Beruflich Dokumente

Kultur Dokumente

Ej 1

Hochgeladen von

NTROriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ej 1

Hochgeladen von

NTRCopyright:

Verfügbare Formate

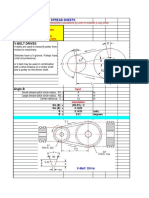

MEN:

DUCT:

Units en

Type 3, Flanged & Flued Type Expansion Joint

NEW SIZE 12

shell thickness t = 0.25 in

joint thickness t1 = 0.25 in

diameter Dod = 42 in

joint height h1 = 12 in

mean diameter of convolutions dp = 54.25 in

inside radius r1 = 2 in

inside radius r2 = 2 in

height h2 = 4 in

corrosion allowance ca = 0.125 in

movement ex = -0.1862 in

movement ec = 0.1862 in

Input Required : Use measurements in inches

Material Used = cs B

Design Temp ,°F T = 543.6 r

Design Pressure,psi P = 7.52 H Ro

Allowable Stress,psi S = 16900 t1 ri x

Mod. of Elast, E = 27.0E+6 A

Poisson's Ratio, m = 0.3

Flanged and Flued type

Shell Thick, t = 0.2500 t expansion joint

Joint Thick, t1= 0.2500 Ri

Inside Shell Radius, Ri= 20.7500 Surface Area of Joint = 28.9 sq.ft.

Inside Joint Radius, Ro= 33.0000 Effective Thrust Area = 1666.4 sq.in.

Inside Radius @ A, ri= 2.0000 Annular Thrust = 12531.5 lbs.

Inside Radius @ B, r = 2.0000 Pressure Thrust = 17382.3 lbs.

Inside Joint Height, H = 4.0000 Logintudinal Stiffness = 13781.2 lb/in

Internal Corrosion, c = 0.0000 Axial Force = 2566.1 lbs.

Joint Opens, +d (positive)= -0.1862 Logintudinal Stiffness = 13781.2 lb/in

Joint Closes, -d (negative)= 0.1862 Axial Force = -2566.1 lbs.

CALCULATIONS: (Variables Adjusted For Corrosion)

G = Ro - Ri = 12.000 in

L =G-0.215(r+ri)= 11.086 in A1=(2b-L)C = 5.748

h =H-0.43r = 3.086 in B1=(2a+L)C = 5.339

a= (Rit)^.5 * (ti)^3 = 0.889 A2=L(3b-L)C/3 = 40.362

2*(3(1-m^2))^.25*t^3 B2=L(3a+L)C/3 = 21.091

b =L+h *1- 1 = 12.468 Y1=L^2+aA1-LB1 = 16.484

2 10Ro^2ti^2 +1.25 3 2

(1-m^2)h^4

Y2=L^3+aA2+LB2 = -89.276

C= L = 0.415 -8 2

2(a+b)

K =|Y2/Y1|= 5.416

D = Et1^3 = 38633.2418 in-lbs R =Ro/Ri= 1.587

12(1-m^2) Y+=+d/2= -0.093

Y-=-d/2= 0.093

W =(R+1)P/2 = 9.726 lb/in F1+=DY+/L/Y1= -19.682

F =KW = 52.678 lbs F1-=DY-/L/Y1= 19.682

Fa=LW-F = 55.152 lbs MA1+=-A1*F1+ = 113.127

MA=A2*W - A1*F = 89.794 MA1-=-A1*F1- = -113.127

MB1+=B1*F1+ = -105.072

MB=B1*F - B2*W = 76.085 MB1-=B1*F1- = 105.072

Z=ti^2/6[(R-1)x/L+1]

Pt. A @ x=0 and x= 12.25 @ Pt. B

RESULTS:

Pt. M M1 Z S1=M/Z St=S1+M1/Z

Stress at Shell Attach, A 89.794 113.127 0.010 8620 19480

89.794 -113.127 0.010 8620 -2240

Stress at Joint Knuckle, B 76.085 -105.072 0.017 4431 -1688

76.085 105.072 0.017 4431 10550

ok Max S1= 1.5*S = 25350 psi

ok Max St= 4.0*S = 67600 psi

Expansion Joint - Shell.XLS.xlsExp Jt (Type 3) 12

Das könnte Ihnen auch gefallen

- Men: 0 Duct: 0 Units En: Expansion Joint - Shell - Xls.Xlsexp JT (Type 3) 22Dokument1 SeiteMen: 0 Duct: 0 Units En: Expansion Joint - Shell - Xls.Xlsexp JT (Type 3) 22NTRNoch keine Bewertungen

