Beruflich Dokumente

Kultur Dokumente

Appendix H Sample Calculations For Branch Reinforcement

Hochgeladen von

estudiemosOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Appendix H Sample Calculations For Branch Reinforcement

Hochgeladen von

estudiemosCopyright:

Verfügbare Formate

ASME B31.

3-2016

APPENDIX H

SAMPLE CALCULATIONS FOR BRANCH

REINFORCEMENT

H300 INTRODUCTION (METRIC) tc p (0.7)(6.02) p 4.21 mm, or 6 mm, whichever is less

p 4.21 mm

The following examples are intended to illustrate the

application of the rules and definitions in para. 304.3.3 Minimum leg dimension of fillet weld

for welded branch connections.

4.21/0.707 p 6.0 mm

(16) H301 EXAMPLE 1 Thus, the required area

A DN 200 (NPS 8) run (header) in an oil piping system A1 p (2.04)(108.8)(2 − sin 90 deg) p 222 mm2

has a DN 100 (NPS 4) branch at right angles (see

Fig. H301). Both pipes are Schedule 40 API 5L Grade A The reinforcement area in run wall

seamless. The design conditions are 2 068 kPa at 200°C.

A2 p (108.8)(7.16 − 2.04 − 2.5) p 285 mm2

The fillet welds at the crotch are minimum size in accor-

dance with para. 328.5.4. A corrosion allowance of in branch wall

2.5 mm is specified. Is additional reinforcement

necessary? A3 p (2)(6.93)关(5.27 − 1.07) − 2.5兴 p 24 mm2

in branch welds

Solution

A 4 p (2)(1⁄2)(6.0)2 p 36 mm2

From Appendix A, S p 110 MPa for API 5L Grade A

(Table A-1M); E p 1.0 for API 5L seamless (Table A-1B); The total reinforcement area p 345 mm2. This is more

W p 1.0. than the 222 mm2 so that no additional reinforcement

is required to sustain the internal pressure.

Th p (8.18)(0.875) p 7.16 mm

H302 EXAMPLE 2 (16)

Tb p (6.02)(0.875) p 5.27 mm

There is a DN 200 (NPS 8) branch at right angles to

L 4 p (2.5)(7.16 − 2.5) p 11.65 mm a DN 300 (NPS 12) header (Fig. H301). Both run and

or (2.5)(5.27 − 2.5) p 6.93 mm, branch are of aluminum alloy Schedule 80 ASTM B241

whichever is less 6061-T6 seamless pipe. The connection is reinforced by

p 6.93 mm a ring 350 mm O.D. (measured along the run) cut from

a piece of DN 300 (NPS 12) Schedule 80 ASTM B241

d1 p 关114.3 − (2)(5.27 − 2.5)兴 /(sin 90 deg) p 108.8 mm 6063-T6 seamless pipe and opened slightly to fit over

the run pipe. Allowable stresses for welded construction

d2 p (5.27 − 2.5) + (7.16 − 2.5) + 109/2 apply in accordance with Appendix A, Note (33). The

p 61.9 mm fillet welds have the minimum dimensions permitted

in para. 328.5.4. A zero corrosion allowance is specified.

Use d1 or d2, whichever is greater. What is the maximum permissible design pressure if

--`,,,,,`,,````,````,````,``,,``-`-`,,`,,`,`,,`---

the design temperature is −195°C?

d1 p 108.8 mm

Solution

(2 068)(219.1)

th p p 2.04 mm From Table A-1, S p 55.2 MPa for Grade 6061-T6

(2)(110,000)(1.0)(1.00) + (2)(0.4)(2 068)

(welded) pipe and S p 39.3 MPa for Grade 6063-T6

(2 068)(114.3) (welded) pad, both at −195°C. From Table A-1B, E p

tb p p 1.07 mm

(2)(110,000)(1.0)(1.00) + (2)(0.4)(2 068) 1.0 for ASTM B241; W p 1.0.

