Beruflich Dokumente

Kultur Dokumente

Concrete Truck Plant Pre-Acceptance Checklist

Hochgeladen von

Herey VixionersOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrete Truck Plant Pre-Acceptance Checklist

Hochgeladen von

Herey VixionersCopyright:

Verfügbare Formate

CONCRETE TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs:

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Verify Check Requirement Verify Check Requirement

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged

Revision No: 1 Document Number: JH-FRM-PAE-001-51 Page 1 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 18/08/2019

CONCRETE TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

Instructions: Verify Box to be ticked by Owner / Supplier / Operator prior to arrival onsite. Check Box to be ticked after visual inspection by the project

Verify Check Cabin Verify Check Environmental Verify Check Engine

Cleanliness Clean, free of organic materials (mud, dirt, weeds or Engine mountings

Handrails and ladders fitted and secure seeds) prior to arrival Engine guarding

Engine baffling or noise reduction equipment fitted as

Seat – adjustments operational secure Exhaust guarding

per manufacturers specifications

Seat belt fitted and in good working order Smoke from internal combustion engines should not be Oil leaks/check levels

UHF Radio Fitted (If not fitted, has a hand held visible for more than ten seconds Coolant leaks/check levels

radio been supplied) Coolant system

First Aid Kit, triangle and road reflectors available Vee belt condition

Warning devices and other lights (flashing, head, Air cleaner system

tail, etc) are appropriate for the environment in

Battery condition / mounting

which plant is being used. (check environment

noise criteria particularly if working out of hours) Verify Check Bowl

Instruments operational & labelled No build-up of concrete

around bowl

Levers / Controls Operational

U bolts mounting bowl to truck

Pedals in good condition frame

Air conditioning operational Brakes system operational

Wipers / Washers operational Discharge Shute and height

Rear View Mirrors adjuster working

Windows not damaged Access ladder clean and

Verify Check Hydraulics System undamaged to bowl

Rams Wash down water present and

operational

Hoses / Connectors TYRES – Record Tread Depth (if required) Bowl spins in both directions

Pins / Mounting

Hoses / connectors

(check for excessive wear, leaks and creep) POS 1 (LF) ____mm POS 2 (RF) ____mm

Speed controls operational

Verify Check Running Gear

POS 3 (LF2) ____mm POS 4 (RF2) ____mm Check for excessive wear,

Tyres / Wheels undamaged leaks and creep

Hand brake is operational POS 5 (LR3) ____mm POS 6 (RR3) ____mm Bowl control from cabin

Brake operational POS 7 (LR4) ____mm POS 8 (RR4) ____mm Bowl control from remote

Body pivot mounts

Hoist mounting bolts

PLANT OWNER / OCCUPIER PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is I certify that I have verified that the described plant has met the inspection criteria stipulated within this

being serviced and maintained in accordance with the manufacturer’s specifications checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date: Name: Signature: Date:

Revision No: 1 Document Number: JH-FRM-PAE-001-51 Page 2 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 18/08/2019

Das könnte Ihnen auch gefallen

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDokument2 SeitenJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

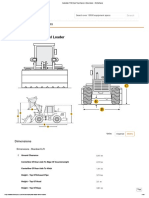

- En Iso 6165 2006Dokument15 SeitenEn Iso 6165 2006Fabio ManenteNoch keine Bewertungen

- Iveco Eurocargo Ml180e28 Rigid 4x2Dokument1 SeiteIveco Eurocargo Ml180e28 Rigid 4x2marianchiNoch keine Bewertungen

- Troubleshooting para Mixer PDFDokument16 SeitenTroubleshooting para Mixer PDFMauricio Ariel H. OrellanaNoch keine Bewertungen

- GD380A-L ListDokument6 SeitenGD380A-L ListNam Won HongNoch keine Bewertungen

- Service Programme: Volvo Construction EquipmentDokument4 SeitenService Programme: Volvo Construction Equipmentp_jankoNoch keine Bewertungen

