Beruflich Dokumente

Kultur Dokumente

Ex.66 - Adaptive Meshing For Moving Parts (II) Twin Screw Extruder

Hochgeladen von

jacksayshiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ex.66 - Adaptive Meshing For Moving Parts (II) Twin Screw Extruder

Hochgeladen von

jacksayshiCopyright:

Verfügbare Formate

Example 66

EXAMPLE 66

ADAPTIVE MESHING FOR MOVING PARTS (II):

TWIN SCREW EXTRUDER

DESCRIPTION

In this example, as in example 38, we want to determine the flow rate generated by a

conveying element in a co-rotating twin screw extruder. The dimensions and the boundary

conditions are the same as in example 38 (screw pitch = 40mm, center distance of screws =

33.9mm, barrel bore diameter = 42mm, flight depth = 7.3mm, and clearance = 1mm). To

summarise, the flow domain is limited to one pitch, small entry and exit sections are added to

surround the conveying element, the fluid is Newtonian and isothermal. In order to calculate

the "natural" flow produced by the rotation of the screws, we impose their angular velocity.

At inflow and outflow, we impose vanishing forces. Along the barrel wall, the velocity

vanishes.

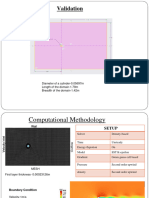

The mesh superposition technique is used to simplify the mesh generation of the flow domain

(see fig. 1). Moreover, contrary to example 38, we start with a coarse mesh, and we will refine

it by using the adaptive meshing technique: we will divide elements in sub-elements in

elements close to or on the border of the moving parts. Eventually, we will compare the

solution of example 38, to the results obtained here without adaptive meshing and after one

step of refinement.

Fig. 1. Initial mesh of the flow domain and the two screws.

January 2017 66.1 Release 18.0

Example 66

KEYWORDS

mesh superposition technique, natural flow rate, twin screw extruder, adaptive meshing

FILENAMES

adtw.msh, adtw_1.dat, adtw_2.dat

NEW CONCEPT

Adaptive meshing

When we use the mesh superposition technique, we evaluate the current location of a moving

part, by determining for each node of the flow domain if it is inside a moving part or not.

This information is stored in a field, called 'INSIDE#I", I for the I -th moving part. Local value

of inside field is equal to zero if the current node is in the real fluid region, otherwise its value

is one. Therefore, if the flow domain mesh is coarse along the border of the moving parts, the

shape of the moving part is not well described, and the flow patterns will not be accurately

evaluated. A way to improve results is to add elements in regions overlapped by the moving

part border. This border is indeed the zone where we observe variation in the inside fields.

With adaptive meshing, elements where variation of inside fields is significant are divided in

smaller elements (recursive sub-division: a segment is divided in 2, a face in 4, a brick in 8).

If one wants that automatic refinement takes place in the clearance between cam and external

boundary, at least one element (in the initial mesh) must be placed in this area.

SYSTEM OF UNITS

Millimeter-gram-second.

MATERIAL PROPERTIES

Model: Gen. Newtonian isothermal flow problem.

- Viscosity: 50000 Pa.s

- Density, inertia and volume forces are neglected

January 2017 66.2 Release 18.0

Example 66

OPERATING CONDITIONS

Boundary conditions for the flow domain:

- BS1: normal and tangential forces vanish (exit)

- BS2: normal and tangential forces vanish (entry)

- BS3: = 10 rpm, same angular velocity and axis than moving part #1

- BS4: = 10 rpm, same angular velocity and axis than moving part #2

- BS5: normal and tangential velocities vanish (barrel wall)

Boundary conditions for the moving parts:

- Moving part #1: subdomain S2,

center of rotation = (0, 0, 0),

axis of rotation = (0, 0, 1),

angular velocity = 10 rpm.

- Moving part #2: subdomain S3,

center of rotation = (33.9, 0, 0),

axis of rotation = (0, 0, 1),

angular velocity = 10 rpm.