- Ej 3Dokument1 SeiteEj 3NTRNoch keine Bewertungen

- Metal Z PurlinsDokument4 SeitenMetal Z PurlinstonyNoch keine Bewertungen

- Z PurlinsDokument49 SeitenZ PurlinsKanchan Raja SinghNoch keine Bewertungen

- Metal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QDokument4 SeitenMetal Z-Purlins Design Based On AISI S100/SI-10: Input Data & Design Summary @: 12 (QMahesh MNoch keine Bewertungen

- This Is ItDokument33 SeitenThis Is ItJames DerechoNoch keine Bewertungen

- Design-Calculations For Pipelines (Onshore)Dokument19 SeitenDesign-Calculations For Pipelines (Onshore)George100% (1)

- FWEFJLNIY4QKLQXDokument13 SeitenFWEFJLNIY4QKLQXSoldan MihaiNoch keine Bewertungen

- Design of Wooden Truss: GivenDokument1 SeiteDesign of Wooden Truss: GivenAljie CañeteNoch keine Bewertungen

- PurlinDokument12 SeitenPurlinKhandaker Khairul Alam0% (1)

- StairDokument1 SeiteStairAek JanNoch keine Bewertungen

- S A D 1.1055 in The Next Available D 1.208 In. Tpi 3 Lead Pitch D D + Lead 1.208 + 0.3333 1.5413 1.3747 inDokument5 SeitenS A D 1.1055 in The Next Available D 1.208 In. Tpi 3 Lead Pitch D D + Lead 1.208 + 0.3333 1.5413 1.3747 inLhance BabacNoch keine Bewertungen

- ME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2022 - HW3 SolutionDokument7 SeitenME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2022 - HW3 SolutionVasanthi ChitturiNoch keine Bewertungen

- Calc Steel Metal PerporatedDokument13 SeitenCalc Steel Metal PerporatedOecoep Iteem100% (1)

- VIAK - Strap - Neighboring Foting Design 22.06Dokument14 SeitenVIAK - Strap - Neighboring Foting Design 22.06mukim0201004Noch keine Bewertungen

- Calculation DrainageDokument375 SeitenCalculation DrainageAzizi RazakNoch keine Bewertungen

- Toriconical Head 87 PsiDokument2 SeitenToriconical Head 87 PsiFabio Augusto Hincapie HenaoNoch keine Bewertungen

- Crossing Calculation API Rp1102 TemplateDokument1 SeiteCrossing Calculation API Rp1102 TemplateBudi SantonyNoch keine Bewertungen

- Api 650 2Dokument1 SeiteApi 650 2Geronimo Zamora0% (1)

- HEATER (H-01) : LMTD (-T) - (T - T) LN - T - TDokument8 SeitenHEATER (H-01) : LMTD (-T) - (T - T) LN - T - TJofanny Ferdian RahmansyahNoch keine Bewertungen

- Foundation DesignDokument13 SeitenFoundation Designregino abuzoNoch keine Bewertungen

- SLAB and STAIRDokument17 SeitenSLAB and STAIRMariya MariyaNoch keine Bewertungen

- Design of Purlins: PT DL PNDokument2 SeitenDesign of Purlins: PT DL PNAljie CañeteNoch keine Bewertungen

- StairDokument1 SeiteStairAek JanNoch keine Bewertungen

- Metal StudsDokument11 SeitenMetal StudsLeeCH LeeCHNoch keine Bewertungen

- V Belt CalculationDokument5 SeitenV Belt Calculationashey7777100% (1)

- HW 1 Ans 7Dokument2 SeitenHW 1 Ans 7Ashkar AwalNoch keine Bewertungen

- PumpDokument4 SeitenPumpJulian TremontNoch keine Bewertungen

- Home Assignment 1 - Ersa Berliana - 04211941000041Dokument6 SeitenHome Assignment 1 - Ersa Berliana - 04211941000041roberto luckyNoch keine Bewertungen

- SH DeaeratorDokument6 SeitenSH DeaeratorMel Andro Delos ReyesNoch keine Bewertungen

- Review GeometryDokument1 SeiteReview GeometryGabby LabsNoch keine Bewertungen

- Structure Design Reinforced Concrete Arch Dome Ring Wall Bs8110 v2015 01Dokument5 SeitenStructure Design Reinforced Concrete Arch Dome Ring Wall Bs8110 v2015 01ifyNoch keine Bewertungen

- Calculation of DavitDokument2 SeitenCalculation of DavitpiziyuNoch keine Bewertungen

- App4-Comp Factor ZDokument5 SeitenApp4-Comp Factor ZNasrul AdliNoch keine Bewertungen

- Aa - Bracket DesignDokument2 SeitenAa - Bracket Design4geniecivilNoch keine Bewertungen