- 1 Specifications D27-D36Dokument4 Seiten1 Specifications D27-D36Mermaid TanajibNoch keine Bewertungen

- Strength at Work: Iveco Genuine PartsDokument4 SeitenStrength at Work: Iveco Genuine PartsEndang WahyudiNoch keine Bewertungen

- TA1 English - Generator SetDokument13 SeitenTA1 English - Generator Setahmad adelNoch keine Bewertungen

- CLS100 Proportional Load Sensing Mobile Valve: Overhaul Manual / Trouble Shooting GuideDokument55 SeitenCLS100 Proportional Load Sensing Mobile Valve: Overhaul Manual / Trouble Shooting GuideSOLID ENGENHARIA & PROJETOSNoch keine Bewertungen

- Tracked Excavator - Js205 LR: Static Dimensions EngineDokument4 SeitenTracked Excavator - Js205 LR: Static Dimensions EngineMoayed M AhmedNoch keine Bewertungen

- Fleet MaintenanceDokument36 SeitenFleet MaintenanceRery Dwi SNoch keine Bewertungen

- 1452177591SanySY215C PDFDokument9 Seiten1452177591SanySY215C PDFSabah100% (1)

- TSR KuDokument16 SeitenTSR KuAngsaNoch keine Bewertungen

- Pre Delivery Inspection ChecklistDokument1 SeitePre Delivery Inspection ChecklistAman MeshramNoch keine Bewertungen

- PC2000 Grease SysteDokument4 SeitenPC2000 Grease SysteInsannulNoch keine Bewertungen

- ShacmanDokument2 SeitenShacmanJulio Muñoz SantistebanNoch keine Bewertungen

- Hydraulic Breaker TOR Series: Break Anything... Except The BankDokument6 SeitenHydraulic Breaker TOR Series: Break Anything... Except The BankYeison RamirezNoch keine Bewertungen

- ISMARTVN - RMX ExpressEnhanceBatchresult To CQC v1Dokument3 SeitenISMARTVN - RMX ExpressEnhanceBatchresult To CQC v1Quoc AnNoch keine Bewertungen

- Roto-Xtend Duty Fluid: Safety Data SheetDokument7 SeitenRoto-Xtend Duty Fluid: Safety Data SheetPEDRO PABLO DUQUENoch keine Bewertungen

- 泵车电控系统基本原理Dokument42 Seiten泵车电控系统基本原理nay hlaing SoeNoch keine Bewertungen

- Cs - cp56 64 74 Specalog (Qehq1241)Dokument20 SeitenCs - cp56 64 74 Specalog (Qehq1241)firman manaluNoch keine Bewertungen

- Maintenance For Landking WP10 Euro III Diesel EnginesDokument67 SeitenMaintenance For Landking WP10 Euro III Diesel EnginesClaudio Curbelo100% (1)

- Copy of SCOPE OF WORK - SERVICE OFFERSDokument12 SeitenCopy of SCOPE OF WORK - SERVICE OFFERSSandeep NikhilNoch keine Bewertungen

- Instruction Manual TC530: KOMTRAX TerminalDokument12 SeitenInstruction Manual TC530: KOMTRAX TerminalEbrahim SabouriNoch keine Bewertungen

- SB Series: Specification SheetDokument18 SeitenSB Series: Specification Sheet'X-fuera' Orchid PhiencNoch keine Bewertungen

- Welding Generator ChecklistDokument1 SeiteWelding Generator ChecklistAbdus SamadNoch keine Bewertungen

- BSB Series BRCDokument6 SeitenBSB Series BRCsamiNoch keine Bewertungen

- Filter/Separator Cartridges For Aviation Fuel HandlingDokument28 SeitenFilter/Separator Cartridges For Aviation Fuel HandlingSergioNoch keine Bewertungen