POLYDATA SESSION (ADTW_1.DAT: NO AUTOMATIC REFINEMENT)

- Read a mesh file: adtw.msh

- Create a new task: 3D, steady state

- Create a subtask: Generalized Newtonian isothermal flow problem

Domain: SD1

Material Data:

Viscosity:

Constant law: fac = 50000

no density, no inertia, no gravity.

Flow Boundary Conditions:

BS1: (fn, fs) = (0, 0)

BS2: (fn, fs) = (0, 0)

BS3: Cartesian Velocity imposed: Vxyz imposed

point 1 = (0, 0, 0)

point 2 = (0, 0, 1)

angular velocity, = 1.0472 rad/s.

BS4: Cartesian Velocity imposed: Vxyz imposed

point 1 = (33.9, 0, 0)

point 2 = (33.9, 0, 1)

angular velocity, = 1.0472 rad/s

BS5 : (vn,vs) = (0,0)

Define moving parts:

Moving part #1

Domain: SD2

Motion:

January 2017 66.3 Release 18.0

Example 66

point of rotation axis: (0, 0, 0)

orientation of axis: (0, 0, 1)

angular velocity: 10 rpm.

Superposition technique:

default values are OK !

Flow boundary condition:

Stick condition

Moving part #2:

Domain: SD3

Motion:

point of rotation axis: (33.9, 0, 0)

orientation of axis: (0, 0, 1)

angular velocity: 10 rpm.

Superposition technique:

default values are OK !

Flow boundary condition:

Stick condition

Interpolation:

Coordinates: linear

Velocities: linear

Pressure: constant

- Create a subtask: Post-processor:

type: local shear rate

domain: SD1

- Ouputs:

- Default output : CFD-Post

- System of units for CFD-POST: metric_mm/g/s/mA+Celsius

- Max. listing

- Filename syntax:

prefix = adtw_1

- Save and Exit:

- Polyflow datafile: adtw_1.dat

- Polyflow resultfile: adtw_1.res

- CFD-Post: adtw_1.cfx.res

POLYDATA SESSION (ADTW_2.DAT: WITH AUTOMATIC REFINEMENT)

- Read a mesh file: adtw.msh

- Read an old data file: adtw_1.dat

- FEM Task 1

- Numerical parameters

Adaptive meshing see note 1

Activate adaptive meshing for moving parts

Enable all the local criteria (default values are OK)

Nstep = 1

January 2017 66.4 Release 18.0

Example 66

Maxdiv = 1

- Ouputs:

- Default output : CFD-Post

- System of units for CFD-POST: metric_mm/g/s/mA+Celsius

- Max. listing

- Filename syntax:

- prefix = adtw_2

- Save and Exit:

- Polyflow datafile: adtw_2.dat

- Polyflow resultfile: adtw_2.res

- CFD-Post: adtw_2.cfx.res

Note 1

In the "adaptive meshing" menu, one must activate adaptive meshing by enabling specific

criteria. In this case, adaptive meshing for moving parts is activated, i.e. criteria based on

variation of inside fields are available. In particular, we want to refine close to the border of

the moving parts, i.e. in regions where the variation of the inside field is large ("S_up = 0.05"

means that we refine elements where variation of inside field through these elements is

higher than 0.05). Also, we wish to coarsen mesh in area of low gradient ("S_do = 0.01" means

that we remove subdivided elements where variation of inside field through these elements is

lower than 0.01).

In general, adaptive meshing for moving parts can be defined with respect to several parts.

When several parts are involved, the definition of criteria can be made globally for all parts or

locally for each part. Also, criteria can be enabled/disabled for a given part or for all parts.

In the present case, “Global Criteria” mode is selected, and all local criteria will be enabled.

As the mesh superposition technique modifies locally the velocity field, the mass conservation

principle can not be satisfied exactly. Moreover, pressure peaks and velocity perturbations

can appear. The adaptive meshing technique will improve this situation. However, the

number or steps of refinement is limited ; after one step, a brick can be divided in 8, but after

two steps some initial bricks can be divided in up to 64 smaller bricks. So, the number of

elements will increase very rapidly. That is why in this example, we refine only one time.