- EQ2 4rth Floor ColumnDokument15 SeitenEQ2 4rth Floor ColumnWilbert Carlo RachoNoch keine Bewertungen

- 8 Ioc CQZ 5 Omsq Cktcic UWDokument21 Seiten8 Ioc CQZ 5 Omsq Cktcic UWYeri KhaNoch keine Bewertungen

- RectangularDokument6 SeitenRectangularhgag selim100% (1)

- PED Mid Term Formula SheetDokument4 SeitenPED Mid Term Formula SheetAvinash Subramanian S 19BCM0079Noch keine Bewertungen

- L' < L'' Not O.K: θs = -0.009409 radiansDokument4 SeitenL' < L'' Not O.K: θs = -0.009409 radiansCHaima GHzayelNoch keine Bewertungen

- Gate Solved Paper - MeDokument38 SeitenGate Solved Paper - MeHarish Jahan MohanNoch keine Bewertungen

- Bolts and Power Screw Lec Online ClassDokument4 SeitenBolts and Power Screw Lec Online Classtest 2Noch keine Bewertungen

- Bolt TorqueDokument3 SeitenBolt TorqueHeri KurniawanNoch keine Bewertungen

- Design of Distillation ColumnDokument21 SeitenDesign of Distillation Columnusmanafzal246100% (1)

- Tie Rod Support For Retangular TanksDokument11 SeitenTie Rod Support For Retangular Tanksmiteshpatel191Noch keine Bewertungen

- Slab Design at FaceDokument8 SeitenSlab Design at Faceankkeshmundra1Noch keine Bewertungen

- Data Sheet: Circlip Ring Type J - DIN 472Dokument1 SeiteData Sheet: Circlip Ring Type J - DIN 472danielNoch keine Bewertungen

- Aliran Dalam PipaDokument15 SeitenAliran Dalam PipaWidya AndaniNoch keine Bewertungen

- Solved Problems - 6 ExerciseDokument6 SeitenSolved Problems - 6 ExerciseRoberto Macias NNoch keine Bewertungen

- Distribution Factors 22mDokument8 SeitenDistribution Factors 22mJose Rivera RamirezNoch keine Bewertungen

- 4 Optimum Channel SectionDokument9 Seiten4 Optimum Channel SectionHalima Sibayan SawanganNoch keine Bewertungen

- Solved Problems of Mass and Heat Conduction: June 2020Dokument29 SeitenSolved Problems of Mass and Heat Conduction: June 2020AlexNoch keine Bewertungen

- M Q CPW T T KG HDokument5 SeitenM Q CPW T T KG HHassanNoch keine Bewertungen

- 2 - 1 Ellipsoidal Head WeightDokument2 Seiten2 - 1 Ellipsoidal Head Weightraja raniNoch keine Bewertungen

- Exer 3Dokument3 SeitenExer 3V.Noch keine Bewertungen

- Enhanced Composite BeamDokument5 SeitenEnhanced Composite BeamgalatiansNoch keine Bewertungen

- Exercise 1Dokument8 SeitenExercise 1Manoj KumarNoch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- C*-Algebra Extensions and K-Homology. (AM-95), Volume 95Von EverandC*-Algebra Extensions and K-Homology. (AM-95), Volume 95Noch keine Bewertungen

- Can Type Constant Effort Spring (CSH) Can Type Variable Spring (VSH)Dokument1 SeiteCan Type Constant Effort Spring (CSH) Can Type Variable Spring (VSH)NTRNoch keine Bewertungen

- ALR CardDokument1 SeiteALR CardNTRNoch keine Bewertungen

- Frequency Spectrum Method-Based Stress Analysis For Oil Pipelines in Earthquake Disaster AreasDokument24 SeitenFrequency Spectrum Method-Based Stress Analysis For Oil Pipelines in Earthquake Disaster AreasNTRNoch keine Bewertungen

- Air ValveDokument1 SeiteAir ValveNTRNoch keine Bewertungen

- Some Guidelines: All The Best!Dokument8 SeitenSome Guidelines: All The Best!NTRNoch keine Bewertungen

- Item Qty Unit Description: and Dresser RandDokument2 SeitenItem Qty Unit Description: and Dresser RandNTRNoch keine Bewertungen

- Vibration in Pumps PDFDokument5 SeitenVibration in Pumps PDFNTRNoch keine Bewertungen

- 7Dokument233 Seiten7Hotib PerwiraNoch keine Bewertungen

- W5 Kinetics of Particle Impulse Momentum (Ch15)Dokument74 SeitenW5 Kinetics of Particle Impulse Momentum (Ch15)Shah KhanNoch keine Bewertungen

- Nozzle TestDokument9 SeitenNozzle TestDarshan PanchalNoch keine Bewertungen

- Quantum ComputingDokument17 SeitenQuantum ComputingAnkush100% (1)