- ZOOMLION - HD SeriesDokument2 SeitenZOOMLION - HD SeriesPM XieNoch keine Bewertungen

- Faster, Easier, Safer: Cat Advansys Tips and AdaptersDokument2 SeitenFaster, Easier, Safer: Cat Advansys Tips and AdaptersKawasakiNoch keine Bewertungen

- Liugong 856h Wheel Loader 17000 KG 3 0 Cum 217 HPDokument5 SeitenLiugong 856h Wheel Loader 17000 KG 3 0 Cum 217 HPPyae GyiNoch keine Bewertungen

- Using The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Dokument27 SeitenUsing The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Ramon HidalgoNoch keine Bewertungen

- Ez03 CW06 Alco Civ PRQ 000013 - 3Dokument176 SeitenEz03 CW06 Alco Civ PRQ 000013 - 3Jason RazatlabNoch keine Bewertungen

- CompactorDokument8 SeitenCompactorkkmech100% (1)

- Zhongtong Bus LCK6125H City Bus Specs 20210727Dokument2 SeitenZhongtong Bus LCK6125H City Bus Specs 20210727刘自星0% (1)

- Form CPT GUIDokument1 SeiteForm CPT GUIAnanda risaNoch keine Bewertungen

- Caterpillar Wheel Loaders Equipment Parts Cutting Edges 7.11Dokument2 SeitenCaterpillar Wheel Loaders Equipment Parts Cutting Edges 7.11Fernando PadillaNoch keine Bewertungen

- LH 110 Port: Material Handling MachineDokument20 SeitenLH 110 Port: Material Handling Machinerobson2015Noch keine Bewertungen

- Oily Water Separator Inspection CertificateDokument6 SeitenOily Water Separator Inspection CertificateMohamed MohamedNoch keine Bewertungen

- C10836843 PDFDokument1 SeiteC10836843 PDFsandrobhaNoch keine Bewertungen

- Mancats-Diagnostic 83-298-53 22.6.20Dokument15 SeitenMancats-Diagnostic 83-298-53 22.6.20חנניה מוסNoch keine Bewertungen

- Hayabusa Turbo Stage Kit CarDokument1 SeiteHayabusa Turbo Stage Kit Carha5611Noch keine Bewertungen

- WWE Filter Press OperationDokument20 SeitenWWE Filter Press OperationMf LuiNoch keine Bewertungen

- Caterpillar: Cat - D6RDokument8 SeitenCaterpillar: Cat - D6Rkkmech100% (1)

- User Manual: Gasoline Power GeneratorsDokument16 SeitenUser Manual: Gasoline Power GeneratorsErickaNoch keine Bewertungen

- Tower Crane Daily Inspection Form PDFDokument1 SeiteTower Crane Daily Inspection Form PDFMd Imteyaz AnsariNoch keine Bewertungen

- New Komtrax Operation Manual For CustomerDokument55 SeitenNew Komtrax Operation Manual For CustomerDezso MogyorosiNoch keine Bewertungen

- YTG30TLV Leaflet PDFDokument1 SeiteYTG30TLV Leaflet PDFEgiNoch keine Bewertungen

- Wirtgen WS 2200Dokument8 SeitenWirtgen WS 2200walk001Noch keine Bewertungen

- Adt - e - b35 b40 b45 b50 - Qer - New ReleaseDokument1 SeiteAdt - e - b35 b40 b45 b50 - Qer - New Releasesfe100% (1)

- SH-CBM-Vehicle Inspection (LMV & HMV) ChecklistDokument1 SeiteSH-CBM-Vehicle Inspection (LMV & HMV) Checklistgo25101992Noch keine Bewertungen

- Service Report: GraderDokument3 SeitenService Report: Graderainul arifNoch keine Bewertungen