POLYFLOW RUN

polyflow < adtw_1.dat > adtw_1.lst &

polyflow < adtw_2.dat > adtw_2.lst &

January 2017 66.5 Release 18.0

Example 66

GRAPHIC POST-PROCESSING

In the next table we compare flow rates, torque along the screws and number of elements for

three solutions: a) solution with no refinement, b) solution with one step of refinement and c)

the solution previously obtained in example 38.

Example 66 Example 38

No refin. 1 step of refin. No refin.

Number of Elements 2660 18823 24120

Flow rate [mm3/s] 1993 2677 2855

Torque Tz [Nm] -43 -49 -49

We observe convergence of the results as the number of elements increases. We observe also

that after one step of refinement, the number of bricks is multiplied by 7: almost 90 % of the

bricks of the initial mesh of the flow domain have been subdivided. A second step of

refinement would be very expensive.

In fig. 2, we present the screws as they are discretized by the 'INSIDE fields': after one step of

refinement, they reproduce very well the exact geometry of the screws. In figs. 3, 4 and 5, we

observe very well the positive effect of refinement: after one step of refinement, we are very

close to results obtained in example 38: this is demonstrated for pressure and for local shear

rate.

January 2017 66.6 Release 18.0

Example 66

a) b)

c)

Fig. 2. - Effect of refinement: a) isovalue (I=0.6) of Inside fields on initial mesh, b) isovalue

(I=0.6) of Inside fields after one step of refinement, c) exact geometry of the screws.

Fig. 3. - Pressure field along line starting at point (0, -20, -5) and ending at point (0, -20, 45).

The fluid is entering the flow domain in cross section Z=45mm and leaves in cross section

Z=-5mm.

January 2017 66.7 Release 18.0

Example 66

a)

b)

Fig. 4. - Pressure field (in Pa) in plane Y=16: a) initial mesh, b) after one step of refinement.

January 2017 66.8 Release 18.0

Example 66

a)

b)

Fig. 5. - Local shear rate (in s-1) along barrel wall: a) initial mesh, b) after one step of

refinement.

January 2017 66.9 Release 18.0

Das könnte Ihnen auch gefallen

- Aerothermodynamics of Turbomachinery: Analysis and DesignVon EverandAerothermodynamics of Turbomachinery: Analysis and DesignNoch keine Bewertungen

- Ex.108 - Sliding Mesh For A Single Screw ExtruderDokument9 SeitenEx.108 - Sliding Mesh For A Single Screw ExtruderjacksayshiNoch keine Bewertungen

- Ex.38 - Twin Screw ExtruderDokument9 SeitenEx.38 - Twin Screw ExtruderjacksayshiNoch keine Bewertungen

- Xample Xisymmetric Swirling Flow of A Ewtonian Liquid: January 2017 8.1 Release 18.0Dokument5 SeitenXample Xisymmetric Swirling Flow of A Ewtonian Liquid: January 2017 8.1 Release 18.0woongs73Noch keine Bewertungen

- Ex.47 - Non-Isothermal Flow in A Twin Screw ExtruderDokument8 SeitenEx.47 - Non-Isothermal Flow in A Twin Screw ExtruderjacksayshiNoch keine Bewertungen

- Midas3 0Dokument9 SeitenMidas3 0Kelly ObrienNoch keine Bewertungen

- Linear Static Analysis of A Cantilever Beam Using Beam Library (SI Units)Dokument18 SeitenLinear Static Analysis of A Cantilever Beam Using Beam Library (SI Units)Luis Enrique Trucios RuizNoch keine Bewertungen

- Xample Ixing in A Rotating Frame of Reference: January 2017 11.1 Release 18.0Dokument5 SeitenXample Ixing in A Rotating Frame of Reference: January 2017 11.1 Release 18.0woongs73Noch keine Bewertungen