- General Catalogue AVAST Surge TankDokument14 SeitenGeneral Catalogue AVAST Surge TankNoor AnterNoch keine Bewertungen

- Plate Tectonic Web QuestDokument5 SeitenPlate Tectonic Web QuestEvan CandyNoch keine Bewertungen

- Lecture 5 09-29-2021 - Development, Anchorage & Splicing of ReinforcementDokument84 SeitenLecture 5 09-29-2021 - Development, Anchorage & Splicing of ReinforcementMoh Sal100% (2)

- Syllabus: M. Tech. Energy Management (Regular)Dokument28 SeitenSyllabus: M. Tech. Energy Management (Regular)Digvijay SinghNoch keine Bewertungen

- The Discovery of Schumann Resonance: CapacitorsDokument5 SeitenThe Discovery of Schumann Resonance: Capacitorssagor sagorNoch keine Bewertungen

- FWEFJLNIY4QKLQXDokument13 SeitenFWEFJLNIY4QKLQXSoldan MihaiNoch keine Bewertungen

- Durehete 950Dokument5 SeitenDurehete 950ellisforheroes100% (1)

- Iitk Eso202Dokument5 SeitenIitk Eso202Shubham ShuklaNoch keine Bewertungen

- Soundblox: Key Features and BenefitsDokument2 SeitenSoundblox: Key Features and BenefitsBogdan ŞerbănescuNoch keine Bewertungen

- A Study of Preparation of Light Colored Photosensitive Lquid NRDokument225 SeitenA Study of Preparation of Light Colored Photosensitive Lquid NRThai KhangNoch keine Bewertungen

- TM 10 4310 392 13 and PDokument43 SeitenTM 10 4310 392 13 and PVitor FreitasNoch keine Bewertungen

- List of Textile Universities in USADokument3 SeitenList of Textile Universities in USAFazle RubbiNoch keine Bewertungen

- MOD09 UserGuide v1 3Dokument40 SeitenMOD09 UserGuide v1 3Argemiro Lucena AraujoNoch keine Bewertungen

- Optimizing Materials Cost and MechanicalDokument8 SeitenOptimizing Materials Cost and MechanicalKaleem UllahNoch keine Bewertungen

- Electrostatic AnalyzerDokument6 SeitenElectrostatic AnalyzerKcirtap ZkethNoch keine Bewertungen

- Differences Between Vapour Comression and Vapour Absorption Refrigeration SystemsDokument2 SeitenDifferences Between Vapour Comression and Vapour Absorption Refrigeration SystemsGorantla Murali KrishnaNoch keine Bewertungen

- Reversible Addition Fragmentation Chain Transfer: by Dr. Dipak Pinjari ICT, MumbaiDokument15 SeitenReversible Addition Fragmentation Chain Transfer: by Dr. Dipak Pinjari ICT, MumbaiNilesh Patil100% (1)

- PG Test Procedure For ACCDokument3 SeitenPG Test Procedure For ACCMadhu BediguthuNoch keine Bewertungen

- Week 4-Stage Continuous Gas-Liquid Separation Processes-CHEM3011-2020-2021Dokument33 SeitenWeek 4-Stage Continuous Gas-Liquid Separation Processes-CHEM3011-2020-2021Nitin RautNoch keine Bewertungen

- Jaffery High School A Cambridge International School: Jhs/Physics Paper 2/first Term Examination/Year 8/nov 2015Dokument5 SeitenJaffery High School A Cambridge International School: Jhs/Physics Paper 2/first Term Examination/Year 8/nov 2015anishNoch keine Bewertungen

- TIG200A User ManualDokument14 SeitenTIG200A User Manualjeffradford9138Noch keine Bewertungen

- Important PointsDokument4 SeitenImportant PointsRashid MinhasNoch keine Bewertungen

- Improving Air Quality of Indoor Swimming Pools: Ir. J.G. MiddendorfDokument18 SeitenImproving Air Quality of Indoor Swimming Pools: Ir. J.G. MiddendorftasabajcNoch keine Bewertungen

- R717 Vs R404A - Do The Advantages Outweigh The DisadvantagesDokument3 SeitenR717 Vs R404A - Do The Advantages Outweigh The DisadvantagesSergio GarciaNoch keine Bewertungen

- Graduation Project'09 Ain Shams University: Seismic Data Processing SequenceDokument9 SeitenGraduation Project'09 Ain Shams University: Seismic Data Processing SequenceAshraf SeragNoch keine Bewertungen

- Icwe14 - Id02441 HfpiDokument36 SeitenIcwe14 - Id02441 HfpiSergio StolovasNoch keine Bewertungen