- Amodis RamonDokument4 SeitenAmodis RamonfabyanoNoch keine Bewertungen

- Hyva Tipping Frontend Brochure PDFDokument16 SeitenHyva Tipping Frontend Brochure PDFJose AndradeNoch keine Bewertungen

- HNC 8 System Commissioning Manual Grinding System v2.4 PDFDokument80 SeitenHNC 8 System Commissioning Manual Grinding System v2.4 PDFSam eagle goodNoch keine Bewertungen

- Motor 250 HPDokument4 SeitenMotor 250 HPwhoisarenas799Noch keine Bewertungen

- 10-F19 Forklifts Daily InspectionDokument1 Seite10-F19 Forklifts Daily InspectionSn AhsanNoch keine Bewertungen

- Concrete Truck Plant Pre-Acceptance ChecklistDokument3 SeitenConcrete Truck Plant Pre-Acceptance ChecklistMohamed El NasharNoch keine Bewertungen

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistDokument3 SeitenJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaNoch keine Bewertungen

- 13 Manpower Training Request - WAHDokument1 Seite13 Manpower Training Request - WAHHerey VixionersNoch keine Bewertungen

- 13 Manpower Training Request - WAHDokument1 Seite13 Manpower Training Request - WAHHerey VixionersNoch keine Bewertungen

- BOXDokument1 SeiteBOXHerey VixionersNoch keine Bewertungen

- BOXDokument1 SeiteBOXHerey VixionersNoch keine Bewertungen

- Hot Work Permit Rev 1Dokument1 SeiteHot Work Permit Rev 1Herey VixionersNoch keine Bewertungen

- Hot Work Permit Rev 1Dokument1 SeiteHot Work Permit Rev 1Herey VixionersNoch keine Bewertungen

- NYK Booking Acknowledgement 2799617228811442901004999Dokument2 SeitenNYK Booking Acknowledgement 2799617228811442901004999Herey VixionersNoch keine Bewertungen

- Text DescriptiveDokument3 SeitenText DescriptiveHerey VixionersNoch keine Bewertungen

- My DayDokument7 SeitenMy DayHerey VixionersNoch keine Bewertungen

- Kandang CagesDokument12 SeitenKandang CagesbarthoNoch keine Bewertungen

- Fikri A A AaaaaaaaaaaaaaaaaaaaaaaaaaDokument1 SeiteFikri A A AaaaaaaaaaaaaaaaaaaaaaaaaaHerey VixionersNoch keine Bewertungen

- 1Dokument4 Seiten1Herey VixionersNoch keine Bewertungen

- Spwla2012 NGD NeoscopeDokument15 SeitenSpwla2012 NGD NeoscopeHerey VixionersNoch keine Bewertungen

- Greeting & Parting: Unit 1 (Salam Perjumpaan & Perpisahan)Dokument11 SeitenGreeting & Parting: Unit 1 (Salam Perjumpaan & Perpisahan)Herey VixionersNoch keine Bewertungen

- My DayDokument7 SeitenMy DayHerey VixionersNoch keine Bewertungen

- Product Guide: FeaturesDokument24 SeitenProduct Guide: FeaturesHoward HoacNoch keine Bewertungen

- GREEN Access-Catalog-Gangways Loading-Racks Tank-Truck Railcar PDFDokument36 SeitenGREEN Access-Catalog-Gangways Loading-Racks Tank-Truck Railcar PDFwilfreNoch keine Bewertungen

- Enclosure 6130 Installation ProceduresDokument111 SeitenEnclosure 6130 Installation ProceduresSenthil Raja100% (2)

- Fendt 700 VarioDokument21 SeitenFendt 700 VarioIgor GaulicaNoch keine Bewertungen

- Handpallet PDFDokument18 SeitenHandpallet PDFAbdul RachmanNoch keine Bewertungen

- Skip Bin CollectionDokument39 SeitenSkip Bin CollectionKarthi Keyan R KNoch keine Bewertungen