- RS 03Dokument7 SeitenRS 03Essenam GOLINoch keine Bewertungen

- 1 SkyCiv ReportDokument8 Seiten1 SkyCiv ReportEve MajinNoch keine Bewertungen

- Xample Tirring ANK: January 2017 13.1 Release 18.0Dokument6 SeitenXample Tirring ANK: January 2017 13.1 Release 18.0woongs73Noch keine Bewertungen

- Final Abstract 1Dokument9 SeitenFinal Abstract 1samarthshetty283Noch keine Bewertungen

- Linear Static Analysis of A Cantilever Beam (SI Units) : LessonDokument16 SeitenLinear Static Analysis of A Cantilever Beam (SI Units) : LessonFernando Paez MendizabalNoch keine Bewertungen

- 20ME68 - Analysis of Beams - IIDokument35 Seiten20ME68 - Analysis of Beams - IIranjithkrajNoch keine Bewertungen

- Formats For The Geoid Models: ContentDokument7 SeitenFormats For The Geoid Models: ContentVic ValdezNoch keine Bewertungen

- FEA (EML 4930) ProjectDokument38 SeitenFEA (EML 4930) ProjectkrishNoch keine Bewertungen

- Chapter 27: Large Sliding Analysis of A BuckleDokument12 SeitenChapter 27: Large Sliding Analysis of A BuckleDan WolfNoch keine Bewertungen

- Linear Static Analysis of A Simply-Supported Truss: Workshop 7Dokument22 SeitenLinear Static Analysis of A Simply-Supported Truss: Workshop 7hfathollahiNoch keine Bewertungen

- 3.4 Pushover AnalysisDokument40 Seiten3.4 Pushover AnalysisKetanNoch keine Bewertungen

- Member Reinforced Concrete Column Design Report (AS-3600) PDFDokument13 SeitenMember Reinforced Concrete Column Design Report (AS-3600) PDFdongshengNoch keine Bewertungen

- Linear Static Analysis of A Cantilever Beam (SI Units) : WorkshopDokument16 SeitenLinear Static Analysis of A Cantilever Beam (SI Units) : WorkshophfathollahiNoch keine Bewertungen

- Torsional Vibration Finite Elements: 6.1 Formation of Traditional Inertia MatrixDokument12 SeitenTorsional Vibration Finite Elements: 6.1 Formation of Traditional Inertia Matrixابو المعالي الهمامNoch keine Bewertungen

- Particle Swarm Optimization (PSO)Dokument34 SeitenParticle Swarm Optimization (PSO)geetesh waghelaNoch keine Bewertungen

- Demonstration of SpringbackDokument7 SeitenDemonstration of SpringbackDan Wolf100% (1)

- Ch7 Digital TransmissionDokument38 SeitenCh7 Digital Transmissionabdullah almohammedaliNoch keine Bewertungen

- Linear Static Analysis of A Simply-Supported Stiffened PlateDokument24 SeitenLinear Static Analysis of A Simply-Supported Stiffened PlatehfathollahiNoch keine Bewertungen

- Assignment 2Dokument3 SeitenAssignment 2MANJUNATHNoch keine Bewertungen

- Prueba: Prepared By: User Date: Saturday, May 02, 2020Dokument12 SeitenPrueba: Prepared By: User Date: Saturday, May 02, 2020Hector Pedraza RomeroNoch keine Bewertungen

- Full Report: System InfoDokument11 SeitenFull Report: System InfodaianasoledadromeroNoch keine Bewertungen

- Xample Oextrusion of A Viscoelastic and A Ewtonian Liquid: January 2017 7.1 Release 18.0Dokument6 SeitenXample Oextrusion of A Viscoelastic and A Ewtonian Liquid: January 2017 7.1 Release 18.0woongs73Noch keine Bewertungen