ASME B31.3-2016

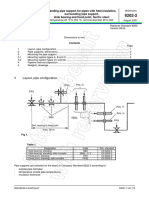

(16) Fig. H301 Illustrations for Metric Examples in Appendix H

6.02 mm nom.

5.27 mm min.

114.3 mm

H301 Example 1 Reinforcement

6.0 mm c = 2.5 mm

4.21 mm zone

8.18 mm nom.

L4 = 6.9 mm

7.16 mm min.

108.8 mm

108.8 mm 108.8 mm 219.1 mm O.D.

c = 2.5 mm

12.7 mm nom.

c = 0.0 mm 11.1 mm min.

219.1 mm

H302 Example 2 350.0 mm

17.48 mm nom. Reinforcement

15.30 mm min. 8.5 mm zone

6.0 mm

17.48 mm nom. 12.36 mm

15.30 mm min. L4 = 38.25 mm

197 mm

197 mm 197 mm 323.8 mm O.D.

c = 0.0 mm

8.74 mm

c = 2.5 mm 16

8 .3

7.11 mm nom. m m

6.22 mm min.

16

0 .7

H303 Example 3 12.7 mm nom. m m 10 mm

Reinforcement

305 mm zone

12.7 mm nom.

11.1 mm min.

60 deg L4 = 21.5 mm

185.7 mm

185.7 mm 185.7 mm

--`,,,,,`,,````,````,````,``,,``-`-`,,`,,`,`,,`---

c = 2.5 mm 406.4 mm O.D.

1.24 mm

6.02 mm nom.

c = 4.03 mm 5.27 mm min.

114.3 mm

H304 Example 4 160 mm

8.18 mm nom. Reinforcement

7.16 mm min. 4.21 mm zone

8.18 mm nom.

2.37 mm 7.16 mm min. L4 = 5.9 mm

112 mm

112 mm 112 mm 219.1 mm O.D.

c = 4.79 mm 4.09 mm

Das könnte Ihnen auch gefallen

- H300 Introduction (Si Units) : Para. 304.3.3Dokument2 SeitenH300 Introduction (Si Units) : Para. 304.3.3NDTInstructorNoch keine Bewertungen

- Branch Reinforcement CalcDokument2 SeitenBranch Reinforcement CalcNisarg PandyaNoch keine Bewertungen

- ASME B31.4-Wall Thickness CalDokument2 SeitenASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Calc' Diesel Fuel (Rev)Dokument10 SeitenCalc' Diesel Fuel (Rev)joko_tm02Noch keine Bewertungen

- Branch RF CalcDokument6 SeitenBranch RF CalcHarish Harish0% (1)

- Pipe Wall Thickness CalculationDokument8 SeitenPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Butt Weld Stainless Steel FittingsDokument16 SeitenButt Weld Stainless Steel Fittingsbayu susiloNoch keine Bewertungen

- Rosemount Seal m1199rtwDokument3 SeitenRosemount Seal m1199rtwMiguel Jiménez FloresNoch keine Bewertungen

- ANSI B16.5 Flange ToleranceDokument2 SeitenANSI B16.5 Flange TolerancevmrameshbeNoch keine Bewertungen

- ASME B31.3.4.8 Wall Thickness CalculatorDokument26 SeitenASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- ASME B31.4-Wall Thickness Calc For 6 InchDokument2 SeitenASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoNoch keine Bewertungen

- Pipe Thickness Calculation AS Per ASME 31.3Dokument11 SeitenPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNoch keine Bewertungen

- Calculation of PipeReinforcement ASMEB31 1Dokument4 SeitenCalculation of PipeReinforcement ASMEB31 1threedlabsNoch keine Bewertungen

- Flange DesignDokument4 SeitenFlange DesignAshish SharmaNoch keine Bewertungen

- Hes B008-03 Hexagon NutsDokument5 SeitenHes B008-03 Hexagon NutsPreetam KumarNoch keine Bewertungen