- Electric Truck Variable Speed Drive Current OscillationsDokument12 SeitenElectric Truck Variable Speed Drive Current OscillationsLiebherr100% (1)

- Linde H16DDokument2 SeitenLinde H16Dfox mulderNoch keine Bewertungen

- Windsor Noise By-Law 6716Dokument10 SeitenWindsor Noise By-Law 6716Naz SNoch keine Bewertungen

- Tle10 Afa Agri-Crop q2 Mod1 Handlingmaterialsandequipment v5Dokument37 SeitenTle10 Afa Agri-Crop q2 Mod1 Handlingmaterialsandequipment v5Panfilo MaglasangNoch keine Bewertungen

- R938Dokument20 SeitenR938equipment9278Noch keine Bewertungen

- 2.5 - FAT - C1574 - FAT Procedure PDFDokument7 Seiten2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- Road Safety IndiaDokument18 SeitenRoad Safety IndiaVinay KutreNoch keine Bewertungen

- Outline Dimensions: XCMG Construction Machinery Co., LTDDokument4 SeitenOutline Dimensions: XCMG Construction Machinery Co., LTD余Noch keine Bewertungen

- Hitachi zx330LcDokument9 SeitenHitachi zx330Lcsugiyono81Noch keine Bewertungen

- CAT 7495 HF NEW DatasheetDokument32 SeitenCAT 7495 HF NEW DatasheetArkadiuszNoch keine Bewertungen

- PeterbiltDokument98 SeitenPeterbiltAndre VP100% (5)

- Rock PickerDokument2 SeitenRock PickerSteve LopesNoch keine Bewertungen

- Stc1300 Truck Crane: 130t Lifting CapacityDokument15 SeitenStc1300 Truck Crane: 130t Lifting CapacityDicky KurniantoNoch keine Bewertungen

- Volvo Op Manual VNL & VNM 2001Dokument353 SeitenVolvo Op Manual VNL & VNM 2001Thomas S Fulford IIINoch keine Bewertungen

- FD70-FD100NH Sales ManualDokument42 SeitenFD70-FD100NH Sales ManualLui DavidNoch keine Bewertungen

- ECC RequirementsDokument38 SeitenECC RequirementsAlathea DonneNoch keine Bewertungen

- Combi-C4000 GST Technical PDFDokument2 SeitenCombi-C4000 GST Technical PDFPatryk CzajkaNoch keine Bewertungen

- The Manitou Power PackDokument8 SeitenThe Manitou Power Packdaniel03_181975Noch keine Bewertungen

- Taylor Dunn Sc1-00 Manual Parts PartsDokument228 SeitenTaylor Dunn Sc1-00 Manual Parts PartsCarlos Garcia PequeñoNoch keine Bewertungen

- Caterpillar CS563E Vibratory Smooth Drum RollerDokument2 SeitenCaterpillar CS563E Vibratory Smooth Drum RollersawwahwahNoch keine Bewertungen

- Safety Industrial Trucks Self-Propelled Trucks To and Including 10 O00 KG and Tractors Drawbar and Including 20 O00Dokument32 SeitenSafety Industrial Trucks Self-Propelled Trucks To and Including 10 O00 KG and Tractors Drawbar and Including 20 O00Chiheb KaanicheNoch keine Bewertungen

- BR-CX50 Emi-002 201803Dokument12 SeitenBR-CX50 Emi-002 201803ryo asg3Noch keine Bewertungen

- Caterpillar 982M Wheel Loader Specs & Dimensions - RitchieSpecsDokument10 SeitenCaterpillar 982M Wheel Loader Specs & Dimensions - RitchieSpecsDCNoch keine Bewertungen

- Vzwkuawpwai1huldterex-Demag Ac 50-1 All Terrain Crane NetworkDokument14 SeitenVzwkuawpwai1huldterex-Demag Ac 50-1 All Terrain Crane NetworkSameh MohamedNoch keine Bewertungen