- Earthquake Response Analysis of A Gravity Dam Considering The RadiationDokument8 SeitenEarthquake Response Analysis of A Gravity Dam Considering The RadiationKevin andres Vivas EscobarNoch keine Bewertungen

- Fea Lab Session4Dokument11 SeitenFea Lab Session4aaqibaminNoch keine Bewertungen

- Bending CalculationDokument8 SeitenBending CalculationsitovillaNoch keine Bewertungen

- Trans: Prepared By: Karina Pilatasig Date: Monday, November 06, 2017Dokument9 SeitenTrans: Prepared By: Karina Pilatasig Date: Monday, November 06, 2017Karina LisbethNoch keine Bewertungen

- Chapter 27: Large Sliding Analysis of A BuckleDokument12 SeitenChapter 27: Large Sliding Analysis of A BuckleDan WolfNoch keine Bewertungen

- Linear Static Analysis of A Cantilever Beam Using Beam Library (SI Units)Dokument16 SeitenLinear Static Analysis of A Cantilever Beam Using Beam Library (SI Units)nawaz0884Noch keine Bewertungen

- Ebook Finite Element Procedures in Engineering Analysis Bathe 1982Dokument20 SeitenEbook Finite Element Procedures in Engineering Analysis Bathe 1982farahNoch keine Bewertungen

- PS4dDokument7 SeitenPS4dgeethkumaraNoch keine Bewertungen

- CFD12 - Final Report Presentation GuideDokument14 SeitenCFD12 - Final Report Presentation GuideBudiAjiNoch keine Bewertungen

- Plaxis 2D-Pile DrivingDokument9 SeitenPlaxis 2D-Pile DrivingcmthebossNoch keine Bewertungen

- Title: Stress Analysis of A Cable Net StructureDokument6 SeitenTitle: Stress Analysis of A Cable Net StructureAnuj AsatiNoch keine Bewertungen

- Fuzzy Logic Control of A Rotary Double Inverted Pendulum SystemDokument8 SeitenFuzzy Logic Control of A Rotary Double Inverted Pendulum SystemNors Noor0% (1)

- 05 Influence DiagramsDokument15 Seiten05 Influence Diagramsgosefij566abudatNoch keine Bewertungen

- Linear Static Analysis of A Simply-Supported Truss: LessonDokument20 SeitenLinear Static Analysis of A Simply-Supported Truss: LessonJEAN ALARCONNoch keine Bewertungen

- Fundamentals of Digital TransmissionDokument38 SeitenFundamentals of Digital TransmissionAsish SubudhiNoch keine Bewertungen

- Assignment 1 JawapanDokument4 SeitenAssignment 1 JawapanSolehah OmarNoch keine Bewertungen

- Cone Angle Choices For Atmospheric Entry Vehicles: A ReviewDokument14 SeitenCone Angle Choices For Atmospheric Entry Vehicles: A ReviewMarcelo MartinezNoch keine Bewertungen

- 1X12X5.5 Vup PDFDokument55 Seiten1X12X5.5 Vup PDFShivam SharmaNoch keine Bewertungen

- STAAD - Pro Report: Job InformationDokument3 SeitenSTAAD - Pro Report: Job Informationaldeto71Noch keine Bewertungen

- Stress Analysis Initial Muhamad SlehanDokument13 SeitenStress Analysis Initial Muhamad SlehansolarNoch keine Bewertungen

- Outline 3 Supersonic WedgeDokument10 SeitenOutline 3 Supersonic WedgetktdNoch keine Bewertungen

- Model Identification and Controller DesignDokument6 SeitenModel Identification and Controller DesignMichaelNoch keine Bewertungen

- 2016 Shwartz PDFDokument45 Seiten2016 Shwartz PDFgood feelNoch keine Bewertungen

- Week 6Dokument50 SeitenWeek 6Andrew SebastianNoch keine Bewertungen

- Transvers Analysis 119iDokument22 SeitenTransvers Analysis 119iruchitaNoch keine Bewertungen