- Exchanger Tube Min ThicknessDokument2 SeitenExchanger Tube Min ThicknessMohamed ElshehnyNoch keine Bewertungen

- ASME B 31.3 Table 304.1.1 Coefficient (Y)Dokument1 SeiteASME B 31.3 Table 304.1.1 Coefficient (Y)groshan20Noch keine Bewertungen

- Branch Reinforcement Pad Requirement CalculationDokument1 SeiteBranch Reinforcement Pad Requirement Calculations.mladinNoch keine Bewertungen

- Interference Fits and PressureDokument21 SeitenInterference Fits and PressurerwmingisNoch keine Bewertungen

- Branch CalculationDokument9 SeitenBranch CalculationricardoNoch keine Bewertungen

- Calculator ASME B31 4Dokument11 SeitenCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDokument4 SeitenGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNoch keine Bewertungen

- Asme B31.8Dokument14 SeitenAsme B31.8omar equihua100% (1)

- Body Flange Design-Appx-2Dokument4 SeitenBody Flange Design-Appx-2Matthieu100% (1)

- Design of Beams-SiDokument2 SeitenDesign of Beams-SiJm CampitanNoch keine Bewertungen

- Hoist Beam Design EurocodeDokument37 SeitenHoist Beam Design EurocodeRajveer SinghNoch keine Bewertungen

- Design of Cylindrical Shell Part 2Dokument14 SeitenDesign of Cylindrical Shell Part 2Tito FebriantoNoch keine Bewertungen

- Castilated Beam DesignDokument10 SeitenCastilated Beam DesignAlphyl BalasabasNoch keine Bewertungen

- Spirax Sarco Fig 33Dokument2 SeitenSpirax Sarco Fig 33Jacobus CalvelageNoch keine Bewertungen

- Examples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013Dokument15 SeitenExamples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013ordenador90Noch keine Bewertungen

- Api - 650 2008Dokument27 SeitenApi - 650 2008WinsonLimHuiWahNoch keine Bewertungen

- Pipes and TubesDokument16 SeitenPipes and TubesDaniel Sandoval FernándezNoch keine Bewertungen

- Parallel Flow Condenser DesignDokument1 SeiteParallel Flow Condenser DesignSaravanan VijayanNoch keine Bewertungen

- Brance Pipe CALDokument6 SeitenBrance Pipe CALKlaikangwol AnuwarnNoch keine Bewertungen

- B31.3 - Reinf Pad CalculationDokument2 SeitenB31.3 - Reinf Pad CalculationasafhoxlNoch keine Bewertungen

- One Way SlabDokument23 SeitenOne Way SlabmeerahNoch keine Bewertungen

- ASME B31 4 Calculator V1 1Dokument11 SeitenASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Pipe THK 3Dokument1 SeitePipe THK 3silvanopipeNoch keine Bewertungen

- Irjet V4i1053 PDFDokument6 SeitenIrjet V4i1053 PDFdynamo ShaikhNoch keine Bewertungen

- 8202 2Dokument10 Seiten8202 2Yang WuNoch keine Bewertungen

- Bolt Torque Calculation - Apr19Dokument69 SeitenBolt Torque Calculation - Apr19Raj SNoch keine Bewertungen

- ASME B31.8 Riser CalcDokument12 SeitenASME B31.8 Riser CalcSalz EngineeringNoch keine Bewertungen

- Sample FLG CalcDokument6 SeitenSample FLG CalcameyyammaiNoch keine Bewertungen

- Nozzle and ReinforcementDokument23 SeitenNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Cálculo de La Silleta ParcialDokument3 SeitenCálculo de La Silleta ParcialALBERTO COCOM CELAYANoch keine Bewertungen

- Structural Bolts CatalogueDokument3 SeitenStructural Bolts CatalogueTom CaineNoch keine Bewertungen

- Idoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318Dokument9 SeitenIdoc - Pub - Thickness Calculations As Per Asme B 313 314 and 318GEMSL MONoch keine Bewertungen

- ASME B31 8 Riser CalcDokument12 SeitenASME B31 8 Riser CalcEmmanuel LawrenceNoch keine Bewertungen

- MDS Diesel TankDokument2 SeitenMDS Diesel TankrifkynetNoch keine Bewertungen

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDokument5 SeitenNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- SHPDDokument32 SeitenSHPDManuel Alvarez MNoch keine Bewertungen

- Doubly Reinforced BeamDokument8 SeitenDoubly Reinforced BeamKARTHIK SGNoch keine Bewertungen

- Asme B31.3 2018 30PDokument7 SeitenAsme B31.3 2018 30PKim JungdaeNoch keine Bewertungen

- Hydrant Stand Post (Double) : Technical Data SheetDokument2 SeitenHydrant Stand Post (Double) : Technical Data SheetshabahatNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 32Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 32estudiemosNoch keine Bewertungen

- Epf OverviewDokument1 SeiteEpf OverviewRenzoNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 34Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 34estudiemosNoch keine Bewertungen

- Full en CircDokument1 SeiteFull en CircestudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 33Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 33estudiemosNoch keine Bewertungen

- APP Carbon Grade Chart v6Dokument1 SeiteAPP Carbon Grade Chart v6Tashrif YusufNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 26Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 26estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 29Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 29estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 31Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 31estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 24Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 24estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 28Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 28estudiemosNoch keine Bewertungen

- AutoCAD NET Basics 8Dokument1 SeiteAutoCAD NET Basics 8estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 30Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 30estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 27Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 27estudiemosNoch keine Bewertungen

- METERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 13 PDFDokument1 SeiteMETERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 13 PDFestudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 20Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 20estudiemosNoch keine Bewertungen

- METERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 25 PDFDokument1 SeiteMETERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 25 PDFestudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 15Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 15estudiemosNoch keine Bewertungen

- METERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 17 PDFDokument1 SeiteMETERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 17 PDFestudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 18Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 18estudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 21Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 21estudiemosNoch keine Bewertungen

- METERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 11 PDFDokument1 SeiteMETERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 11 PDFestudiemosNoch keine Bewertungen

- METERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 14 PDFDokument1 SeiteMETERRUN Technical-Guide-Danieenior-Orifice-Fitting-En-44048 14 PDFestudiemosNoch keine Bewertungen

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 19Dokument1 SeiteMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 19estudiemosNoch keine Bewertungen

- AutoCAD NET Basics 7Dokument1 SeiteAutoCAD NET Basics 7estudiemosNoch keine Bewertungen

- Acmgd - DLL Exposes All The Editor Functionality (Selectionsets, Commands and KeywordsDokument1 SeiteAcmgd - DLL Exposes All The Editor Functionality (Selectionsets, Commands and KeywordsestudiemosNoch keine Bewertungen

- AutoCAD NET Basics 5Dokument1 SeiteAutoCAD NET Basics 5estudiemosNoch keine Bewertungen

- AutoCAD NET Basics 3Dokument1 SeiteAutoCAD NET Basics 3estudiemosNoch keine Bewertungen

- AutoCAD NET Basics 4Dokument1 SeiteAutoCAD NET Basics 4estudiemosNoch keine Bewertungen

- Low Profile Spider Elevator 400 PDFDokument2 SeitenLow Profile Spider Elevator 400 PDFMohamed AbozeimaNoch keine Bewertungen

- Hardware Catalogue 2020Dokument24 SeitenHardware Catalogue 2020reynaldo widiantoNoch keine Bewertungen

- RCP, Typ - Detailsfor Ceiling, Shadow Gap ImageDokument7 SeitenRCP, Typ - Detailsfor Ceiling, Shadow Gap ImageWagih NabihNoch keine Bewertungen

