2007abdul ghafoorNoch keine Bewertungen

- RCD ExcelDokument17 SeitenRCD ExceljunNoch keine Bewertungen

- Ilovepdf MergedDokument21 SeitenIlovepdf MergedJasani PiyushNoch keine Bewertungen

- Presentation On Summer InternshipDokument19 SeitenPresentation On Summer InternshipBadal NayakNoch keine Bewertungen

- Boq Gisu OkDokument61 SeitenBoq Gisu OkYedid Amq100% (2)

- Civil Third Semester Revised Syllabus Effective From 2021 BatchDokument59 SeitenCivil Third Semester Revised Syllabus Effective From 2021 BatchDipesh KhadkaNoch keine Bewertungen

- Second Floor Framing Plan: Schedule of BeamsDokument1 SeiteSecond Floor Framing Plan: Schedule of BeamsChristian MataNoch keine Bewertungen