- Lebon 2020Dokument9 SeitenLebon 2020Rasha KaNoch keine Bewertungen

- Lab 06Dokument8 SeitenLab 06Juan José Leiva AlegreNoch keine Bewertungen

- Experiment NoDokument9 SeitenExperiment NoAli RazaNoch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Ex.112 - Effects of Slipping Along Screws and Back Pressure On Energy Dissipation and Backflows in A Twin Screw ExtruderDokument10 SeitenEx.112 - Effects of Slipping Along Screws and Back Pressure On Energy Dissipation and Backflows in A Twin Screw ExtruderjacksayshiNoch keine Bewertungen

- Souflle PancakesDokument3 SeitenSouflle PancakesjacksayshiNoch keine Bewertungen

- Ex.115 - Non-Isothermal Flow in A Single Screw ExtruderDokument11 SeitenEx.115 - Non-Isothermal Flow in A Single Screw ExtruderjacksayshiNoch keine Bewertungen

- Carbide Tipped Pens Seventeen Tales of Hard 9781466810198Dokument2 SeitenCarbide Tipped Pens Seventeen Tales of Hard 9781466810198jacksayshiNoch keine Bewertungen

- Proteus 200 Flowmeter Data SheetDokument3 SeitenProteus 200 Flowmeter Data SheetjacksayshiNoch keine Bewertungen

- Adventure Skeletons One-PageDokument1 SeiteAdventure Skeletons One-PagejacksayshiNoch keine Bewertungen

- Fundamentals of Music Theory RedditDokument22 SeitenFundamentals of Music Theory RedditjacksayshiNoch keine Bewertungen

- Recitation 15 1Dokument1 SeiteRecitation 15 1jacksayshiNoch keine Bewertungen

- EGN 3353C Fluid Mechanics: Chapter 7: Dimensional Analysis and ModelingDokument5 SeitenEGN 3353C Fluid Mechanics: Chapter 7: Dimensional Analysis and ModelingjacksayshiNoch keine Bewertungen

- Lesson 28 and 29 - Isentropic Flow With Area Change - Handout VersionDokument16 SeitenLesson 28 and 29 - Isentropic Flow With Area Change - Handout VersionjacksayshiNoch keine Bewertungen

- Furuta Pendulum Final Report - MIT Student Group Project PDFDokument33 SeitenFuruta Pendulum Final Report - MIT Student Group Project PDFjacksayshiNoch keine Bewertungen

- Solar Observing Project 2017Dokument5 SeitenSolar Observing Project 2017jacksayshiNoch keine Bewertungen

- Nelsondiana Eml4501 Report1Dokument52 SeitenNelsondiana Eml4501 Report1jacksayshiNoch keine Bewertungen

- Introduction of The Mercedes 0M651 EngineDokument58 SeitenIntroduction of The Mercedes 0M651 Enginejacksayshi100% (14)

- F16 EML4321 SyllabusDokument5 SeitenF16 EML4321 SyllabusjacksayshiNoch keine Bewertungen

- Weld Joint Geometry and Weld Symbols: Parts of A Weld Joint Welding Technology Lee Co. ATCDokument9 SeitenWeld Joint Geometry and Weld Symbols: Parts of A Weld Joint Welding Technology Lee Co. ATCjacksayshiNoch keine Bewertungen

- WHeel Hub BDokument1 SeiteWHeel Hub BjacksayshiNoch keine Bewertungen

- Due Start of Class 2 November: EML 4321 - Homework #7Dokument1 SeiteDue Start of Class 2 November: EML 4321 - Homework #7jacksayshiNoch keine Bewertungen

- Rman Command DocumentDokument22 SeitenRman Command DocumentanandNoch keine Bewertungen

- Robotech - TimelineDokument9 SeitenRobotech - TimelineRobert BestNoch keine Bewertungen

- Leadership Course OutlineDokument3 SeitenLeadership Course OutlineKashif Mahmood100% (2)

- ACCT561 Quiz Week 3Dokument2 SeitenACCT561 Quiz Week 3alparktuckerNoch keine Bewertungen