- Technical Offer Sama Baghdad Company 31st DEC 2020 Solicitation W56KGZ21Q7017Dokument120 SeitenTechnical Offer Sama Baghdad Company 31st DEC 2020 Solicitation W56KGZ21Q7017Ra'ad HaniNoch keine Bewertungen

- Secondary Composite ExampleDokument12 SeitenSecondary Composite Examplef2662961Noch keine Bewertungen

- Casing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogDokument3 SeitenCasing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogNihad PaşazadəNoch keine Bewertungen

- Summary of Fluoropolymer Properties - 1Dokument1 SeiteSummary of Fluoropolymer Properties - 1Amir KhanNoch keine Bewertungen

- Soil: CDOT Class 1 Backfill-Drained: Material PropertiesDokument8 SeitenSoil: CDOT Class 1 Backfill-Drained: Material PropertiesBraggyyy BarreraNoch keine Bewertungen

- Ladder SafetyDokument27 SeitenLadder SafetyKama Efendiyeva100% (1)

- Blurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)Dokument52 SeitenBlurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)sherinshaji2002Noch keine Bewertungen

- G1 - Construction Process of Retaining WallDokument1 SeiteG1 - Construction Process of Retaining WallNur Azlin IdayuNoch keine Bewertungen

- Pavement Condition Evaluation ManualDokument27 SeitenPavement Condition Evaluation ManualcrojastNoch keine Bewertungen

- Prokon Geek SLAB DETAILING 101 NotesDokument1 SeiteProkon Geek SLAB DETAILING 101 NotesProkon GeekNoch keine Bewertungen

- Fen Do LiteDokument2 SeitenFen Do LiteArmie May RicoNoch keine Bewertungen

- Condensate Water RecoveryDokument4 SeitenCondensate Water RecoveryTy Smith100% (2)

- Introduction To StairsDokument13 SeitenIntroduction To StairsShilpa BhargavaNoch keine Bewertungen

- Speech by Premier Job Mokgoro 2019Dokument37 SeitenSpeech by Premier Job Mokgoro 2019Paras Kumar SinghNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument23 SeitenFibre Reinforced ConcreteGaurav SinghNoch keine Bewertungen

- ADM Masonry M1Dokument26 SeitenADM Masonry M1Ronel ConstantinoNoch keine Bewertungen

- Material Consumption Norms For Various Civil Works - Civil4MDokument1 SeiteMaterial Consumption Norms For Various Civil Works - Civil4MAnubhav NautiyalNoch keine Bewertungen

- Fabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Dokument7 SeitenFabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Sejadah MaryamNoch keine Bewertungen

- WTI UK Screw Thread Inserts and Kits CatalogueDokument16 SeitenWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalNoch keine Bewertungen

- Epolam2500 GB PDFDokument2 SeitenEpolam2500 GB PDFMcFlyNoch keine Bewertungen

- Quikrete Concrete Product GuideDokument28 SeitenQuikrete Concrete Product GuideBurak Yanar100% (1)

- Wet Abrasive Blasting System and MethodDokument13 SeitenWet Abrasive Blasting System and MethodhainguyenbkvhvNoch keine Bewertungen

- Advisory Note 11 ASFP Cell Beam RationaleDokument2 SeitenAdvisory Note 11 ASFP Cell Beam RationalePavaloaie Marian ConstantinNoch keine Bewertungen

- Component Parts of Flexible and Rigid Road Pavements Structure and Their FunctionDokument4 SeitenComponent Parts of Flexible and Rigid Road Pavements Structure and Their FunctionRajesh KhadkaNoch keine Bewertungen

- Mandatory Spare ListDokument13 SeitenMandatory Spare ListHimanshu ShekharNoch keine Bewertungen

- Alloy Temperature ChartDokument2 SeitenAlloy Temperature ChartDaymer AularNoch keine Bewertungen

- Asphalt Mix ProductionDokument26 SeitenAsphalt Mix ProductionRatih D Shima100% (1)