- Report Text: Hydrologic CycleDokument5 SeitenReport Text: Hydrologic CycleSAFFANA6401Noch keine Bewertungen

- Meanings Symbols and Local Wisdomin The Pinakang Dance Movements Costumesand Accessories of The Kimaragang in SabahDokument6 SeitenMeanings Symbols and Local Wisdomin The Pinakang Dance Movements Costumesand Accessories of The Kimaragang in SabahFredBTC007Noch keine Bewertungen

- Prometheus 2.0 - New Storage Layer Dramatically Increases Monitoring Scalability For Kubernetes and Other Distributed Systems - CoreOSDokument10 SeitenPrometheus 2.0 - New Storage Layer Dramatically Increases Monitoring Scalability For Kubernetes and Other Distributed Systems - CoreOSFrankie LiuNoch keine Bewertungen

- Credit Card Customer AnalysisDokument18 SeitenCredit Card Customer AnalysisBetka AbNoch keine Bewertungen

- Cri AssignmentDokument23 SeitenCri AssignmentNyx JawadNoch keine Bewertungen

- GIS Project ProposalDokument2 SeitenGIS Project ProposalKevin OdonnellNoch keine Bewertungen

- Amateur Photographer - May 28, 2016Dokument84 SeitenAmateur Photographer - May 28, 2016Lee100% (1)

- MCU ArchitectureDokument232 SeitenMCU Architecturesachinshetty001Noch keine Bewertungen

- Strategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKDokument12 SeitenStrategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKtedzmedicalNoch keine Bewertungen

- Six Levels of Linguistic AnalysisDokument12 SeitenSix Levels of Linguistic AnalysisRoshio Tsuyu Tejido67% (3)

- DB Qwik Site 5Dokument382 SeitenDB Qwik Site 5vhin_d_2005Noch keine Bewertungen

- Layout Strategies: © 2008 Prentice Hall, Inc. 9 - 1Dokument17 SeitenLayout Strategies: © 2008 Prentice Hall, Inc. 9 - 1jeams vidalNoch keine Bewertungen

- Dispute CaseDokument4 SeitenDispute CasedilansNoch keine Bewertungen

- A Ride in The Safari ParkDokument8 SeitenA Ride in The Safari ParkSyahida Saharin AbdullahNoch keine Bewertungen

- Expository Essay Thesis Statement ExamplesDokument4 SeitenExpository Essay Thesis Statement Examplesl0d1l1puzos3100% (2)

- Acoustical Determinations On A Composite Materials (Extruded Polystyrene Type/ Cork)Dokument6 SeitenAcoustical Determinations On A Composite Materials (Extruded Polystyrene Type/ Cork)pinoyarkiNoch keine Bewertungen

- GEH-6721 Vol II PDFDokument908 SeitenGEH-6721 Vol II PDFMARIO OLIVIERINoch keine Bewertungen

- Weld Simulator PDFDokument4 SeitenWeld Simulator PDFAmilin HatiaraNoch keine Bewertungen

- SmurfDokument2 SeitenSmurfapi-3739770Noch keine Bewertungen

- Traumatic Memories and EmotionalDokument22 SeitenTraumatic Memories and EmotionalXochitl MayoNoch keine Bewertungen

- Visual ModelingDokument6 SeitenVisual ModelingAlinordinNoch keine Bewertungen

- Bojan ResumeDokument2 SeitenBojan ResumebokiNoch keine Bewertungen

- Choosing A SolverDokument12 SeitenChoosing A SolversnthejNoch keine Bewertungen

- Presentation Template IR For ManagementDokument13 SeitenPresentation Template IR For ManagementYosia SuhermanNoch keine Bewertungen

- Tissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoDokument14 SeitenTissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoAndrea BaduaNoch keine Bewertungen

- Research Las 1Dokument4 SeitenResearch Las 1Lorianne ArcuenoNoch keine Bewertungen